Patents

Literature

136results about How to "Realize factory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

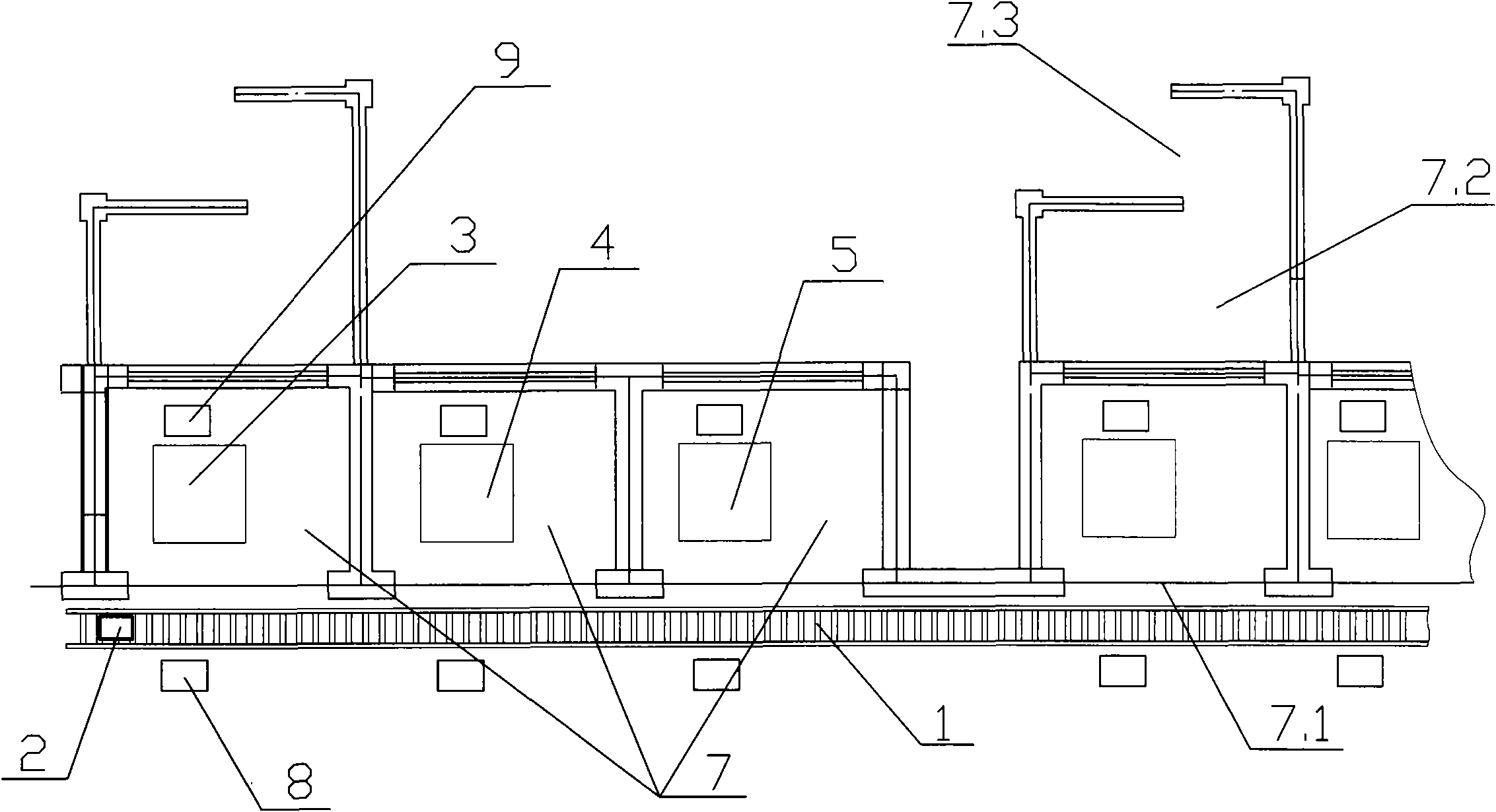

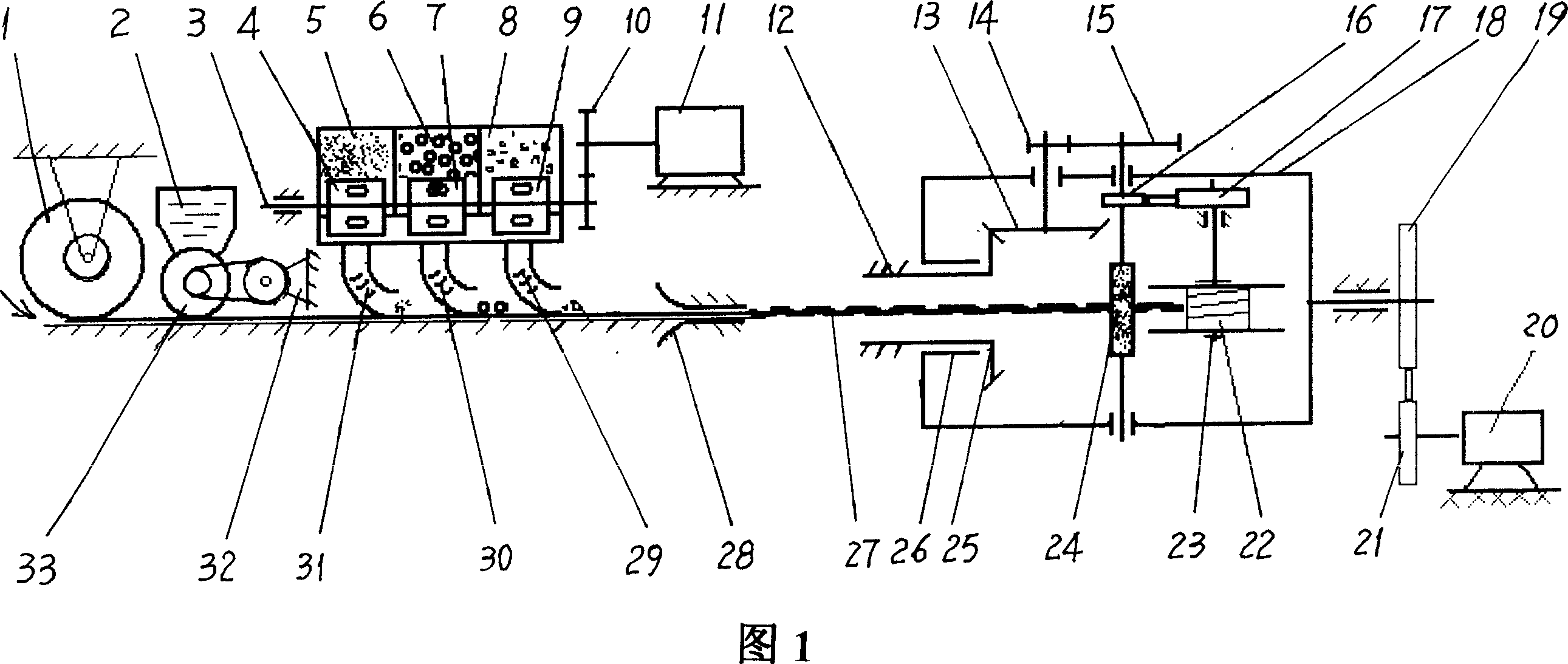

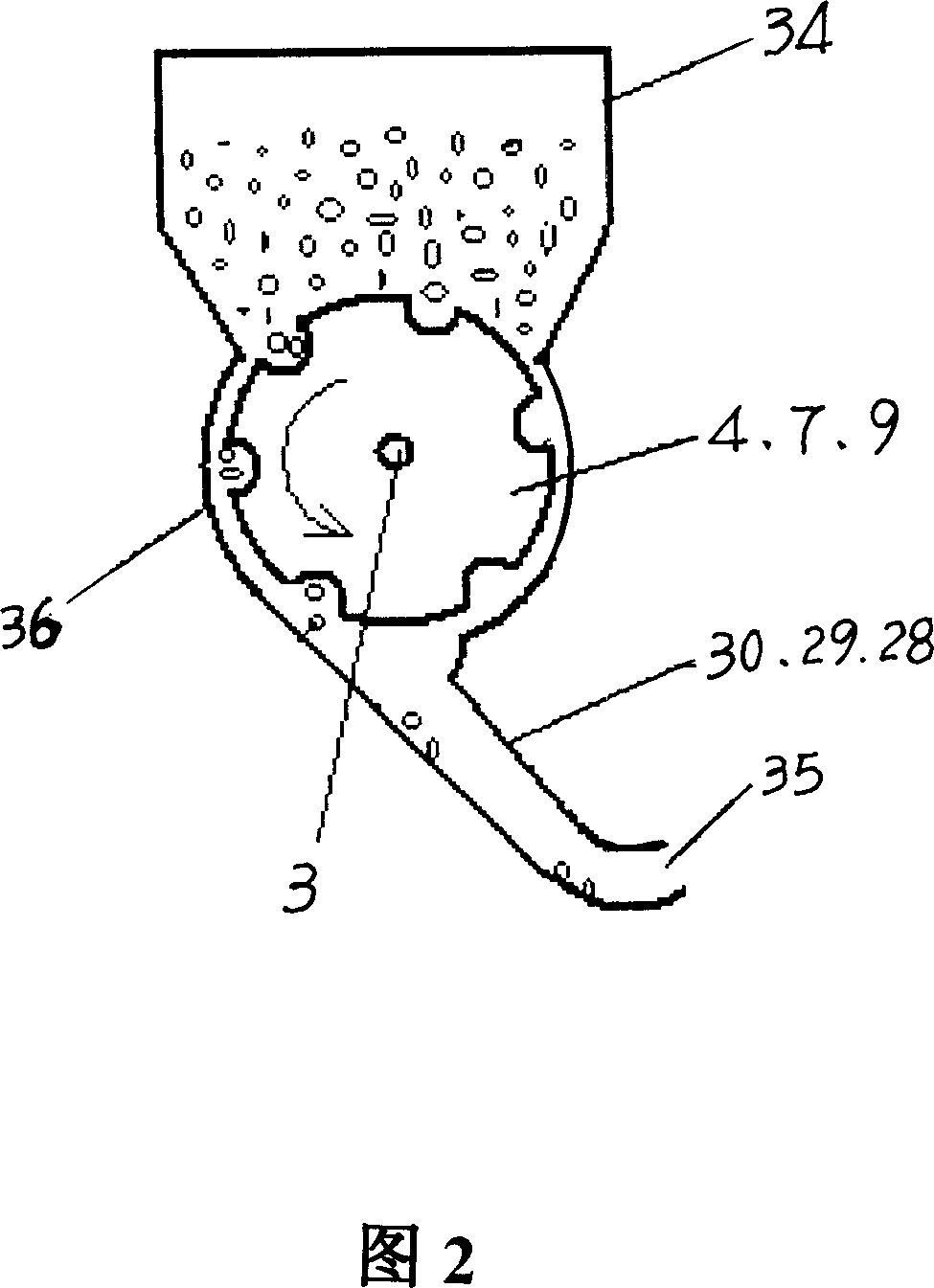

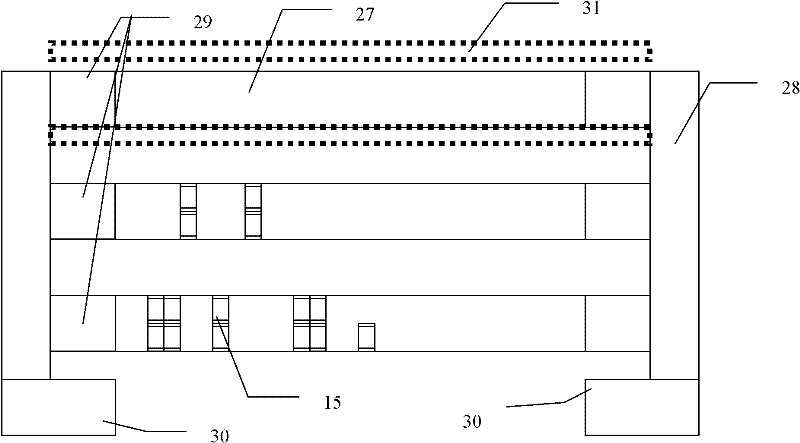

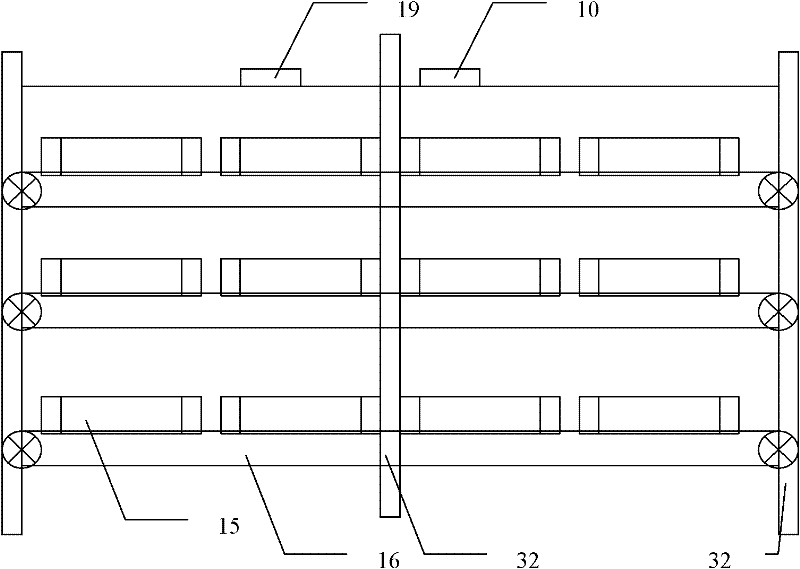

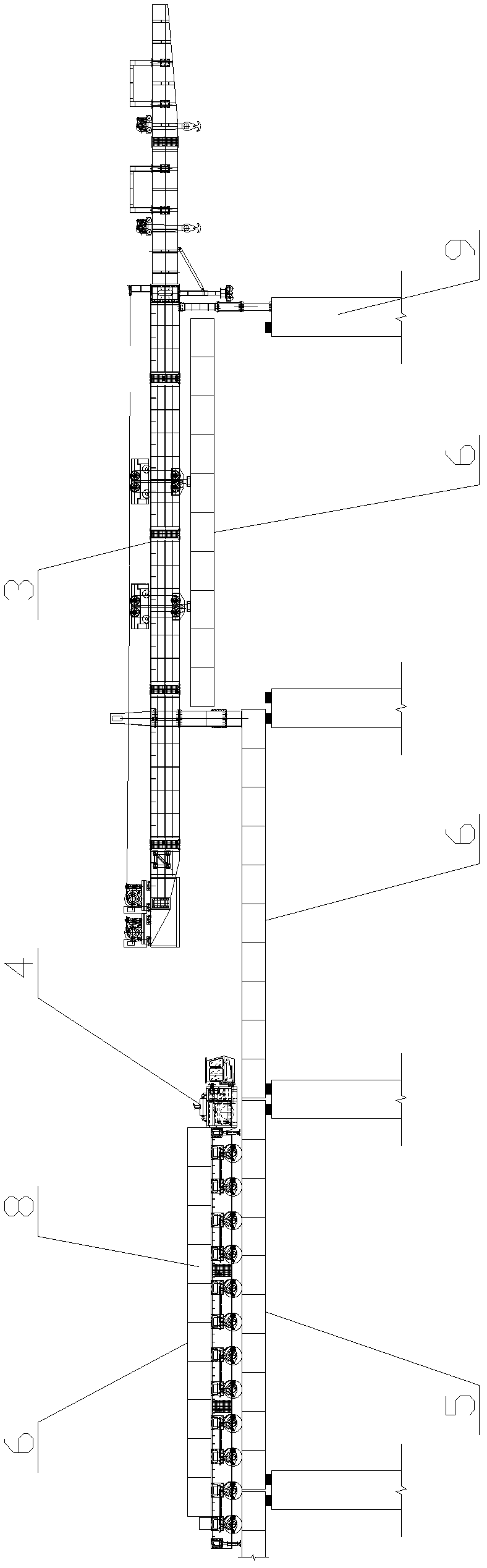

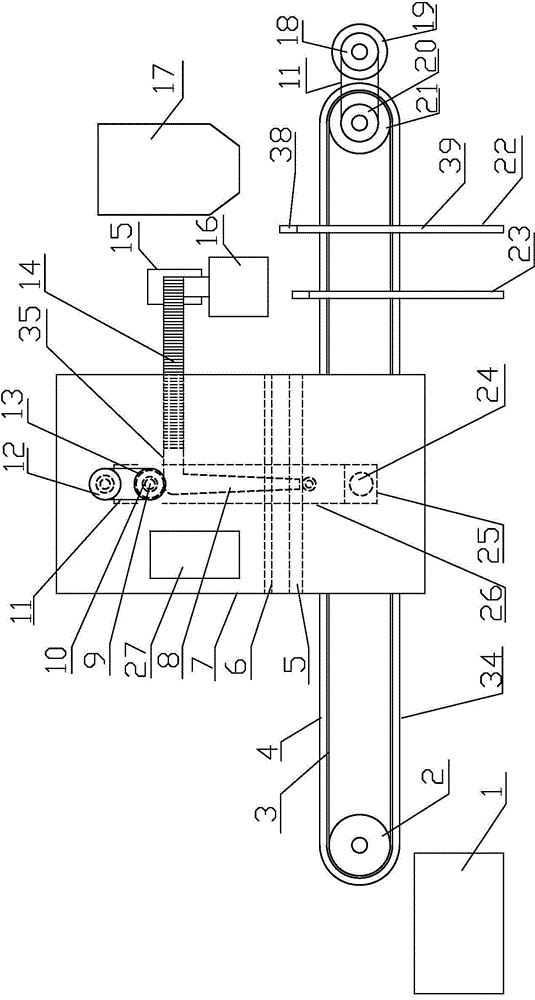

Method for automatically assembling and producing fireworks

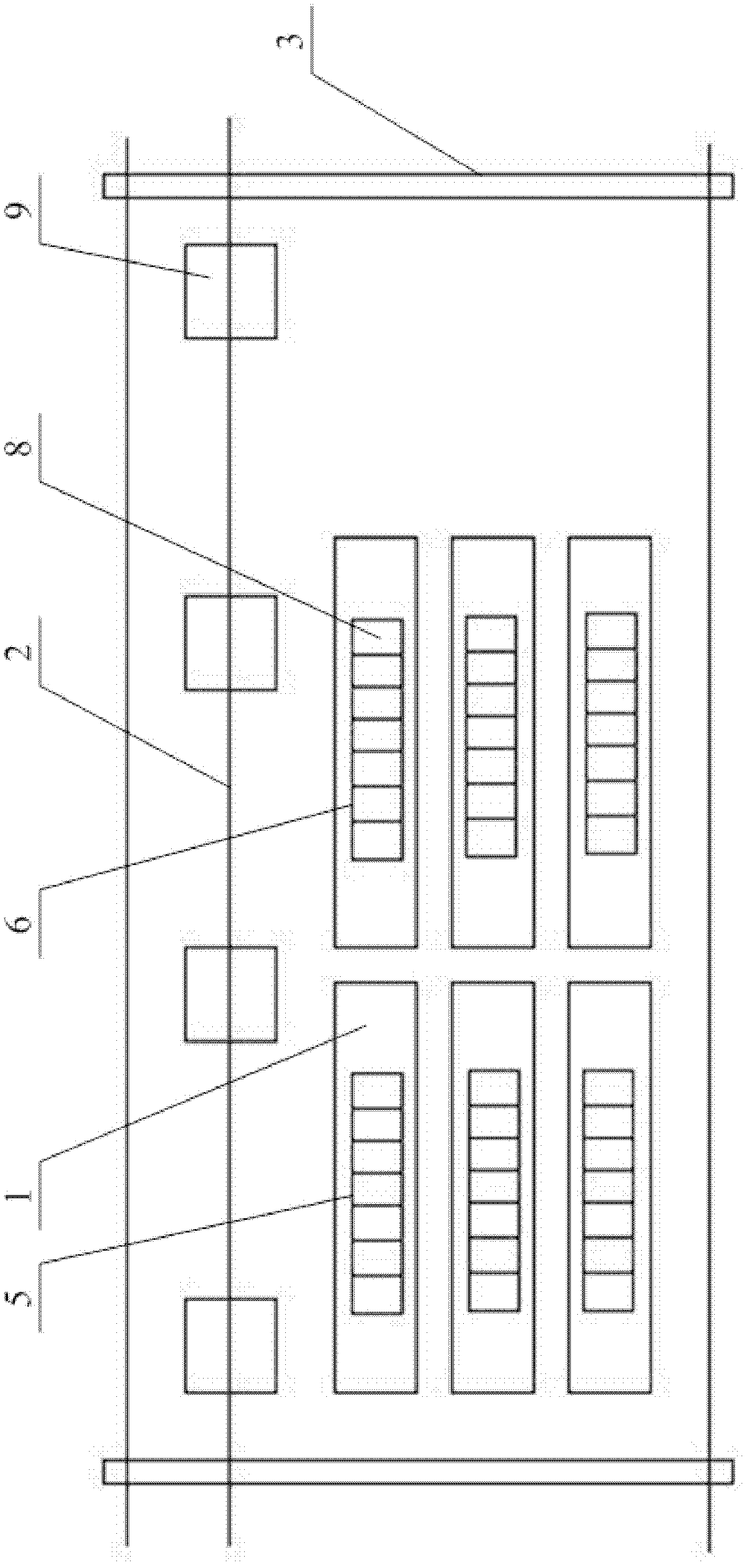

The invention discloses a method for automatically assembling and producing fireworks. A conveyor belt (1) is adopted to convey a tube mold frame (2) to an automatic powder charging machine (3) for charging powder, to an automatic bead charging machine (4) for charging beads and to an automatic soil loader (5) for loading soil, and the one-bang loading process is finished. The load for the tube body (6) in the tube mold frame (2) is at least over one bang load, and the equipment for each bang load is positioned in each explosion-proof chamber (7) arranged in turn on one side of the conveyor belt. An input push device (8) of the tube mold frame is arranged outside the conveyor belt (1) outside the door of each explosion-proof chamber (7), and an output push device (9) of the tube mold frame is arranged in each explosion-proof chamber (7) corresponding to each input push device (8). The method for automatically assembling and producing fireworks can assemble 100 flash bangs totally, and provides convenient labor-saving high-production efficiency equipment for the firecracker industry; and the equipment has the advantages of novel design, simple structure, convenient maintenance, low cost and high production efficiency, and ends manual work for assembling flash bangs and beads.

