Patents

Literature

99results about How to "Increase mechanical bite force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

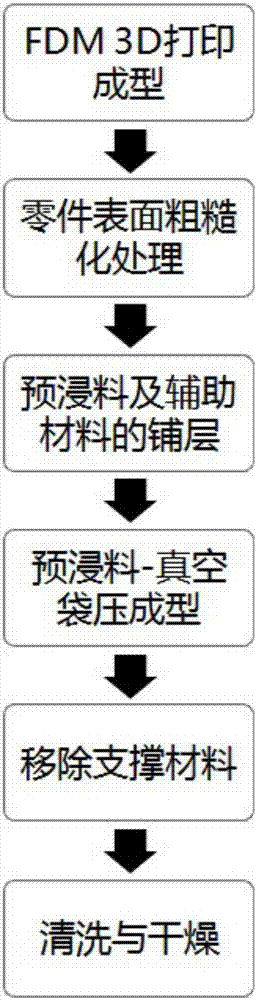

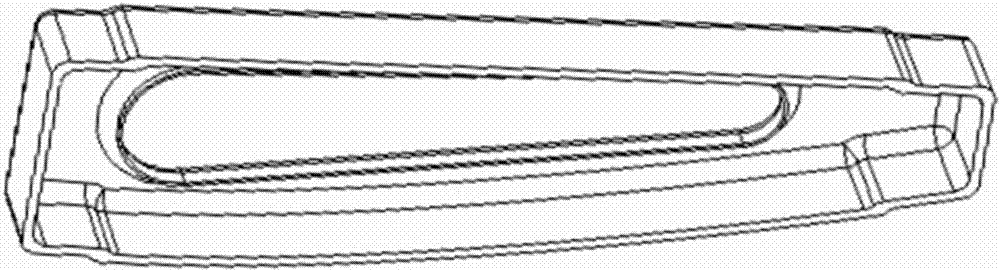

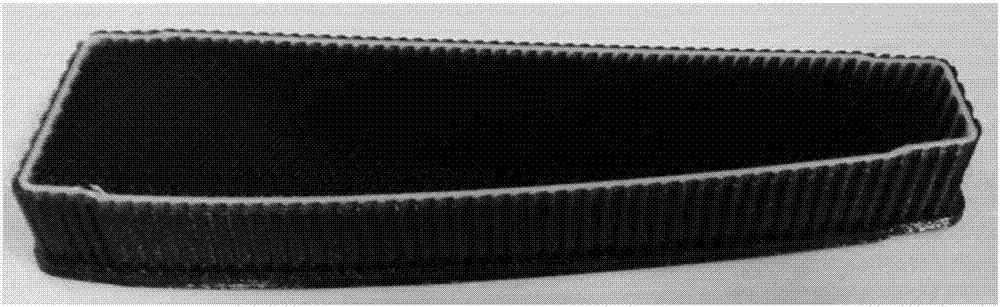

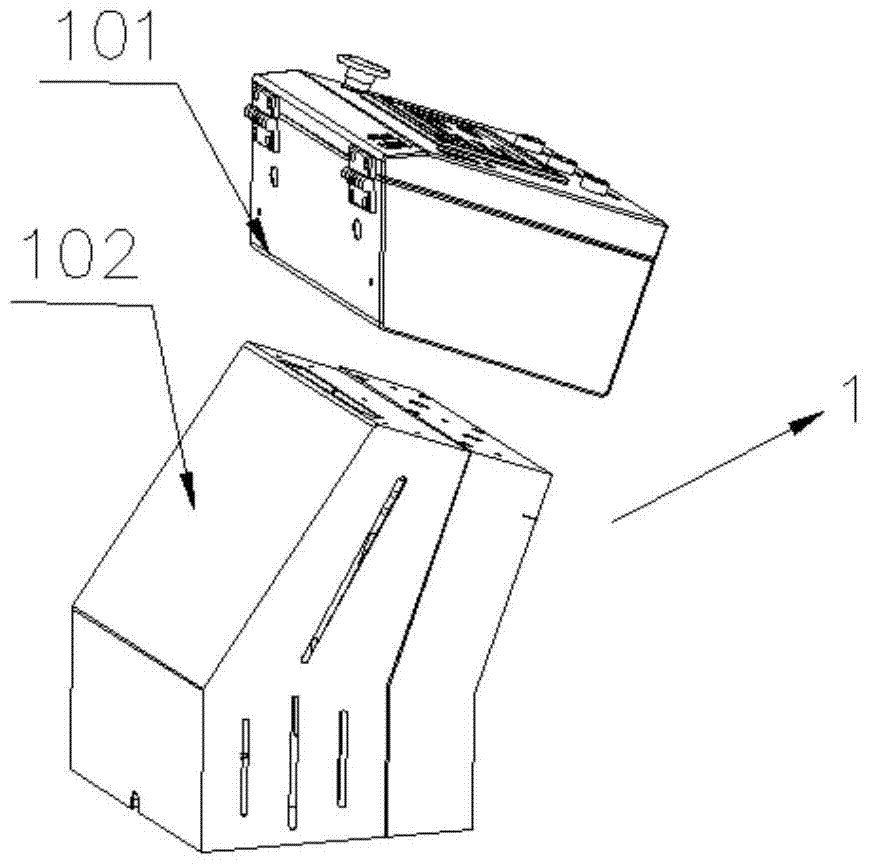

3D printing assisted forming method for fiber reinforced composite material

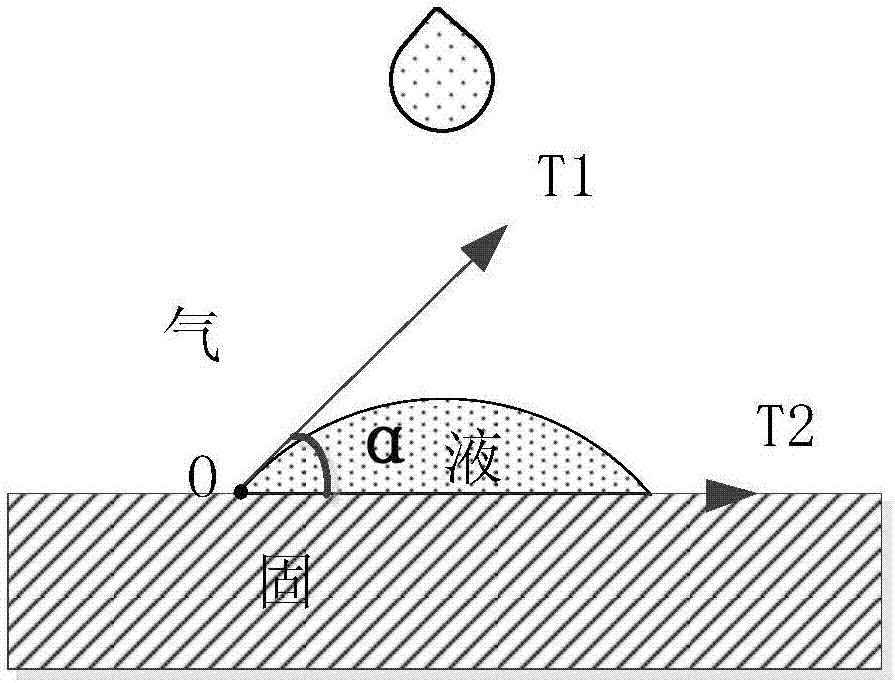

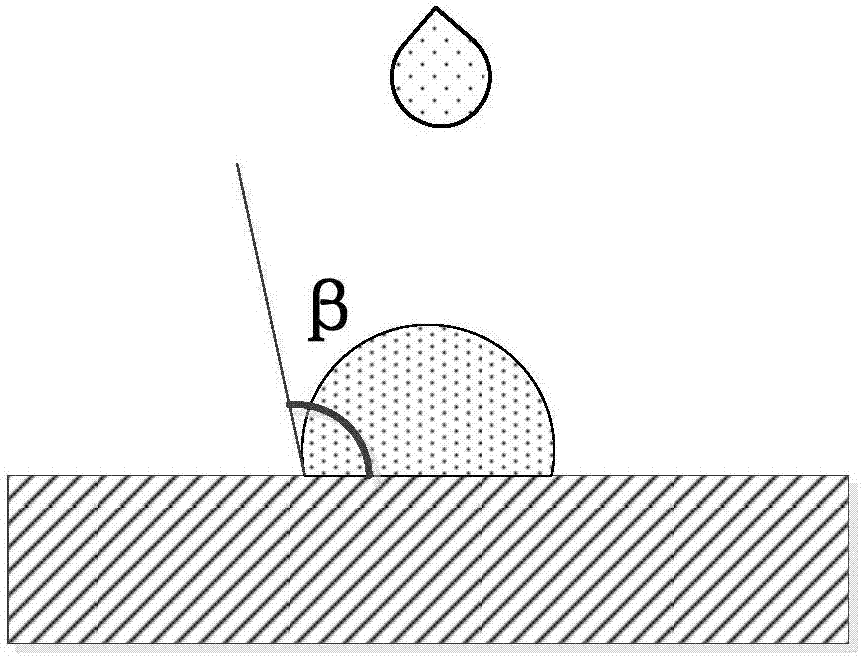

ActiveCN107187020AImprove surface roughnessIncrease mechanical bite forceAdditive manufacturing apparatus3D object support structuresFiber-reinforced compositeInvestment material

Provided is a 3D printing assisted forming method for a fiber reinforced composite material. An FDM 3D printing forming method and a continuous fiber composite material forming method are combined, a prepreg coating and an assisting material are laid on the surface of a part in a prepreg-vacuum bag molding composite material forming mode with an FDM 3D formed part as a forming mold, curing of prepreg is completed under a certain degree of temperature and pressure, and a supporting material is removed, cleaned and dried. By integrating the advantages of the flexibility and high precision of FDM 3D printing forming and the advantages of low weight and high strength of the composite material, the defects that FDM 3D printing forming is low in strength while the composite material is can not be separated from the mold easily are overcome, and the fiber reinforced composite material of a complex structure can be formed and manufactured into parts.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Magnesium alloy surface treatment method

InactiveCN104805345AReduce heat sensitivityImprove solderabilityMolten spray coatingMetallurgyMaterials science

The invention discloses a magnesium alloy surface treatment method which comprises three stages including a pretreatment stage, a spraying stage and an after-spraying treatment stage. By adoption of a compound spraying method, an anti-corrosion and anti-abrasion coating layer which is high in bonding strength, high in compactness and small in environment pollution is formed on the magnesium alloy surface; the surface treatment method is simple and feasible and is low in cost.

