Construction method for splicing and erecting concrete precast beam sections

A construction method and technology of prefabricated beams, applied in bridge construction, erection/assembly of bridges, bridges, etc., can solve the problems of unreasonable time and economy, and the time occupied by bridge erecting machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0033] A construction method for assembling and erecting concrete prefabricated beam segments, comprising the following steps:

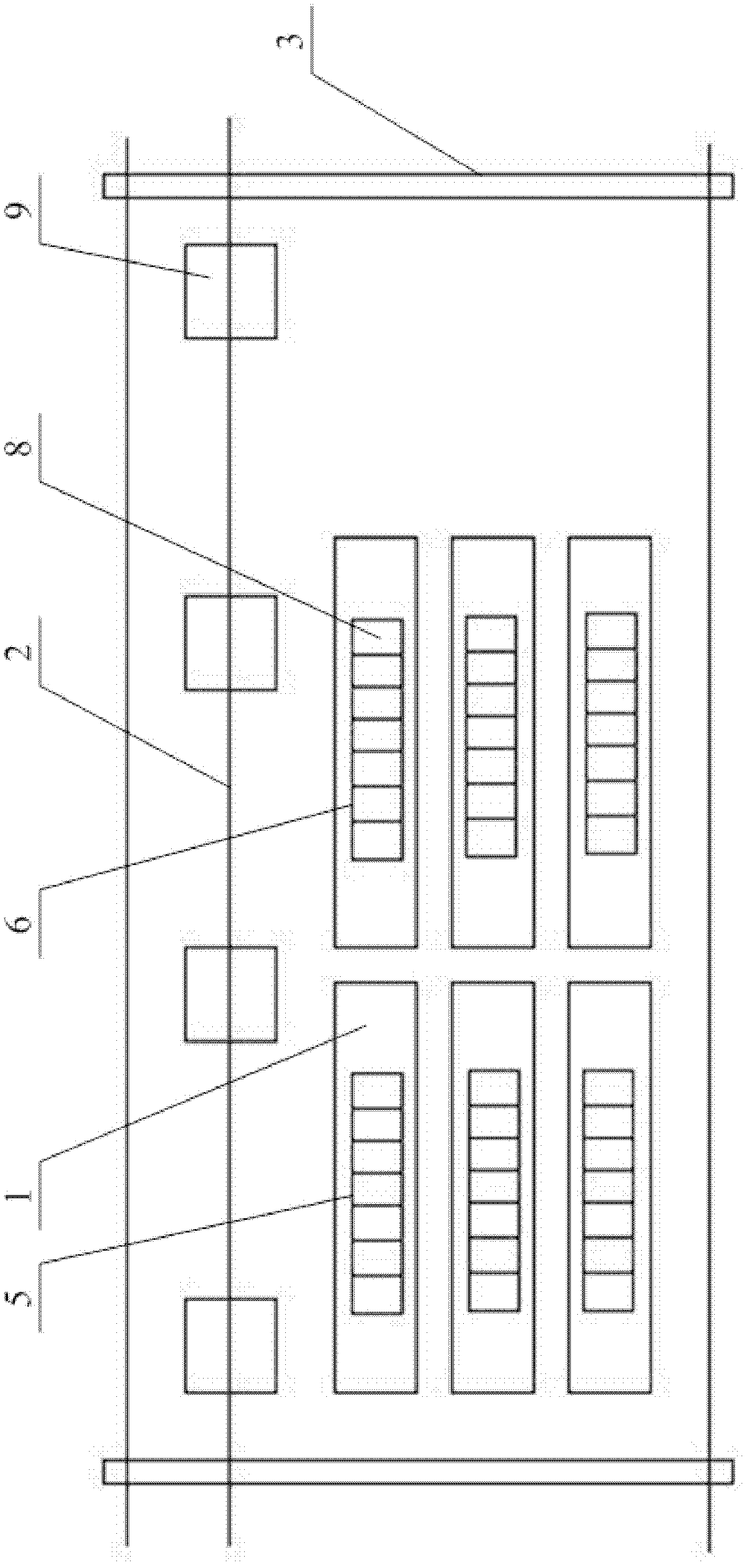

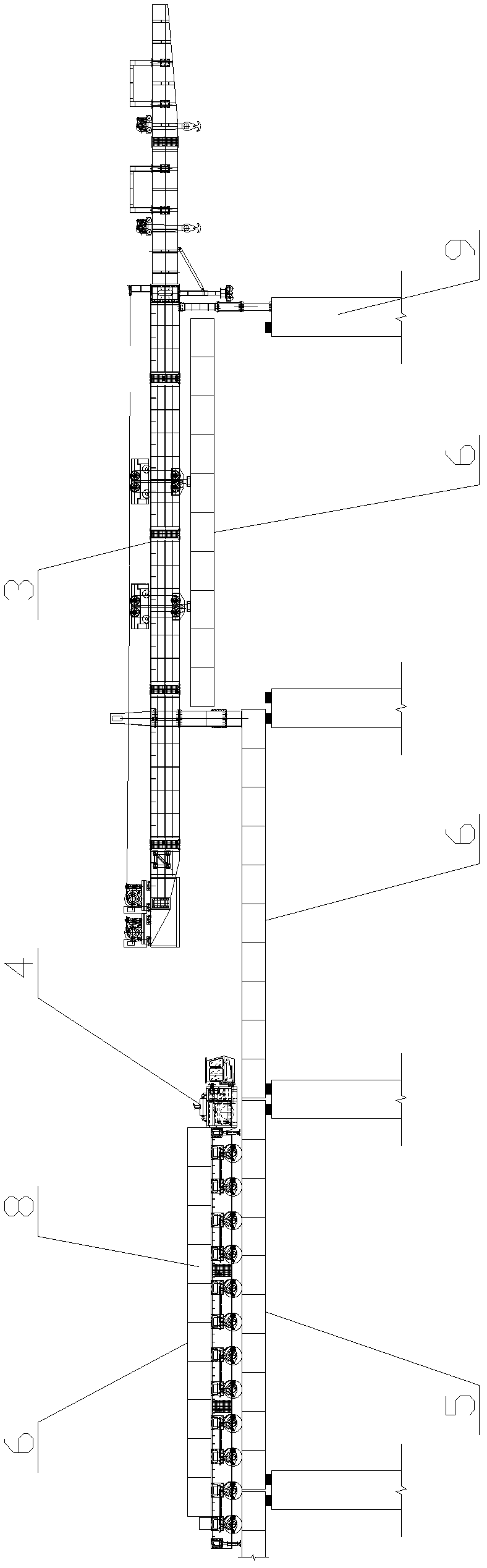

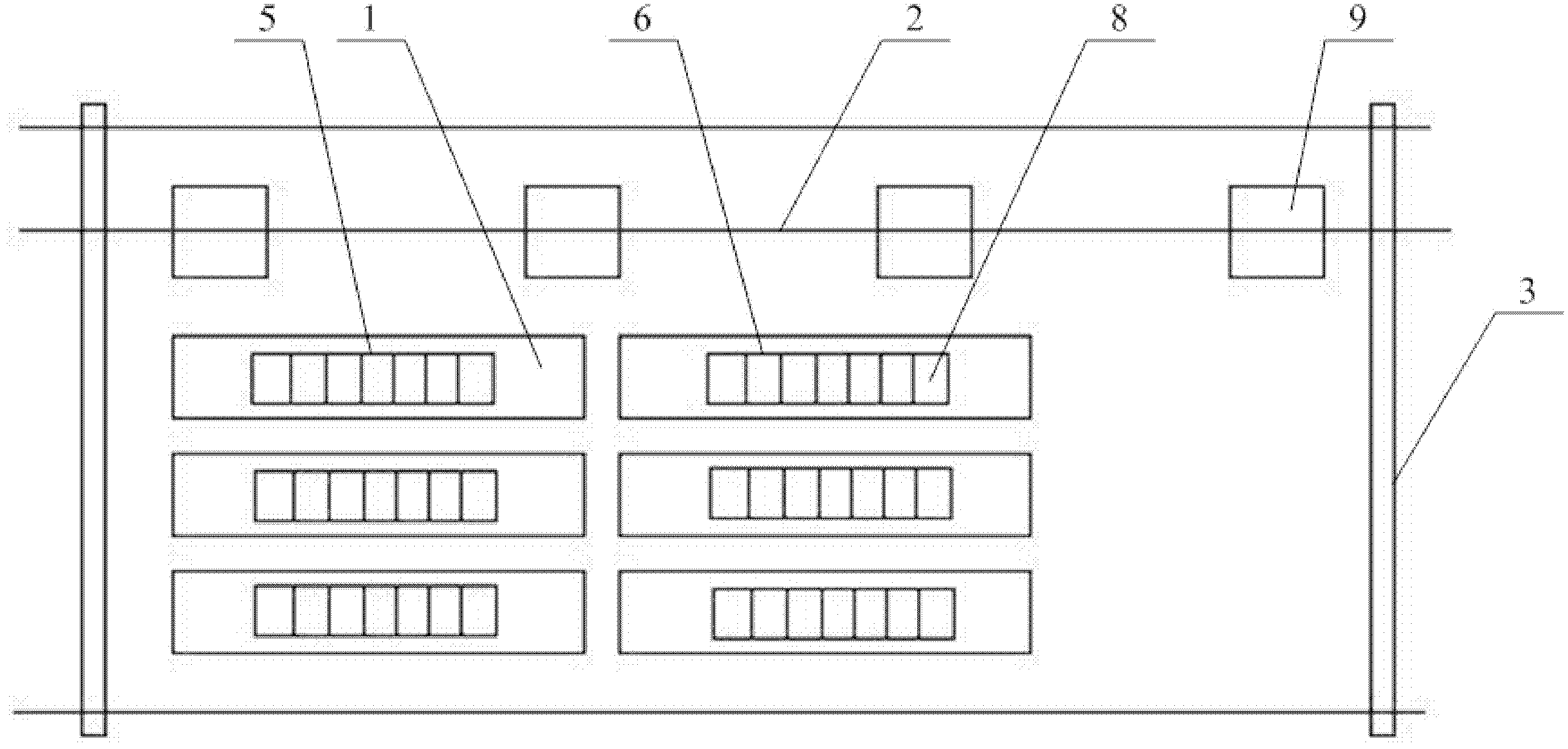

[0034] Such as figure 1 as shown,

[0035] The first step: set several on-site assembly platforms 1 beside the beam line 2 to be erected;

[0036] Among them, the location selection of the on-site assembly platform 1 needs to ensure the implementation of a series of constructions such as segmental transportation, assembly, lifting, and installation; the number of on-site assembly platforms 1 should be set according to the site layout and construction period requirements; Assembled platform 1 should be processed according to the line of the bridge, and the coordinates, elevation and pre-arch of each control point on the line of the bridge must be determined through accura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com