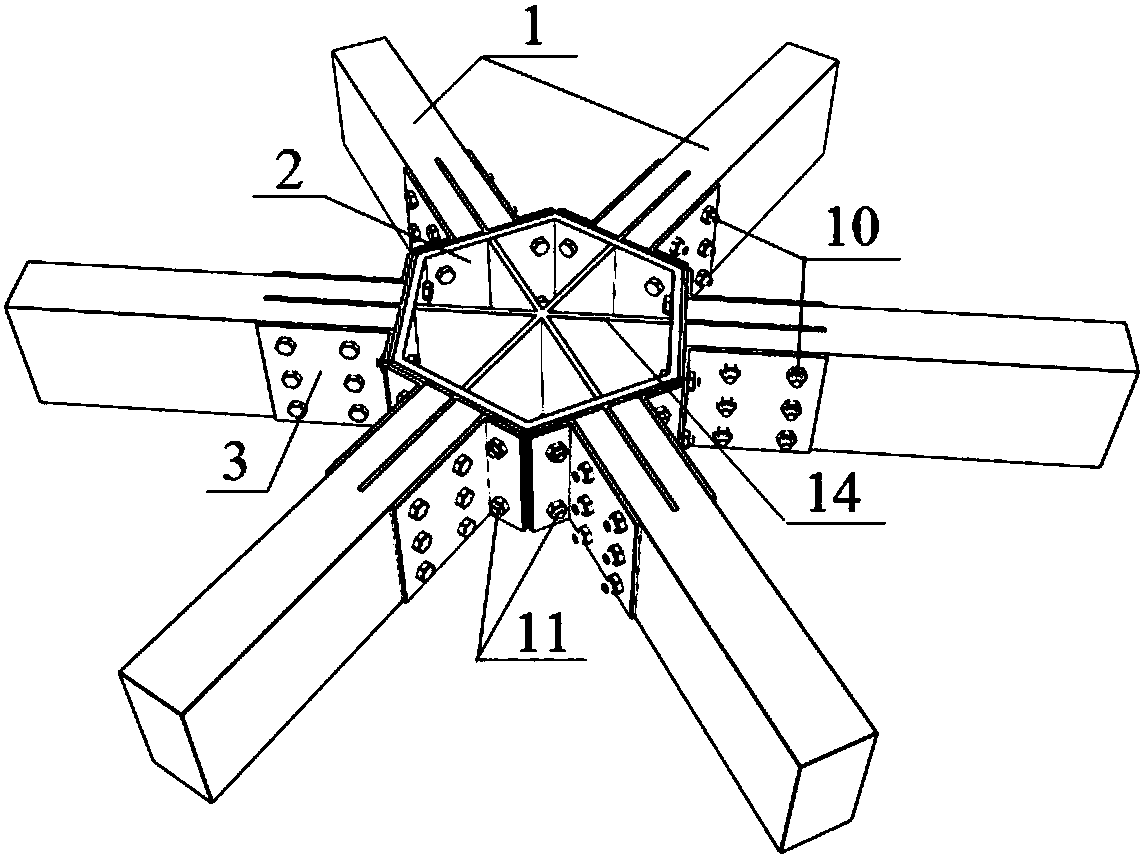

Inner ring ribbing large-span wood structure assembly type joint

A wooden structure and prefabricated technology, which is applied in the direction of building structure and construction, can solve the problems of reducing structural rigidity, low ultimate bearing capacity, and low construction efficiency, so as to improve the degree of assembly, increase initial stiffness, and high construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