Owner:林红斌

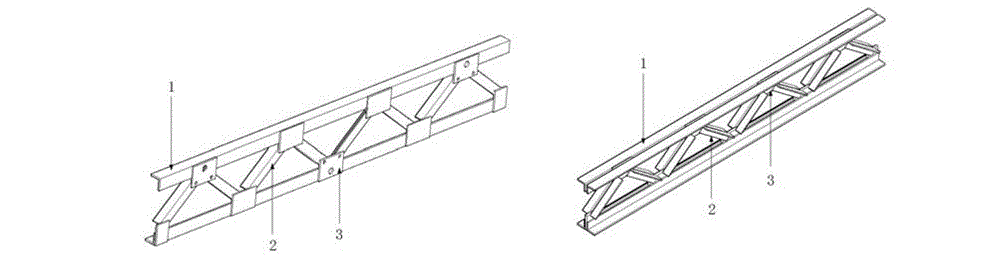

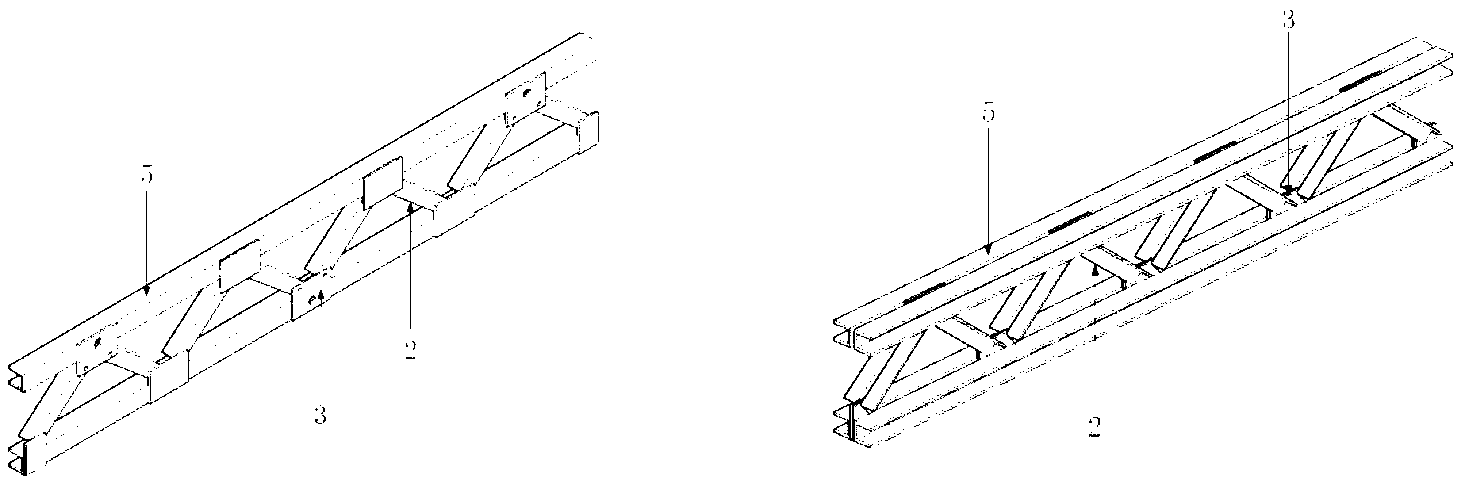

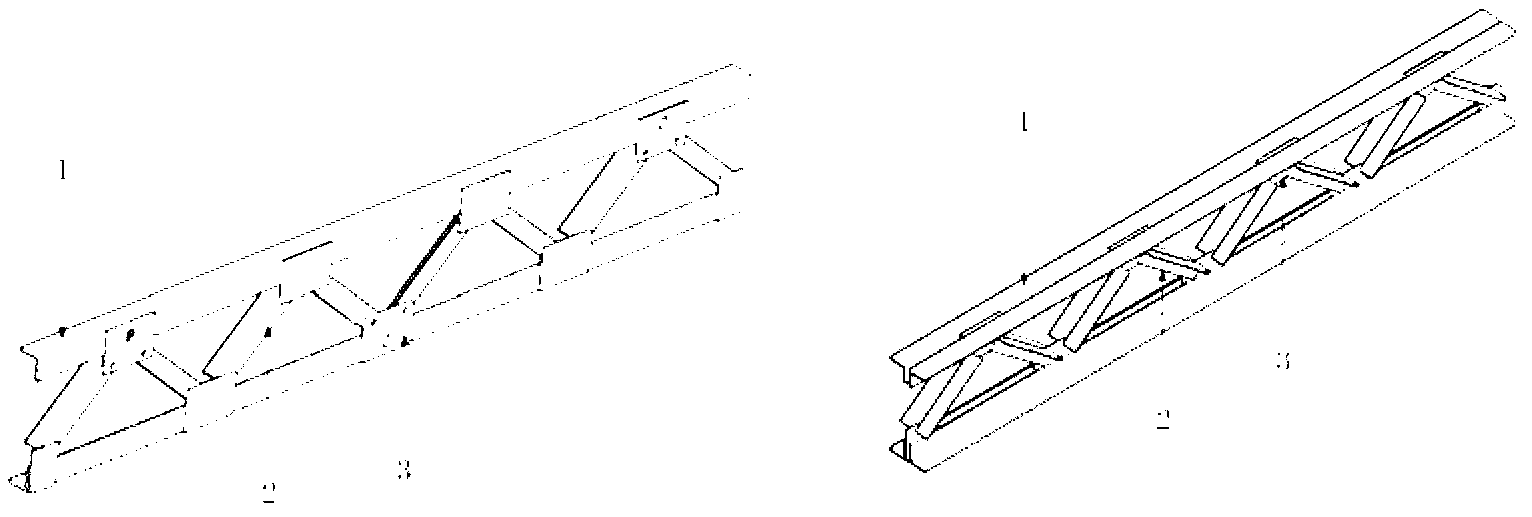

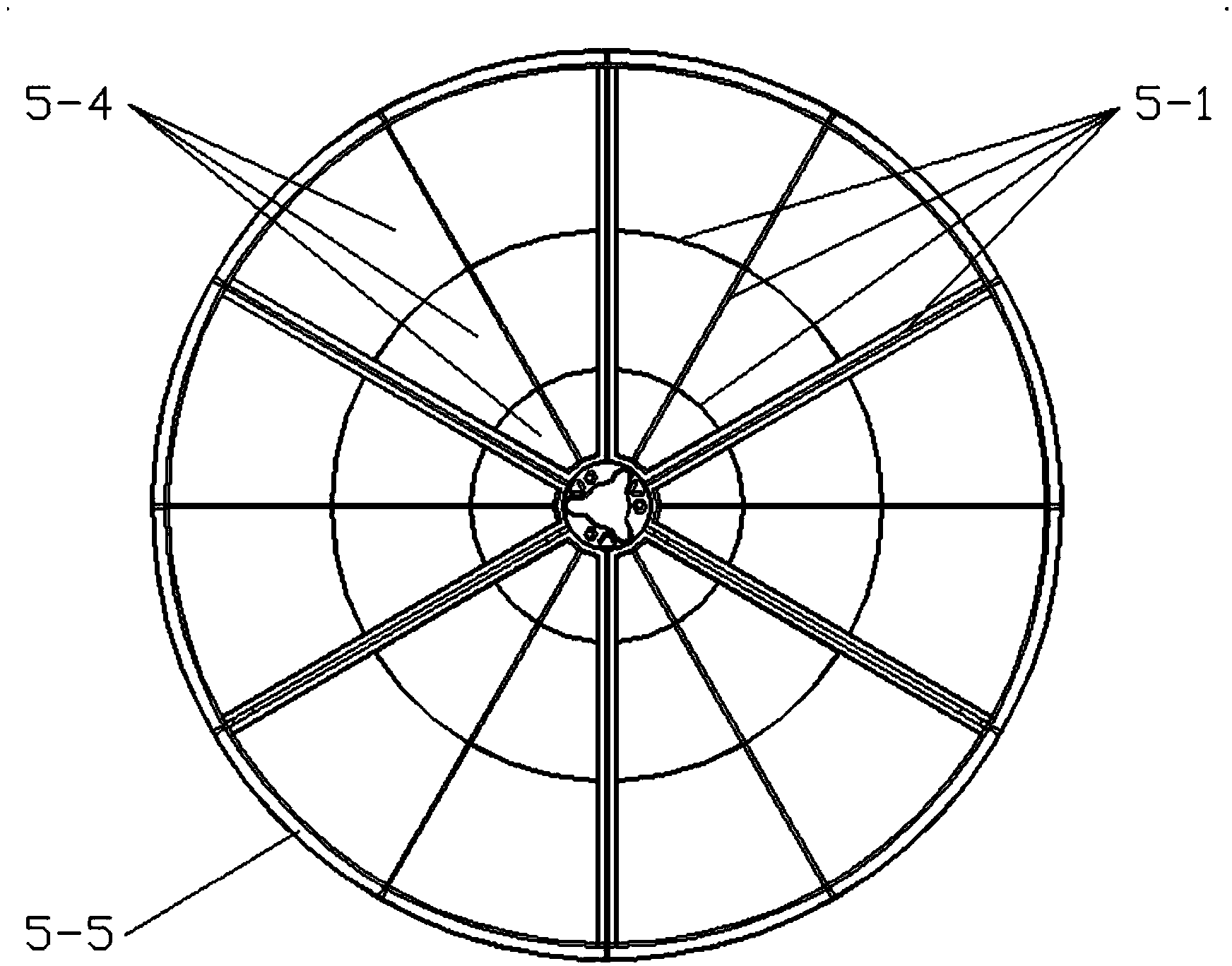

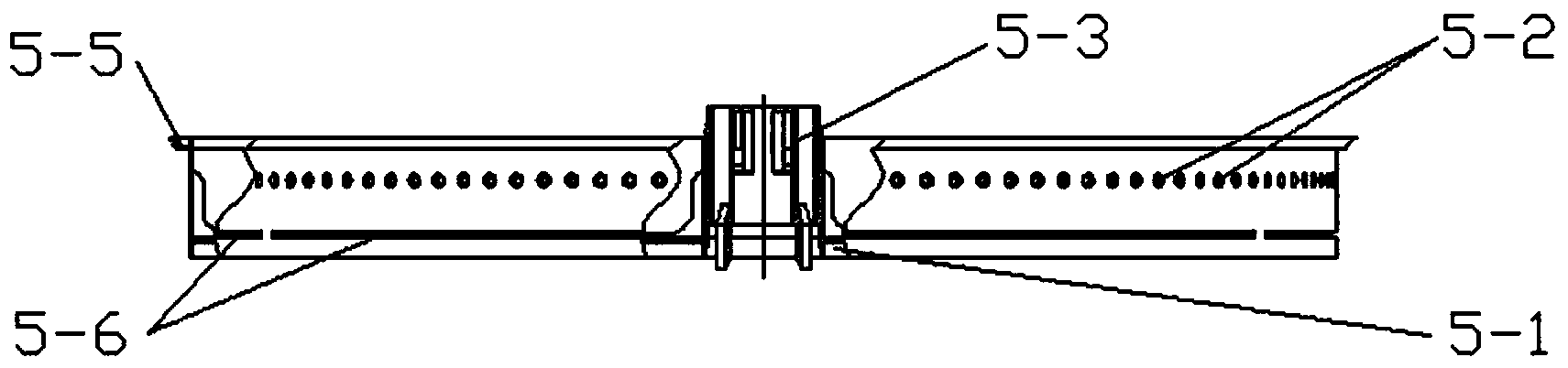

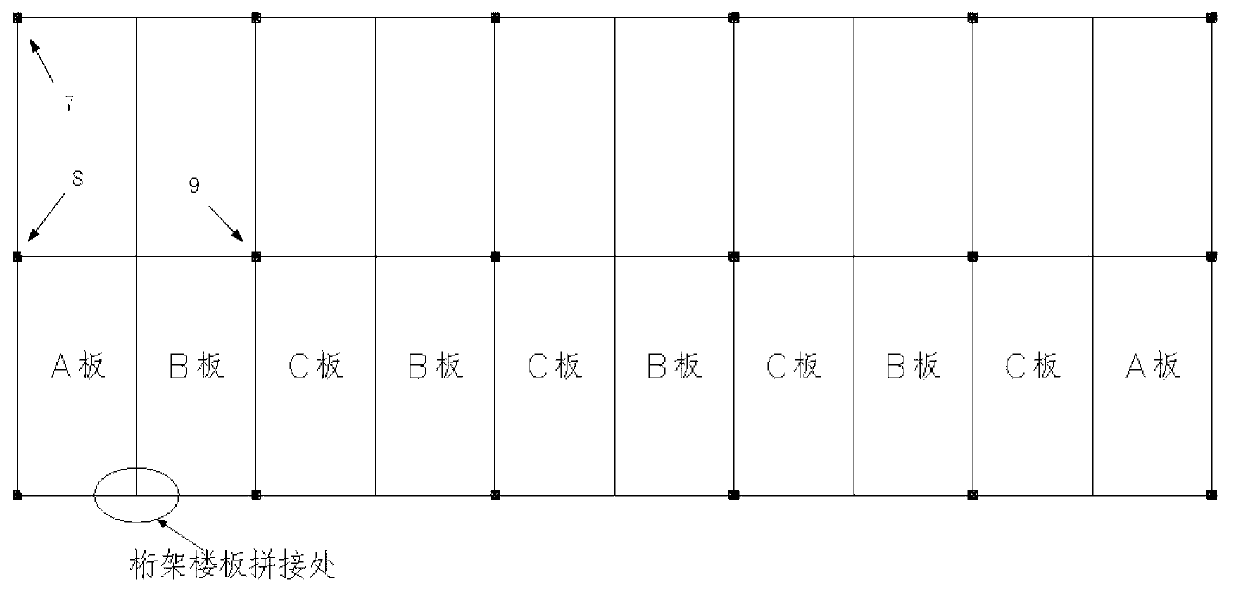

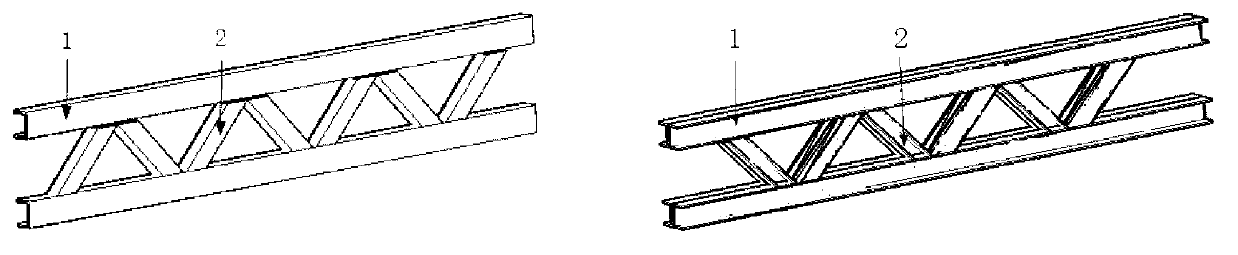

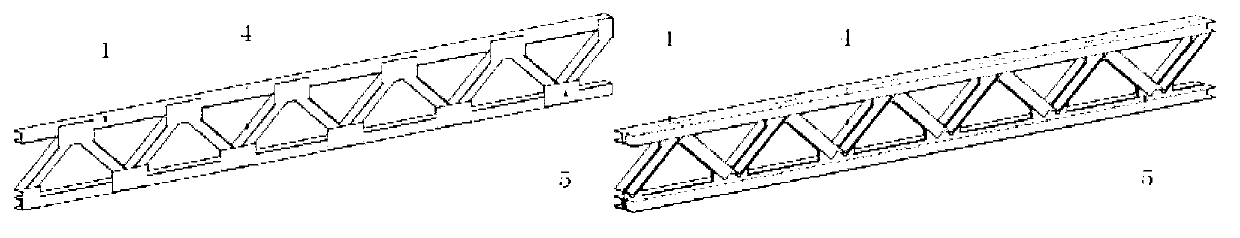

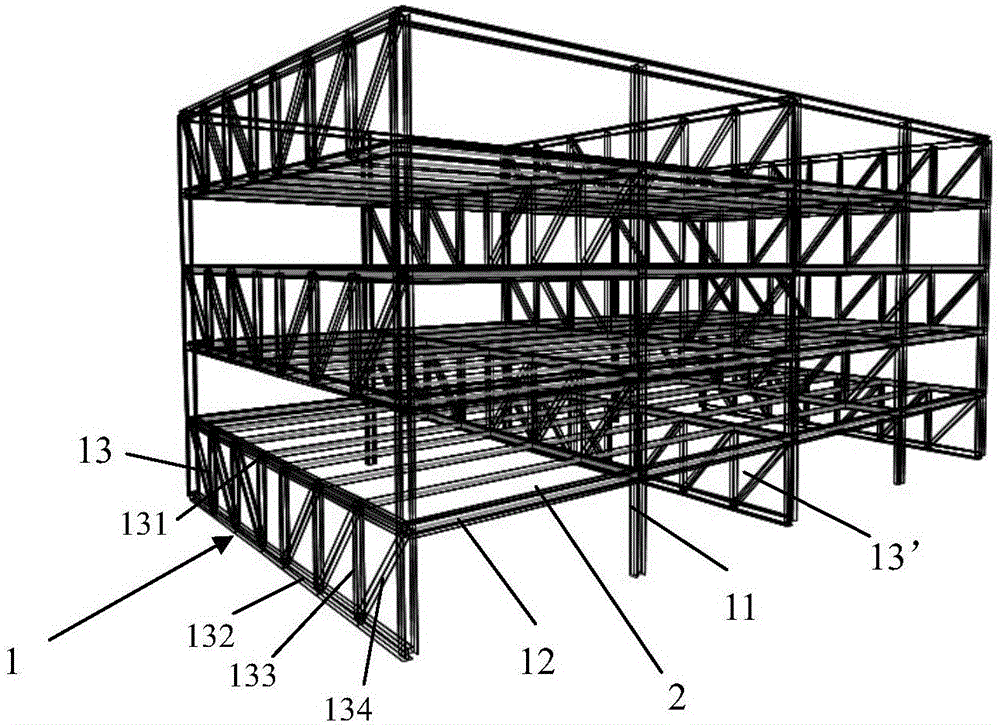

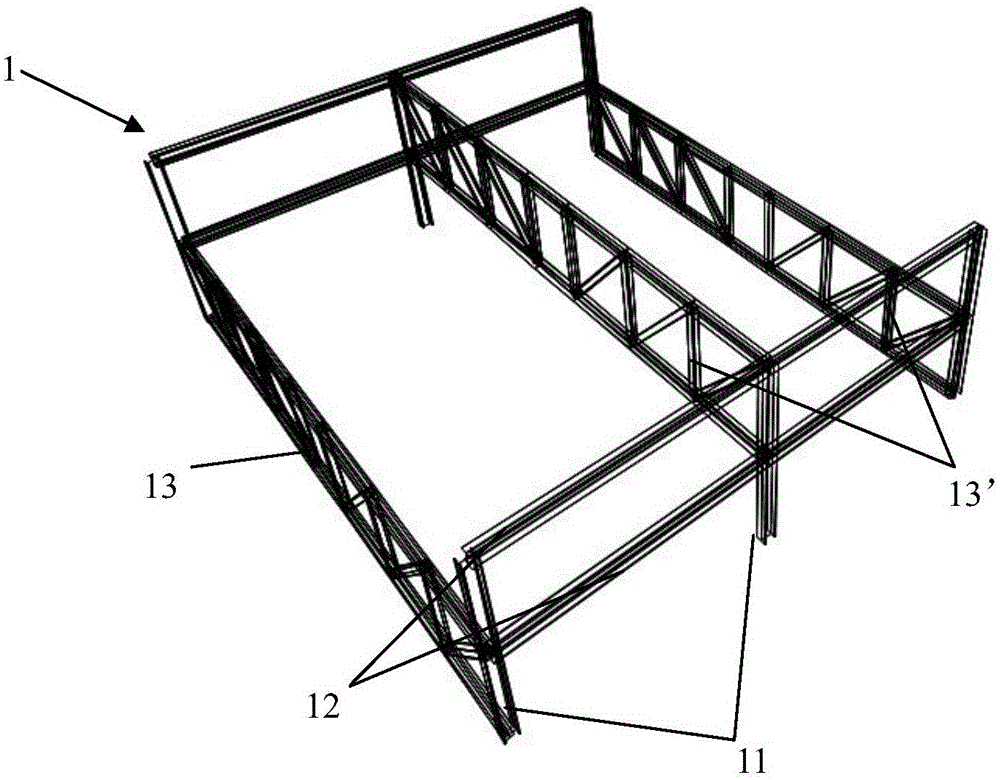

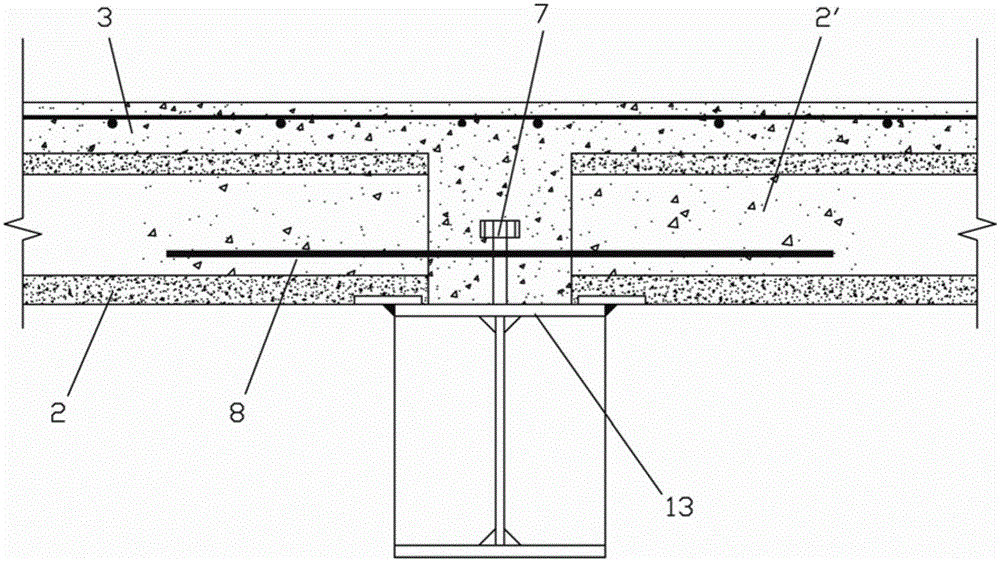

Industrialized multi-story high-rise assembled steel structure system

The invention relates to an industrialized multi-story high-rise assembled steel structure system, belonging to the technical field of structure engineering. The industrialized multi-story high-rise assembled steel structure system comprises assembled truss plates and assembled flange columns. The assembled truss plates comprise latticed truss beams with angle steel web members, column base joints and slabs. The assembled truss plates are prefabricated in a factory. On a construction site, the assembled truss plates are spliced together through beam end closing plates or the column base joints to form frame structure beam-slab layers; the frame structure beam-slab layers are vertically connected through the assembled flange columns to form a multilayer steel frame structure, and the assembled flange columns are arranged on the column base joints on the assembled truss plates; and the assembled truss plates and the assembled flange columns are prefabricated in the factory and are assembled through bolts on the construction site. In combination with modularization, factory production, standardization and assembling, the industrialized multi-story high-rise assembled steel