High specific surface area mesoporous zinc oxide nano-cluster and preparation method thereof

A zinc oxide nanotechnology, high specific surface area technology, applied in zinc oxide/zinc hydroxide, nanotechnology and other directions, can solve the problems of difficult to synthesize zinc oxide powder materials, complicated and tedious reaction steps, high reaction temperature, etc. Catalytic degradation characteristics, good experimental repeatability, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of Mesoporous ZnO Nanoclusters with High Specific Surface Area

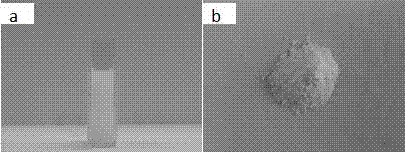

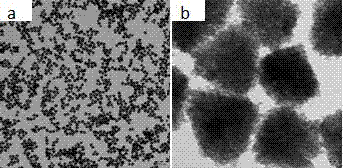

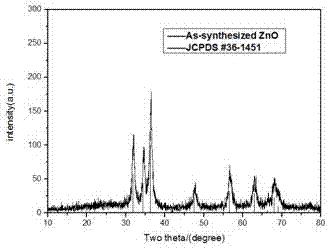

[0029] First, add 6 ml of deionized water to 32 ml of ethylene glycol solution, stir well to obtain a mixed solution of ethylene glycol and water; Add 0.5 ml of 4 mol / L zinc nitrate aqueous solution, 1 ml of 10 mol / L sodium hydroxide aqueous solution, and 0.5 ml of 2 mol / L sodium chloride aqueous solution in sequence to obtain a reaction precursor for preparing mesoporous zinc oxide nanoclusters with high specific surface area solution, wherein the volume ratio of ethylene glycol and water in the precursor is 80:20, and the concentrations of zinc nitrate, sodium hydroxide, and sodium chloride are respectively 0.05 mol / liter, 0.25 mol / liter, and 0.025 mol / liter; finally The prepared reaction precursor solution was reacted under stirring at room temperature for 1 hour to obtain the following: figure 1 The color shown in a is a milky white mesoporous zinc oxide nanocluster colloidal solution; aft...

Embodiment 2

[0031] Preparation of Mesoporous ZnO Nanoclusters with Different Scales and High Specific Surface Area

[0032] First, take 4 parts of 32 ml ethylene glycol solution and add them to 4 50 ml centrifuge tubes respectively, and mark them as A, B, C, D, and then add them to the centrifuge tube A sequentially under the condition of rapid stirring (800 rpm). Add 7.2 ml deionized water, 0.1 ml 4 mol / L zinc nitrate aqueous solution, 0.2 ml 10 mol / L sodium hydroxide aqueous solution, 0.5 ml 2 mol / L sodium chloride aqueous solution; add 4.5 ml deionized Water, 1 mL 4 mol / L zinc nitrate aqueous solution, 2 mL 10 mol / L sodium hydroxide aqueous solution, 0.5 mL 2 mol / L sodium chloride aqueous solution; add 1.5 mL deionized water, 2 mL 4 / L zinc nitrate aqueous solution, 4 ml 10 mol / L sodium hydroxide aqueous solution, 0.5 ml 2 mol / L sodium chloride aqueous solution; add 6 ml 10 mol / L sodium hydroxide aqueous solution, 1.5 ml 8 mol / L sodium hydroxide aqueous solution to centrifuge tube D 1...

Embodiment 3

[0034] Preparation of High Specific Surface Area Mesoporous ZnO Nanoclusters in Mixed Solutions with Different Volume Ratio of Ethylene Glycol and Water

[0035] Take four 50ml centrifuge tubes and mark them as A, B, C, D respectively, then add 34ml ethylene glycol, 4ml deionized water, 0.5 ml 4 mol / L zinc nitrate aqueous solution, 1 ml 10 mol / L sodium hydroxide aqueous solution, 0.5 ml 2 mol / L sodium chloride aqueous solution; add 32 ml ethylene glycol, 6 ml deionized water, 0.5 ml 4 mol / L zinc nitrate aqueous solution, 1 ml 10 mol / L sodium hydroxide aqueous solution, 0.5 ml 2 mol / L sodium chloride aqueous solution; add 30 ml ethylene glycol, 8 ml deionized water, 0.5 ml 4 mol / L zinc nitrate aqueous solution, 1 ml 10 mol / L sodium hydroxide aqueous solution, 0.5 ml 2 mol / L sodium chloride aqueous solution; add 24 ml ethylene glycol, 14 ml deionized water, 0.5 milliliters of 4 moles / liter zinc nitrate aqueous solution, 1 milliliter of 10 moles / liter sodium hydroxide aqueous so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com