Assembly-type building bottom-layer composite floor and connection mode thereof

A combined floor slab and prefabricated technology, applied in slabs, buildings, building components, etc., can solve the problems of affecting the construction period of prefabricated buildings, poor green environmental protection performance, and large amount of wet work on site, so as to improve the degree and speed of assembly. , Improve the connection efficiency and tensile strength, reduce the effect of wet work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and implementation methods.

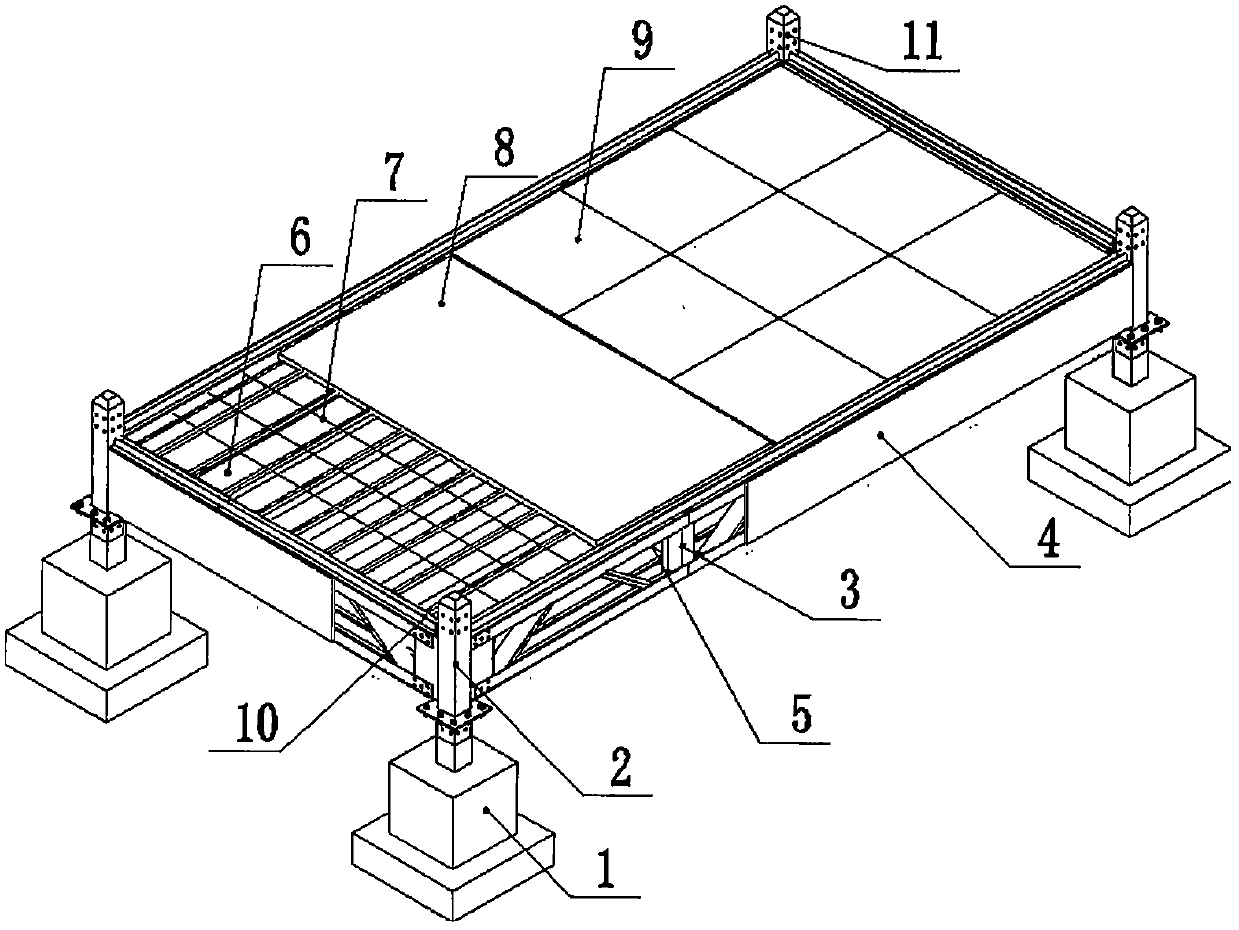

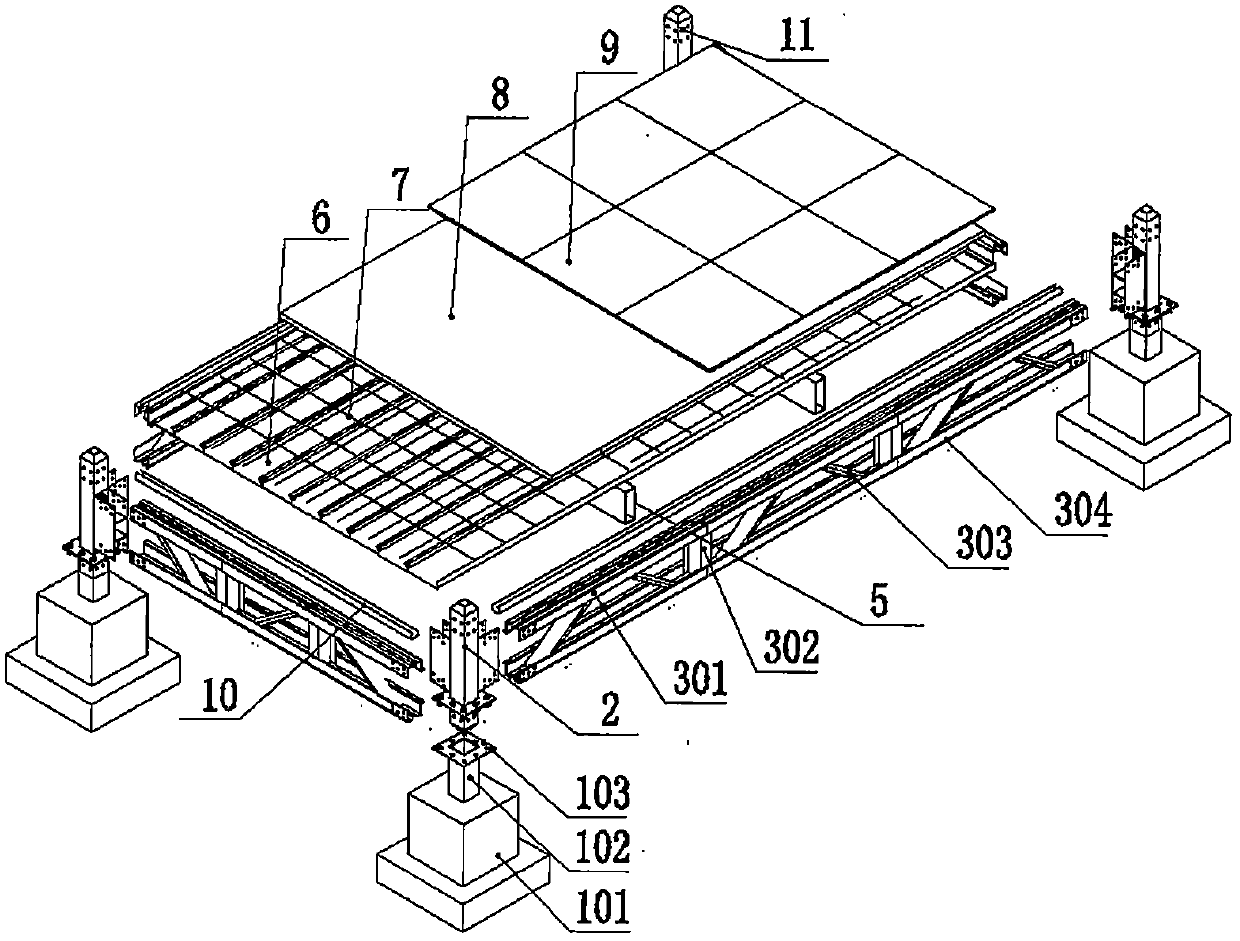

[0032] Such as figure 1 , 2 As shown, a prefabricated building bottom composite floor, including independent foundation (1), square head short column (2), main beam (3), maintenance plate (4), secondary beam (5), profiled steel plate (6 ), steel mesh (7), surface layer (8), decorative layer (9), horizontal fastener (10), and pull rivet (11).