structure system has the advantages that the factory production and the on-site rapid assembling are realized; and on the premise that the construction quality is guaranteed, the construction speed is improved, the construction period is shortened and the construction cost is decreased.

Owner:CHINA RAILWAY CONSTR GROUP +1

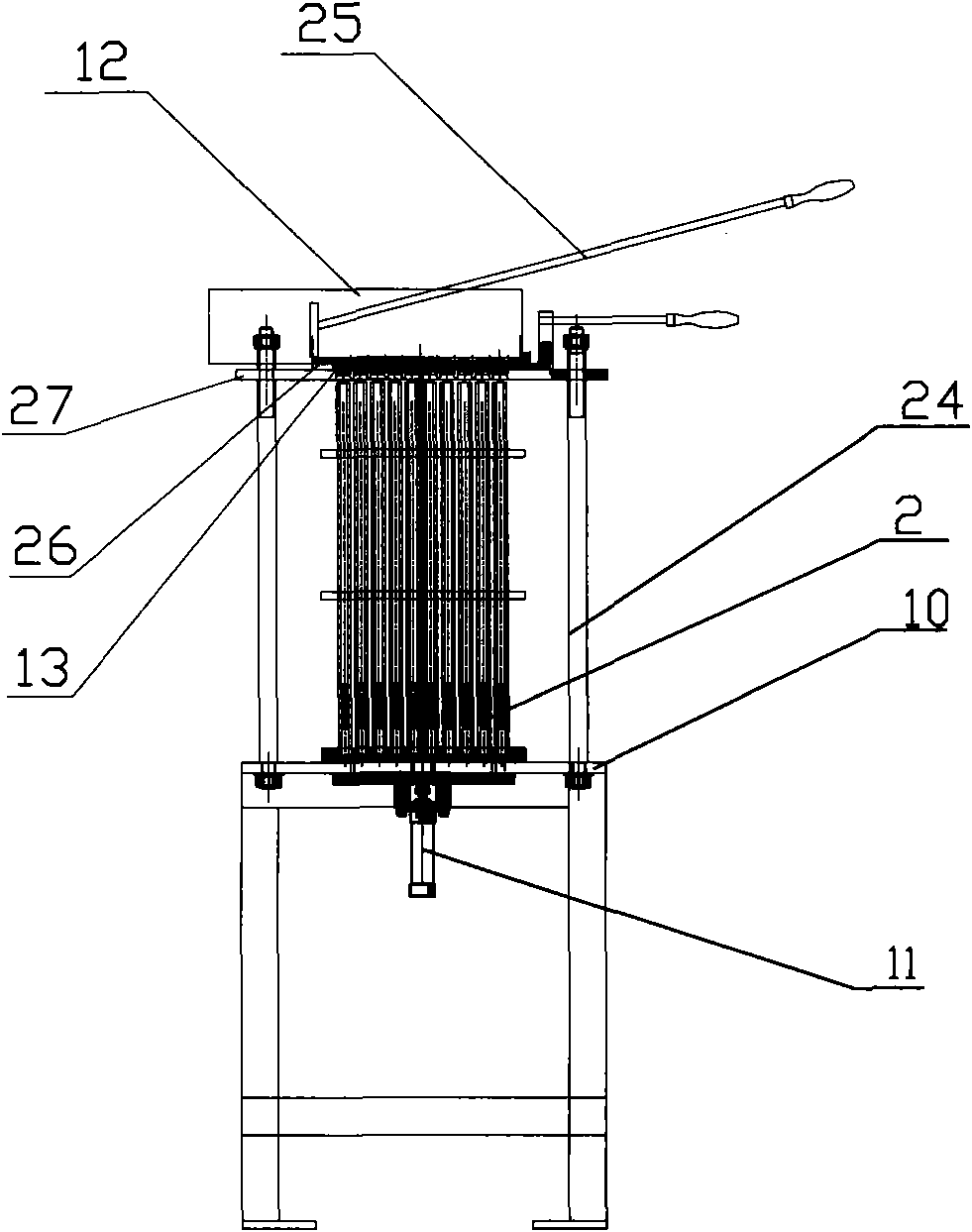

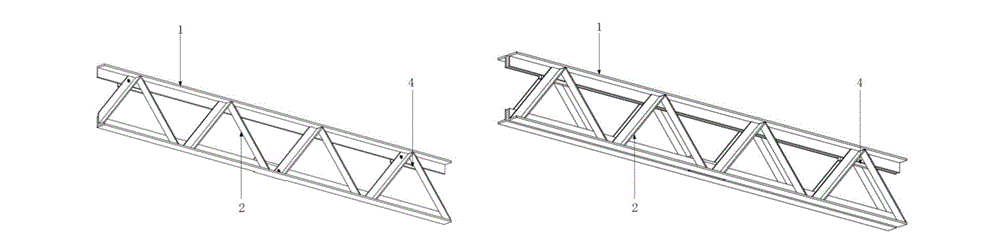

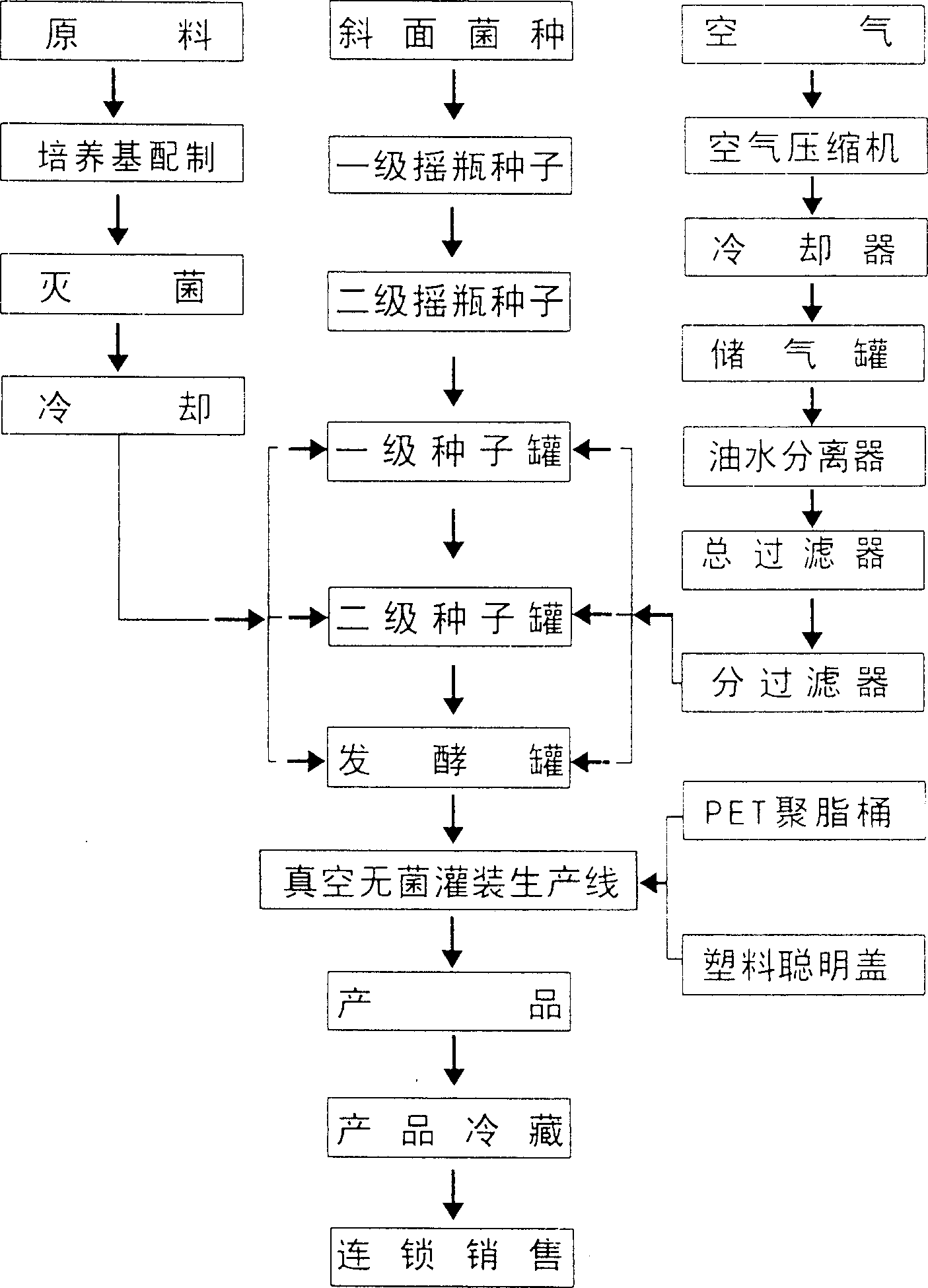

Commercial production method for edible mushroom liquid culture bacteria, apparatus and automatic sterilized inoculator

InactiveCN1742543AConvenient storage and transportationHigh degree of automationHorticultureBiotechnologyIt equipment

The present invention discloses an edible fungus liquid culture strain commercial production method, its equipment and automatic sterile inoculating machine. It is characterized by that the edible fungus production is divided into two portions. One portion is edible fungus strain-making industry and the other portion is edible fungus cultivation industry.

Owner:付嵘

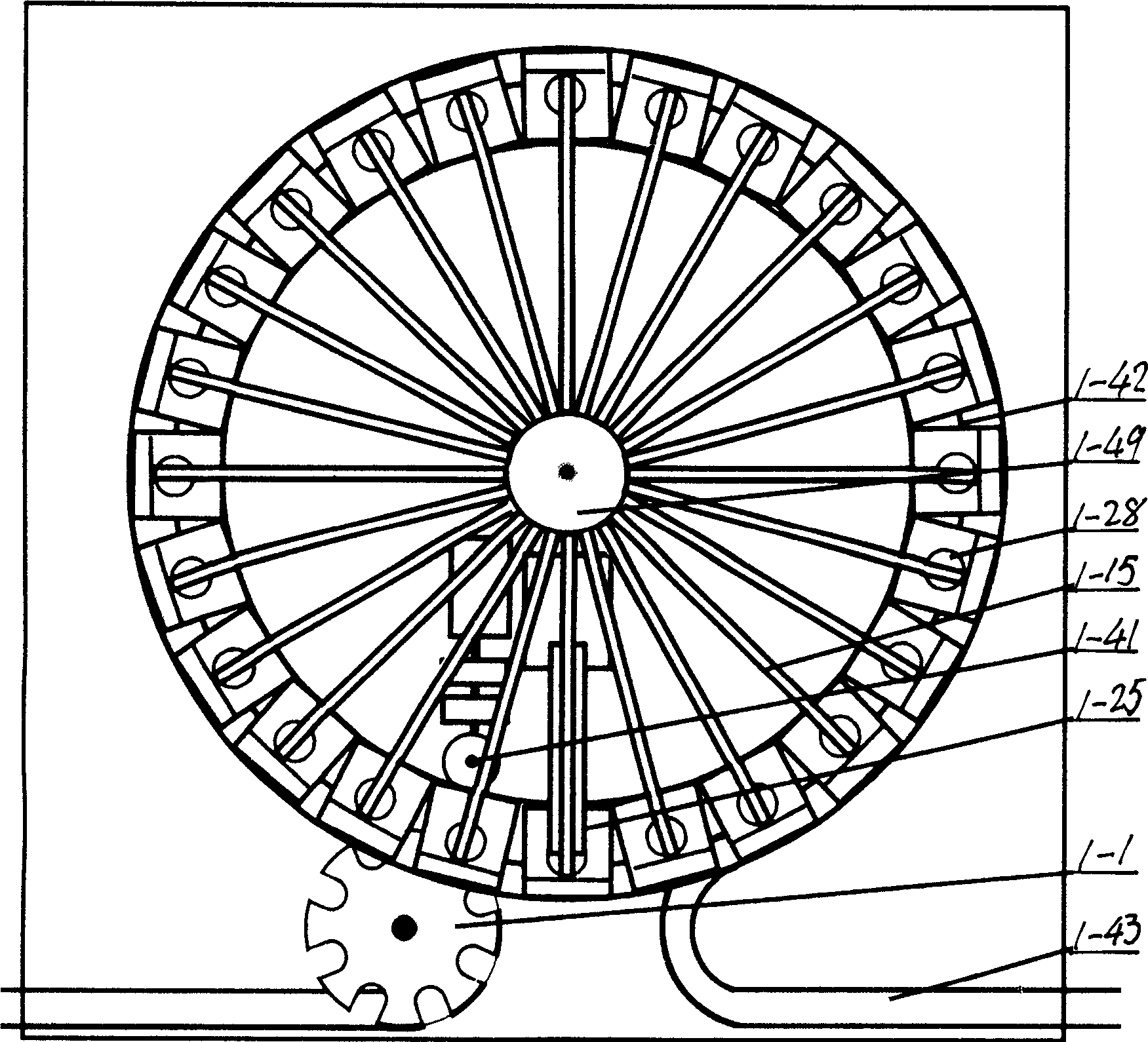

Seed rope and machine for twisting the same

InactiveCN100998278ALightweightAccelerate the process of live mechanizationPlantingSeed arrangmentsPaper tapeAgricultural engineering

A seed rope made of paper for agricultural crops including rice contains quantitatively seed, fertilizer and herbicide arranged at intervals. Its twisting machine is composed of paper tape feeder, adhesive coating roller, the seed, fertilizer and herbicide feeders, and a twisting unit consisting of motor, drive mechanism, rotary frame, planetary gear engaged with the gear on machine frame, rope releasing wheel with axle, and rope winding wheel with axle.

