Composite bioactive factor liposome and preparation method thereof

A technology of bioactive factors and liposomes, which is applied in liposome delivery, animal cells, pharmaceutical formulations, etc., can solve the problems of limited liposome application, incomplete nutritional components, and low activity of complex bioactive factors, achieving The effect of preventing ultraviolet rays, improving storage conditions, and stabilizing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

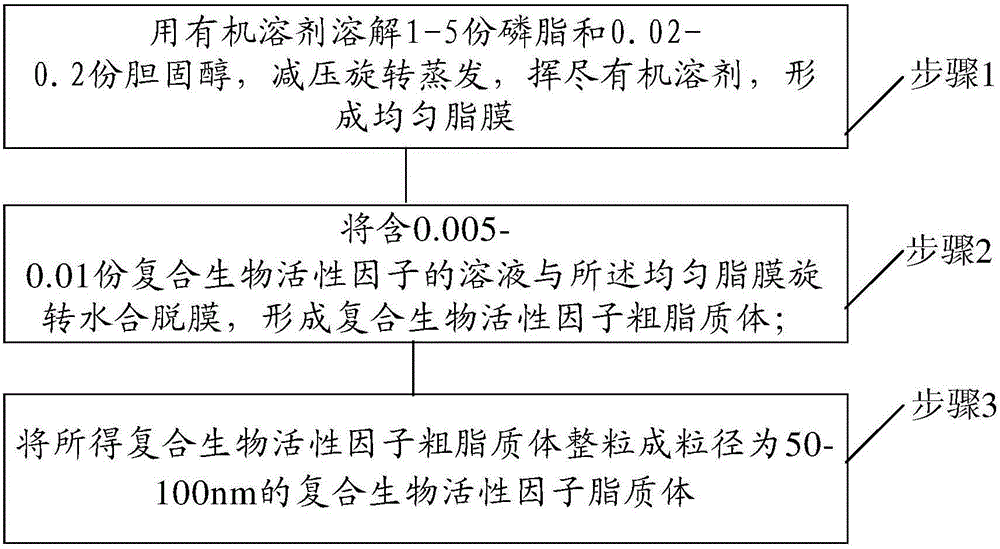

[0049] On the one hand, the embodiment of the present invention provides a kind of preparation method of composite bioactive factor liposome, see figure 1 , including the steps:

[0050] Step 1. Dissolve 1-5 parts of phospholipids and 0.02-0.2 parts of cholesterol with an organic solvent, rotate and evaporate under reduced pressure, and evaporate the organic solvent to form a uniform and transparent lipid film;

[0051] Step 2, the solution containing 0.005-0.01 part of the complex biologically active factor and the uniform lipid film are rotated and hydrated to form a thick liposome of the complex biologically active factor;

[0052] Step 3, preparing the obtained composite biologically active factor crude liposomes into composite biologically active factor liposomes with a particle size of 50-100 nm.

Embodiment 1

[0066] Dissolve 0.5 part of HSPC, 0.5 part of soybean lecithin and 0.02 part of cholesterol in chloroform, add purified water to 100 parts, and rotate under reduced pressure at 70 rpm to evaporate the organic solvent to form a uniform lipid film;

[0067] After mixing the solution containing 0.005 parts of the complex biologically active factor with the uniform lipid film, the membrane is hydrated and removed by rotating at 20°C and 40 rpm to form the crude liposome of the complex biologically active factor;

[0068] The obtained composite bioactive factor crude liposome is granulated into a composite bioactive factor liposome with a particle diameter of 50 nm.

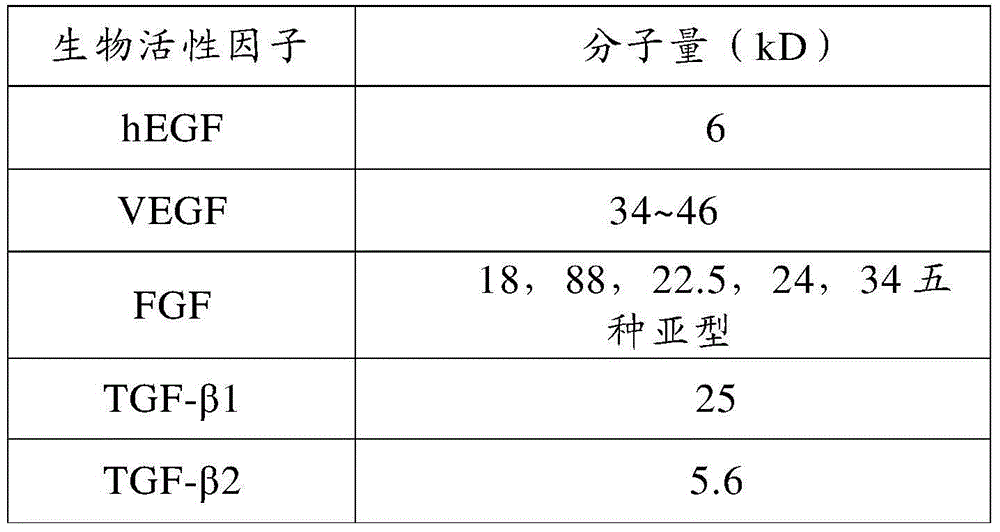

[0069] In conclusion, the encapsulation efficiency of the obtained composite bioactive factor liposome is 32%, and the activity of more than 64% of the bioactive factors in the composite bioactive factor solution is kept, mainly EGF, BFGF, VEGF, IGF1, IGF2, TGF-B1 , TGF-B2, PDGF and KGF, after being stored at 2-8°C fo...

Embodiment 2

[0071] Dissolve 1 part of HSPC, 1 part of soybean lecithin and 0.1 part of cholesterol in ethanol, add purified water to 100 parts, and rotate under reduced pressure at 100 rpm to evaporate the organic solvent to form a uniform lipid film;

[0072] After mixing the solution containing 0.01 part of the complex bioactive factor with the uniform lipid film, the membrane is hydrated and removed by rotating at 25° C. and 70 rpm to form a thick liposome of the complex bioactive factor;

[0073] The obtained compound bioactive factor crude liposome is granulated into a compound bioactive factor liposome with a particle diameter of 100 nm.

[0074] In conclusion, the encapsulation efficiency of the obtained composite bioactive factor liposome is 46%, and the activity of more than 70% of the bioactive factors in the composite bioactive factor solution is kept, mainly EGF, BFGF, VEGF, IGF1, IGF2, TGF-B1 , TGF-B2, PDGF and KGF, after being stored at 2-8°C for 6 months, the encapsulation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com