Precast concrete monolithic ground floor for kitchen and toilet and installation method

A prefabricated concrete, integral ground technology, applied in the direction of floor slabs, special buildings, small buildings, etc., can solve the problems of large labor input, slow construction speed, and the prefabrication rate of building components cannot be improved, so as to achieve convenient operation and speed up construction. Simple and reasonable effect of speed and technical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

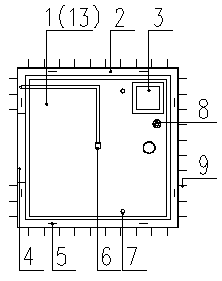

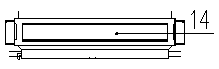

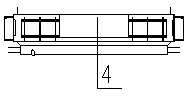

[0038] The prefabricated concrete integral ground floor slab for the kitchen and bathroom, including the kitchen and bathroom floor 1, the kitchen and bathroom floor 1 is provided with a guide wall 2 around it, the guide wall 2 and the kitchen and bathroom floor 1 are integrated, and the plane position of the guide wall 2 It overlaps with the position of the lower structural beam or part of the plane position of the guide wall 2 overlaps with the position of the lower structural beam or the plane position of the guide wall 2 does not overlap with the position of the lower structural beam, and the root of the outer surface of the guide wall 2 is set with an inward slope At the foot of the slope, there is a reserved hole 3 for the exhaust duct at one corner of the floor 1 of the kitchen and bathroom. A floor drain 8 is provided on one side of the opening 3, a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com