Owner:SHENYANG AGRI UNIV

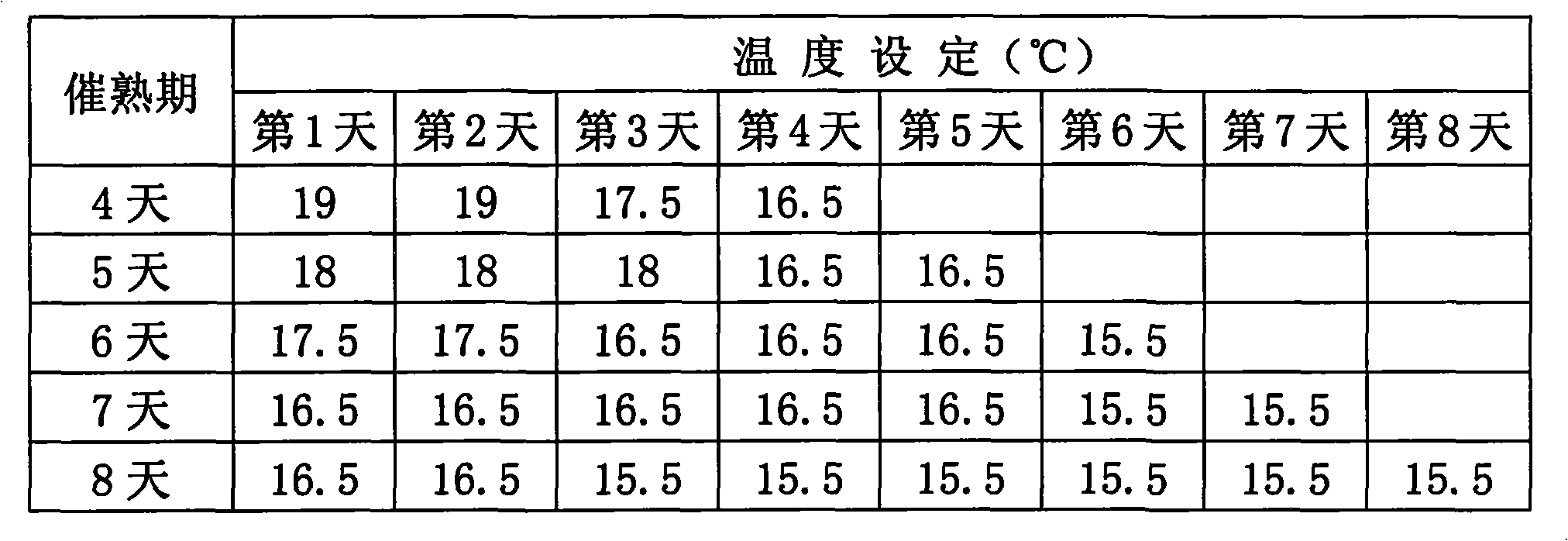

Flower forcing method enabling blossom of rhododendron lapponicum in Spring Festival

The invention relates to a flower forcing method enabling blossom of rhododendron lapponicum in Spring Festival. The method comprises the following steps: preparing a greenhouse, processing the potted rhododendron lapponicum before flower forcing, controlling the temperature, humidity, illumination, ventilation, moisture, fertilizers and sterilization management in the greenhouse when buds appear, managing the temperature and humidity when the buds show colors and the like. The method provided by the invention is simple and practical, is easy to operate, can be used for accurately controlling the flower forcing time of the rhododendron lapponicum in Spring Festival within 30-42 days and shortening the flower forcing time and is a key technology in the large-scale production of rhododendron lapponicum.

Owner:宜昌市科力生实业有限公司

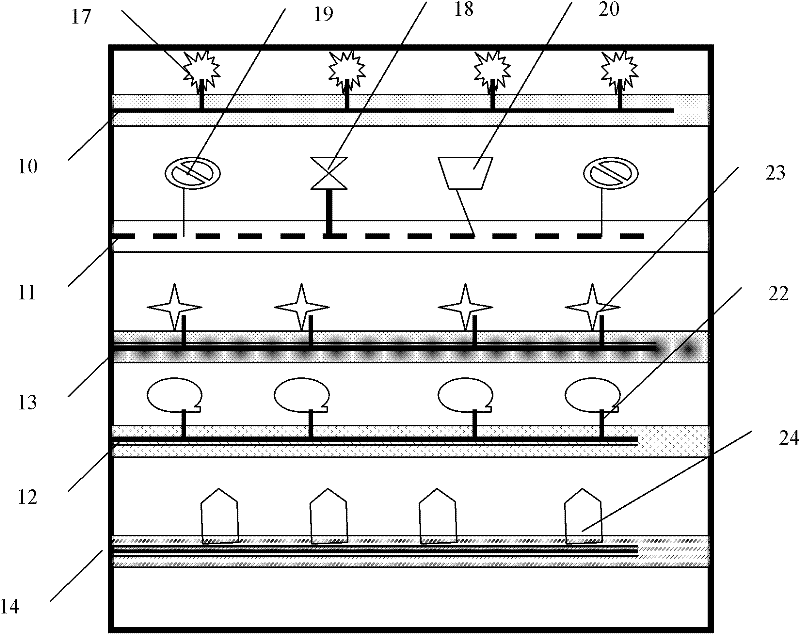

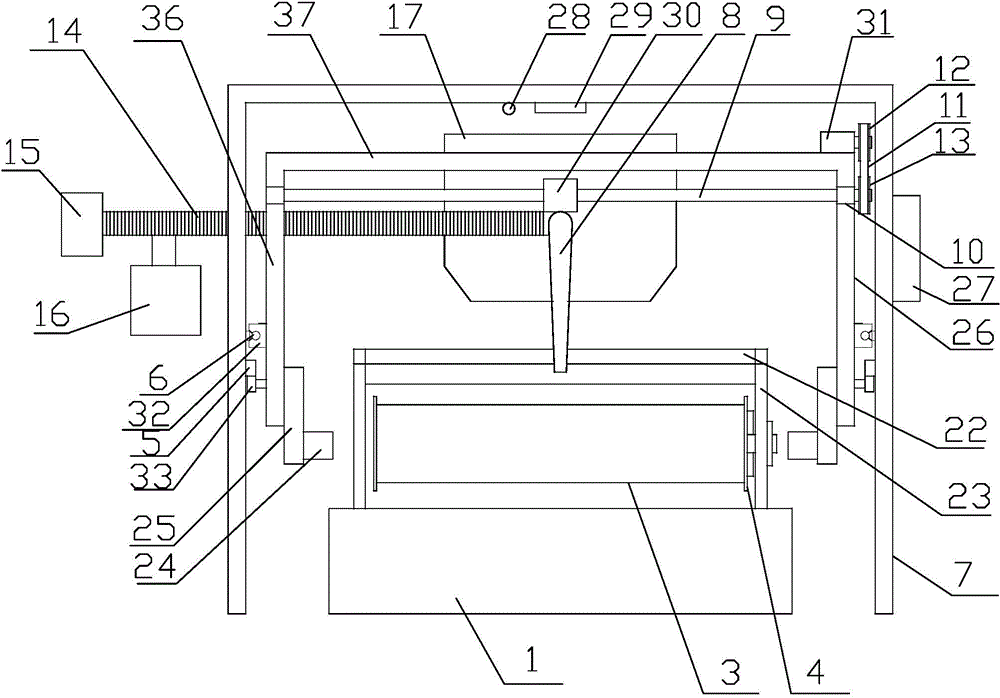

Factory agricultural automatic production line

InactiveCN102293133AAchieve high volumeRealize intelligenceClimate change adaptationGreenhouse cultivationTemperature controlProduction line

The purpose of the present invention is to provide a factory agricultural automatic production line, which can realize large-scale, intelligent, modularized, new energy, and factory-like facilities for agricultural production. The agricultural production box is placed on the transmission equipment, and through Temperature control, light supplement, liquid supply, information collection and other devices are installed around the planting box to realize accurate, dynamic, partitioned, intelligent, and energy-saving control of temperature, humidity, carbon dioxide concentration, and nutrient solution concentration in the production process, which realizes agricultural The transmission of the production box also realizes the control of its artificial environment, thereby realizing industrialization and low-cost agricultural production, suitable for mass production of breeding, aquatic products, livestock, fungi, etc.

Owner:CHENGDU AONENGPU TECH

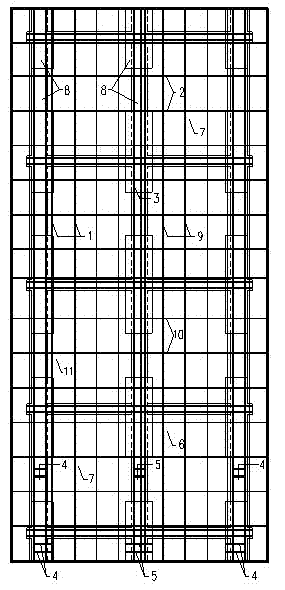

Manufacturing method of fabricated support-free prefabricated ribbed light superposed floor slab

ActiveCN103031952ARealize factoryEasy to install on siteFloorsBuilding material handlingFalseworkFloor slab

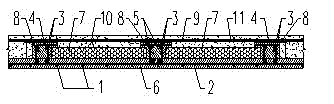

The invention provides a manufacturing method of a fabricated support-free prefabricated ribbed light superposed floor slab, and relates to a manufacturing method of a building floor slab. The method comprises the following steps of: firstly processing bottom longitudinal ribs (or prestressed tendons) and transverse reinforcing steel bars of a prefabricated slab, slab rib longitudinal bars (or prestressed tendons) 3, stirrups 4 or bonding ribs 5 of the prefabricated slab; placing the reinforcing steel bars in a production mold of the prefabricated slab; binding the reinforcing steel bars; casting concrete 6 of a bottom plate of the prefabricating part; putting polyphenyl plates 7 or other light materials in corresponding amount according to requirements; then pouring arris of slab 8; finishing factory processing through curing; in the construction site, hanging the floor slab in place, and then putting the longitudinal and transverse reinforcing steel bars 10 at the upper part of the floor slab; and casting the concrete 11 at the upper part of the floor slab, and curing to finish the support-free prefabricated ribbed light superposed floor slab. By adopting the technology, the slab forms and scaffolding work can be basically eliminated at the construction site; the waste of the building material can be reduced to a maximum extent; the industrial and standardized production of the floor slab can be satisfied; and the integral site assembly of the floor slab can be satisfied.

Owner:LIAONING YIZHU BUILDING MATERIALS CO LTD

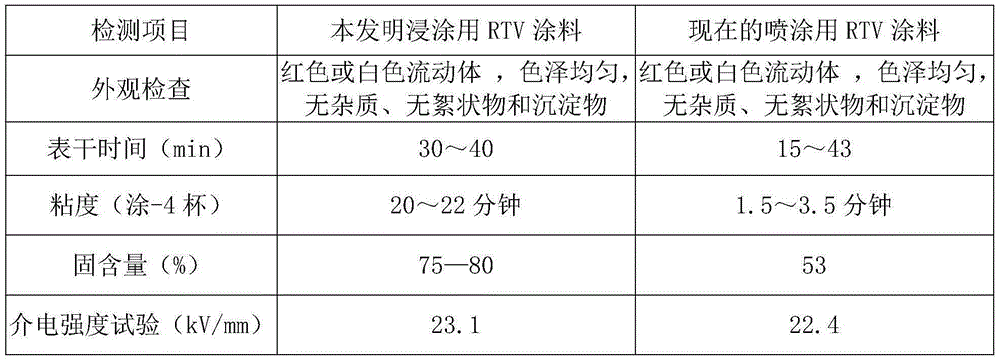

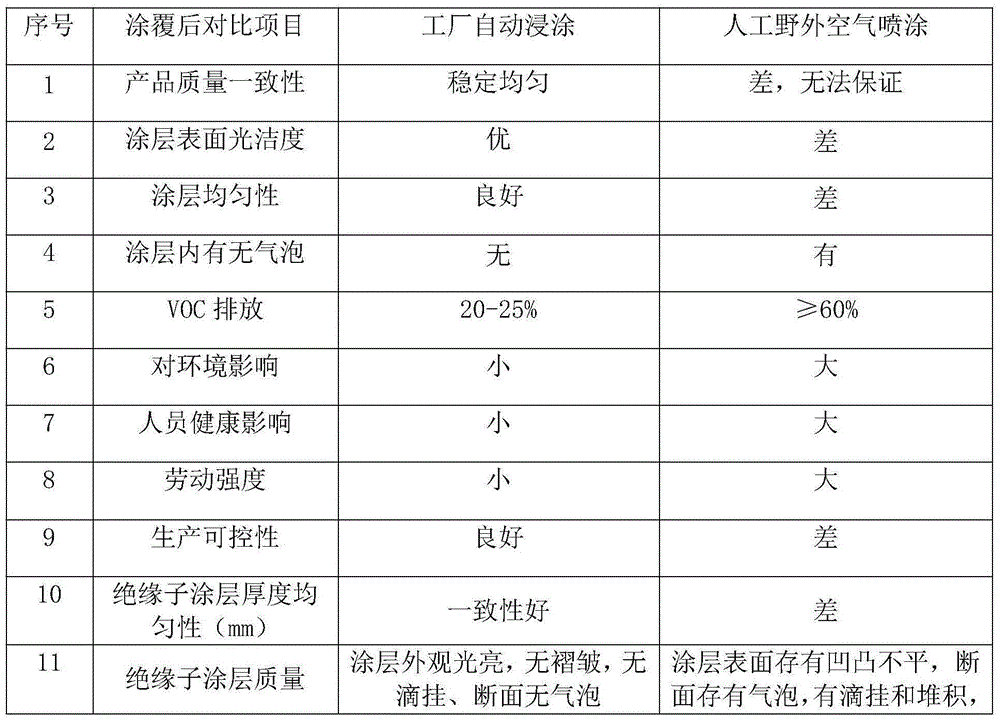

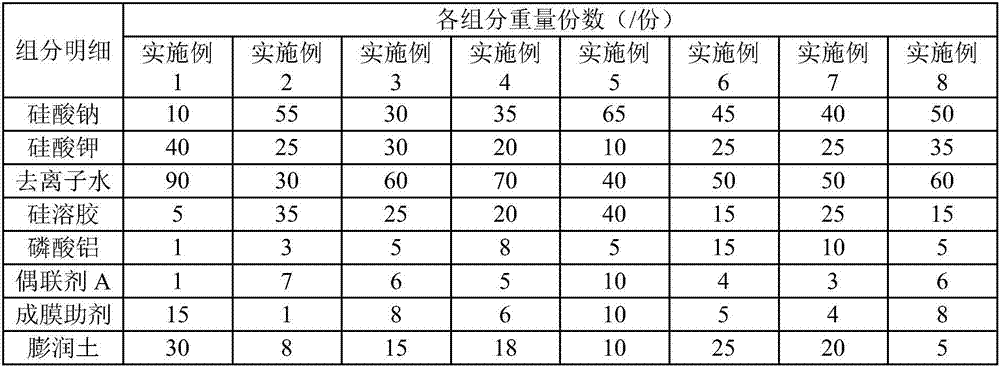

RTV anti-pollution flashover coating suitable for automatic dip-coating of insulator and preparation method of RTV anti-pollution flashover coating

InactiveCN104673091AHigh viscosityHigh solid contentFireproof paintsAntifouling/underwater paintsGas phaseDip-coating

The invention relates to the technical field of organic silicon coatings, and particularly relates to an RTV anti-pollution flashover coating suitable for automatic dip-coating of an insulator and a preparation method of the RTV anti-pollution flashover coating. The RTV anti-pollution flashover coating comprises the following components in parts by weight: 40-60 parts of an active polydimethylsiloxane mixture, 5-10 parts of a hydrophobic transferring aid, 8-30 parts of reinforcing gas-phase-method white carbon black, 15-32 parts of fire retarding filler, 3-8 parts of a crosslinking agent, 0.5-5 parts of a tackifier, 0.01-1.0 part of a sulfurization accelerator, 0.1-5 parts of a pigment and 15-35 parts of solvent oil. The preparation method of the RTV anti-pollution flashover coating comprises the following steps: (1) kneading; (2) grinding; (3) drying; (4) cooling; (5) mixing, and finally packaging to obtain a finished product. The RTV anti-pollution flashover coating disclosed by the invention has the service characteristics of a common RTV anti-pollution flashover coating and also has higher viscosity, higher solid content, suitable surface drying speed and better foam self-discharging speed, so that the RTV anti-pollution flashover coating can satisfy the coating requirements of an automatic dip-coating technique of ceramics and glass insulators.