Owner:SUZHOU TONGMING MACHINERY

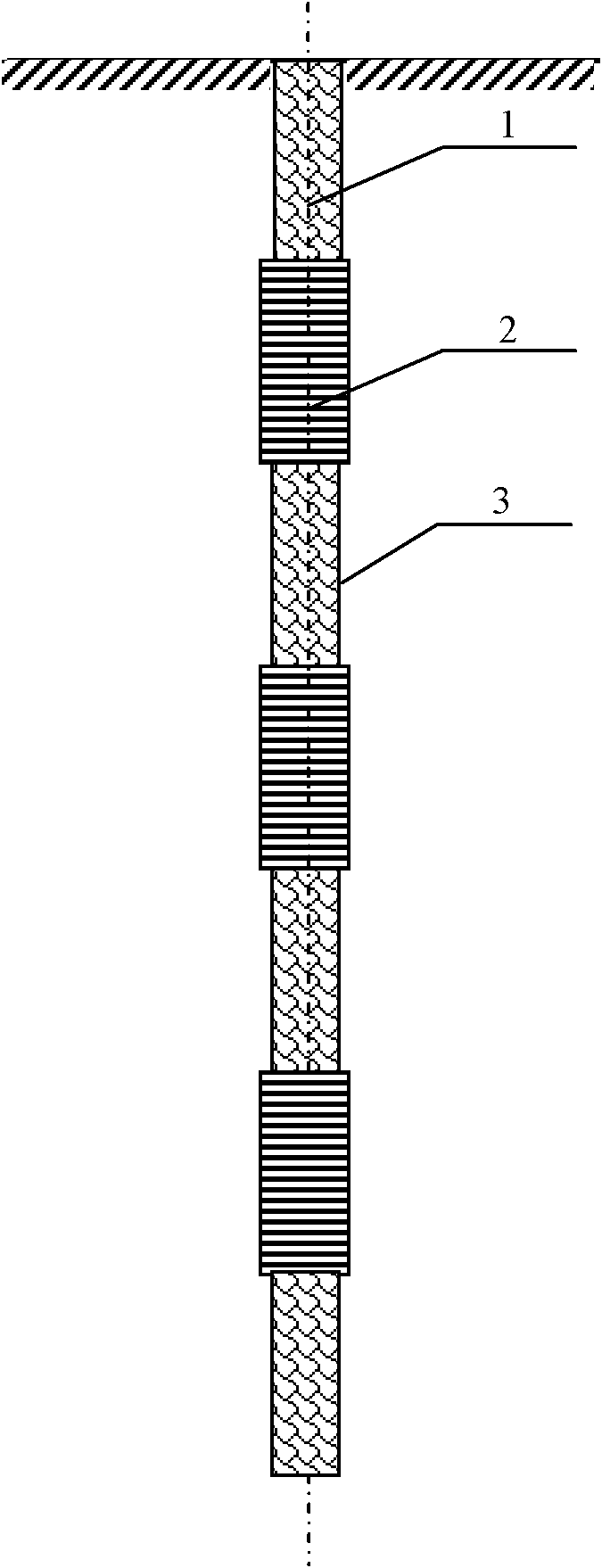

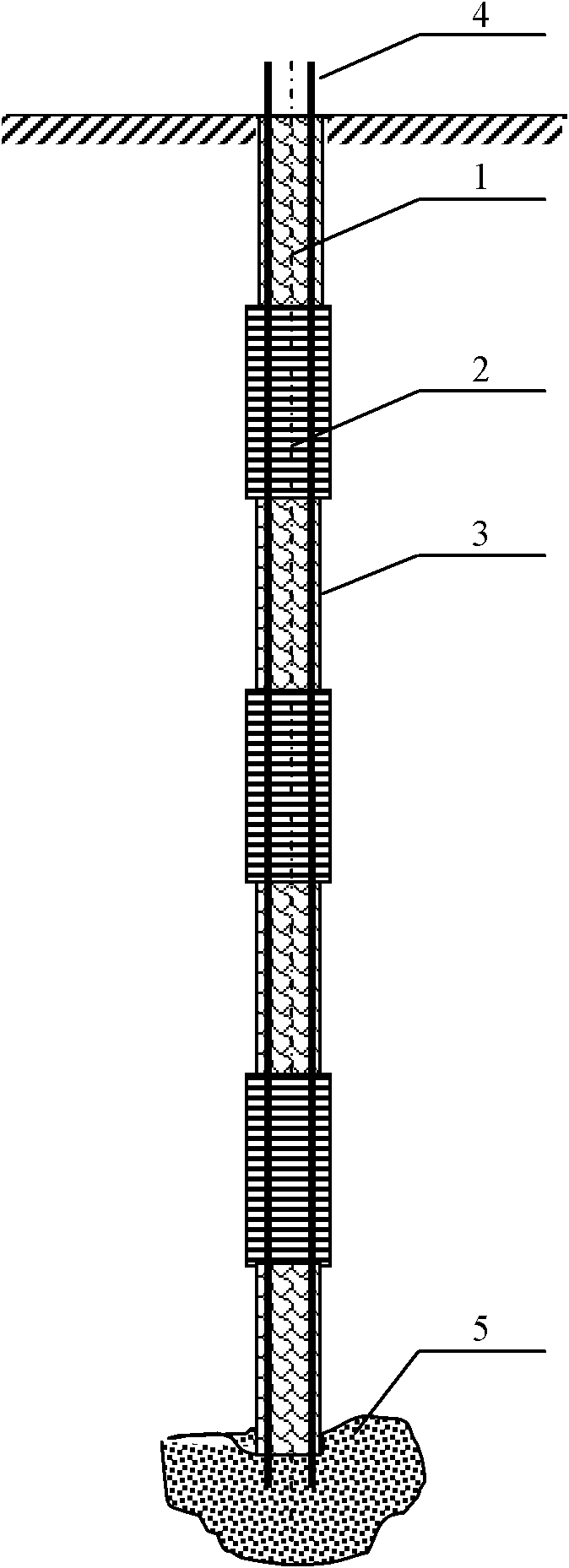

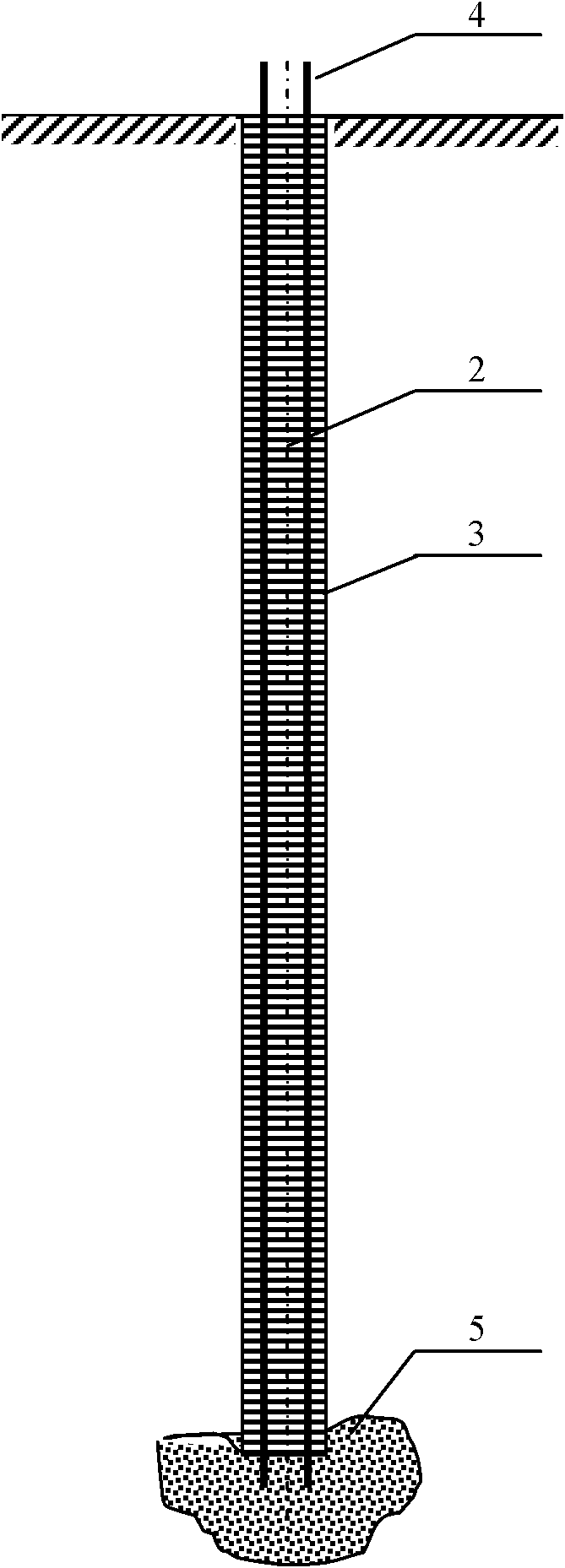

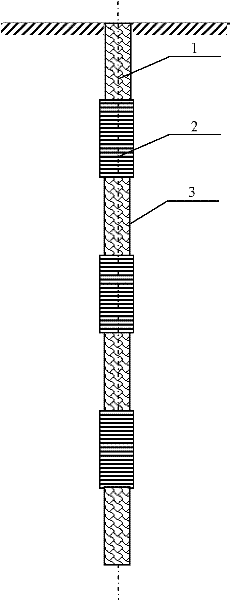

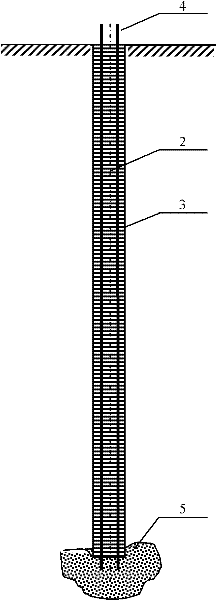

Expansive concrete caisson pile and manufacturing method thereof, and concrete expanding agent

