Segmental prefabricated assembled pier and construction method thereof

A technology for prefabricating and assembling bridge piers, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc. It can solve the problems of long construction period and insufficient integrity, and achieve the effects of improving construction quality, significant economic benefits, and strong shear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The accompanying drawings constituting a part of this application are used to provide further understanding of the present invention, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, and do not constitute an improper limitation of the present invention.

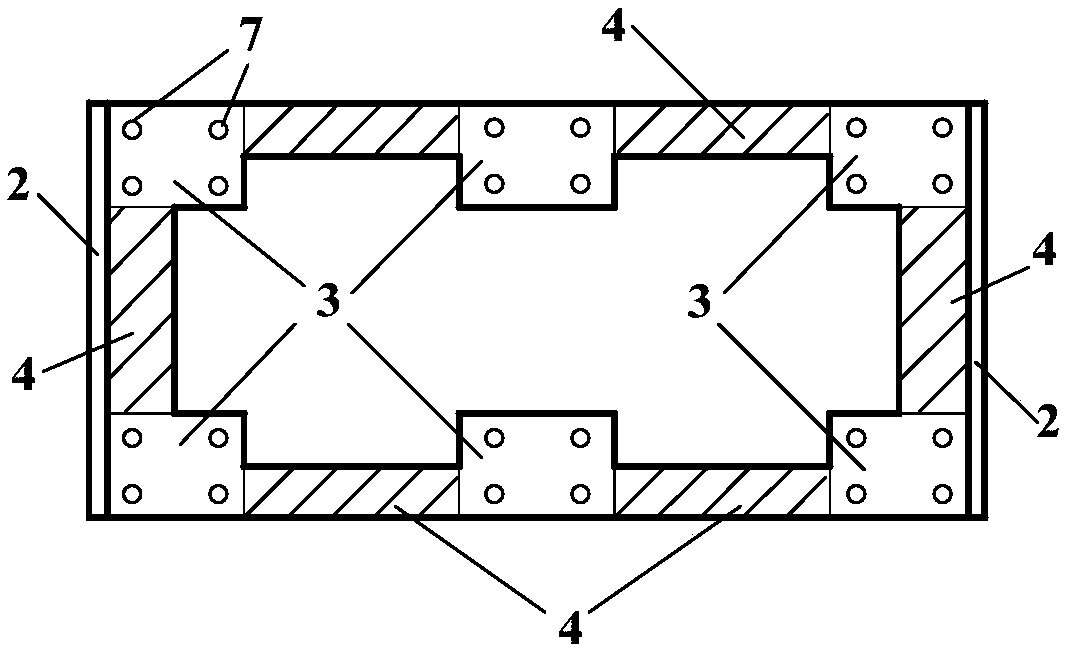

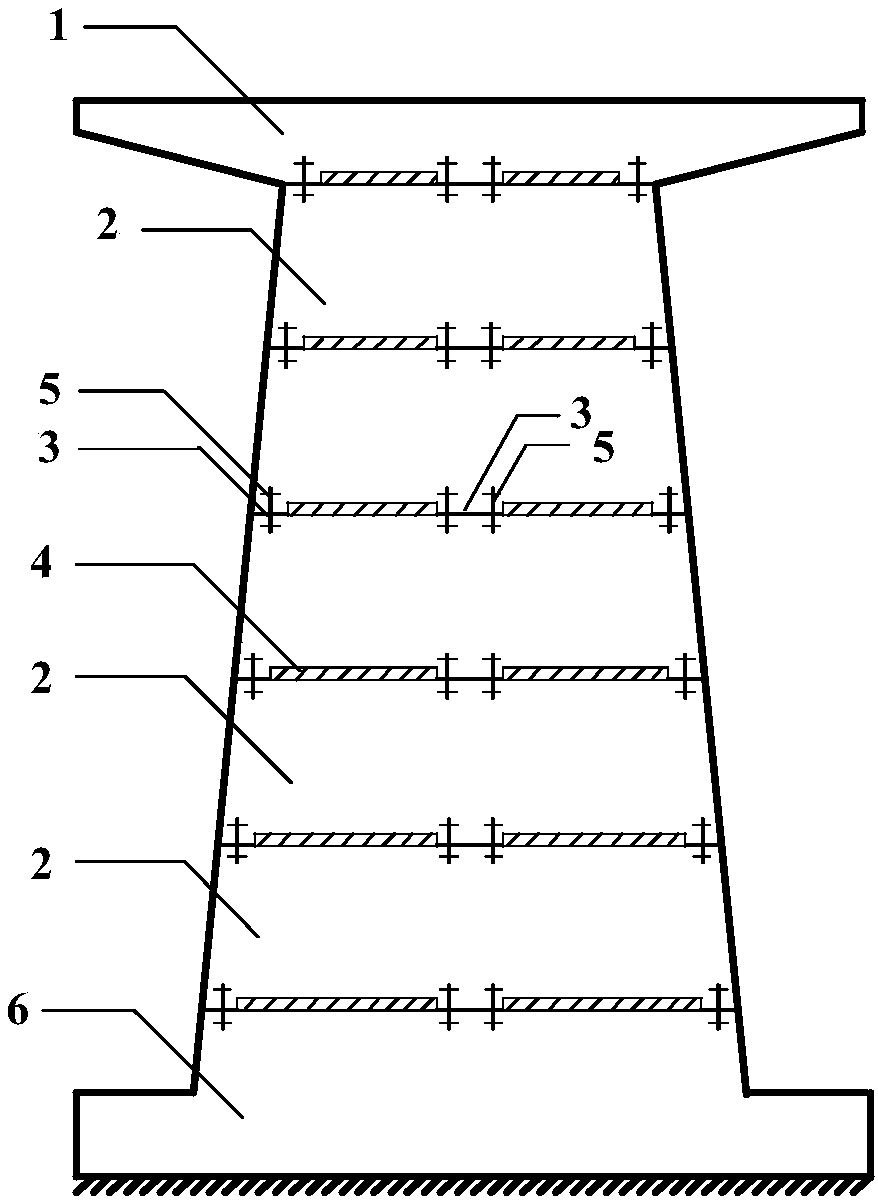