Owner:CHENGDU TALY TECH CO LTD

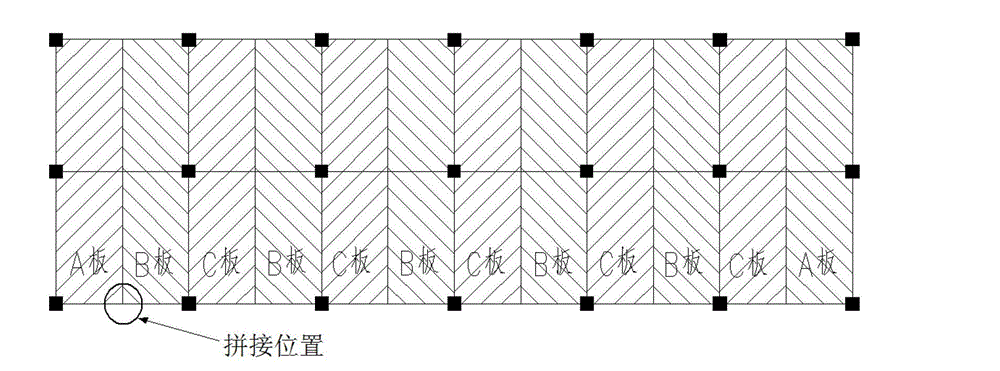

Construction method for splicing and erecting concrete precast beam sections

The invention discloses a construction method for splicing and erecting concrete precast beam sections, comprising the following steps of: 1) arranging a plurality of site splicing platforms beside a beam line to be erected; 2) arranging a plurality of precast beam sections on the site splicing platforms, and carrying out section splicing, glue joint, rope penetration, pre-stressed reinforcement tension and grouting on the plurality of precast beam sections so that the precast beam section are spliced into a beam to be erected; 3) hoisting a first spliced beam to be erected on a pier through a hoisting device and mounting the first spliced beam to be erected; 4) hoisting a beam transportation truck on the mounted first spliced beam to be erected through the hoisting device; 5) arranging a bridge girder erection machine on the beam line to be erected; 6) hoisting following mounted beams to be erected on the beam transportation truck through the hoisting device, and feeding the beams to the bridge girder erection machine through the beam transportation truck; and 7) mounting the beams to be erected through the bridge girder erection machine. By additionally arranging the site splicing platforms, the time for each process is reasonably distributed, so as to ensure the splicing quality and improve the mounting efficiency and the security.

Owner:JIANGYIN BRIDGE BEIJING ENG

Artificial large-scale armyworm culture method

The invention discloses an artificial large-scale armyworm culture method. The method comprises the steps of A, egg mass collection and larva hatch, B, 1-3 age larva feeding, C, 3-5 age larva feeding,D, 5-6 age larva feeding, E, pupation and pupa feeding and F, adult eclosion, mating and spawning. An inventor has been committed to research on the biological nature, predatory function and artificial feeding of natural enemy insects for a long time, under the weather of heavy rain, high humidity and insufficient illumination in Suiyang County of Guizhou province, large-scale armyworm feeding isachieved, the yearly yield reaches 20 million or above, Arma chinensis and Picromerus lewisi Scott in Suiyang County are fed with armyworms, and the Arma chinensis yield reaches one million or aboveand Picromerus lewisi Scott yield reaches 400 thousand or above; the achievement of the natural enemy insects is guaranteed.

Owner:ZUNYI TOBACCO OF GUIZHOU TOBACCO CORP +1

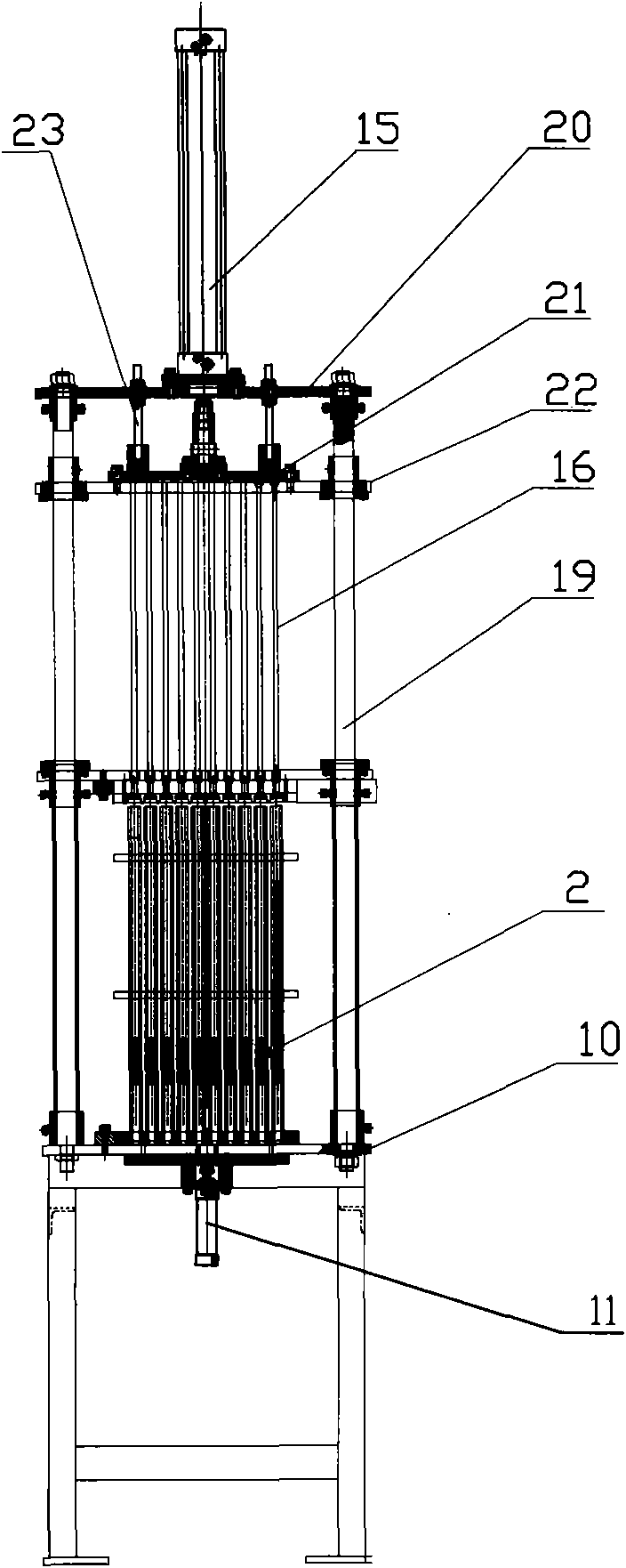

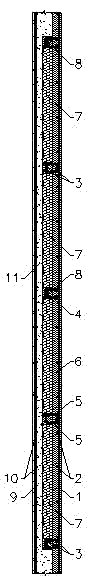

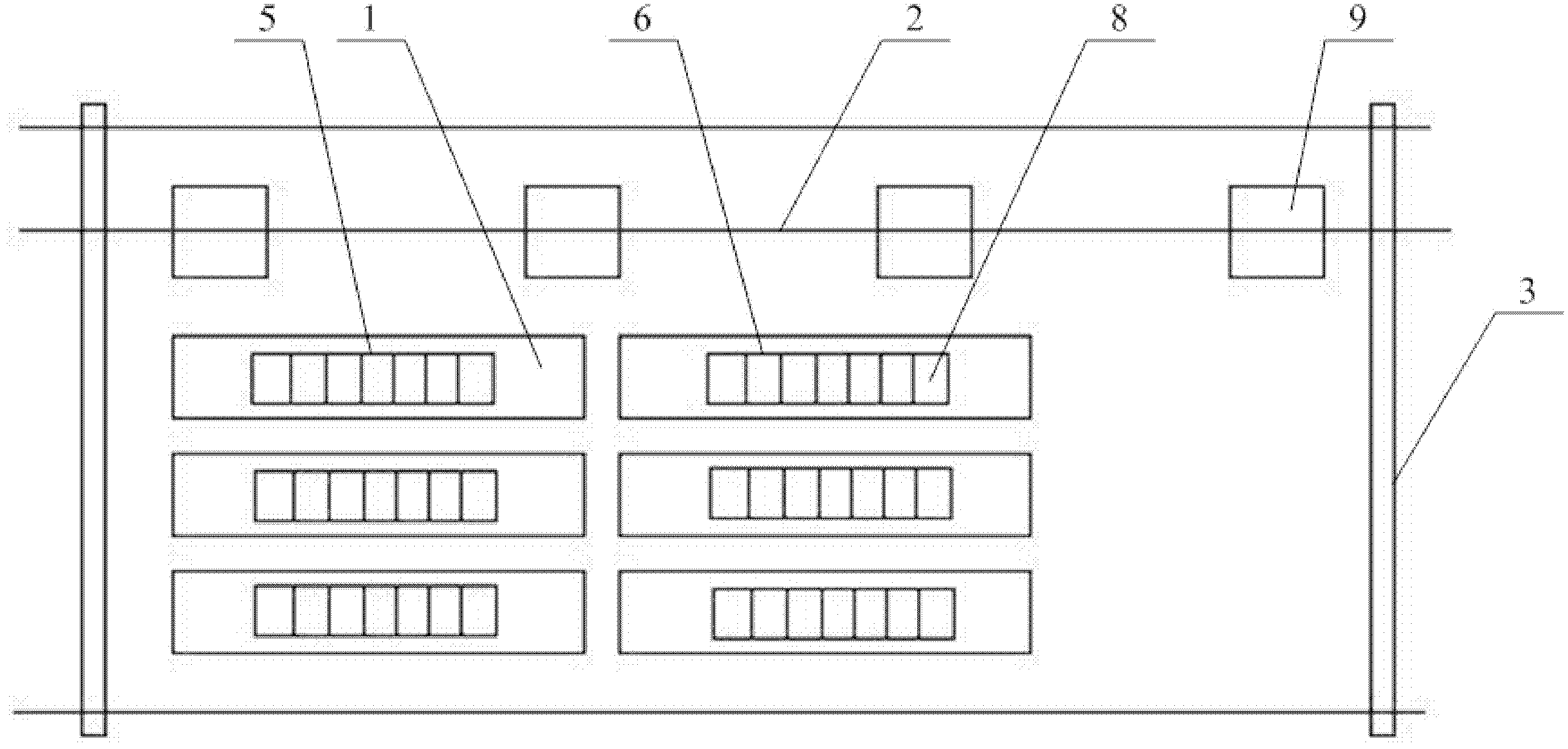

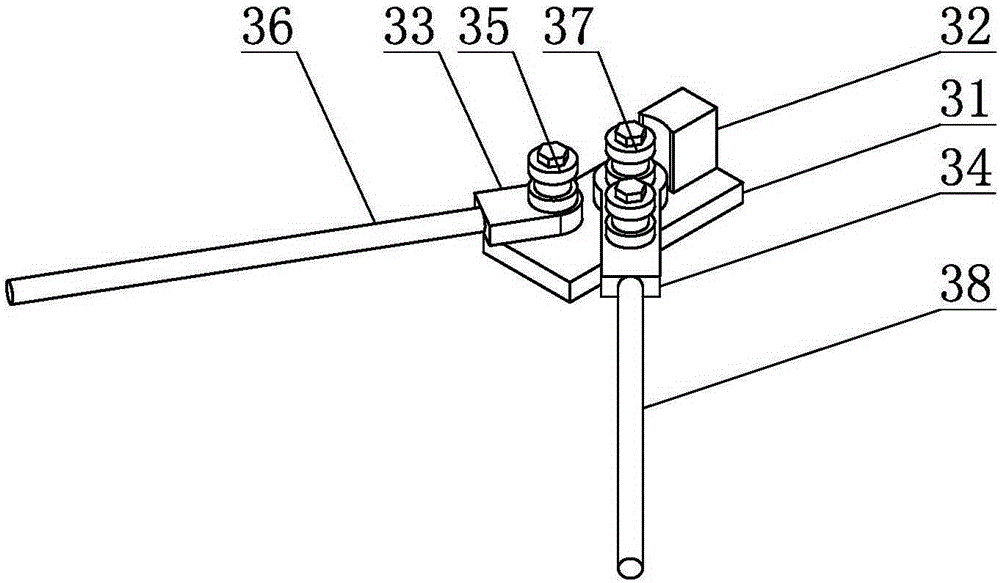

Manufacturing process and manufacturing apparatus for high-voltage lead wires of transformer

ActiveCN105185566ARealize factoryReduce working at heightsTransformers/inductances coils/windings/connectionsCoils manufactureTransformerManufactured apparatus

The invention discloses a manufacturing process and a manufacturing apparatus for high-voltage lead wires of a transformer, and mainly relates to the field of electric power engineering construction processes. The manufacturing apparatus for the high-voltage lead wires of the transformer comprises a worktable, wherein a curve device, a curve shaper, an insulator bracket, a lightning arrester fixing bracket and an insulated wire bracket are arranged on the worktable. The manufacturing process and the manufacturing apparatus have the beneficial effects that the high-voltage lead wires of the transformer are assembled and manufactured on the manufacturing apparatus for the high-voltage lead wire of the transformer and then are transported to a construction site in a unified way for installation, so that excessive overhead work can be reduced, the construction difficulty can be lowered, the field operation progress can be accelerated, the potential safety hazards can be reduced, the manufacturing process can be standardized, the assembly quality can be effectively controlled, and the material waste can be avoided.

Owner:国网山东夏津县供电公司

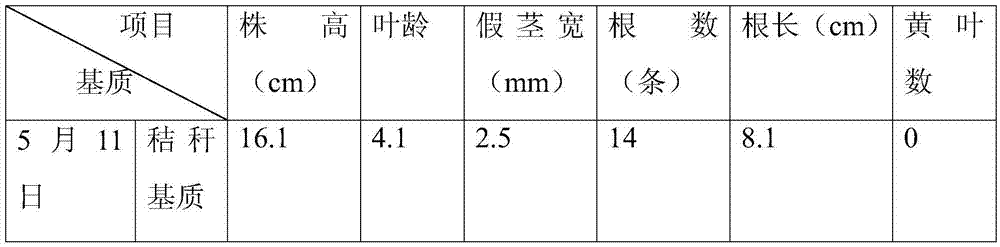

Soilless straw matrix of rice dry-raising water pipe and seedling culture method

ActiveCN105432449AReduce conflictMeet the needs of large-area productionGrowth substratesCulture mediaRoot numberDisinfectant

The invention discloses a soilless straw matrix of rice dry-raising water pipe and a seedling culture method. The method includes the following steps that a seedbed and the soilless straw matrix are manufactured; by means of the deep-ditch and high-box mode, water and fertilizer are controlled and growth of rice seedlings is regulated through a seedling box, wherein the seedling age of seedlings transplanted by machines is prolonged by 5-10 days, and the crop rotation contradiction of rice transplantation is effectively relieved; meanwhile, the soilless straw matrix matched with seedling culture of the method is formed by smashing oilseed rape straw serving as the main raw material and adding disinfectant, a water-retaining agent, modifier, an acid regulating agent, fertilizer and the like; a plastic tray with the specification of 58.8 cm*28 cm*2 cm is used for seedling culture; seedlings grow in the disinfected and appropriate acid condition; growth of seedlings is regulated through the water control and fertilizer control measures in the seedling culture process, and therefore the aims of being strong in seedling, large in root number, thick in rod and green in leaf are achieved. Straw is directly used as the soilless straw matrix after being smashed, the production processes of soil taking, soil screening and the like are reduced, and the labor intensity of rice farmers is lowered.

Owner:绵阳市农业科学研究院

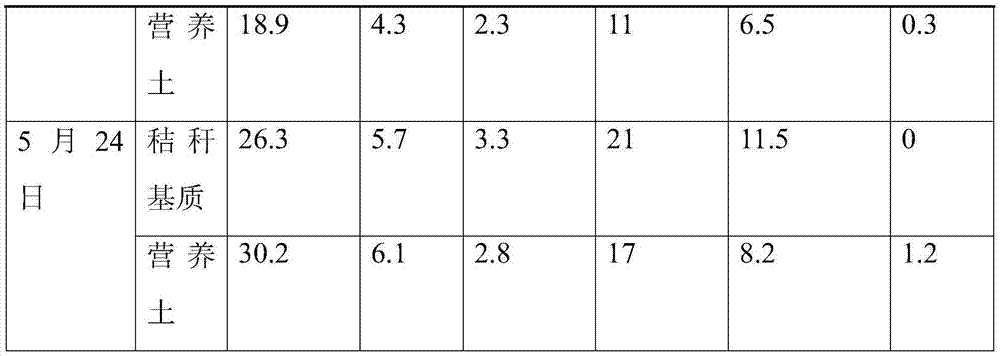

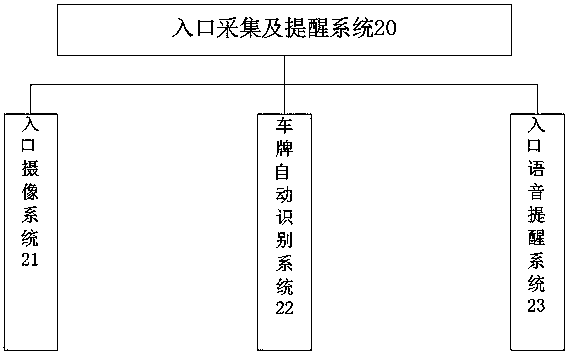

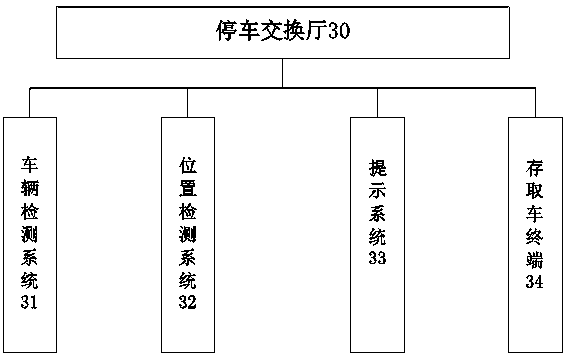

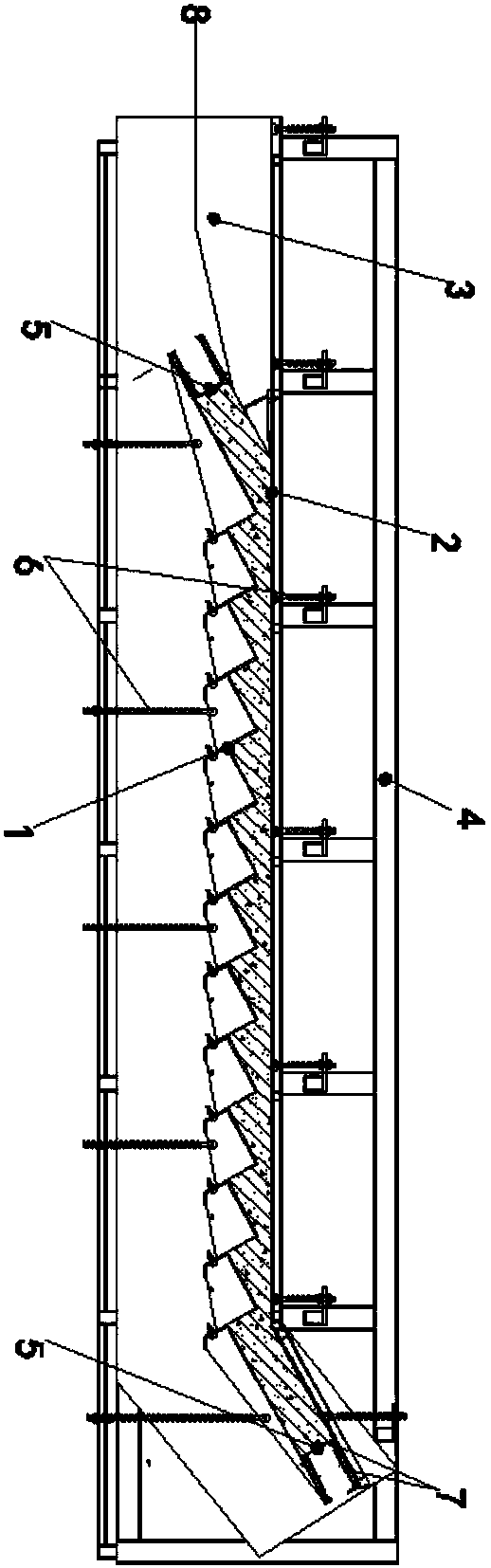

Intelligent parking method and system

InactiveCN111173339AEasy to get offEasy to leaveTelevision system detailsTicket-issuing apparatusTraffic signalImaging analysis

The invention discloses an intelligent parking method and system. The system is characterized in that a parking exchange unit is mainly adopted in the parking system, the parking exchange unit involves a bottom plate which is matched with a vehicle in shape and larger than the projection area of the vehicle in area, four stand columns are installed at the four corners of the bottom plate, the topsof the four stand columns are connected through a ceiling, and the bottom plate, the stand columns and the ceiling form a parking exchange hall; door curtains capable of ascending and descending aremounted on all or part of four vertical surfaces formed by the four stand columns; a man-machine interaction terminal is mounted on the outer side of the vertical surface on the left side of the vehicle advancing direction; traffic signal indicator light mounting cross beams are mounted on the stand columns, and driving indicator lights are mounted on the mounting cross beams; and a vehicle detection device is installed on the ceiling, and the vehicle detection device sends collected images of the vehicle and detection scale marks to a background central processing unit for image analysis, anda vehicle wheelbase is calculated and sent to a vehicle carrying robot. The method and system are complete in function and beneficial to improving the carrying efficiency and the vehicle storing andtaking efficiency.