ActiveCN102162244AIncrease relative resistance to motionImprove bearing capacityBulkheads/pilesSlurryJoints types

The invention provides an expansive concrete caisson pile and a manufacturing method thereof, and a concrete expanding agent, and belongs to the technical field of engineering materials and construction of concrete pile foundation. The method comprises the following steps of: alternatively pouring common concrete and expansive concrete into a caisson pile hole sequentially so as to form bamboo joint type I-shaped pile; and pouring slurry at the pile end of the I-shaped pile or the expansive concrete pile so as to form a II-shaped pile or a III-shaped pile. The expanding agent is manufactured by pulverizing 40 to 80 percent of limestone and 20 to 60 percent of gypsum, calcining the powder in a rotary kiln at the high temperature of 1,300 to 1,500 DEG C, and pulverizing 20 to 80 weight percent of the calcined substance and 20 to 80 weight percent of calcium sulfoaluminate cement or alunite or calcium aluminate cement or a mixture of the calcium sulfoaluminate cement, the alunite and the calcium aluminate cement until the specific surface area is 150 to 400 square meters per kilogram. By the method, the manufacturing cost of the expansive concrete caisson pile can be reduced obviously; and compared with the common expansive concrete caisson pile, the expansive concrete caisson pile has the advantage of obviously increasing the bearing capacity of a single caisson pile.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

Protection method for rust removal, paint removal and anticorrosion of metal surface

InactiveCN102218386ASolve the work of rust removal and rust preventionReduce labor intensityPretreated surfacesCoatingsBenzeneKetone

The invention relates to a protection method for rust removal, paint removal and anticorrosion of a metal surface. The method comprises three steps of (1) metal surface lossless rust removal technology, (2) conversion of rust iron on a metal surface and antirust processing, (3) painting of anticorrosion paint on the metal surface. Compared with prior art, the protection processing on the metal surface of the invention employs a high-pressure water-sand blending technology to remove rust, so that rust removal efficiency is higher and the method is safe and environment-friendly. Free rust on the metal surface can be conversed into antirust priming paint when a rust removal transforming agent is being painted, so as to complete metal rust removal and rust prevention by one step, and solve problems, that harm antirust quality, such as local corrosion and free rust at one time. The rust transforming agent employed in the technology belongs to an aqueous system, is without harmful solvents of benzene, ketone, etc., or heavy metal compositions and is nontoxic and environmental-friendly, so that base materials with rust can be used in construction to save costs and raise efficiency. Anticorrosion coating on the metal surface employs a high-pressure air-free coating spraying, so that construction quality is more reliable and the efficiency is higher.

Owner:SHANGHAI FAHE BRIDGE & TUNNEL MAINTENANCE ENG TECH

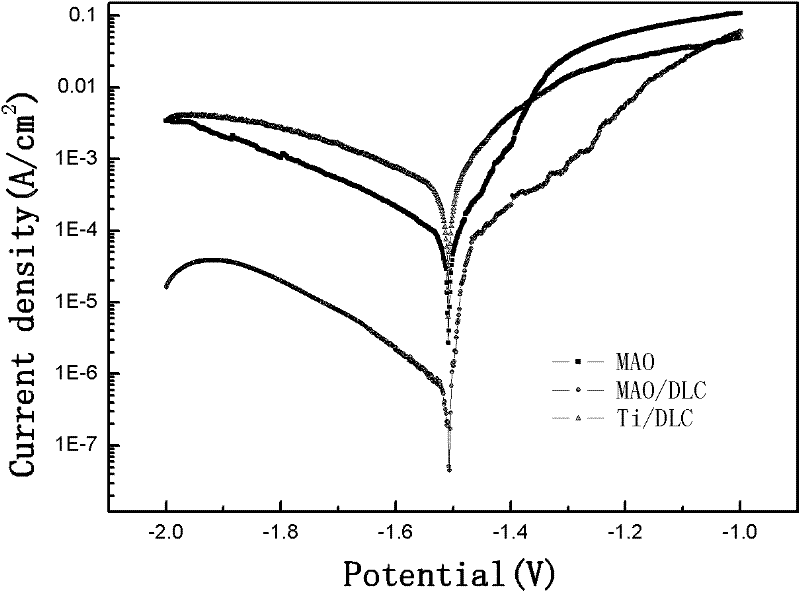

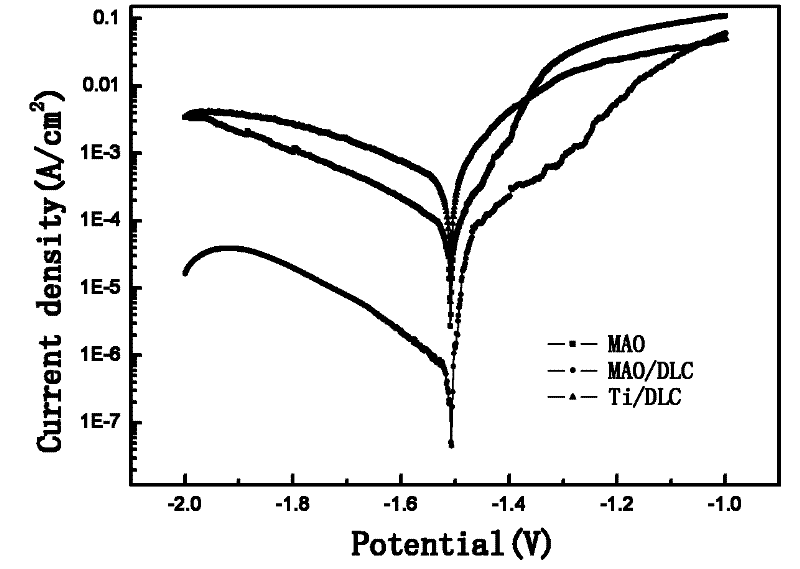

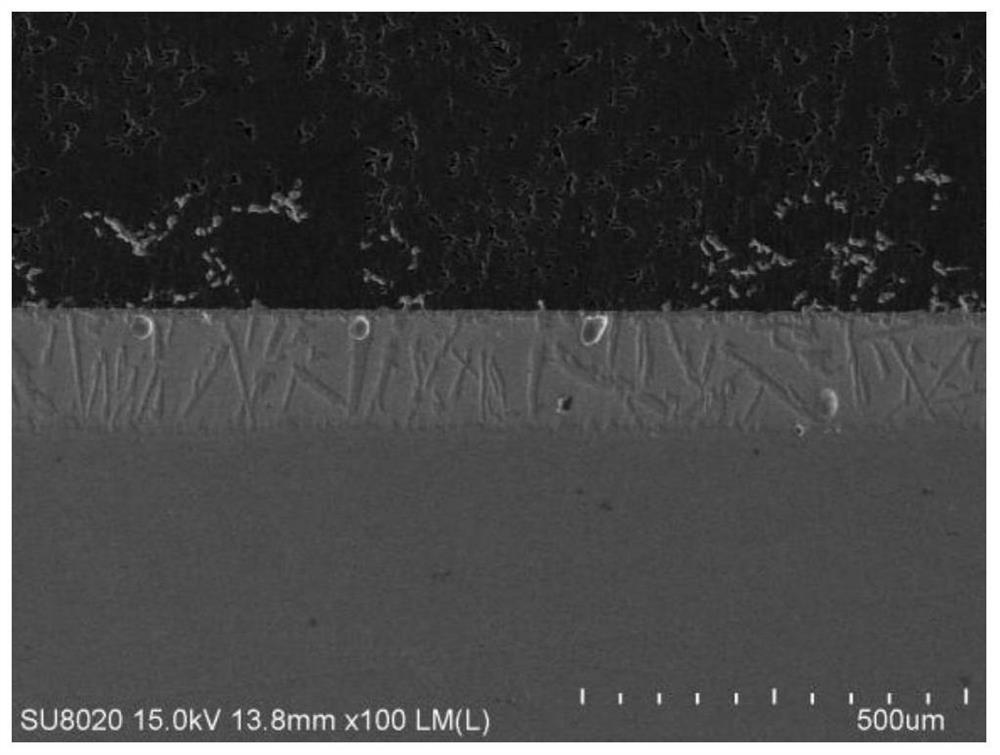

Composite coating on the surface of a magnesium alloy biological implant material and its preparation method

ActiveCN102286767AImprove performanceSimple processAnodisationLayered productsPlasma electrolytic oxidationBiocompatibility Testing