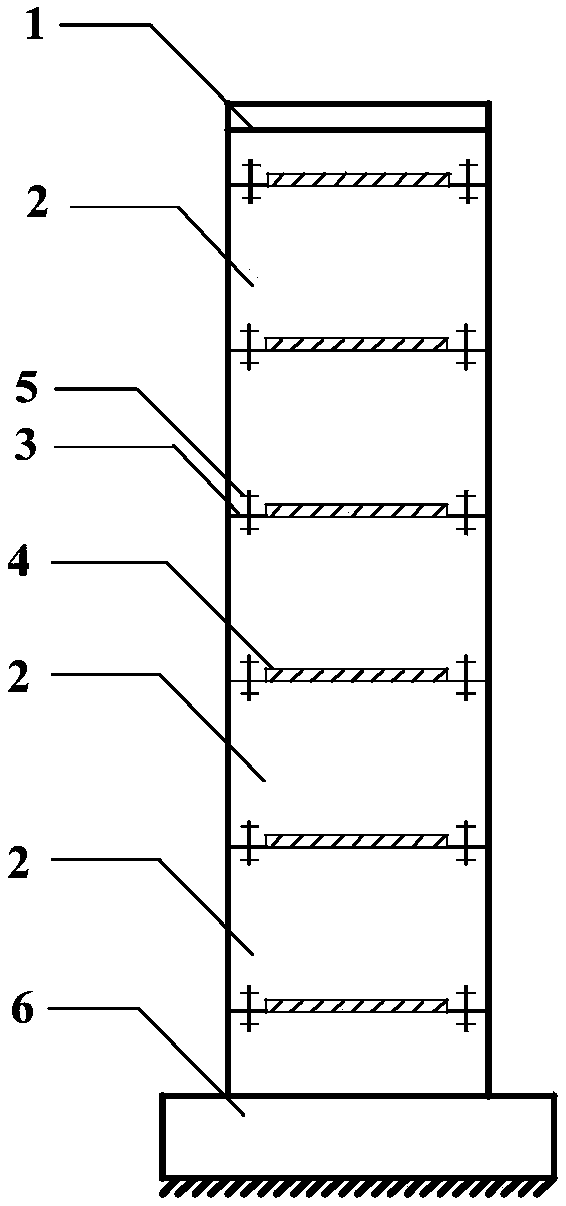

[0031] see Figure 1~2 , the segmental prefabricated assembled pier provided by the present invention comprises: a prefabricated standard pier segment 2 and at least one prestressed tendon 5, the two opposite faces of the prefabricated standard segment 2 of the pier are installation surfaces, and each installation surface is provided with a plurality of Dry joint work surface 3 and multiple wet joint work surfaces 4 . The dry joint operation surface 3 is arranged on the opposite top corners of the installation surface and on the middle area of each side. The wet joint operation surface 4 is arranged between the dry joint operation surfaces 3 . The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com