Owner:JIANGSU LITTLE WHITE RABBIT INTELLIGENT MFG SCI INC

Fireproofing-thermal insulation-decoration integrated board and preparation method thereof

ActiveCN107263948AFree from destructionShorten the replacement periodCovering/liningsNon-macromolecular adhesive additivesAdhesiveThermal insulation

The invention belongs to the technical field of energy-saving and environment-friendly material, and particularly relates to a fireproofing-thermal insulation-decoration integrated board and a preparation method thereof. The fireproofing-thermal insulation-decoration integrated board disclosed by the invention comprises a fireproofing and thermal insulation felt, adhesive A, and a decorative board, and the fireproofing and thermal insulation felt is stuck on the decorative board by the adhesive A, so that the fireproofing-thermal insulation-decoration integrated board is formed. The invention overcomes the problems of high cost and easy powder dropping existing in conventional thermal insulation felts, and the product has better performance, and is more environment-friendly; the fireproofing and thermal insulation felt of the fireproofing-thermal insulation-decoration integrated board does not drop powder, and can be firmly combined with the decorative board under the effect of the adhesive A to form the fireproofing-thermal insulation-decoration integrated board, and thereby the effect of integrating fireproofing, thermal insulation and decoration together is achieved; the fireproofing grade of the fireproofing-thermal insulation-decoration integrated board disclosed by the invention is grade A1, the thermal insulation effect is good, product industrialization can be realized, and the difficulty of construction is low.

Owner:天津朗华科技发展有限公司

Banana fresh-keeping and variable-temperature gas-regulation ripening technique process flow

InactiveCN101347148AExtended storage timeExtended shelf lifeFruit and vegetables preservationFruit FlavorBiology

The present invention discloses a banana preservation and variable-temperature air-adjusting ripening flow. Fruit lossless harvest, batch processing and vacuum packaging are carried out by constructing a banana air-adjusting storehouse; air-adjusting preservation and a series flow of variable-temperature air-adjusting ripening are utilized for banana preservation and accelerating maturity. The flow can obviously improve the exterior and interior quality of the banana finished product and achieve the controllability of ripening period. The product can be on a par with imported banana and has the advantages of dense fruit flavor, good taste, long shelf life, and the like, thus having good market prospect.

Owner:漳州市庄怡农业发展有限公司

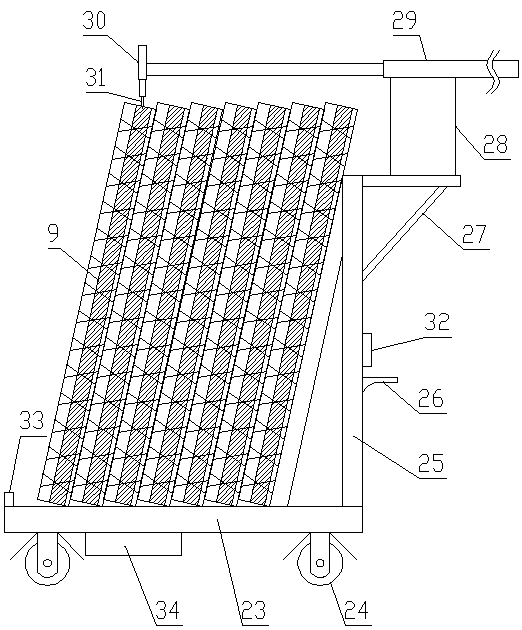

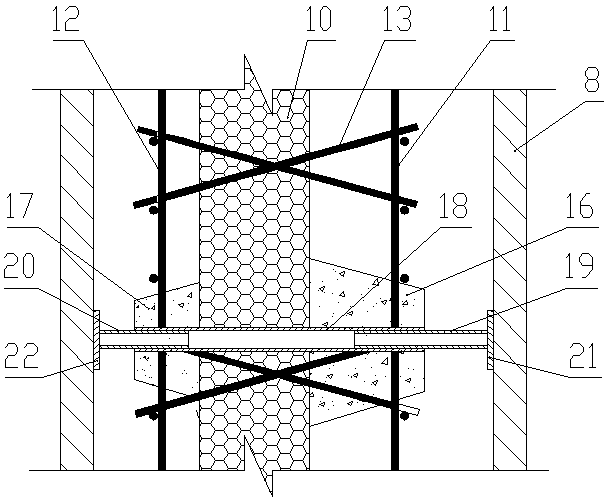

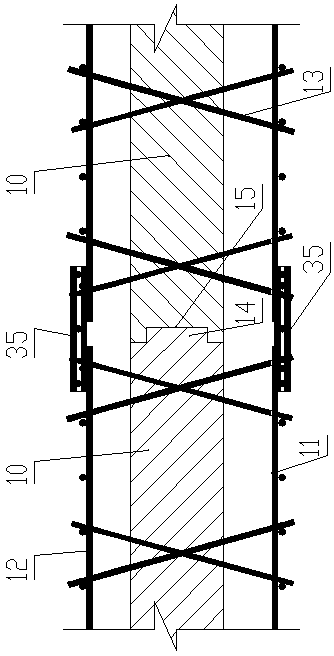

CL composite concrete shear wall construction method

InactiveCN108505644AImprove connection strengthImprove insulation effectCovering/liningsWallsBuilding productButt joint

A CL composite concrete shear wall construction method comprises the following steps that (1) CL grid frame plates are supplied; (2) The CL grid frame plates are placed in a temporary site adjacent toa construction site; (3) a plurality of positioning adjusting assemblies are evenly arranged on the two side surfaces of the CL grid frame plates; (4) the CL grid frame plates provided with the positioning adjusting assemblies are conveyed to a wall body construction site through a trolley, and the CL grid frame plates are sequentially hoisted into CL grid frame plate mounting control wires through a tower crane and are in butt joint with the CL grid frame plate mounting control wires; (5) wall templates are mounted; (6) automatic close concrete is poured downwards from the top of the wall templates; (7) the wall templates are removed; (8) a wall body is cured; and (9) the wall body is subjected to quality acceptance check. The CL composite concrete shear wall construction method is applicable to the construction of composite concrete shear walls with different thicknesses, the levelness of the edges of the upper ends of the wall templates of the inner wall of the wall body are ensured, the construction quality is improved, and the defects of insufficient durability of external wall external heat insulation and internal wall internal heat insulation are avoided; and construction industry modernization and construction product industrialization are achieved.

Owner:HUANGHE S & T COLLEGE

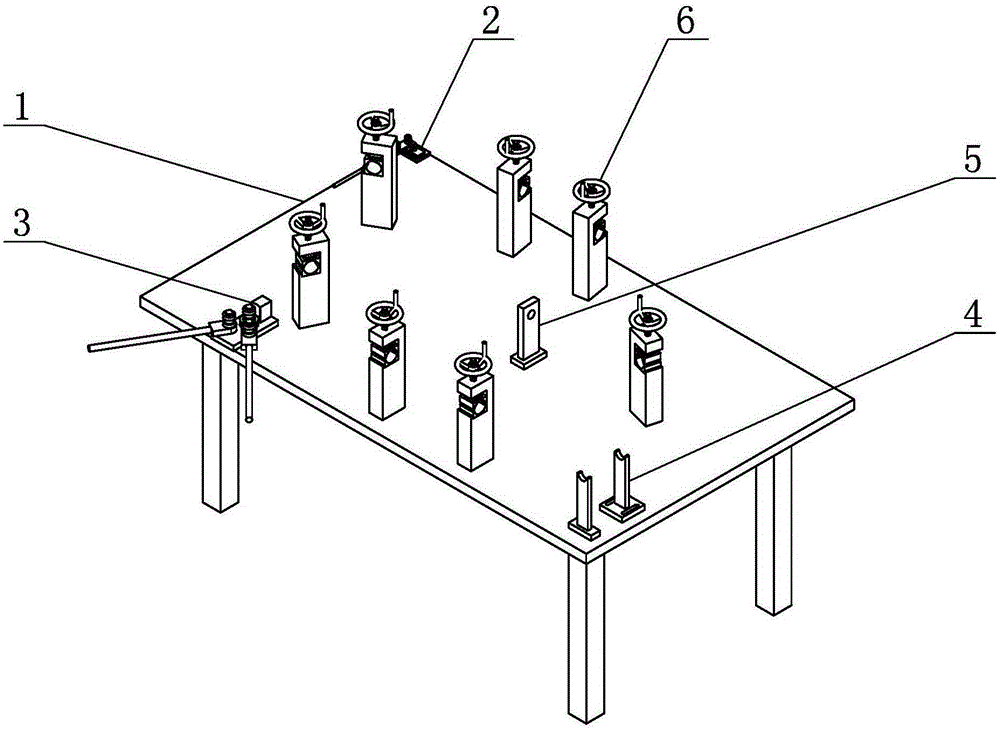

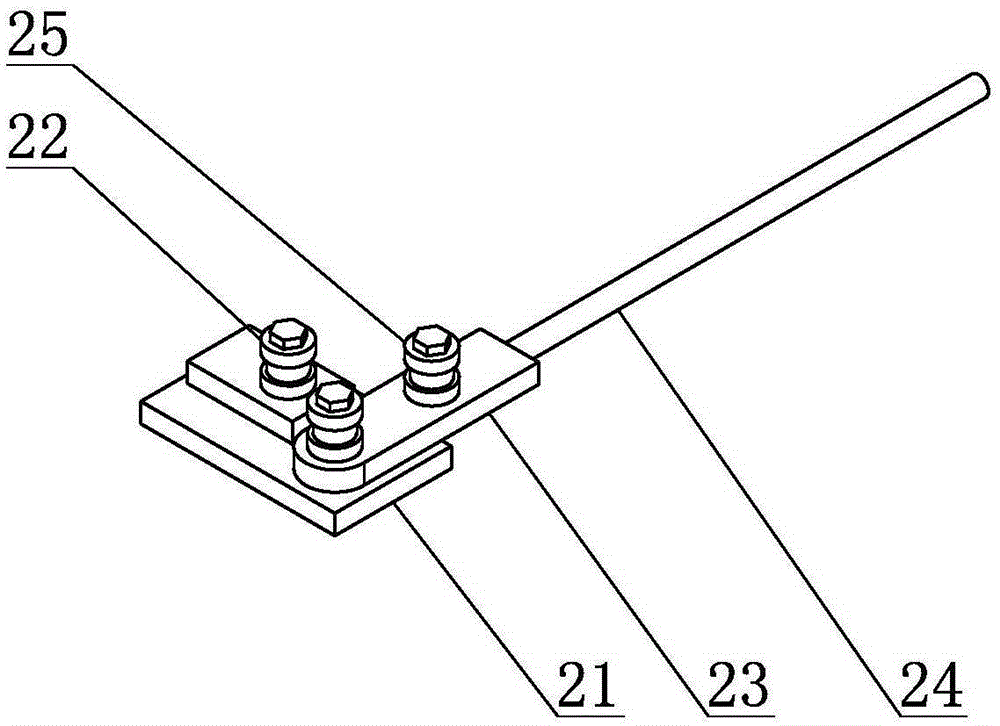

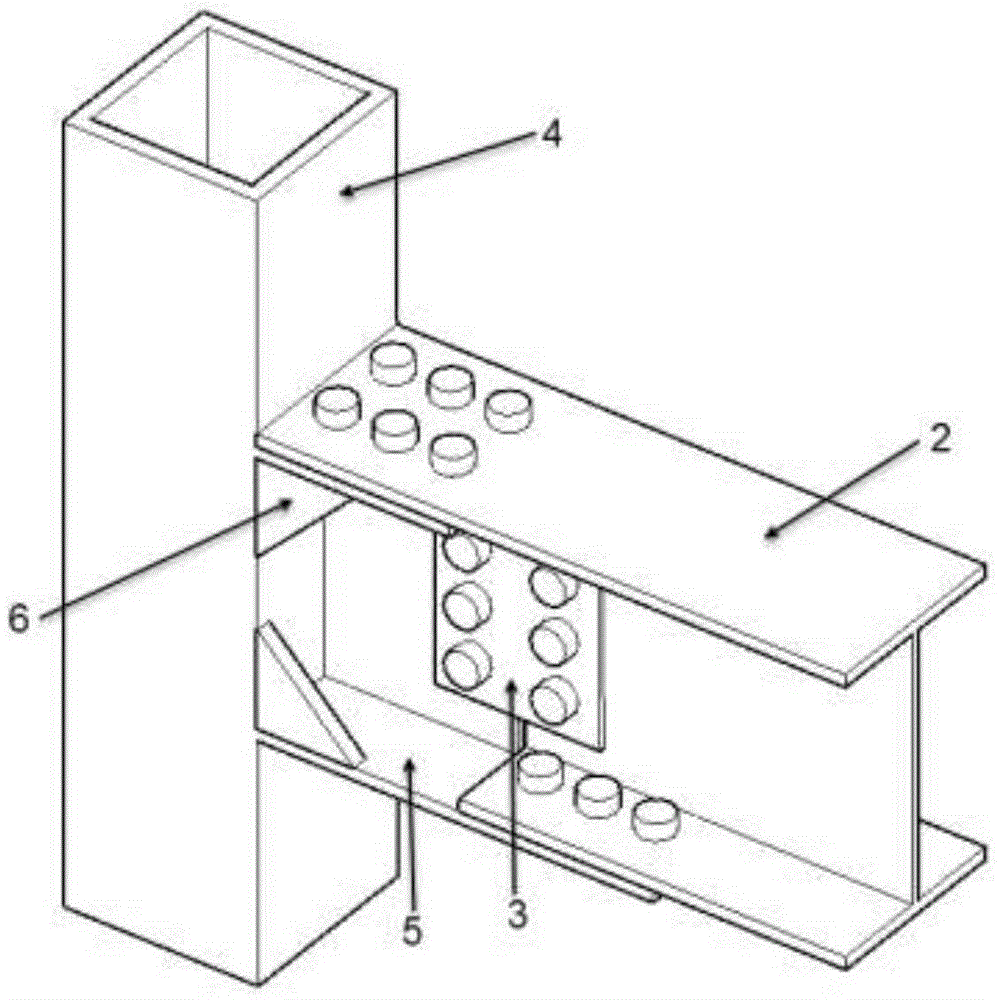

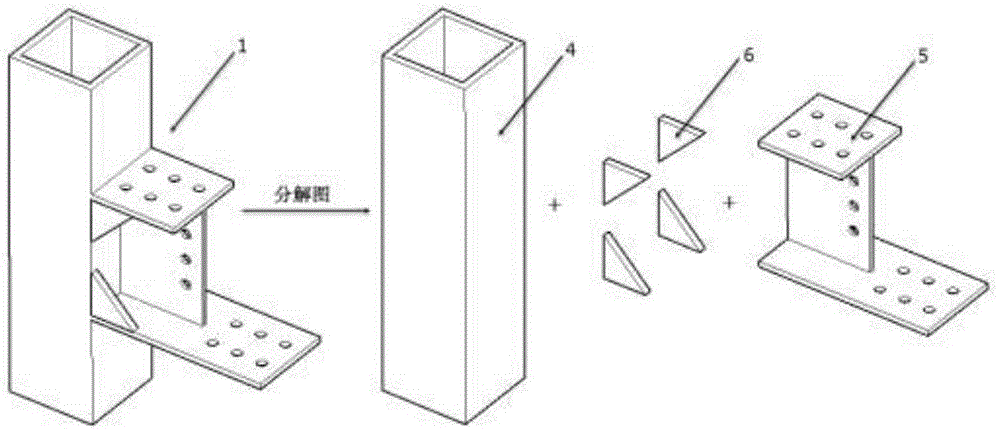

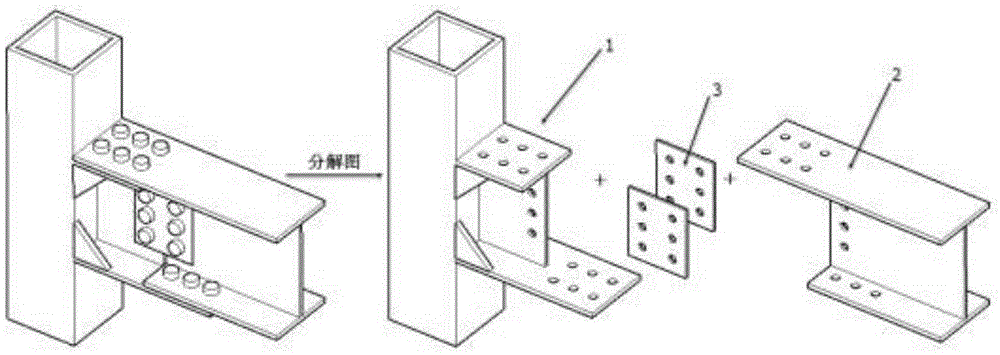

Vertical outer rib beam-column joint connector applicable to prefabricated steel structural systems

InactiveCN105332422AAchieving Yield Energy DissipationRealize factoryBuilding constructionsSteel columnsCantilever

The invention belongs to the technical field of structural engineering and relates to a vertical outer rib beam-column joint connector applicable to prefabricated steel structural systems. The connector comprises a square steel column with a cantilever beam segment, an H-shaped steel beam with an upper flange extended out, and flitch plates; the square steel column with the cantilever beam segment comprises a square steel column, an H-shaped cantilever steel beam with a lower flange extended out and a triangular vertical outer rib; the H-shaped steel beam with the upper flange extended out is made by cutting off the partial lower flange and corresponding web of an H-shaped steel beam; all the square steel column with the cantilever beam segment, the H-shaped steel beam with the upper flange extended out and the flitch plates are prefabricated in a factory, bolt holes are reserved in corresponding positions, the square steel column with the cantilever beam segment and the H-shaped steel beam with the upper flange extended out are lapped on a construction site, the upper and lower flanges are connected through bolts, and the webs are connected through flitch plate bolts. The connector is convenient to manufacture in a factory and quick to assemble in situ with increased construction speed and quality, and a joint of the invention has good aseismic performance.

