Factory agricultural automatic production line

An automatic production line, factory-like technology, applied in agriculture, climate change adaptation, greenhouse cultivation, etc., can solve the problems of low degree of mechanization, the level of facility agricultural operation and management needs to be improved, and the operation efficiency is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

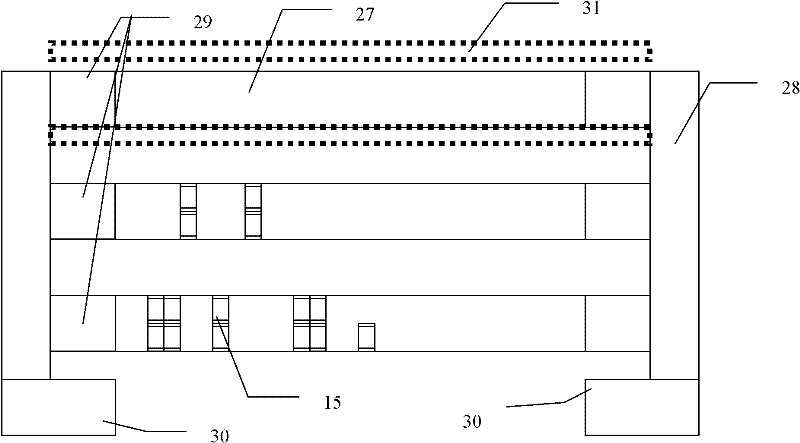

[0031] Example 1: Three horizontal and two vertical production lines such as figure 1 As shown, this figure is a three-horizontal and two-vertical production line, which is provided with three horizontal production lines 27 and two vertical transmission equipment 28, and heat preservation curtains 31 that can be opened are arranged on both sides of a horizontal production line to provide heat preservation for it as required; A lift 29 is provided at the connection between the horizontal production line and the vertical transmission equipment, and 6 are provided in this embodiment, which are used to lift the agricultural production box; on one side of the vertical production line, a work area 30 is provided for Agricultural production boxes for processing. After the staff process the agricultural production box in the vertical working area, the agricultural production box is transported to the side of the third horizontal production line through the vertical transmission equipm...

Embodiment 2

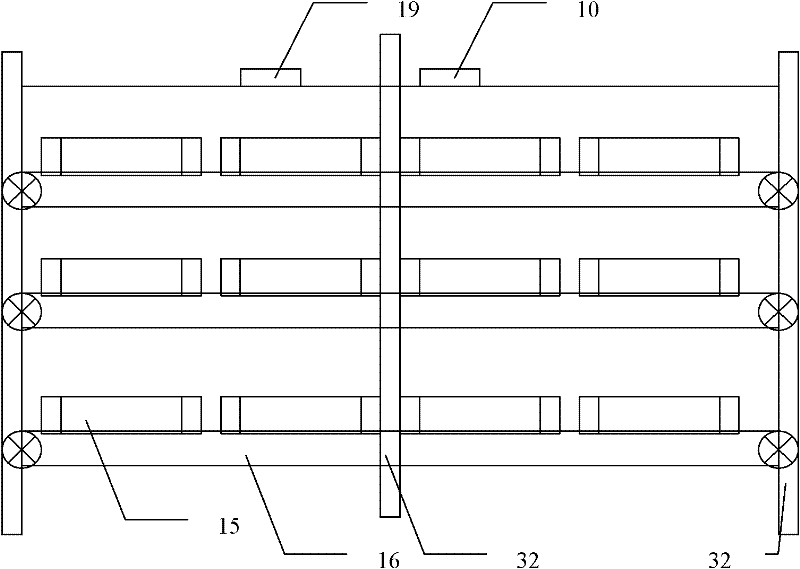

[0032] Embodiment 2: Three-layer belt conveyor production line such as figure 2 As shown, three brackets 32 are provided in this figure, two on both sides and one in the center, and three layers of transmission equipment are also provided. The transmission equipment selects a belt conveyor, and the transmission bearings of the transmission equipment are welded, screwed, plugged, and connected to the brackets. Binding connection or bonding, the transmission belt is set on the upper part of the transmission bearing and can roll on the bearing, the agricultural production box is set on the upper part of the conveyor belt, and the upper part of the agricultural production box is provided with a supplementary light device and a nutrient solution delivery device.

Embodiment 3

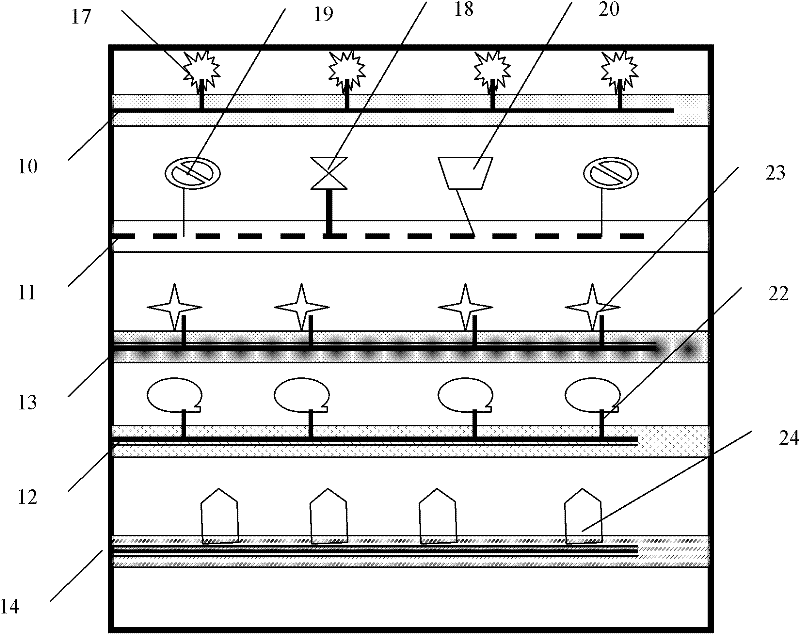

[0033] Embodiment three: the management control system set on the production line is as follows: image 3 As shown, this picture shows the central control system installed on the production line, which is set around the agricultural production box and used to manage and control the agricultural production box.

[0034]Five pipelines are arranged inside the agricultural production box, liquid delivery pipeline 10, power transmission pipeline 11, air-conditioning heat energy (cold) transmission pipeline 12, information transmission pipeline 13, gas delivery pipeline 14, provide all the plants for the inside of the box The five pipelines can pass through the box body and connect with corresponding devices outside the box body. On the liquid delivery pipeline 10 inside the tank, at least one of the following devices is provided: an aerosol device, a spray device or a pipeline outlet to deliver water to the inside of the agricultural production tank. The power transmission pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com