Seed rope and machine for twisting the same

A technology for planting ropes and crops, applied in planting methods, seed treatment methods, seed and rhizome treatment, etc., can solve problems that affect yield, time-consuming, laborious, etc., and achieve the effect of realizing light weight and accelerating the process of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

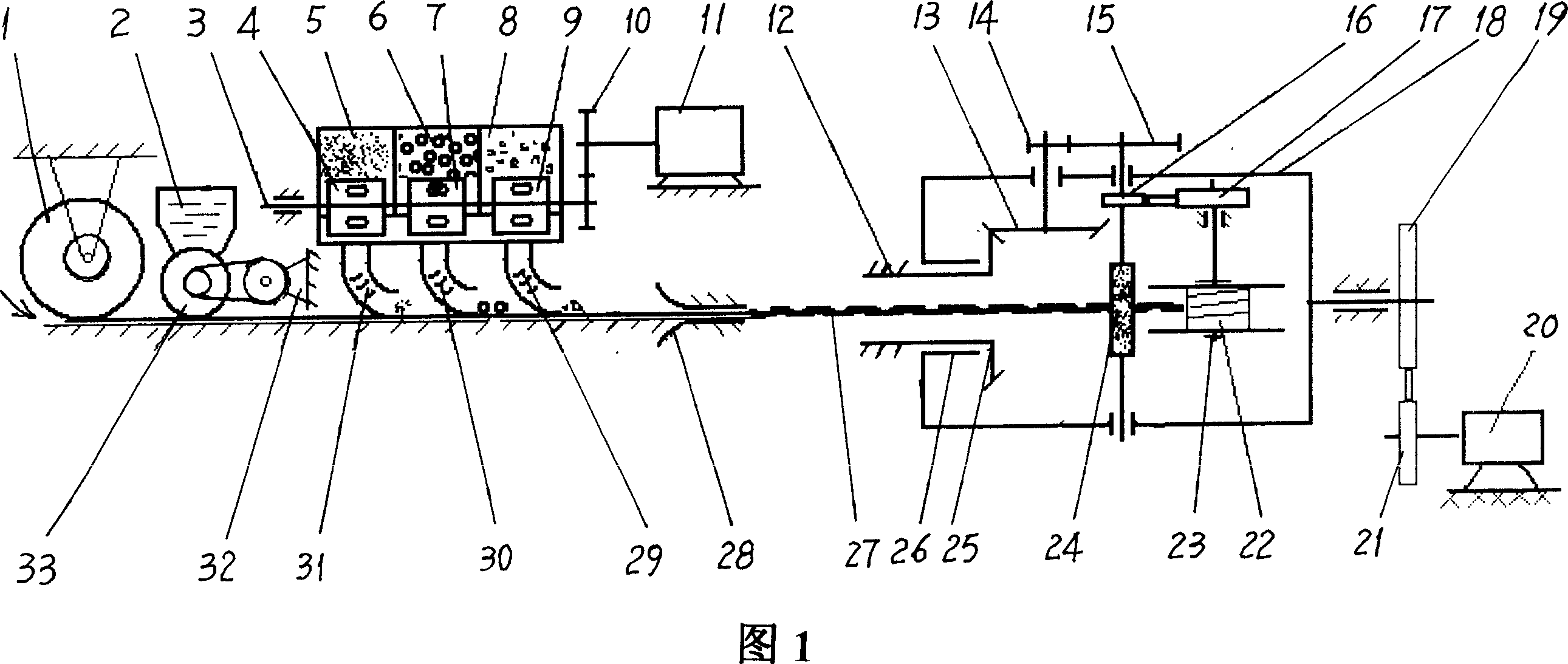

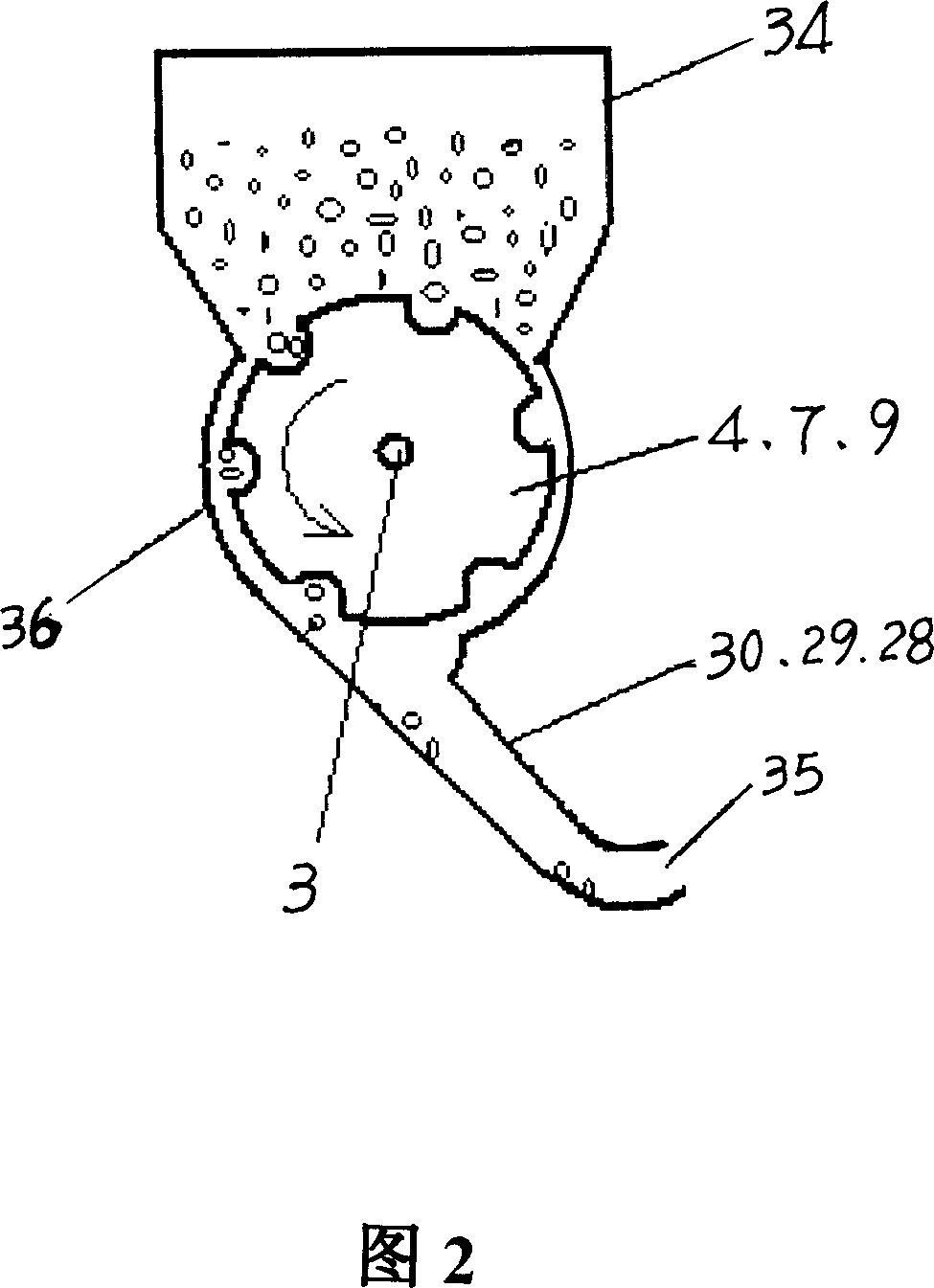

[0012] The crop seed rope provided by the invention is made of twisted non-woven fabric with high strength, no environmental pollution and easy decomposing. The rope body contains a certain amount of plant seeds, fertilizers and herbicides according to requirements.

[0013] See Figures 1 and 2, the structure of the twisting machine for the crop seed rope is as follows: the paper roll 1 of the roller type paper tape delivery mechanism is wrapped with a non-woven fabric belt, and the non-woven fabric belt is pulled on the working surface of the frame On the winding rope wheel 22 of the planting rope twisting system mechanism, arrange the adhesive agent brushing wheel, seeds, fertilizer, and herbicide feeding mechanism successively from the paper belt output end on the working surface of the frame, and the adhesive agent coating The plastic box 2 on the top of the brush wheel 33 is equipped with adhesive, and the adhesive brushing wheel 33 is driven to rotate by the motor 32, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com