Owner:BEIJING UNIV OF TECH

Factory culture method of phellinus igniarius fruiting bodies and culture medium thereof

InactiveCN108264390AHigh in active ingredientsShort training periodMagnesium fertilisersAlkali orthophosphate fertiliserAdditive ingredientPhellinus igniarius

The invention discloses a factory culture method of phellinus igniarius fruiting bodies and a culture medium thereof. The method comprises the steps of phellinus igniarius seed preparation, factory production culture medium preparation, inoculation, culture management, harvesting and drying, wherein a solid strain amplification culture medium is prepared from corn powder, maltose, peptone, MgSO4,KH2PO4 and agar; a liquid strain amplification culture medium is prepared from glucose, yeast powder, MgSO4, KH2PO4, ammonium citrate tribasic, ramulus mori water extracts and vitamin B1; a factory production culture medium is prepared from grain seeds, distilled water, MgSO4, KH2PO4 and ramulus mori water extracts. The method and the culture medium have the advantages that the pollution rate is low; the culture period is short; the product quality is stable; the cost is low; the factory standardized production can be realized. By using the culture medium, the phellinus igniarius hyphae growsfast and exuberantly; the obtained phellinus igniarius seed quantity is large; the time is short; the raw materials are simple and can be easily bought; the price is low; the culture time of the phellinus igniarius fruiting bodies is shortened; the biological conversion efficiency is high; the contents of ingredients of polysaccharide, flavone and triterpenoids can be kept higher.

Owner:LUDONG UNIVERSITY

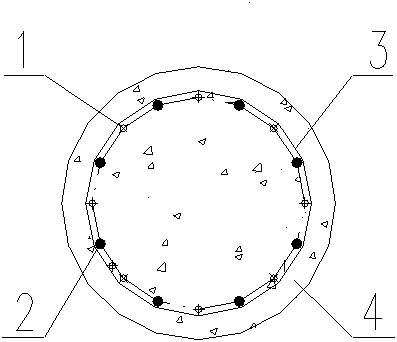

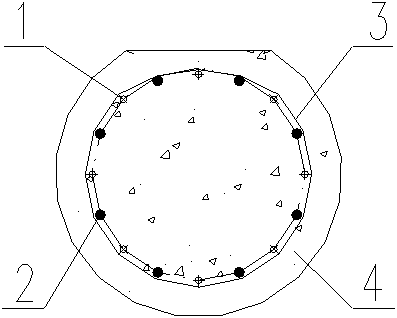

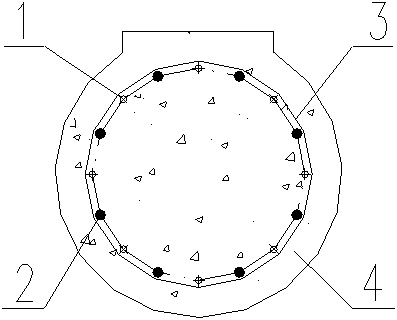

Concrete circular pile and processing method thereof

InactiveCN102373702AImprove the compressive capacityImprove tensile capacityShaping reinforcementsBulkheads/pilesHoopingPile cap

The invention provides a concrete circular pile and a method for processing the concrete circular pile. The concrete circular pile comprises a plurality of pre-stressed main ribs and a plurality of ordinary main ribs which are arranged circularly at intervals, wherein at least one circle of hooping is helically wound outside the pre-stressed main ribs and the ordinary main ribs; the pre-stressed main ribs, the ordinary main ribs and the hooping are inserted into concrete of a pile body along a longitudinal axis; the two ends of the concrete circular pile are provided with an end plate and a pile cap consisting of a skirt; the pre-stressed main ribs are fixed with the end plate; and the end plate is connected with a short pipe which is provided with a sealing head at one end and is inserted into the concrete of the pile body. The concrete circular pile provided by the invention has the advantages of large vertical bearing force, large pile foundation bearing force and capabilities of realizing mechanization and increasing the production efficiency.

Owner:朱月琴

Hollow irregular column multi-layer high-rise assembling steel structure system

ActiveCN103276803AEasy to pass throughIncrease net heightBuilding constructionsFloor slabSteel frame

A hollow irregular column multi-layer high-rise assembling steel structure system relates to the technical field of engineering and comprises assembling truss plates and assembling flange columns. Each assembling truss plate comprises a lattice truss beam with an angle steel web member, a column base node and a floor slab. The assembling truss plates are prefabricated in a factory and spliced with one another through beam end sealing plates or the column base nodes on a construction site to form frame structure beam plate layers. The frame structure beam plate layers are connected vertically through the assembling flange columns to form a multi-layer steel frame structure, and the assembling flange columns are arranged on the column base nodes of the assembling truss plates. The assembling truss plates and the assembling flange columns are all prefabricated in the factory and assembled through bolts on the construction site.

Owner:镇江电力设计院有限公司

Manufacture and transportation technology for double-joint integrally-welded trusses

PendingCN105772969AImprove manufacturing precisionReduce the difficulty of construction site operationsBridge erection/assemblyWelding apparatusDimensional precisionStructural engineering

The invention discloses a manufacture and transportation technology for double-joint integrally-welded trusses. The manufacture and transportation technology comprises a 30 m long rod and integrally-welded truss size dimension control technology, a truss replacing-curve-by-straight-line matching and splicing technology, a large superheavy truss overturning and transporting technology and a truss three-dimensional shipping and delivering technology. The manufacture and transportation technology for the double-joint integrally-welded trusses is characterized in that a replacing-curve-by-straight-line splicing scheme is adopted for match and manufacture of truss matching and splicing, and welding parameters are optimized on a basis of software simulation welding; a welding sequence is detailed; overturning hoops, lifting appliances and a transportation support for the trusses are designed according to the structure characteristics of the trusses; and a shipping fastening scheme is designed. By adopting the manufacture and transportation technology, difficulty and cost of truss matching and splicing manufacture are lowered; deformation of the trusses in splicing and welding processes is well controlled; deformation of the trusses during hoisting, transporting and conveying processes is reduced; and a complete manufacture and transportation technology for the double-joint integrally-welded trusses is formed.

Owner:CHINA RAILWAY JIUJIANG BRIDGE ENG +1

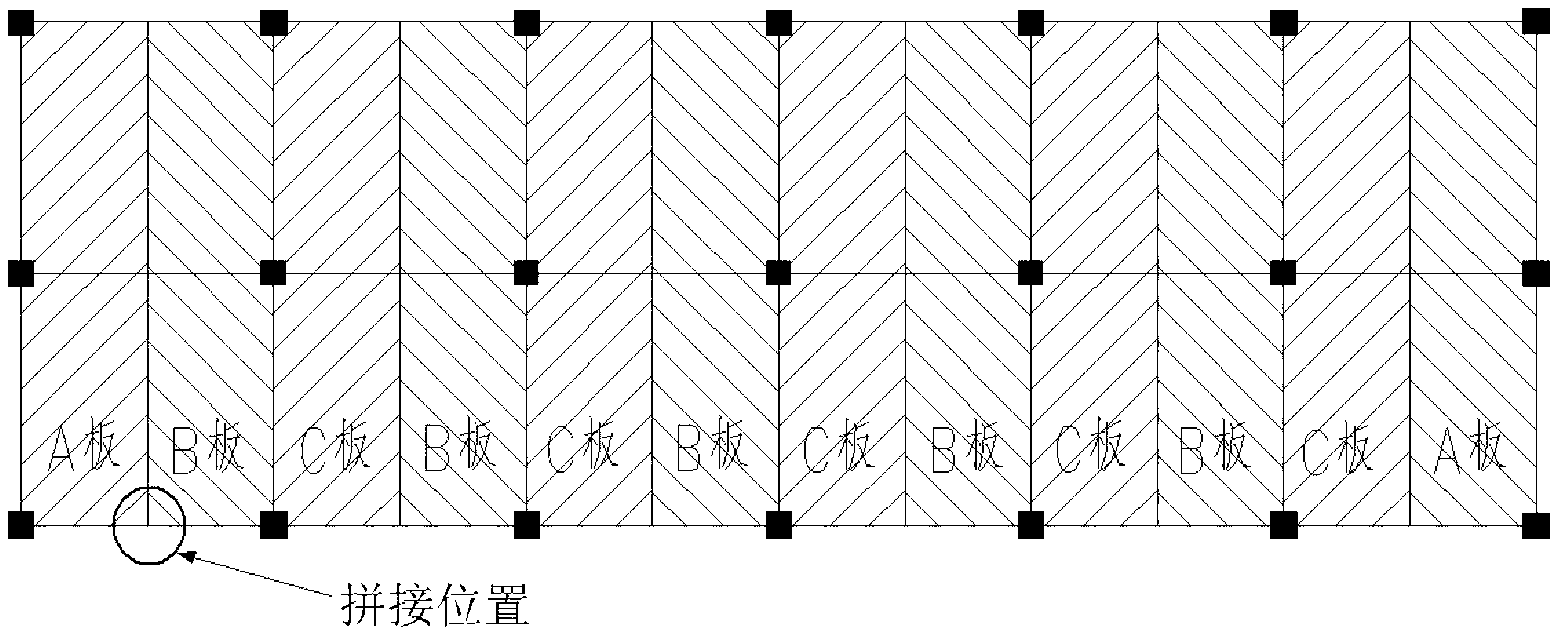

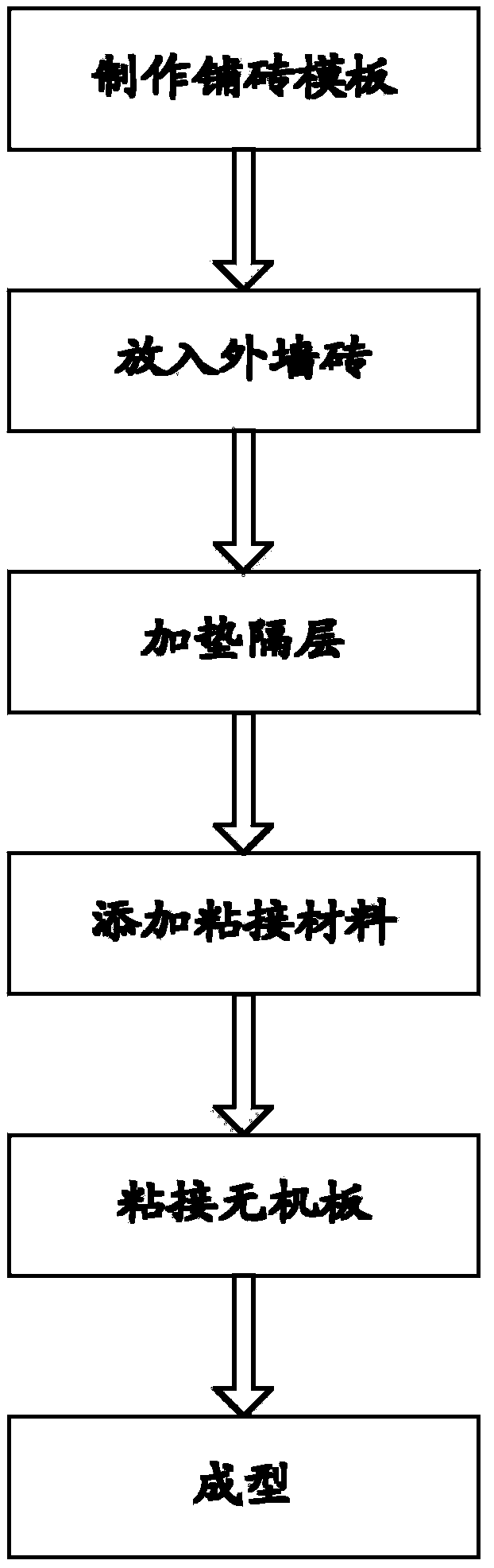

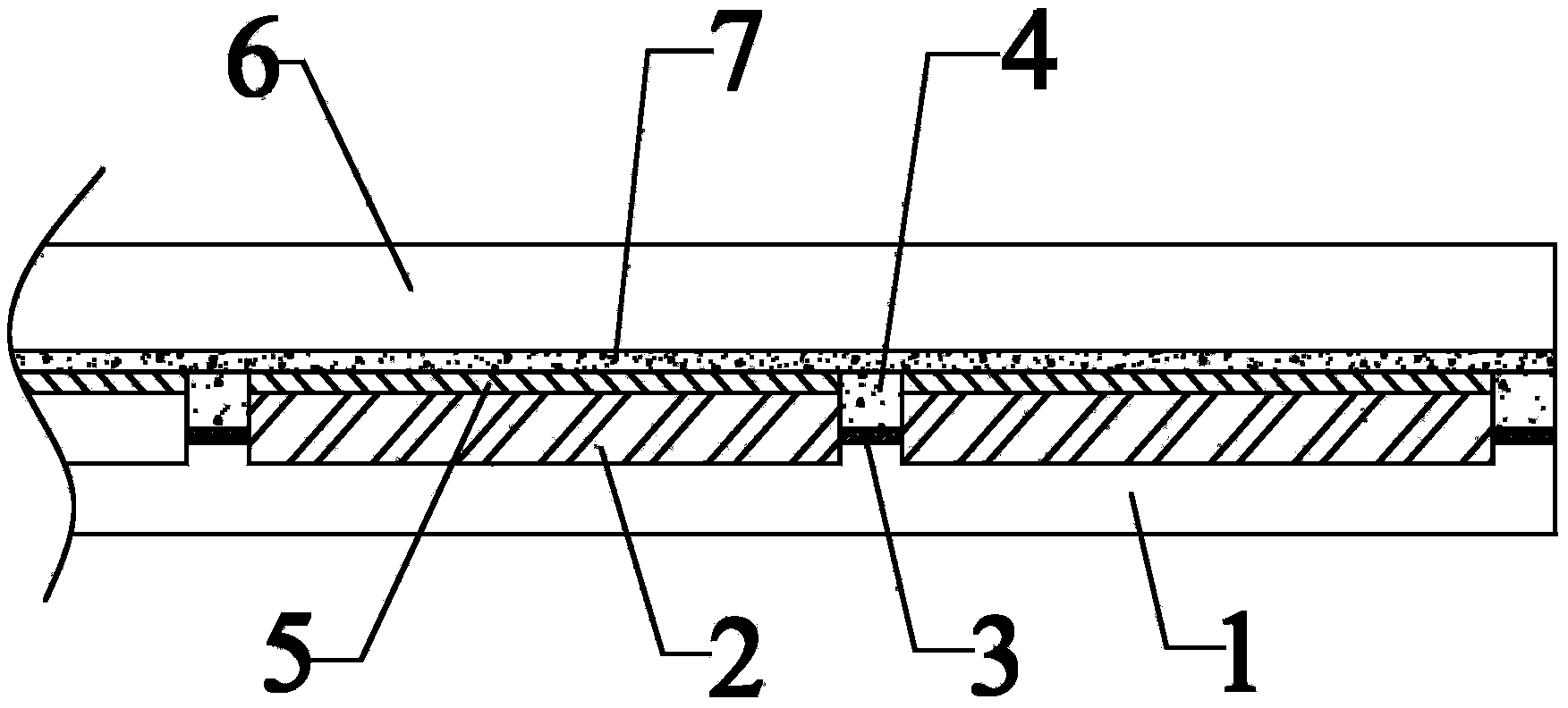

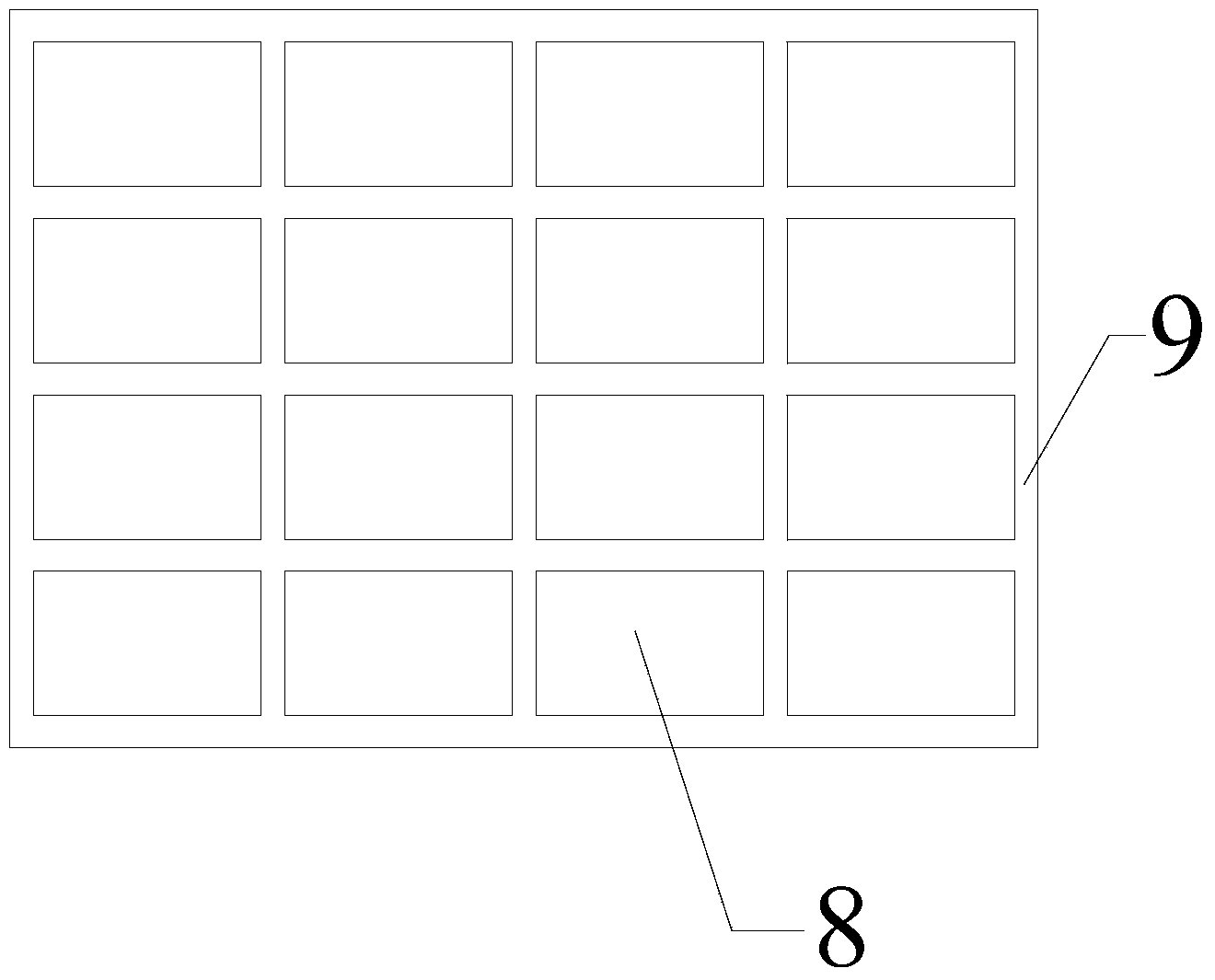

Brick paving technology of exterior wall brick and brick paving template

InactiveCN104264952AImprove the decorative effectAvoid pollutionBuilding constructionsBrickMaterials science

The invention relates to the field of building walls, and particularly to a brick paving technology o an exterior wall brick and a brick paving template. The brick paving technology of the exterior wall brick comprises the following steps of: producing the brick paving template; putting the brick paving template in the exterior wall brick; adding a padding and isolating layer; adding a bonding material; binding an inorganic plate; shaping. According to the brick paving technology of the exterior wall brick and the brick paving template provided by the invention, pollution from construction such as binding and joint filling to the surface of the exterior wall brick can be avoided, and an optimal decorative effect of the exterior wall brick can be realized. Joint filling among the exterior wall bricks is neat, precise, compact and free from hole, and relatively good waterproof performance is obtained. Hidden danger that empty drums are easy to appear when the exterior wall bricks are bound manually, the binding quality is uniform and firm, and the exterior wall brick can be prevented from falling off to the maximum extent. Paving industrialization of the exterior wall bricks can be realized; an exterior wall brick composite integrated plate only needs to be dry-hung or hung and bound, so that the efficiency is far higher than manual wet binding of the exterior wall brick.