The invention discloses a composite coating on the surface of a magnesium alloy biological implant material. The composite coating consists of a transition layer and a diamond-like carbon (DLC) film layer, wherein the transition layer is positioned on the surface of a magnesium alloy matrix; the DLC film layer is positioned on the surface of the transition layer; the transition layer is an oxide porous film formed by magnesium atoms of the surface layer of the magnesium alloy in situ by a microarc oxidation technology; the surface aperture of the oxide porous film is less than or equal to 1,000 nm; the thickness of the transition layer is 3 to 15 mu m; and the thickness of the DLC film layer is 300 to 1,000 nm. Compared with the conventional magnesium alloy biological implant material, the composite coating has biocompatibility, corrosion resistance more excellent than that of the Ti / DLC composite coating, wear resistance and excellent film-based bonding force with the magnesium alloy matrix, can beneficially modify the surface of the magnesium alloy matrix, and promotes application of the magnesium alloy biological implant material to the organism.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

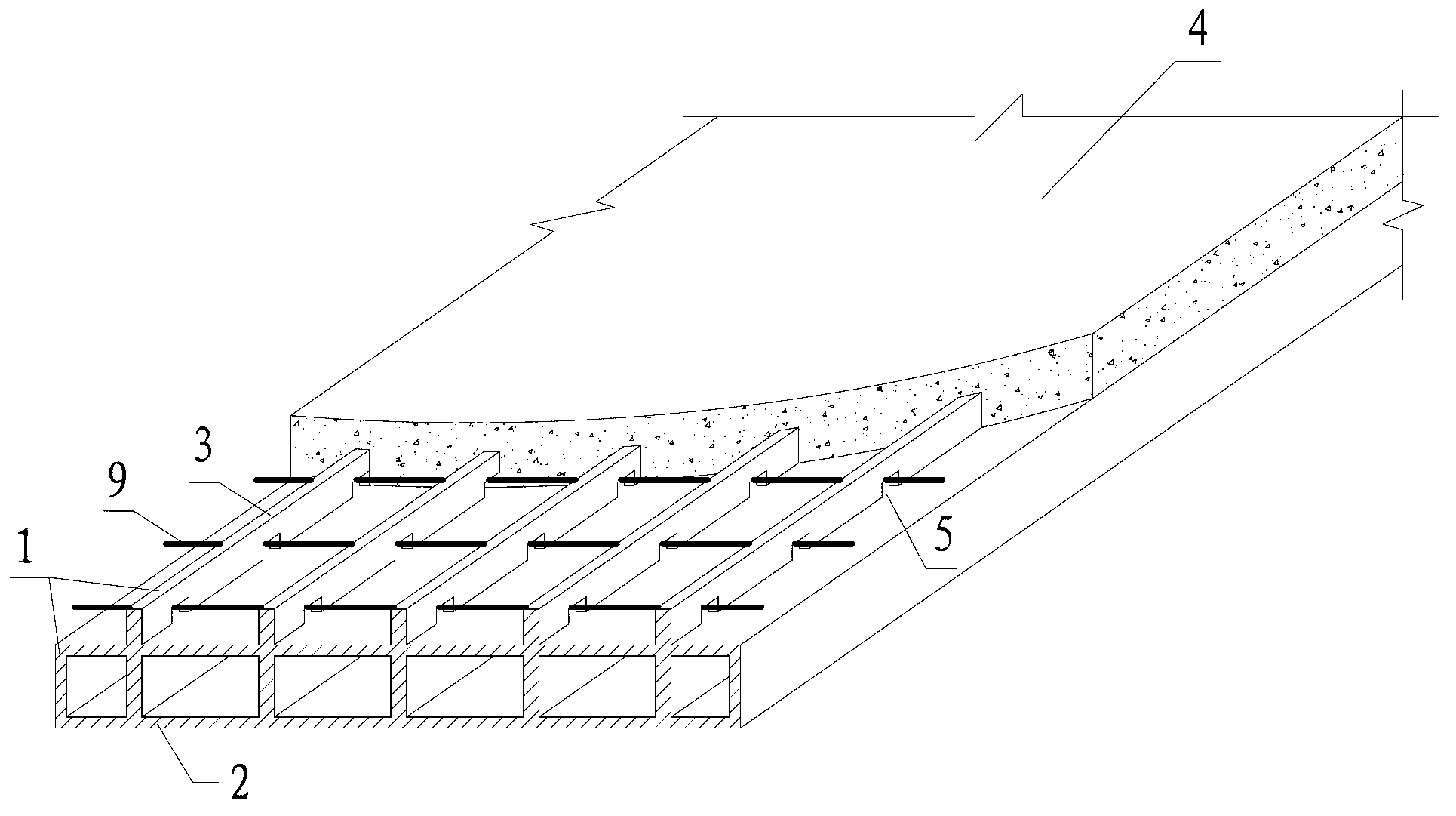

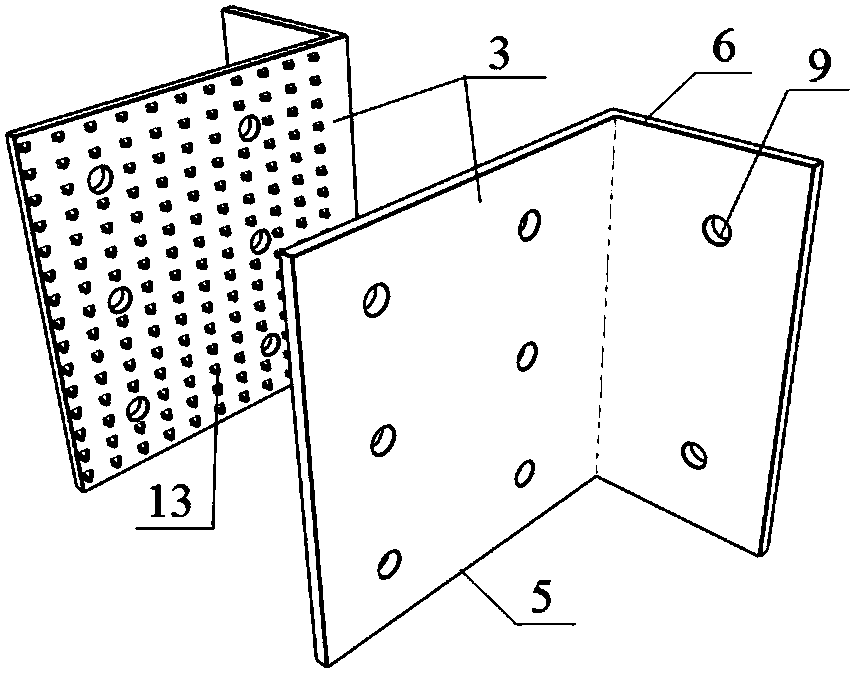

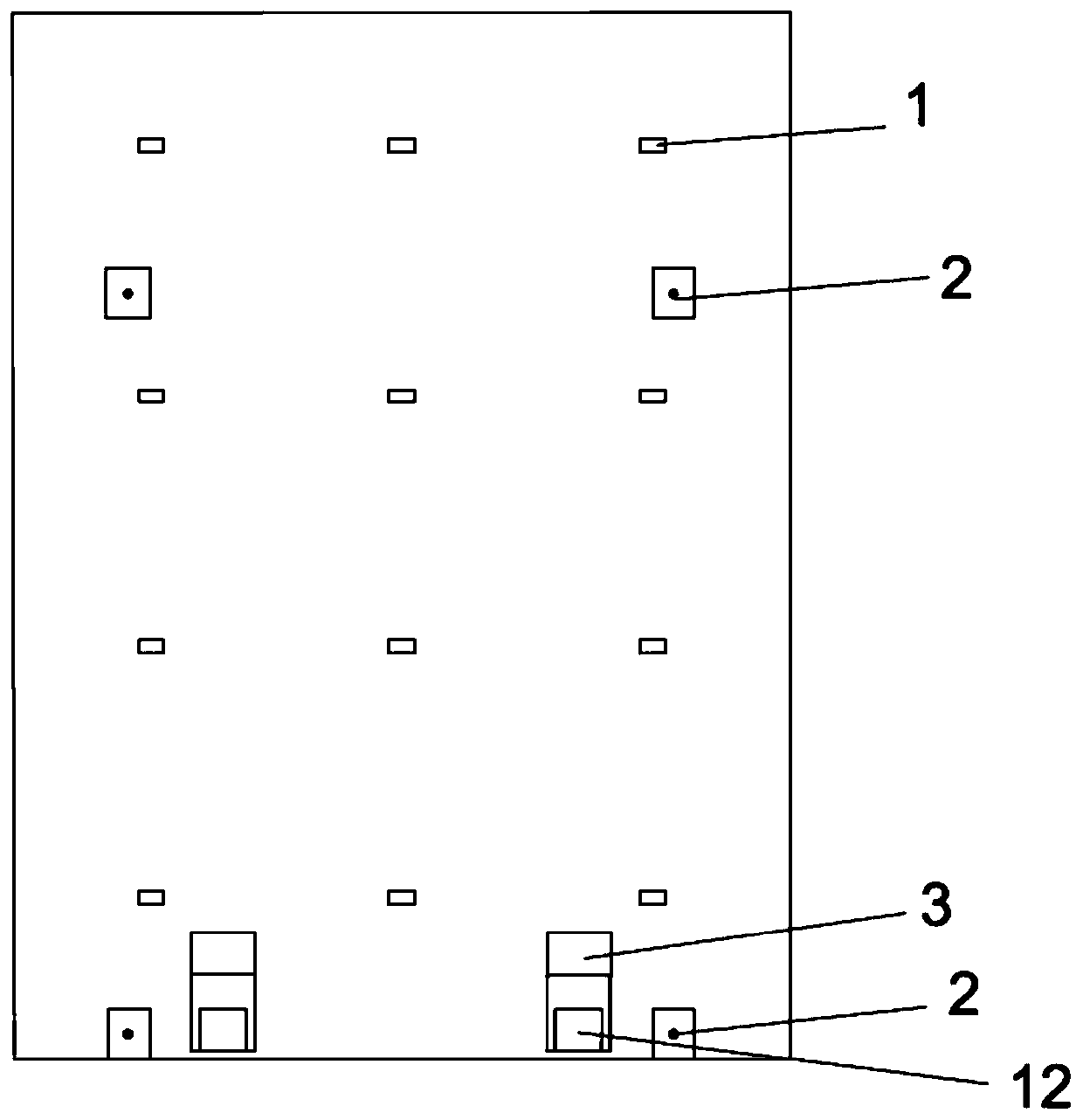

Ribbed FRP (fiber reinforced plastic) component and concrete composite bridge deck