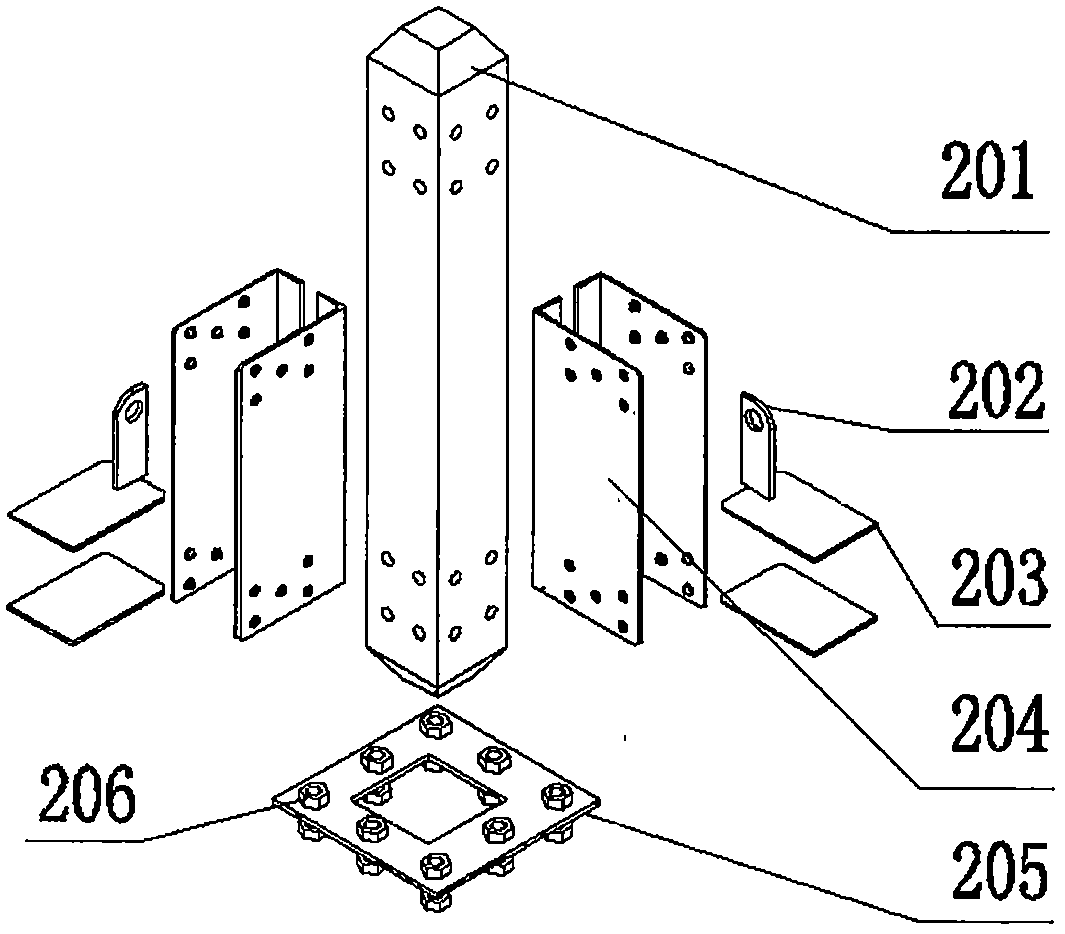

[0033] refer to figure 2, the independent foundation (1) is a reinforced concrete foundation prefabricated in the factory to determine its size according to the self-weight of the superstructure, and the independent foundation (1) includes concrete piers (101), foundation short columns (102), and foundation end plates (103); The pier (101) determines its cross-sectional area, reinforcement, and height according to the self-weight of the upper structure and the soi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com