Owner:吕国兵

Industrial horseradish planting method

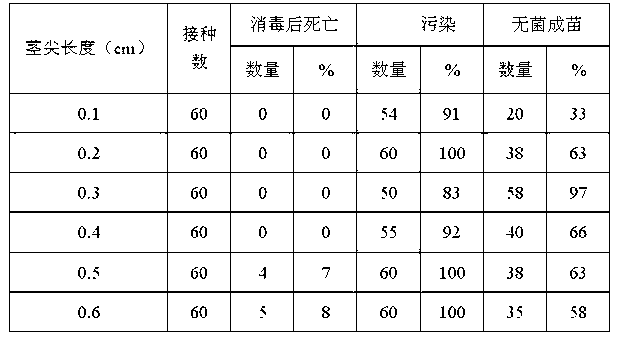

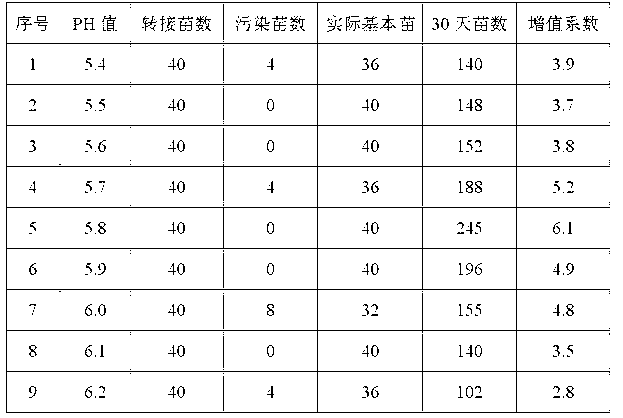

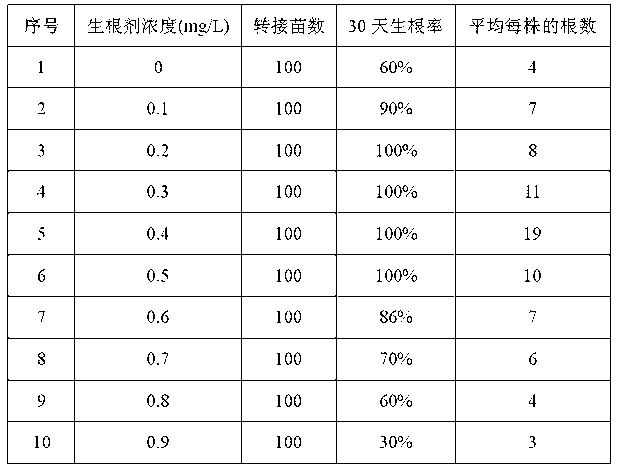

ActiveCN103125386AHigh reproductive coefficientReduce the number of infectionsCultivating equipmentsHorticulture methodsWasabia japonicaEnrichment culture

The invention discloses a horseradish seedling culturing method. The horseradish seedling culturing method comprises the following steps: (A) rooting cultivation, (B) hardening seedling transplanting and (C) filed planting, wherein the rooting cultivation comprises the step that primarily cultured stem tip meristem tissue which undergoes sterilization and detoxification is transferred into a 1 / 2 Murashige and Skoog (MS) culture medium to grow, the hardening seedling transplanting comprises the step of transferring the tissue into a tray after the step (A) lasts for 28-32 days, and the field planting comprises the step of transplanting finished horseradish seedlings to fields after the step (B) lasts for 75-85 days. The method of adding rooting agents into the culture medium for enrichment culture is adopted to replace the method of using cytokinin, so that the problems that rooting is slow and roots are thin and long are solved, and the purpose of increasing the length of the root of a single seedling quickly in a short period is achieved. At the same time, the price of the rooting agents is far lower than that of the cytokinin. Compared with the auxin culturing method which is large in waste quantity and low in use ratio, the horseradish seedling culturing method is smaller in dosage, higher in use ratio and capable of greatly reducing cost.

Owner:四川华阳蓝公府实业有限公司

Seedling culture method utilizing ineffective tillers of healthy sugarcane seedlings

InactiveCN110506600AFast growthEnhanced tillering abilityCalcareous fertilisersSugarcane cultivationBudFirst generation

The invention discloses a seedling culture method utilizing ineffective tillers of healthy sugarcane seedlings. The method comprises the steps that sugarcane tissue culture seedlings are cultured, theineffective tillers of first-generation sugarcane stems after the sugarcane tissue culture seedlings are transplanted are collected, buds of the ineffective tillers are taken for seedling culture ina seedling culture plate, and then mechanical transplanting is conducted. According to the method, the ineffective tillers of the healthy sugarcane seedlings are effectively utilized, healthy sugarcane seed stems are increased, the production cost of the healthy sugarcane seedlings is reduced, and the income of sugarcane growers is increased.

Owner:SUGARCANE RES INST GUANGXI ACADEMY OF AGRI SCI +1

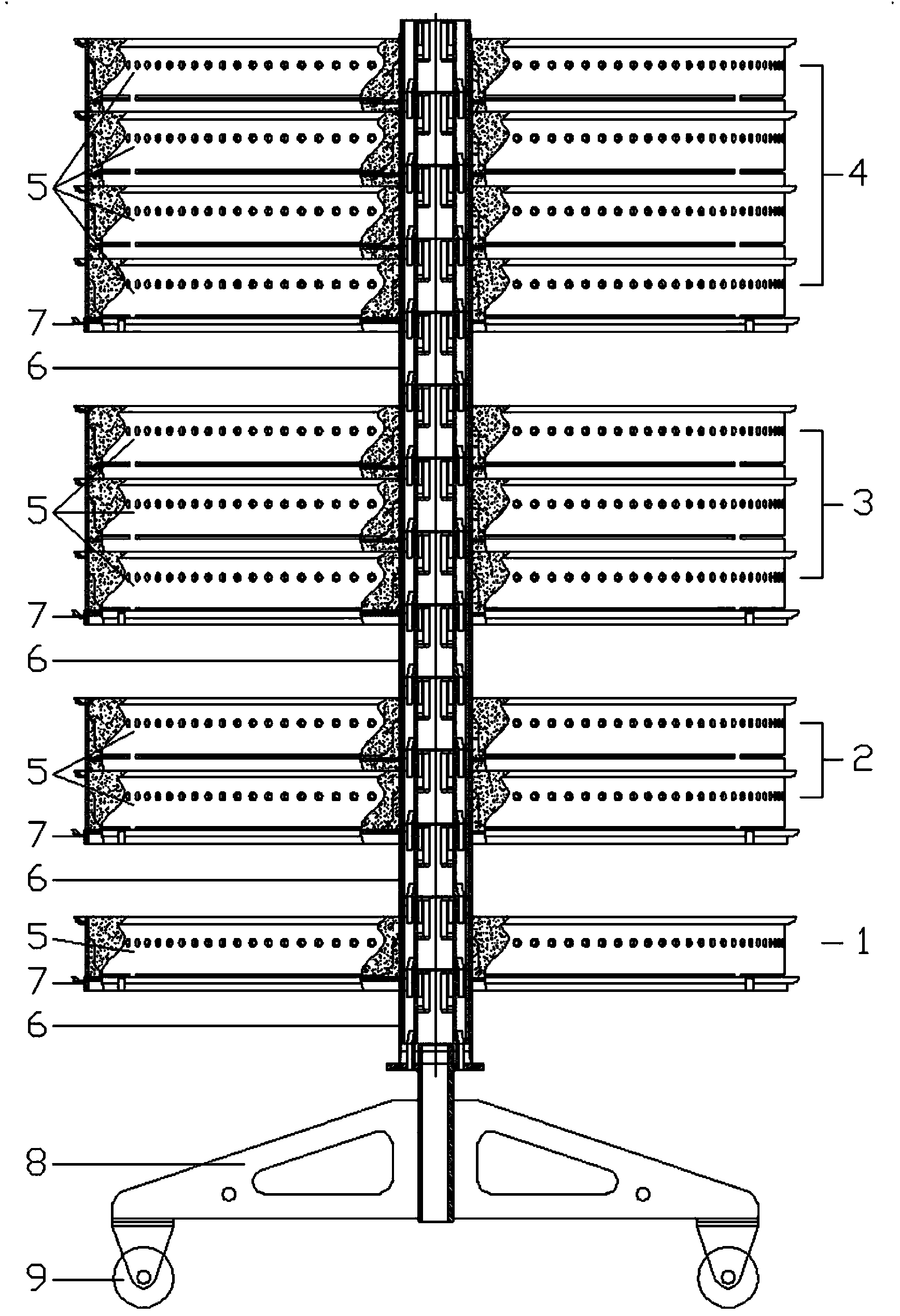

Indoor stereoscopically-assembled vermiculture equipment

ActiveCN103975904ARealize factoryRealize mechanized three-dimensional farmingAnimal husbandryFisheryEarthworm

Owner:吉林省合润生物科技有限责任公司

Industrialized assembly type multi-high-rise steel specially shaped column frame structure system

InactiveCN103276802AEasy to pass throughIncrease net heightBuilding constructionsFloor slabSteel frame

The invention provides an industrialized assembly type multi-high-rise steel specially shaped column frame structure system and relates to the technical field of structure engineering. The industrialized assembly type multi-high-rise steel specially shaped column frame structure system comprises assembly type truss plates and assembly type specially shaped columns. Each assembly type truss plate comprises a lattice type truss girder provided with a channel steel web member and a floor plate. Each assembly type truss plate is prefabricated in a factory and is mutually spliced with a flange plate of one assembly type specially shaped column through a girder end sealing plate of the assembly type truss plate at a construction site. The assembly type specially shaped columns are spliced among floors in site through bolts so that a multi-layer truss plate steel frame structure can be formed. The assembly type truss plates and the assembly type specially shaped columns are all prefabricated in the factory and assembled through bolts at the construction site.

Owner:BEIJING UNIV OF TECH

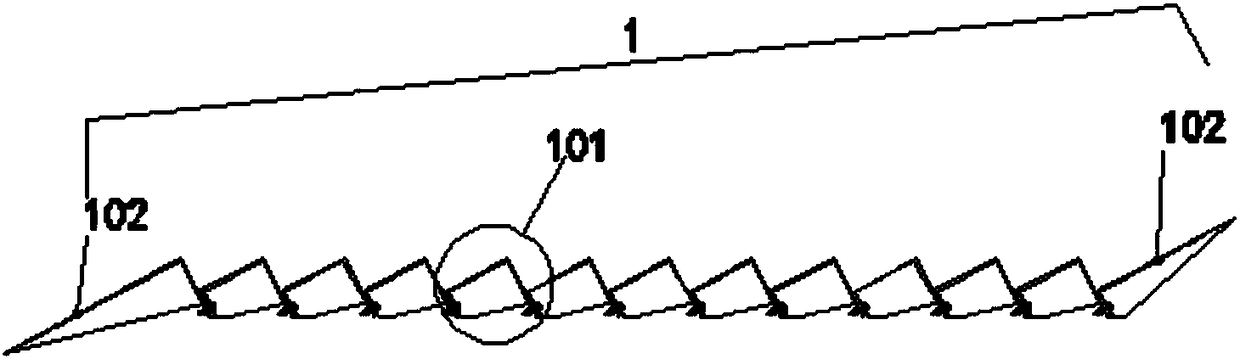

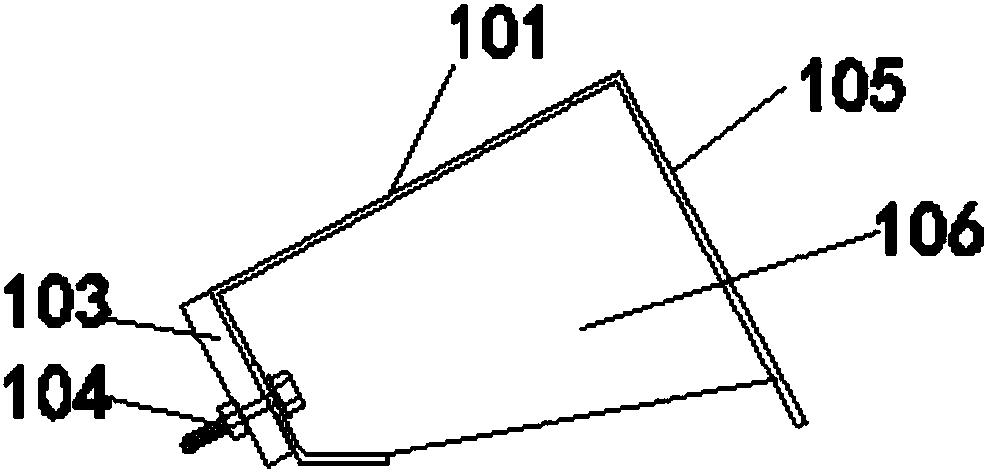

Vertical type adjustable prefabricated stair mold

PendingCN108214840AImprove turnover rateImprove general performanceMouldsMould auxillary partsMaterials scienceStairs

The invention relates to the technical field of stair mold, in particular to a vertical type adjustable prefabricated stair mold. The vertical type adjustable prefabricated stair mold comprises a stair step mold, a mold support, stair mold end molds, an adjusting system, a supporting fixing system, adjustable end molds, a stair base plate mold and a stair mold bottom mold, the stair step mold andthe stair base plate mold are vertical to the stair mold bottom mold and are arranged in parallel, the stair mold bottom mold is paved on the mold support, the stair step mold adjusts the space relative positions of the stair step mold and the stair base plate mold through an adjusting system, the mold support is composed of a square pipe, an adjusting rod fixed vertical framework is fixed to themold support, the two ends of the stair step mold are provided with the stair mold end molds, and the adjusting end molds are arranged at the positions, on one sides of the stair mold end molds, of the stair step mold. According to the vertical type adjustable prefabricated stair mold, quick prefabricating is achieved, on-site operation amount is reduced, the construction period is short, resources are saved, operation is easy, errors are controlled to be in millimeter stage, and the building quality is improved.

Owner:BEIJING ZHIHUI YUNJIAN TECH CO LTD

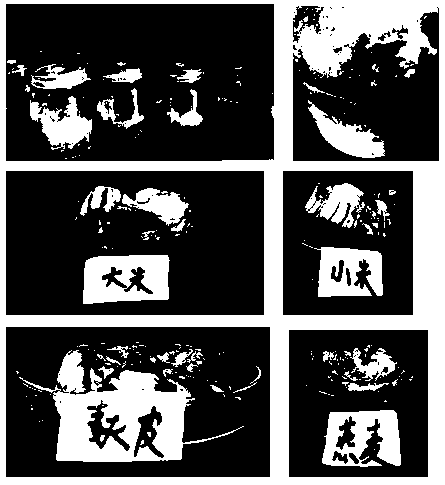

Screening method of mildewed seeds

ActiveCN104475356ARealize factoryAvoid damageProgramme-controlled manipulatorGripping headsElectricityOrganic solvent

The invention discloses a screening method of mildewed seeds, and belongs to the field of seed selection. A device comprises an ultraviolet fluorescent tube, a visible light single-color CCD (charge coupled device) sensor, a two-dimension grabbing mechanism, a single-layer seed conveying device and a control system, wherein the ultraviolet fluorescent tube, the visible light single-color CCD sensor, the two-dimension grabbing mechanism and the single-layer seed conveying device are electrically connected with the control system respectively. The autofluorescence characteristic of fungi is used, that is, to-be-processed seeds are irradiated by 356 nm ultraviolet rays, and the mildewed seeds are identified by detecting fluorescence excitation of the mildewed seeds under radiation of 356 nm ultraviolet rays. The method has the characteristics that the cost is low, industrialized screening of the mildewed seed is realized, and the demand of seed engineering for automatic production is met; the screening efficiency and the accuracy are higher, seed processing by an organic solvent and the like is reduced, and damage to healthy seeds is reduced, growth of the seeds cannot be influenced, environmental pollution is reduced, the cost is reduced and the like.

Owner:SHANDONG CROP GERMPLASM CENT

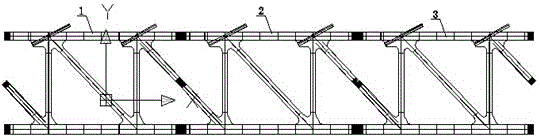

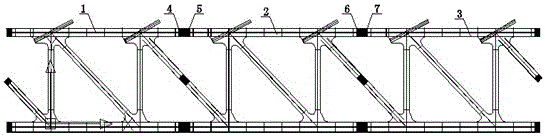

Large-span, secondary-beam-free and high-assembly industrialized steel structure system

A large-span, secondary-beam-free and high-assembly industrialized steel structure system comprises a staggered steel structure truss, a plurality of prefabricated large-span prestressed hollow slabs and concrete composite layer, wherein the staggered steel structure truss adopts a multilayer structure with at least double spans, and comprises framework columns, framework beams and plane trusses; the framework columns and the framework beams are vertically arranged at the periphery of the staggered steel structure truss to form a framework structure; the plane trusses are arranged in an upper-and-lower staggered manner in the height direction of the framework columns, and the plane trusses on the adjacent framework columns are arranged in an upper-and-lower staggered manner; the two ends of each plane truss are supported on the framework columns on the two sides; each plane truss is formed by connecting upper chords, lower chords, straight web members and diagonal web members; the prefabricated large-span prestressed hollow slabs are arranged on the staggered steel structure truss; one ends of the prestressed hollow slabs are supported on the upper chords of the plane trusses, and the other ends of the prestressed hollow slabs are supported on the lower chords of the adjacent plane trusses; the concrete composite layers are paved on the prefabricated large-span prestressed hollow slabs. The large-span, secondary-beam-free and high-assembly industrialized steel structure system is economical in steel consumption, standard in element production, convenient and fast to construct, and convenient for industrialized production.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

Deodorizing and sterilizing agent for faeces and urine

The deodorizing and sterilizing agent for faeces and urine consists of ferrous sulfate 50-60 wt%, potassium dihydrogen phosphate 4-6 wt%, magnesium sulfate 4-6 wt%, sodium dihydrogen phosphate 3-5 wt%, boric acid 8-16 wt%, sodium dichloroisocyanurate 4-6 wt% and borax 12-16 wt%. It is mixed with faeces and urine in the ratio of 1 to 70-80. Test shows that after the deodorizing and sterilizing agent is applied, the bad smell may be eliminated in 4 hr, evildoers may be killed completely in 6 hr, the salt in the organic compound may be decomposed completely in 24 hr, and the faeces and urine may be then proceeded for drying treatment.

Owner:马子鳌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com