Electrocatalyst of ruthenium-based transition metal oxide solid solution as well as preparation method and application thereof

A technology of oxide solid solution and transition metal, which is applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems that it is difficult to withstand high current, the electrocatalytic performance of carrier oxide is poor, and the oxygen evolution reaction of acidic electrolytic water cannot be applied, so as to achieve The effect of high oxygen evolution reaction activity and stability, good catalytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

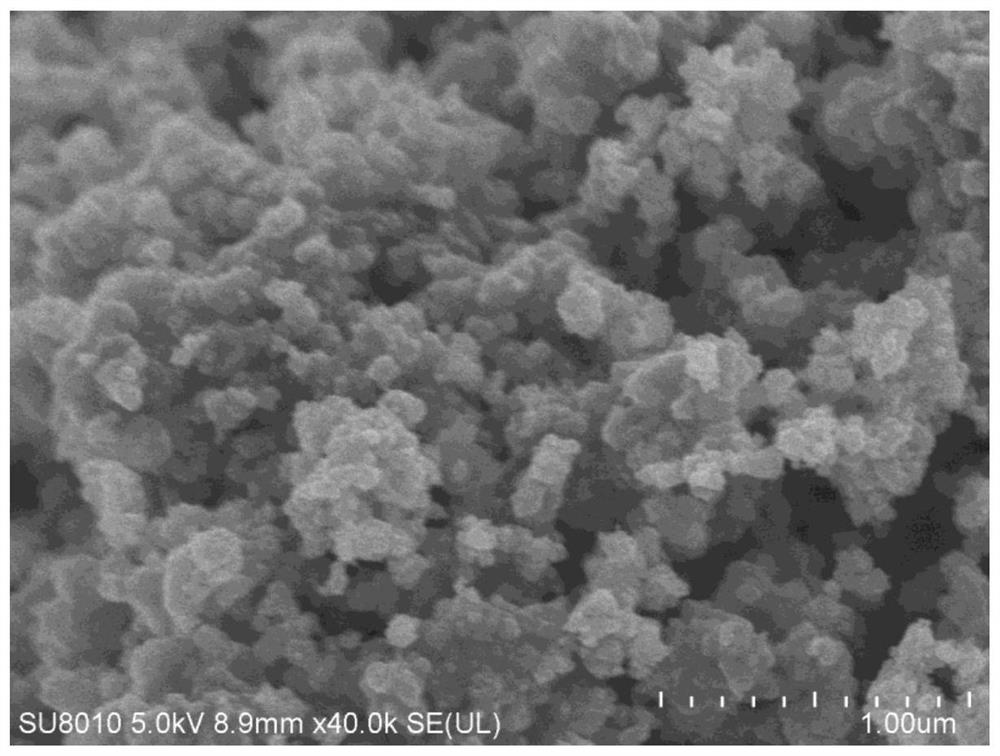

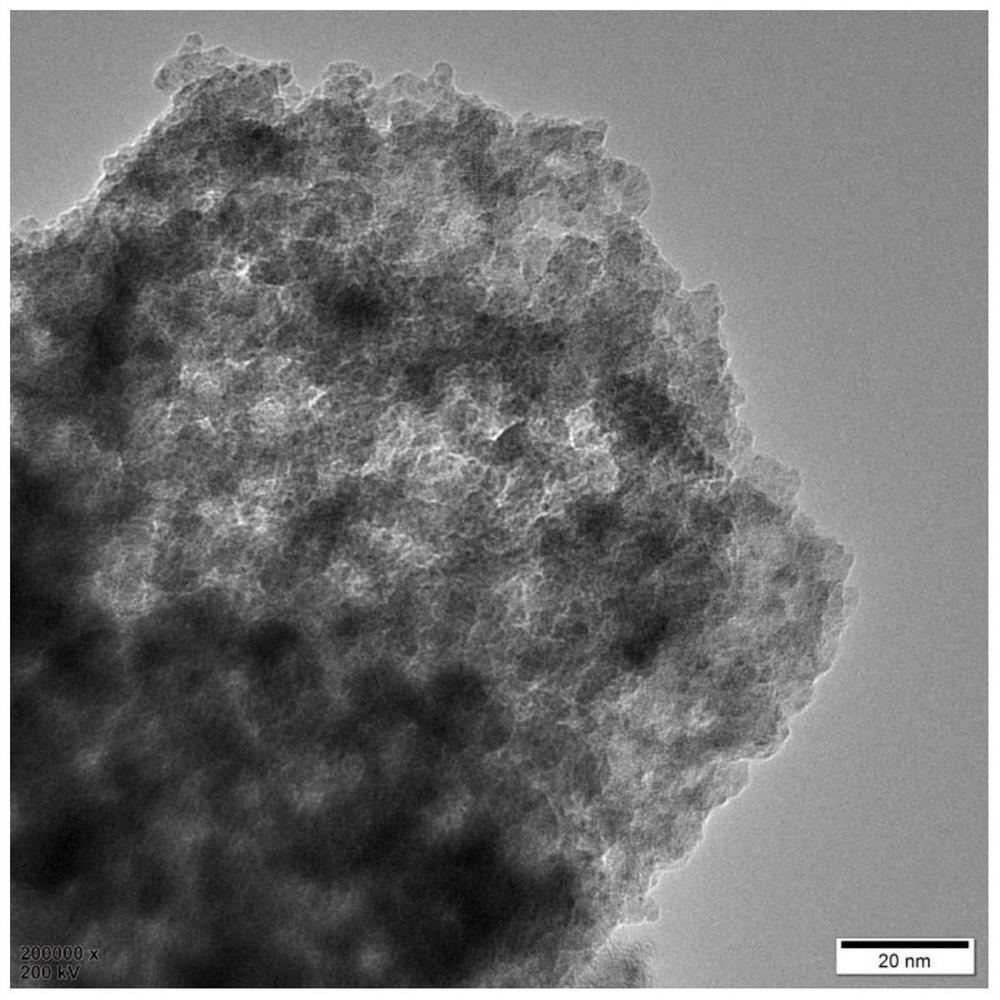

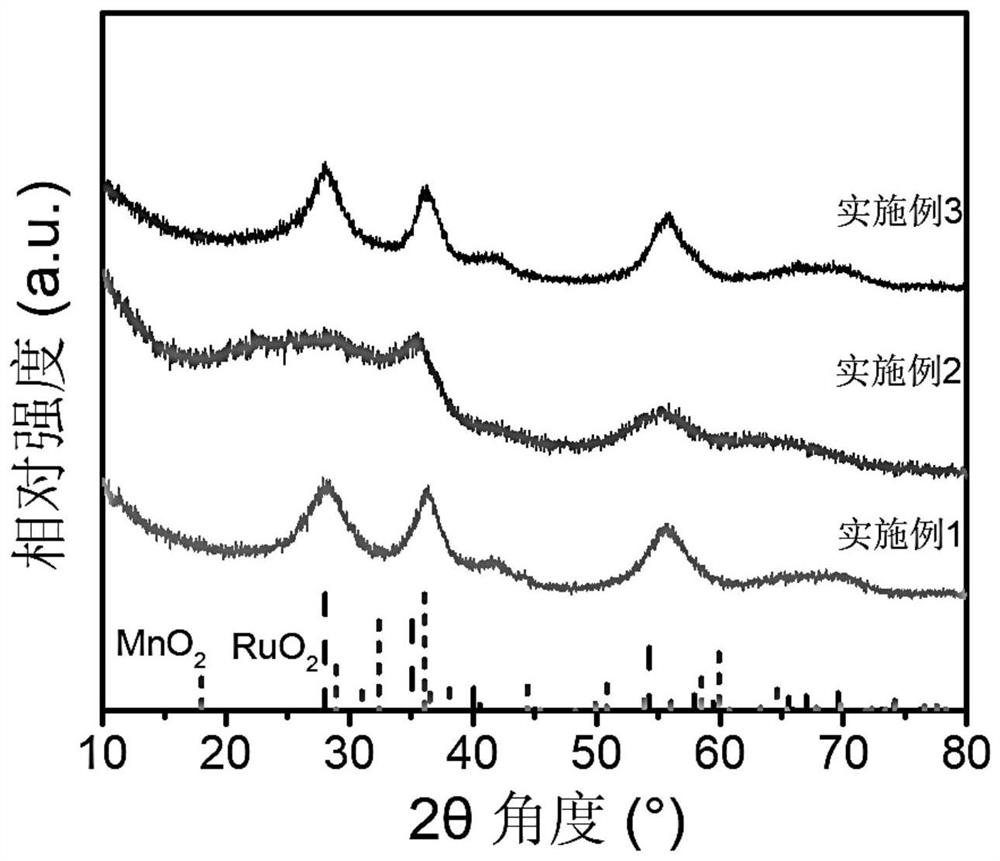

[0043] Example 1 Mn 0.6 Ru 0.4 o 2 Preparation of solid solution electrocatalyst

[0044] (1) Dissolve 1.5mmol manganese acetate tetrahydrate powder in 25mL deionized water to form a manganese acetate solution, dissolve 1mmol potassium permanganate powder in 25mL deionized water to form a potassium permanganate solution, and dissolve 2mmol ruthenium chloride powder in 3mL deionized water to form a ruthenium chloride solution;

[0045] Potassium permanganate solution and ruthenium chloride solution were sequentially added to the manganese acetate solution, stirred at room temperature for 1 hour, filtered with suction, and washed with deionized water three times to obtain a black amorphous oxide powder;

[0046] (2) Place the amorphous oxide powder prepared in step (1) in a vacuum drying oven, keep the temperature at 60°C, and dry for 3 hours; put the obtained dry powder into a mortar and grind until uniform, put it in a tube Calcined in a type furnace, using argon as the pr...

Embodiment 2

[0048] Example 2 Mn 0.5 Ru 0.5 o 2 Preparation of solid solution electrocatalyst

[0049] As in the preparation method of Example 1, the ruthenium chloride content in step (1) is changed to 2.2 mmol, and all the other steps are unchanged to obtain Mn 0.5 Ru 0.5 o 2 solid solution electrocatalysts.

Embodiment 3

[0050] Example 3 Mn 0.7 Ru 0.3 o 2 Preparation of solid solution electrocatalyst

[0051] As in the preparation method of Example 1, the ruthenium chloride content in step (1) is changed to 1.3 mmol, and all the other steps are unchanged to obtain Mn 0.7 Ru 0.3 o 2 solid solution electrocatalysts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com