Production method of wire harness and wire harness

A production method and wire harness technology, applied in the field of electronic components, can solve the problems of high processing cost and complex production process, achieve the effects of high molding efficiency, increase the application environment, and ensure the effect of insulation protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

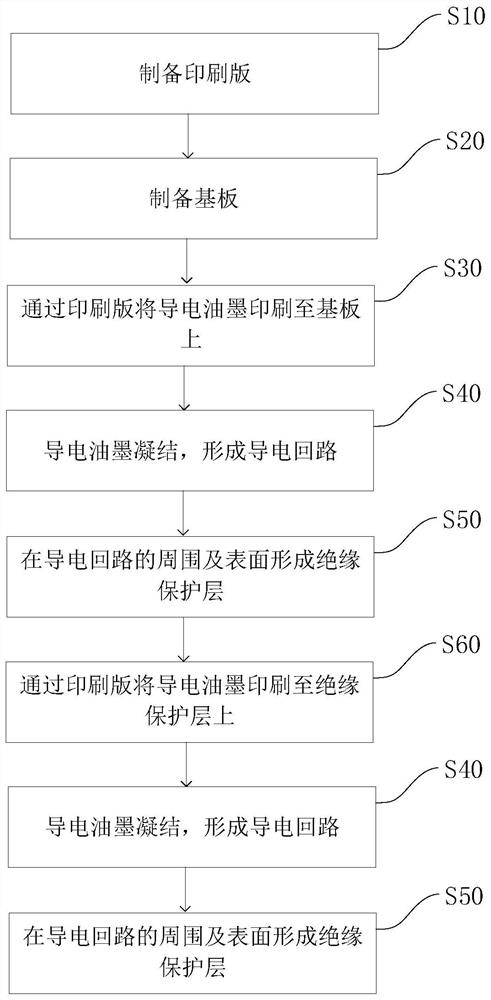

[0066] The invention provides a production method of a wire harness, such as figure 1 As shown, the production method of the wiring harness includes: step S10, preparing a printing plate; step S20, preparing the substrate 10; step S30, printing conductive ink on the substrate 10 through the printing plate; step S40, condensing the conductive ink to form a conductive circuit 21 ; Step S50 , forming an insulating protective layer 40 around and on the surface of the conductive circuit 21 .

[0067] The production method of the wire harness adopts the method of conductive ink printing to form a conductive loop 21 on the substrate 10, and the conductive loop 21 can be connected with external electrical devices to realize the electrical connection function of the wire harness; and the insulating protection layer 40 is used for insulation protection, thereby Realize rapid prototyping of wiring harness loops. By adopting the production method of the wire harness, the forming efficien...

Embodiment 2

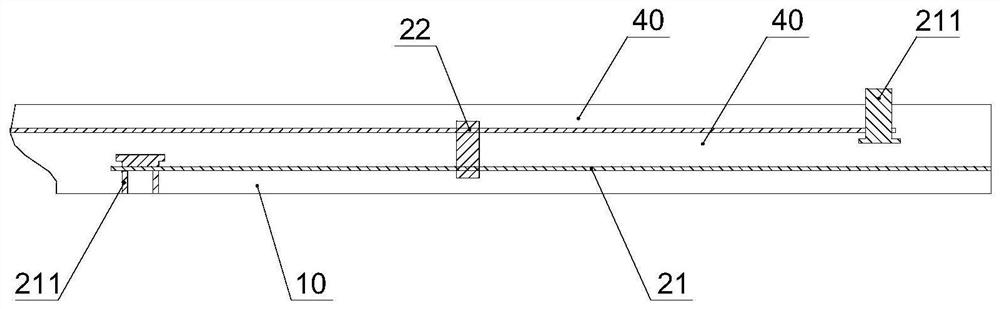

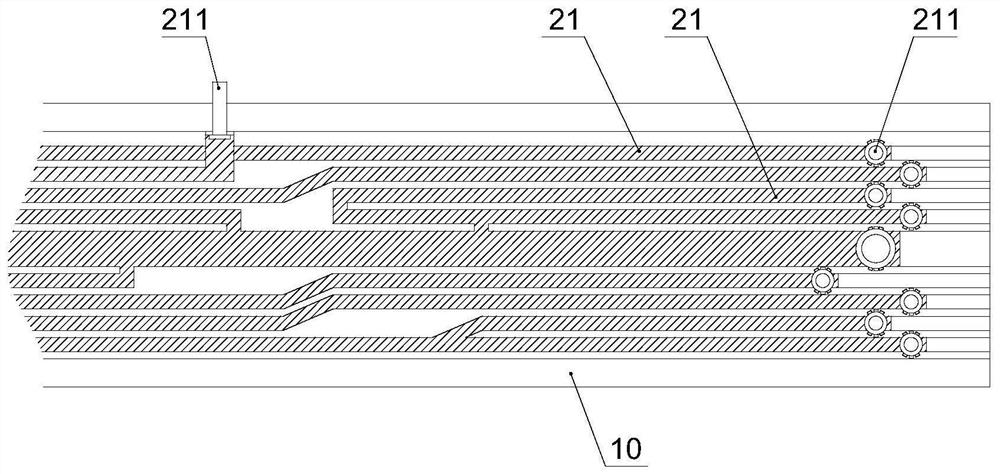

[0100] The present invention provides a wire harness, which is produced by the above wire harness production method. The wire harness includes: a substrate 10, at least one conductive circuit 21 and at least one insulating protective layer 40, and each conductive circuit 21 is located between the substrate 10 and the outermost Between the insulating protection layers 40 of the layers, the conductive loops 21 and the insulating protection layers 40 are alternately distributed. The wire harness is suitable for automatic, large-scale and rapid production, the conductive loop 21 can be formed at one time, the production automation degree is relatively high, the efficiency is high, and the production cost is reduced; it is convenient for installation and disassembly, and the assembly efficiency is improved.

[0101] In one embodiment, the section width of the conductive loop is 0.1mm-68mm. In the wiring harness, the cross-sectional area of the conductor determines the current tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com