InactiveCN103194970AIncrease contact areaIncrease mechanical bite forceBridge structural detailsFiberSurface layer

The invention discloses a ribbed FRP (fiber reinforced plastic) component and concrete composite bridge deck which comprises a ribbed FRP component and a later-poured concrete surface layer. The ribbed FRP component comprises two parts including an FRP baseplate on the lower portion and longitudinal FRP plate ribs on the FRP baseplate, at least one of the FRP baseplate and the longitudinal FRP plate ribs has a hollow section, and transverse through holes are arranged in the longitudinal FRP plate ribs. The longitudinal FRP plate ribs and the transverse through holes thereon increase contact area of the ribbed FRP component and concrete, improve anti-shearing capacity of a contact face and improve performance of a laminated face; the FRP baseplate or / and the longitudinal FRP plate ribs in hollow-section forms can lower material consumption, increase component stiffness and enable overall performance of the composited bridge deck to be substantially improved. The ribbed FRP component and concrete composite bridge deck is simple in structure, convenient to manufacture and construct, free of additional formworks and supports, and excellent in structural mechanics performance, and can effectively solve many problems of current composite bridge deck structures.

Owner:黄海林

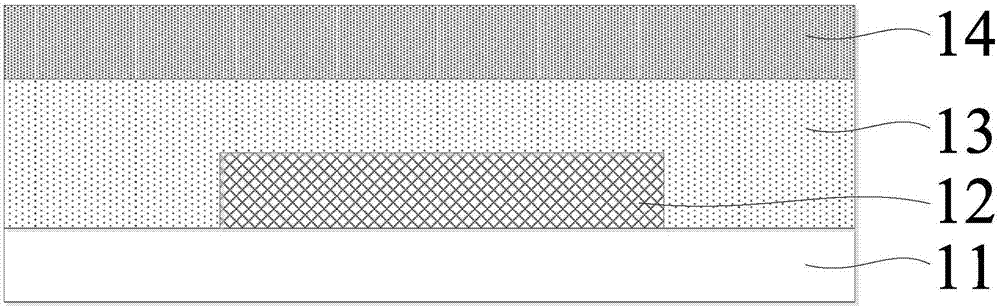

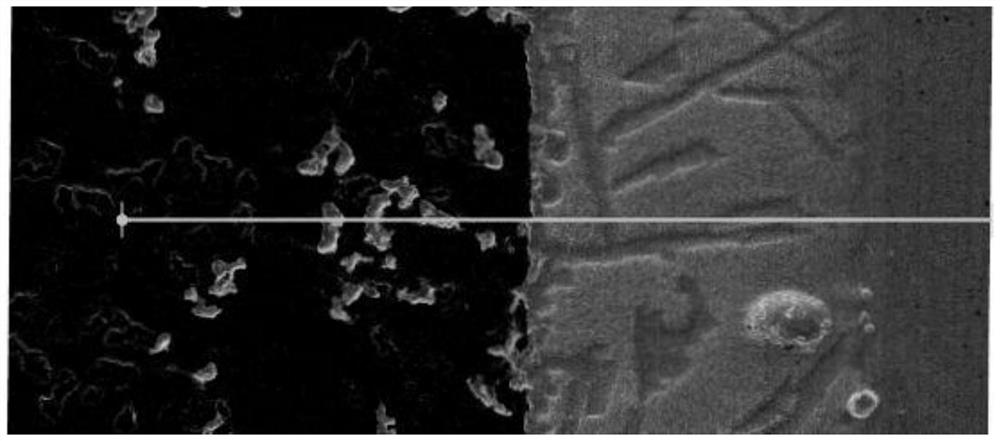

Display panel and display panel manufacturing method

ActiveCN106935633AImprove surface roughnessImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingSurface roughnessEngineering

The embodiment of the invention discloses a display panel and a display panel manufacturing method. The display panel comprises an array substrate, a plurality of organic light-emitting elements arranged on one side of an array substrate, and a thin-film packaging layer located on one side of the organic light-emitting elements that is far away from the array substrate and used for covering the plurality of organic light-emitting elements. The thin-film packaging layer comprises at least one barrier layer. The surface roughness of the barrier layer is 0 nm-5 nm. One side of the at least one barrier layer, away from the array substrate, is provided with a roughness layer. The roughness layer is in contact with the barrier layer. The surface roughness of the roughness layer is larger than 5 nm. According to the technical scheme of the invention, on the basis that the reliable encapsulation of the display panel is effectively guaranteed, a film layer above the barrier layer can be firmly combined with the barrier layer. The peeling problem of the film layer is solved. The performance of the display panel is improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

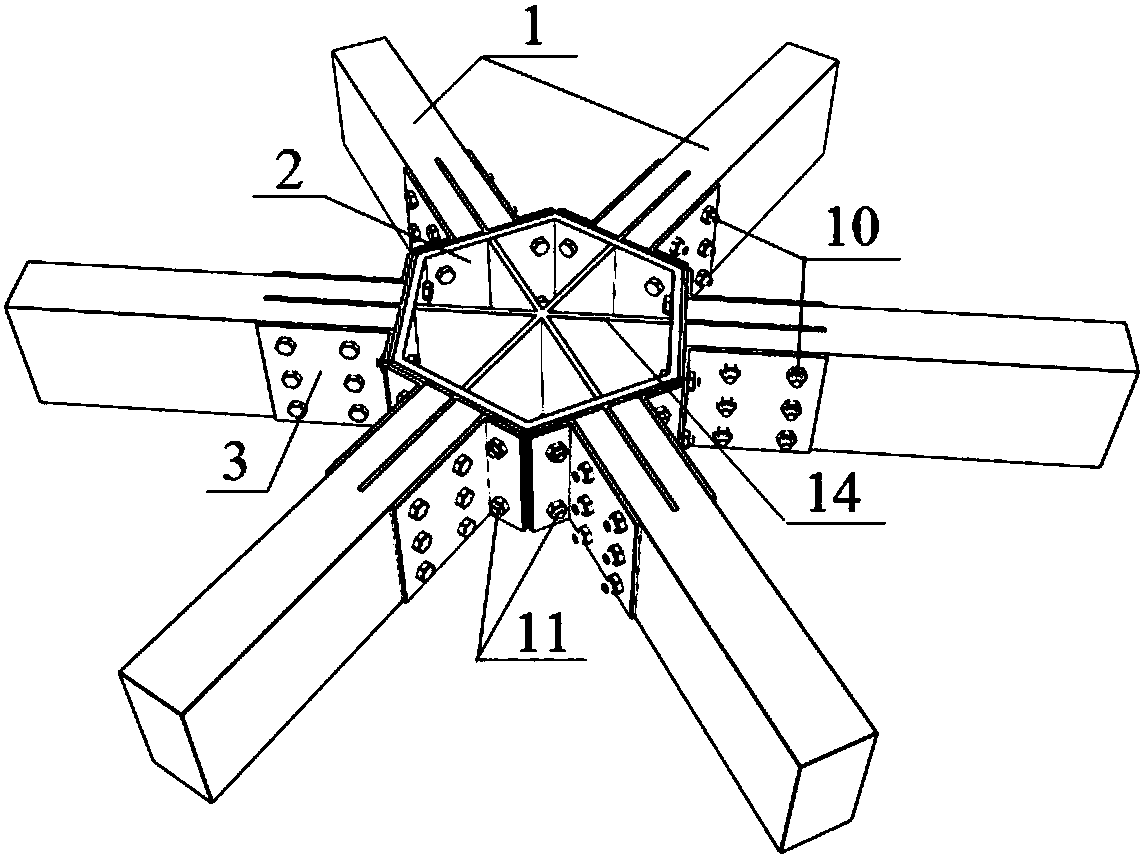

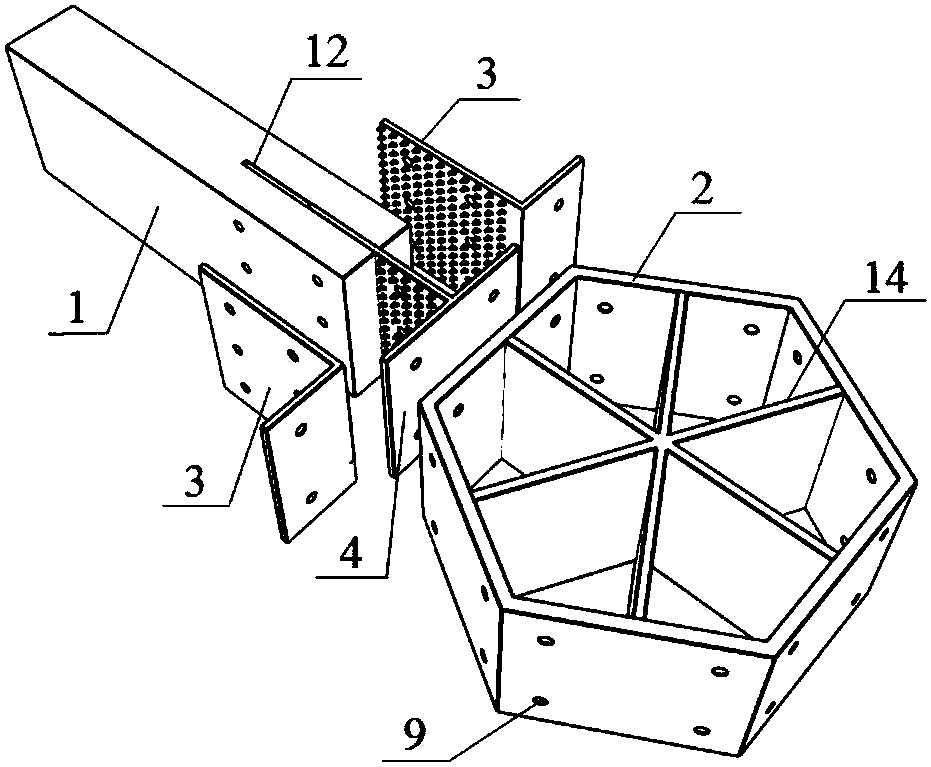

Inner ring ribbing large-span wood structure assembly type joint

InactiveCN107605043AHigh degree of assemblyImprove construction efficiencyBuilding constructionsSteel platesOcclusal forces