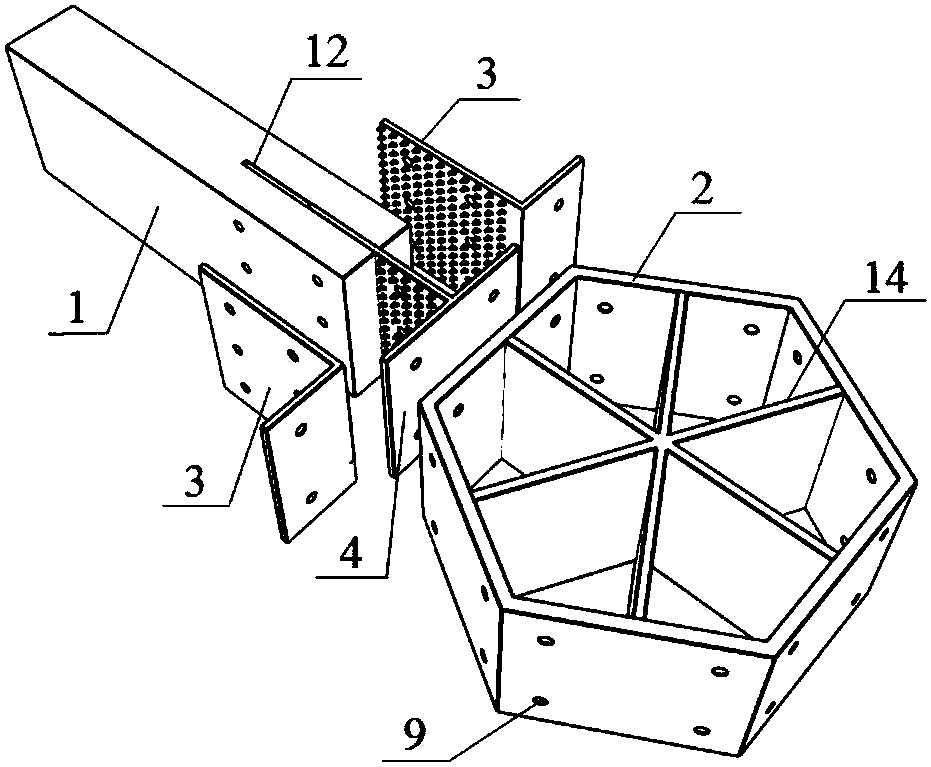

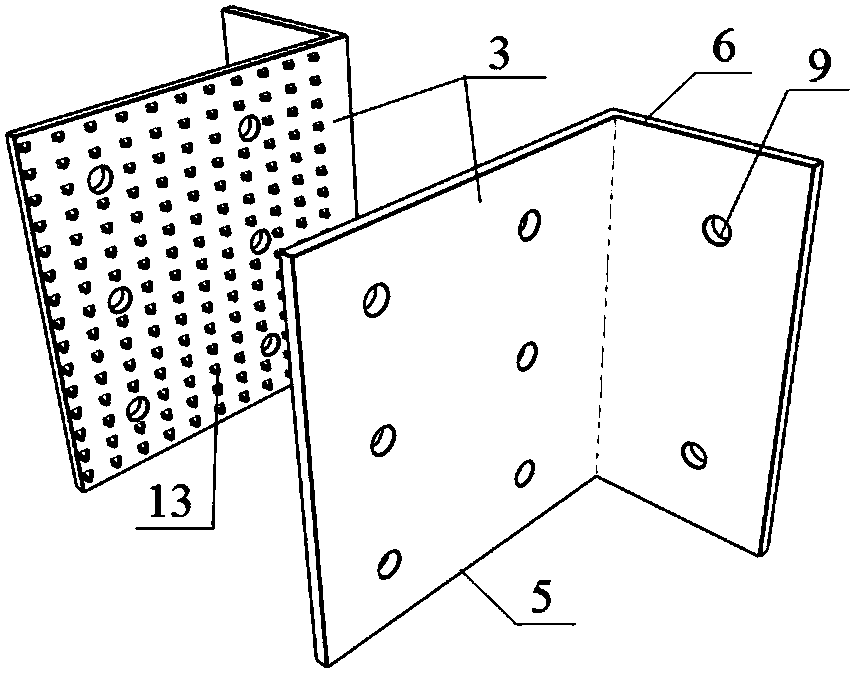

[0016] An assembled node of an inner-ring ribbed long-span timber structure, including a wooden member 1, a core steel cylinder 2, a steel splint 3, and a steel filling plate 4, and L-shaped steel splints 3 are arranged on the left and right sides of the end of the wooden member 1, and the L-shaped steel splints The long board 5 of the wooden member 1 is attached to the longitudinal direction of the wooden member 1, and the vertical board 7 of the T-shaped steel filling board is inserted in the plate groove 12 at the end of the wooden member 1, and the vertical board 7 of the wooden member 1, the long board 5 of the steel plywood and the vertical board of the steel filling board The plates 7 are connected by ordinary bolts 10, the long plate 5 of the L-shaped steel splint, and the vertical plate 7 of the T-shaped steel filler plate are provided with steel teeth 13, and under the pretightening force of the ordinary bolts 10, the steel teeth 13 are embedded in the wooden member 1,...

Embodiment 2

[0018] Different from Embodiment 1, the core steel cylinder 2 is a regular pentagon, heptagon, octagon or circle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com