Prefabricated drainage bamboo pile and preparation method thereof

A technology of bamboo piles and drainage pipes, applied in sheet pile walls, reinforced molding, protection devices, etc., can solve the problems of single drainage pipe and easy blockage of pile body drainage, achieve a high degree of assembly, avoid pile tip damage, Easy to assemble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

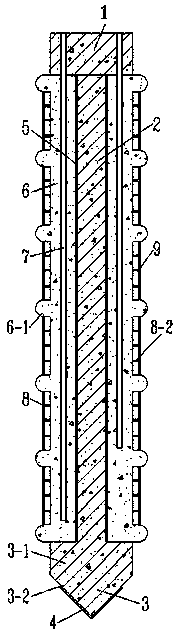

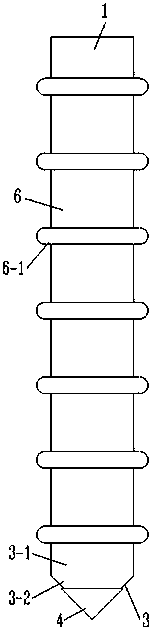

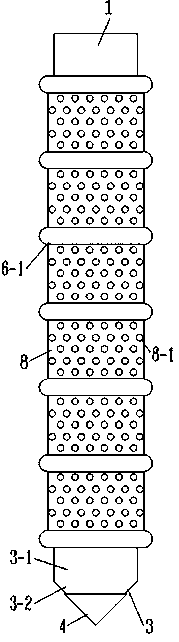

[0036] Example: such as Figure 1-Figure 5 As shown, the prefabricated drainage bamboo pile includes interconnected pile cap 1, prefabricated reinforced concrete pile core 2, pile tip 3, pile tip metal protection head 4, waterproof layer 5, prefabricated permeable concrete pipe 6, drainage pipe 7, prefabricated Metal filter 8, geotextile filter layer 9; the overall pile body is a cylindrical bamboo pile, and the pile cap 1 is cylindrical and made of reinforced concrete, located on the upper part of the prefabricated reinforced concrete pile core 2 and the prefabricated permeable concrete pipe 6 ;The prefabricated reinforced concrete pile core 2 is cylindrical, the diameter is smaller than that of the pile cap 1, runs through the entire pile body, the upper part is connected with the pile cap 1, and the lower part is connected with the pile tip 3; the pile tip 3 is divided into the upper cylindrical section 3-1 And the lower conical section 3-2, the upper cylindrical section 3-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com