Concrete circular pile and processing method thereof

A concrete pile and concrete technology, which is used in sheet pile wall, reinforcement forming, infrastructure engineering and other directions, can solve the problems of inconvenient connection, poor bearing capacity, low production efficiency, etc., and achieve shortened assembly time and high compressive bearing capacity. , the effect of simple shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Present embodiment is the preparation of short pile, and its production process mainly comprises the following steps:

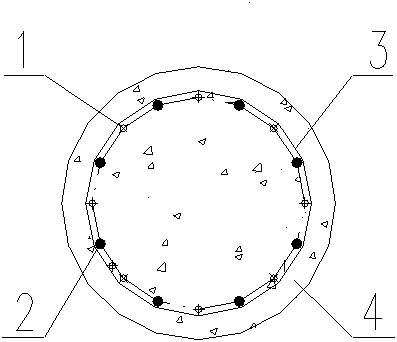

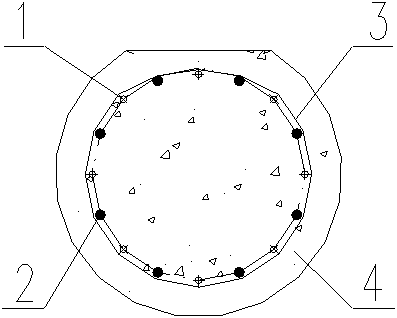

[0045] The first is the preparation of raw materials. The prestressed main reinforcement 1 is made of prestressed steel rods, and the common main reinforcement 2 is made of hot-rolled grade III steel bars, which are connected with the stirrup 3 by roll welding to form a reinforcement cage; the end plate 5 and the skirt 6 are welded to form a pile cap The short tube 7 is connected with the end plate 5 by welding; the anchor rib 8 penetrates the anchor rib anchor hole 10 on the end plate 5 and is fixed on the end plate.

[0046] Install the pile cap at the end of the reinforcement cage, penetrate the prestressed main reinforcement 1 of the reinforcement cage into the anchorage hole 9 of the prestressed main reinforcement on the end plate 5, and realize the connection between the reinforcement cage and the pile cap; install the tail plate 16 at the end of ...

Embodiment 2

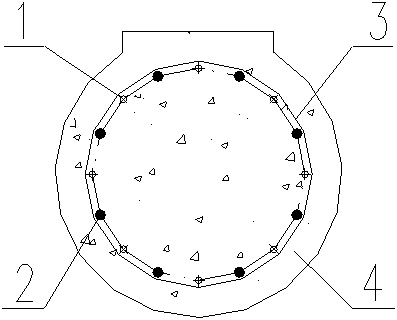

[0056] Such as Figure 6 As shown, the present invention can also be used in Figure 6 The concrete round pile with lifting lug is provided with lifting lug, and when making the concrete round pile with lifting lug, the end plate 5 is a solid disc shape. The position of the lifting lug is determined according to the length of the pile and the way of hoisting. In this embodiment, the two-point hanging method is adopted, and the lifting lugs 24 are ring-shaped, and there are two sets, and the distance from the pile end is 0.207L, where L is the length of the pile body.

[0057] Prestressed main reinforcement 1, ordinary main reinforcement 2 and stirrup 3 are connected by roll welding to form a reinforcement cage; the lifting lugs are fixed on the reinforcement cage by binding.

[0058] When the reinforcement cage with the pile cap, tail plate 16 and tension link plate 17 installed is placed in the lower mold 12, attention should be paid to making the lifting lug 24 in the top ...

Embodiment 3

[0061] When making the cross section of the pile body as a standard circle, please refer to Figure 7 , can be produced by adding a cover plate 25, the size and shape of the upper cover plate 25 are consistent with the intersecting line between the bottom of the chute 14 and the upper mold 13.

[0062] After the cloth forming process, take out the cutting trough 14, put the upper cover plate 25 vertically into the feeding port on the top of the upper mold 13, and apply pressure properly so that the upper cover plate 25 is in close contact with the upper mold 13.

[0063] All the other are identical with embodiment 1, no longer repeat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com