The invention belongs to the field of wood structure joint design, and relates to an inner ring ribbing large-span wood structure assembly type joint. Steel clamping plates are arranged on the left side and the right side of the end of each wood component, steel filling plates are inserted into plate slots at the ends of the wood components, the wood components, the steel clamping plates and the steel filling plates are connected through common bolts, and steel teeth are arranged on the faces where the steel clamping plates and the steel filling plates are in contact with the wood components;and under the effect of bolt pretightening force, the steel teeth are embedded into the wood components, the steel clamping plates and the steel filling plates are connected with a core steel cylinderthrough high-strength bolts, and steel plate ribs are arranged in the core steel cylinder. Bolt holes are formed in the corresponding positions of the wood components, the steel clamping plates, thesteel filling plates and the core steel cylinder in a factory, the parts are assembled through the bolts on a construction site, and the assembly degree of the large-span wood structure is improved; and the steel teeth on the steel clamping plates and the steel filling plates enhance mechanical occlusal force among the steel clamping plates, the steel filling plates and the wood components, slipping between the wood components and the steel plates is reduced, the initial rigidity of the joint is improved, so that the joint is close to a rigid joint, and the joint can be applied to a hectometer-grade large-span wood structure.

Owner:QINGDAO TENGYUAN DESIGN ACCOUNTANTS CO LTD

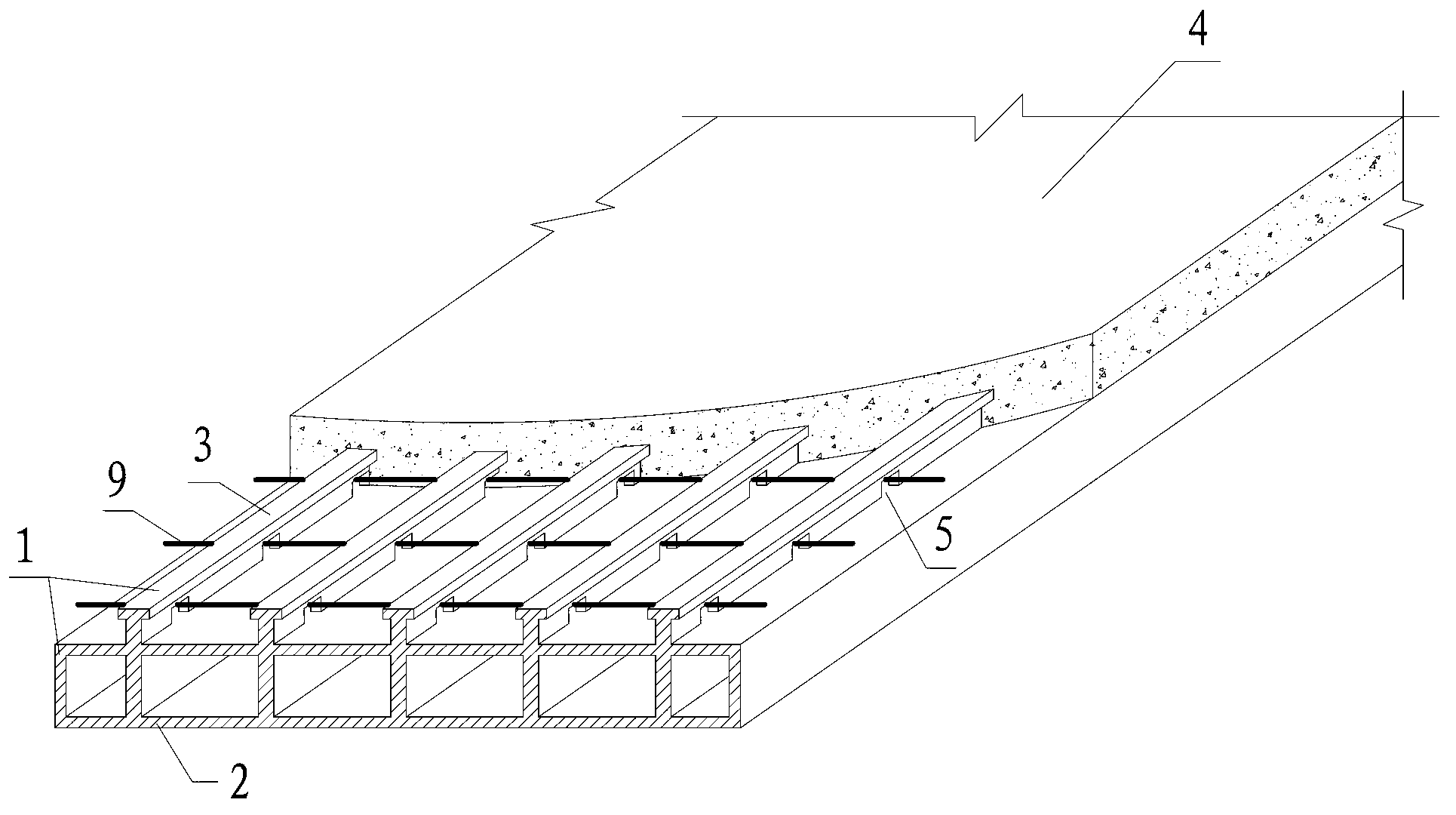

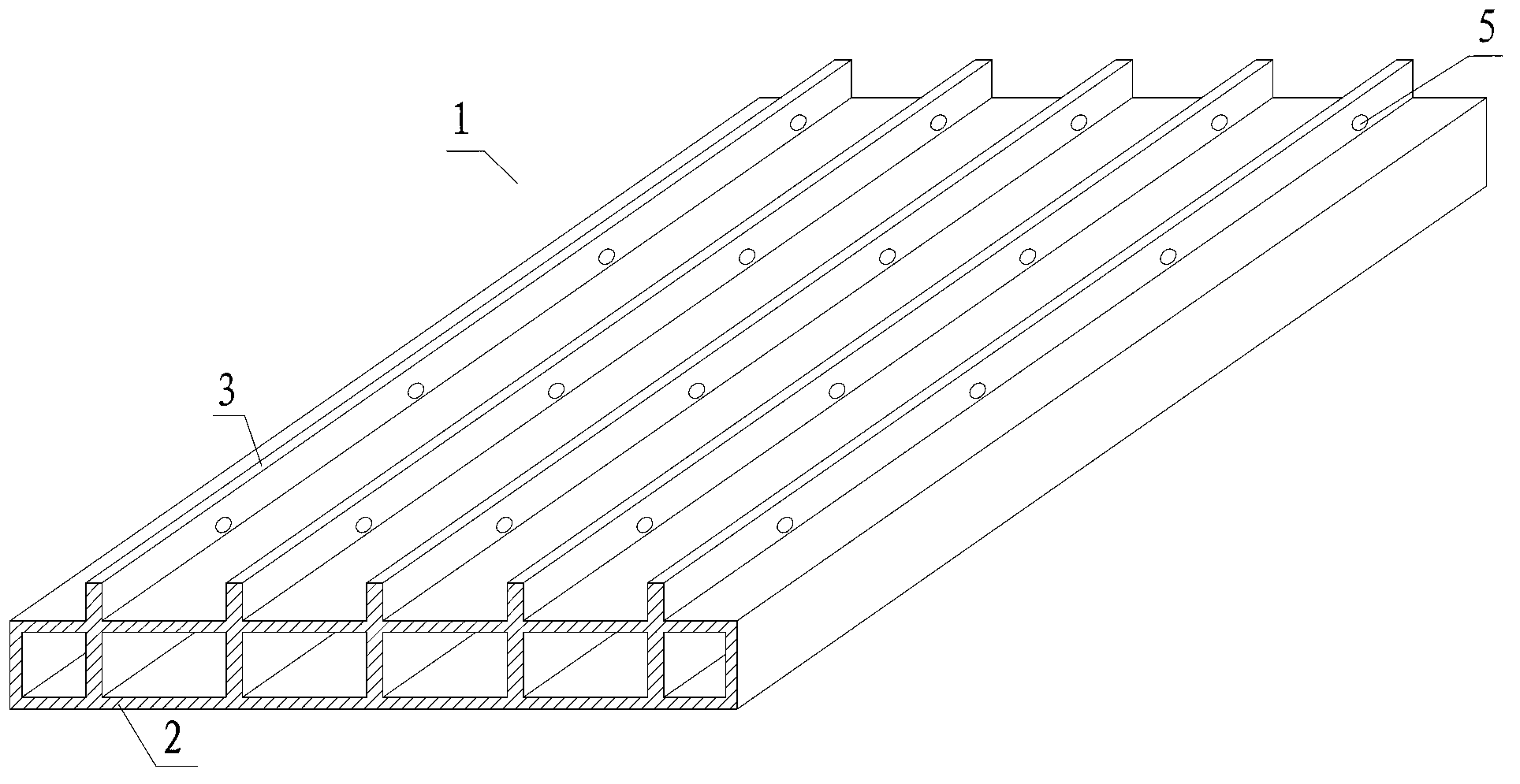

Prefabricated pre-stressed beam member, fabricated combined frame structure and installation method of fabricated combined frame structure

