Vertical outer rib beam-column joint connector applicable to prefabricated steel structural systems

A node connection and steel structure technology, applied in building construction, construction, etc., can solve problems such as affecting construction speed and quality, poor node ductility, and easy brittle failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

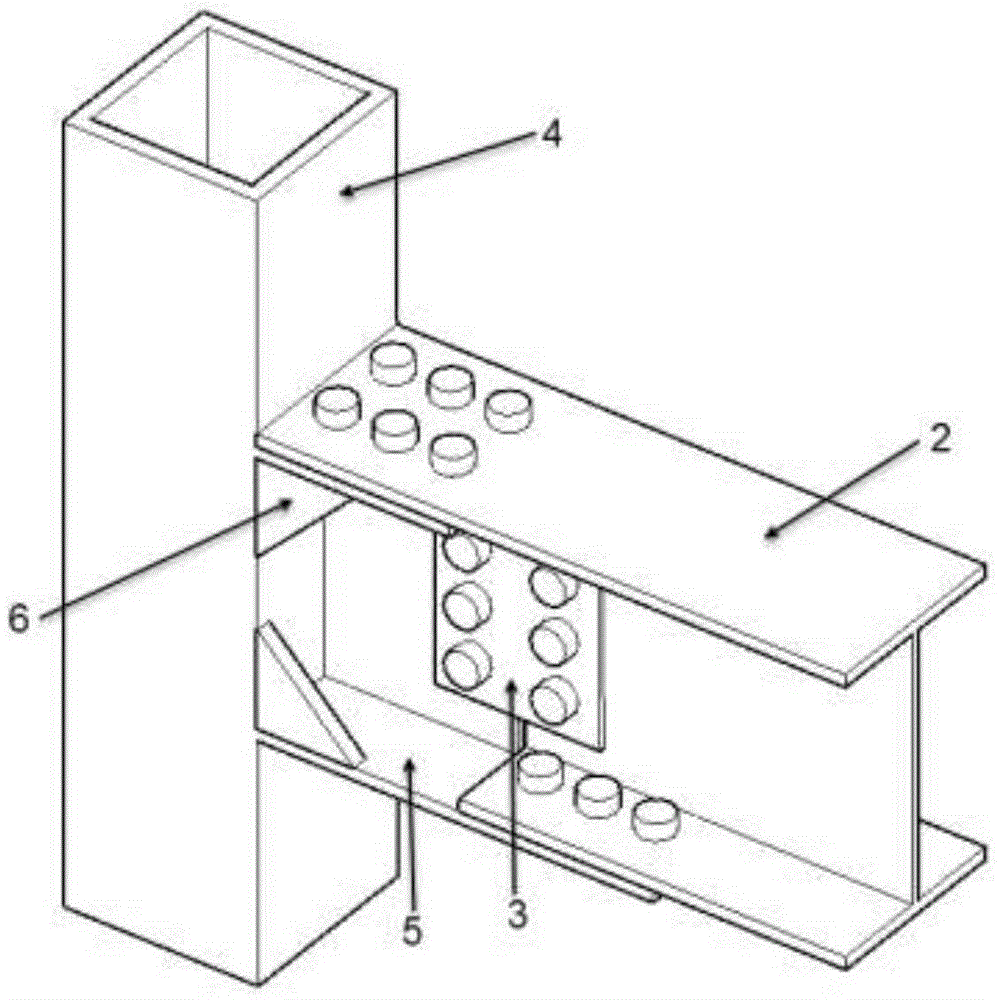

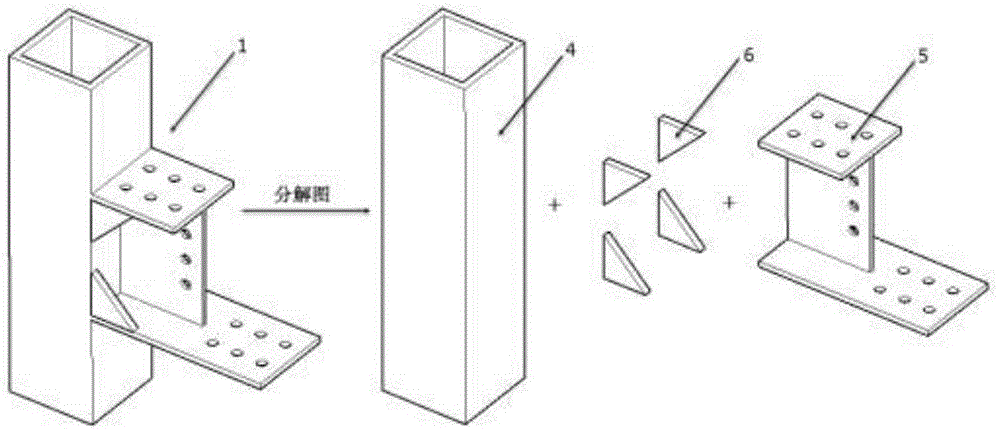

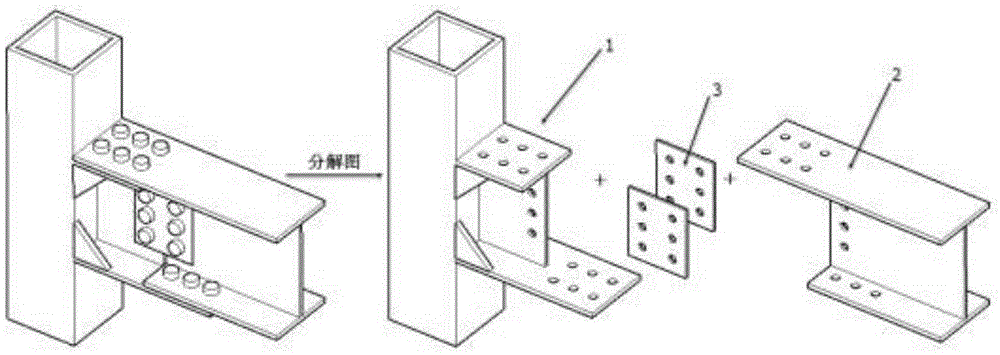

[0031] as attached Figure 1~3 As shown, a vertical outer rib beam-column node connection device applicable to the assembled steel structure system of the present invention includes a square steel column 1 with a cantilever beam section, an H-shaped steel beam 2 with an upper flange extending outward, and a plate 3; The square steel column 1 with a cantilever beam section includes a square steel column 4, a lower flange overhanging H-shaped cantilever steel beam 5 and a triangular vertical outer rib 6; the upper flange overhanging H-shaped steel beam 2 passes the H-shaped steel A part of the lower flange of the beam and the corresponding web are cut and removed; the lower flange overhanging H-shaped cantilever steel beam 5 is formed by cutting and removing a part of the upper flange of the H-shaped steel beam and the corresponding web; the belt The square steel column 1 of the cantilever beam section, the overhanging H-shaped steel beam 2 of the upper flange and the pasting pl...

Embodiment 2

[0033] Example 2: See Figure 4 ~ Figure 5 , the triangular vertical outer ribs 6 in Embodiment 1 are replaced by rectangular vertical outer ribs 7 .

Embodiment 3

[0034] Example 3: See Figure 6 ~ Figure 7 , Embodiment 1 The upper flange extended H-shaped steel beam 2 is replaced by the upper flange extended H-shaped steel beam 8 with a weakened section (the weakened section is the top and bottom of the upper flange extended H-shaped steel beam 2 Both sides of the flange are symmetrically missing an arc).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com