CL composite concrete shear wall construction method

A concrete shear wall and construction method technology, applied in the direction of walls, formwork/formwork/work racks, transportation and packaging, etc., can solve the problems affecting the quality of cast-in-place reinforced concrete walls, steel wire mesh damage, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

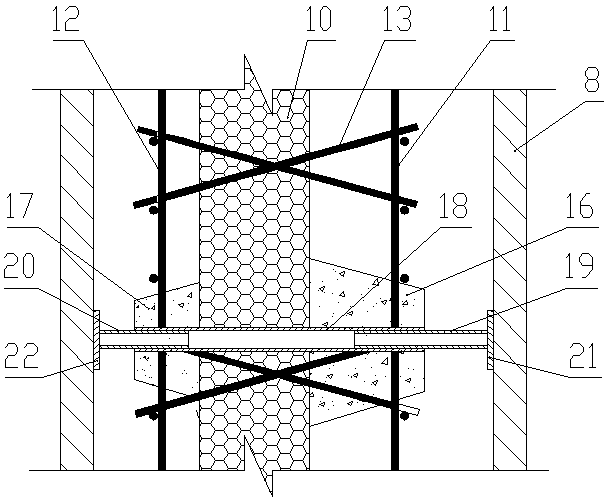

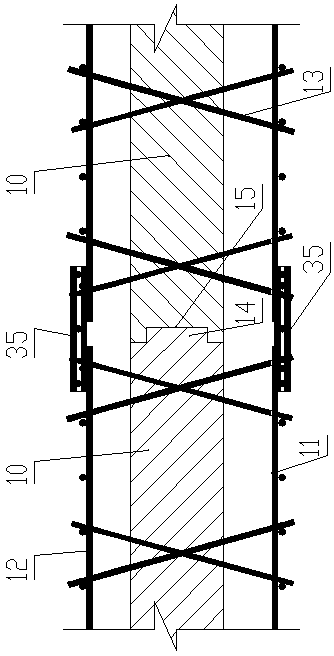

[0042] CL composite concrete shear wall construction method of the present invention, comprises the following steps,

[0043] (1) Lifting of CL grid slabs: CL grid slabs are non-standard blocks. According to the layout of CL composite shear walls in the construction drawings, according to the details of the nodes in the construction drawings and relevant technical regulations, the construction joints are left The situation decomposes the CL composite shear wall, expresses in detail the specification, size, surrounding node characteristics, quantity and position of the CL grid slab, and communicates with the professional manufacturer in advance about the production and supply plan through the form of an order;

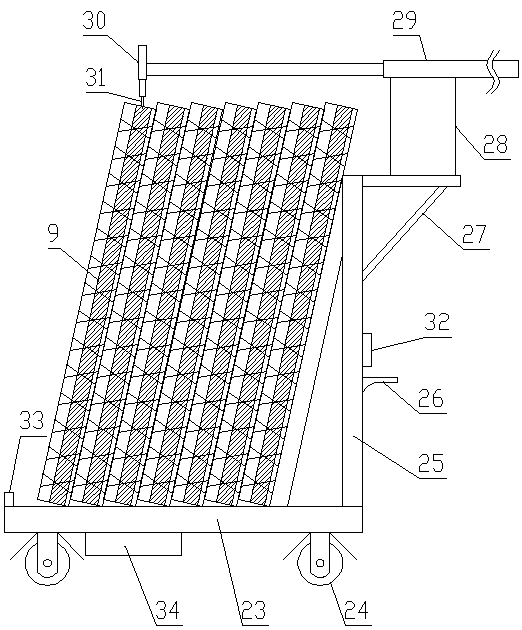

[0044] (2) Place the purchased CL grid slabs in a temporary site adjacent to the construction site;

[0045] (3) Evenly arrange several positioning adjustment components on both sides of the CL grid plate in the leveled construction site; at the same time, pop up the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com