PendingCN108457422AReduce shipping weightSave on rental costsLoad-supporting elementsFloor slabSurface layer

The invention discloses a prefabricated pre-stressed beam member, a fabricated combined frame structure and an installation method of the fabricated combined frame structure. The fabricated combined frame structure comprises prefabricated column members with hollow steel pipes inside, prefabricated pre-stressed beam members, cast-in-place concrete inside the prefabricated column hollow steel pipes, a laminated floor slab prefabricated base plate and laminated surface layer concrete. The middle sections of the hollow steel pipes of the prefabricated column members are covered with concrete, anda beam-column joint zone provided with short H-shaped steel beams is arranged at both ends of each middle section. The prefabricated pre-stressed beam member comprises a concrete laminated pre-stressed beam and interposed H-shaped steel beams at both ends of the pre-stressed beam. The short H-shaped steel beams in the beam-column joint zone and the interposed H-shaped steel beams of the prefabricated pre-stressed beam member are combined by bolt welding or connected by bolting. Joints of the hollow steel pipes of the upper and lower sections of the prefabricated column members are connected by welding. The fabricated combined frame structure integrates the advantages of a steel structure and a prefabricated concrete structure, and has high installation efficiency and good safety, and manpower and material resources are greatly saved.

Owner:SOUTHEAST UNIV +2

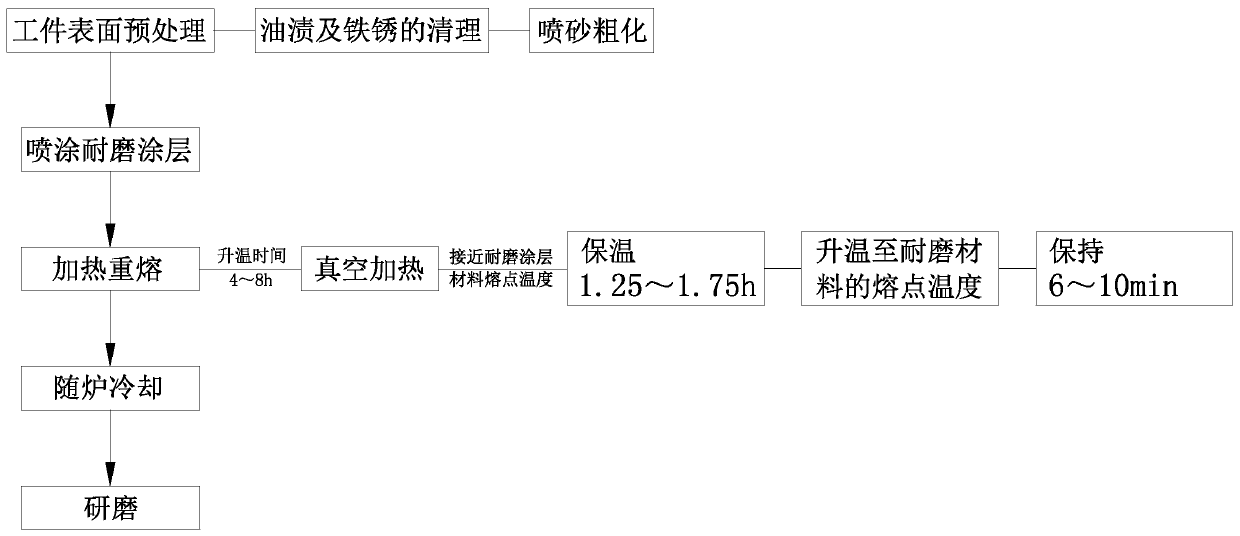

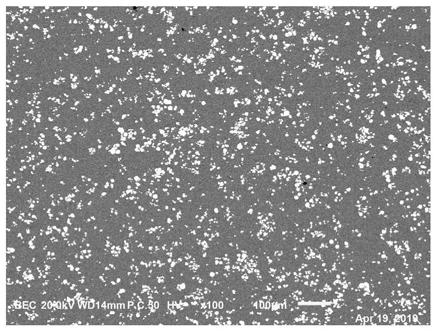

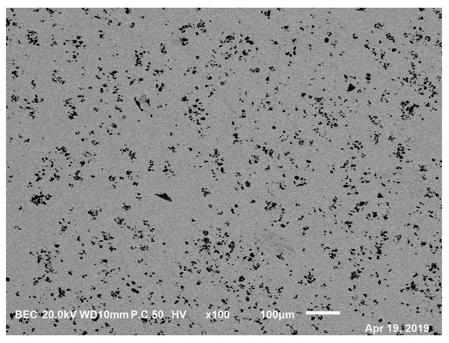

Manufacturing process of metal seated ball valve nickel-based tungsten carbide wear-proof coating

InactiveCN111455306AAvoid crackingImprove compactnessMolten spray coatingSurface cleaningWear resistance

The invention discloses a manufacturing process of a metal seated ball valve nickel-based tungsten carbide wear-proof coating. The manufacturing process includes the following steps that S1, the surfaces of workpieces are pre-treated, wherein a machined ball body and a machined valve seat are subjected to surface cleaning and coarsening; S2, a wear-proof coating is sprayed, wherein a wear-proof coating powder material is evenly sprayed to the surfaces of the ball body and the valve seat through a hypersonic flame spraying process; S3, heating and remelting are carried out, wherein the sprayedball body and the sprayed valve seat are put in a vacuum furnace in batches for heating and remelting, and the ball body and the valve seat are metallurgically bound with the wear-proof material; S4,cooling is carried out, wherein after being remelted, the ball body and the valve seat are slowly cooled along with the vacuum furnace; and S5, grinding is carried out, wherein the cooled ball body and the cooled valve seat are precisely ground in sequence through a grinding device. The strength of the wear-proof coating on the sealing face of a ball valve can be improved, then the wear-proof performance of the sealing face of the ball valve is enhanced, and the service life of the ball valve is prolonged.

Owner:CHAODA VALVE GRP

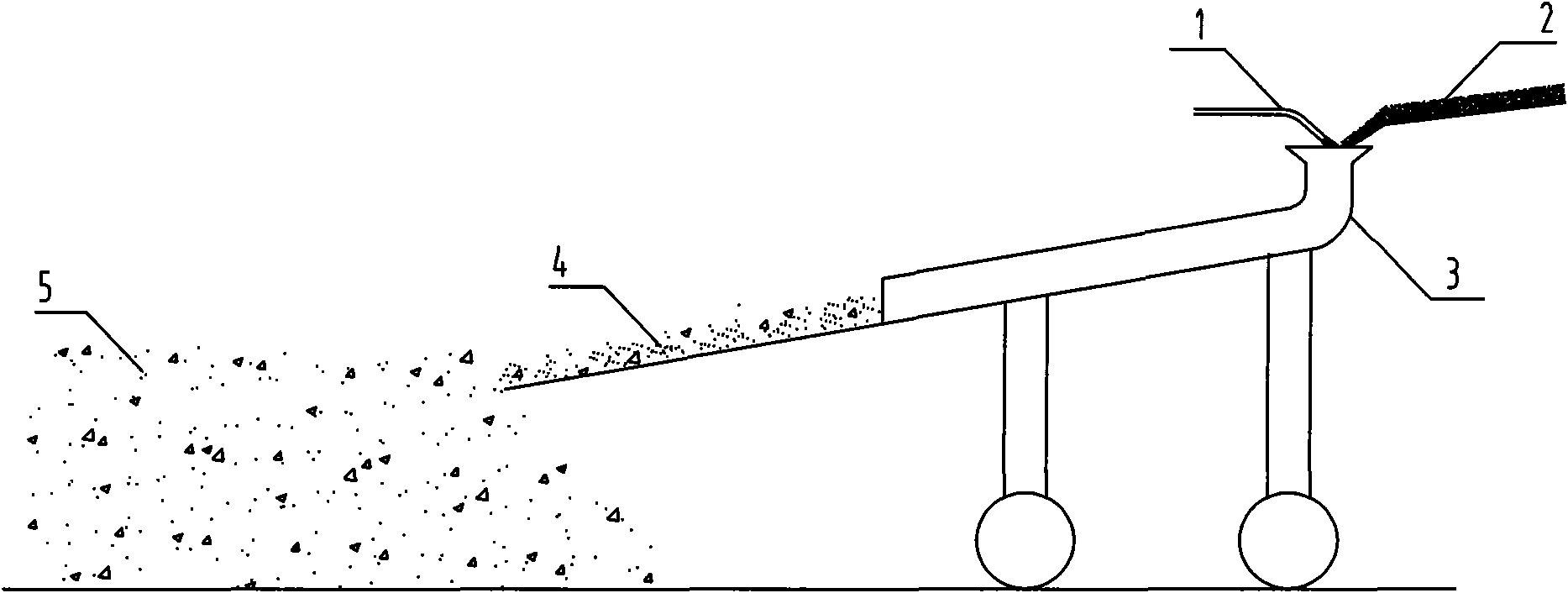

Construction method of gunite concrete

InactiveCN101624826AIncrease mechanical bite forceGuaranteed uniformityFoundation engineeringBuilding material handlingMechanical indexIncomplete mixing

The invention discloses a construction method of gunite concrete, comprising the following steps: adopting normal pure cement paste consisting of water and cement or mixed cement paste consisting of water and cement mixed with fly ash, which is provided by a high-speed stirring slurrying device; respectively injecting dynamic gravel mixed material of a free falling body or respectively injecting dynamic sand and aggregate of the free falling body via a slurry transmission device; injecting cement paste and dynamic gravel mixed material or dynamic sand and aggregate to cause that the mixture enters a mixed conveyor entrance in an imperfect-mixing state; after stirred into even mixed material, directly sending the mixed material into a cabin via the gravity of the mixed material or sending the mixed material into a cabin via a mixed material sending device for vibrating and pouring into concrete. The invention combines concrete mixing, transporting and pouring technology into a whole, directly pours in site to continuously perform concrete construction, which simplifies concrete construction technology; the invention has few in-site construction devices, convenient operation, quick pouring, low cost and short construction period, effectively strengthens various mechanical indexes of concrete and obviously improves construction efficiency.

