Water-borne inflation type refractory coating and preparation method thereof

A kind of technology of fireproof coating and expansion type, which is applied in the direction of fireproof coating, coating, etc., can solve the problems of poor durability and water resistance, loss of fireproof performance of coating, unsuitable for development needs, etc., and achieve excellent environmental performance, prevent ultraviolet rays, and source of raw materials sufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

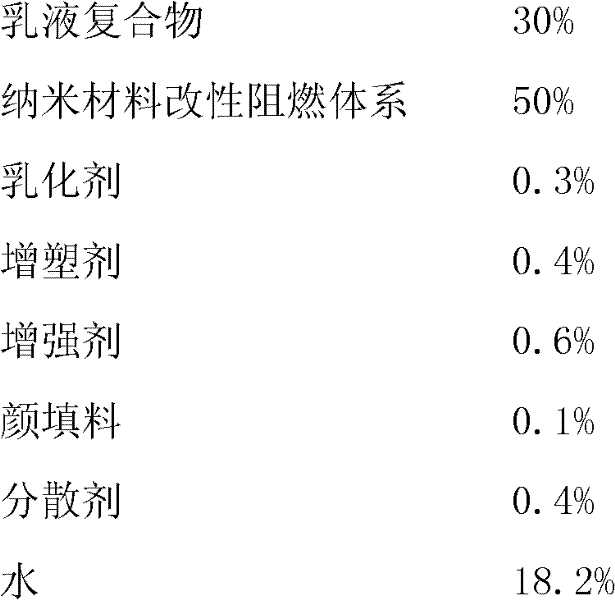

[0044] Embodiment 1: a kind of water-based intumescent type fireproof coating is prepared from following components, and each component content (gross weight is calculated by 100%) is:

[0045]

[0046] The above-mentioned raw materials are all commercially available commodities.

[0047] The preparation method of this embodiment: put a certain amount of water and sodium hexametaphosphate into the reaction kettle, stir at a low speed, and then add nano-TiO 2 , melamine, pentaerythritol and ammonium polyphosphate solution. Take another part of water, add emulsifier OP-9, stir at high speed to form a uniform emulsion. Combine the above aqueous solution and emulsion, then gradually add tricresyl phosphate, β-trichloroethylene phosphate, zinc oxide, antimony trioxide, talcum powder, titanium dioxide, and finally add silicone modified polyacrylate emulsion, stirring at high speed After 1 to 2 hours, use a ball mill to grind to a fineness of less than 60um, and then the finishe...

Embodiment 2

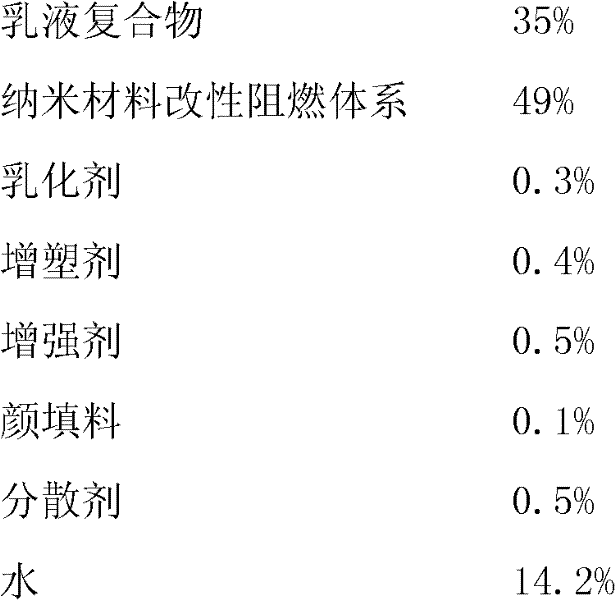

[0058] Embodiment 2: a kind of water-based intumescent type fireproof coating is prepared from following components, and each component content (gross weight is calculated by 100%) is:

[0059]

[0060] The above-mentioned raw materials are all commercially available commodities.

[0061] The preparation method of this embodiment: put a certain amount of water and sodium hexametaphosphate into the reaction kettle, stir at a low speed, and then add nano-TiO 2 , melamine, pentaerythritol and ammonium polyphosphate solution. Take another part of water, add emulsifier OP-9, stir at high speed to form a uniform emulsion. Combine the above aqueous solution and emulsion, then gradually add tricresyl phosphate, β-trichloroethylene phosphate, zinc oxide, antimony trioxide, talcum powder, titanium dioxide, and finally add silicone modified polyacrylate emulsion, stirring at high speed After 1 to 2 hours, use a ball mill to grind to a fineness of less than 60um, and then the finishe...

Embodiment 3

[0072] Embodiment 3: a kind of water-borne expansion type fireproof coating is prepared from following components, and each component content (gross weight is calculated by 100%) is:

[0073] Emulsion Complex 38%,

[0074] Nano-material modified flame retardant system 49%,

[0075] Emulsifier 0.4%,

[0076] Plasticizer 0.3%,

[0077] Enhancer 0.5%,

[0078] Pigment and filler 0.05%,

[0079] Dispersant 0.4%,

[0080] Water 11.35%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com