Owner:沈阳乾玉水利有限公司

Resin-based artificial stone decoration plate

InactiveCN108395148AGood for winding and anchoringIncrease mechanical bite forceFiberFilling materials

The invention discloses a resin-based artificial stone decoration plate, and belongs to the technical field of a decoration material. The resin-based artificial stone decoration plate provided by theinvention is prepared from base body resin, modified fiber filling materials, modified particle filling materials, organic filling materials, polymine, crosslinking agents, curing agents, acceleratorsand pigments. During the preparation, firstly, the modified particle filling materials and the pigments are stirred and mixed to obtain a first mixture; then, the organic filling materials, the polymine and the crosslinking agents are heated, stirred and mixed; then, the base body resin, the curing agents, the accelerators and the modified fiber filling materials are added; stirring, mixing and discharging are performed to obtain a second mixture; then, the first mixture and the second mixture are mixed and are injected into a mold; after the hot pressing forming, demolding and trimming are performed, the resin-based artificial stone decoration plate is obtained. The obtained resin-based artificial stone decoration plate has excellent mechanical properties.

Owner:朱东洋

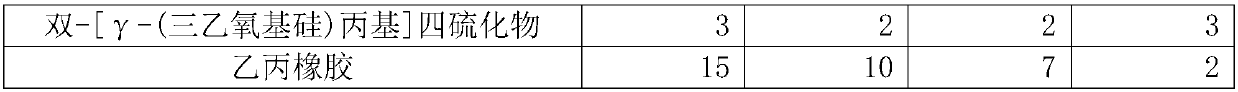

Softwood and rubber composite floor

The invention discloses a softwood and rubber composite floor and belongs to the technical field of decorative materials. The softwood and rubber composite floor consists of an elastomer binder, a glass body binder, aggregate fiber, a compound filler and other auxiliaries, wherein the elastomer binder is prepared by blending natural rubber, nitrile rubber and ethylene propylene diene monomer, andthe glass body binder is prepared from polymethyl methacrylate, polyurethane and phenolic resin. In addition, the compound filler is prepared from modified granulated corks, an inorganic mineral filler and nano expanded graphite, the glass body binder, the aggregate fiber, the compound filler and other auxiliaries are added after the elastomer binder is plastified, and after mixing, tableting, vulcanization forming and cutting are performed to obtain the softwood and rubber composite floor. The tensile strength of the softwood and rubber composite floor is effectively improved, and the softwood and rubber composite floor has good surface soiling resistance.

Owner:JIASHAN HUIJIALE DECORATION MATERIALS CO LTD

Epoxy resin conductive adhesive for electronic packaging

InactiveCN107686713AIncrease chance of contactImprove conductivityEpoxy resin adhesivesElectrically-conducting adhesivesEpoxyAdhesive

The invention discloses epoxy resin conductive adhesive for electronic packaging, and belongs to the technical field of adhesive. The epoxy resin conductive adhesive for electronic packaging is prepared from the following steps: stirring and mixing graphene oxide and water in an amount which is 10 to 20 times of the weight of the graphene oxide, cryogenic grinding, dissolving, filtering and dryingto obtain pretreated graphene oxide; and performing heating, stirring and refluxing reaction on 5 to 6 parts of graphene oxide, 8 to 10 parts of polyamine curing agent and 15 to 20 parts of diluent,adding 50 to 60 parts of epoxy resin, 5 to 6 parts of modified nano-copper powder, 5 to 6 parts of modified silver nanowire and 1 to 2 parts of coupling agent, stirring and mixing to obtain the epoxyresin conductive adhesive for electronic packaging. The epoxy resin conductive adhesive for electronic packaging, which is provided by the technical scheme of the invention, has excellent electrical conductivity and shearing strength.

Owner:常州市沃兰特电子有限公司

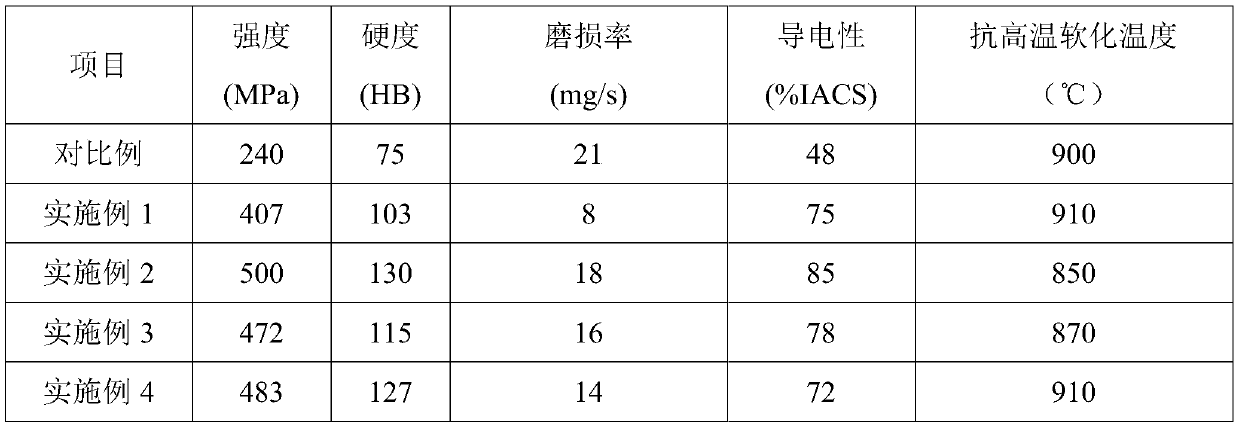

High-temperature high-strength high-conductivity high-wear-resistant copper-based composite material and preparation method thereof

The invention relates to a high-temperature high-strength high-conductivity high-wear-resistant copper-based composite material and a preparation method thereof. The preparation method of the high-temperature high-strength high-conductivity high-wear-resistant copper-based composite material comprises the following steps of adopting a copper-based electrode as a consumable electrode, adopting a vacuum consumable arc melting method for melting and ingot-casting, and obtaining the high-temperature high-strength high-conductivity high-wear-resistant copper-based composite material. The copper-based electrode comprises a copper matrix and nanoscale ceramic particles and micro-scale reinforced particles dispersed in the copper matrix; the strength of the copper matrix is improved through the nanoscale ceramic particles; the additive amount of the nanoscale ceramic particles is 0.1 to 1.5 percents by weight of the copper matrix; the wear resistance of the copper matrix is improved through the micro-scale reinforced particles; and the additive amount of the micro-scale reinforced particles is 0.5 to 20 percents by weight of the composite material. According to the preparation method, theinterface bondability of the nanoscale ceramic particles and the copper matrix is effectively improved, the effect on improving the strength and the hardness of the matrix through the nanoscale ceramic particles is ensured, and the plasticity and the toughness of the composite material are improved.

Owner:HENAN UNIV OF SCI & TECH

Special paper tube adhesive for paper

InactiveCN107556946ARich porosityEasy to embedMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPolyvinyl alcoholAdhesive

The invention discloses a special paper tube adhesive for paper and belongs to the technical field of binding agents. The special paper tube adhesive for the paper is prepared by the following steps:stirring and mixing nano silicon dioxide, a silane coupling agent and an ethanol solution and reacting; then filtering, washing and drying to obtain modified nano silicon dioxide; then carrying out ultrasonic dispersion on the modified nano silicon dioxide and absolute ethyl alcohol to obtain a modified nano silicon dioxide dispersed solution; mixing glass fibers and the modified nano silicon dioxide dispersed solution and immersing; then drying the immersed glass fibers until the weight is constant; mixing the immersed glass fibers and a dopamine solution and immersing; then drying the immersed glass fibers until the weight is constant, so as to obtain modified glass fibers; stirring and mixing polyvinyl alcohol, a cyclodextrin derivative and water; then adding polyvinyl acetate emulsion,cellulase, the glass fibers and polystyrene emulsion, and stirring and mixing to obtain the special paper tube adhesive for the paper. The special paper tube adhesive for the paper, which is preparedby the technical scheme, has the characteristics of excellent bonding performance and has a wider application and development field.

Owner:常州市绿意管道有限公司

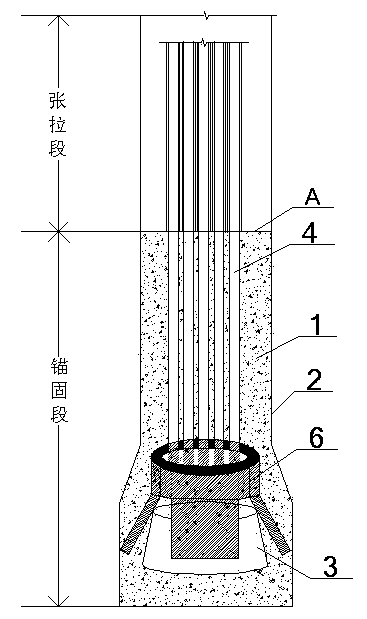

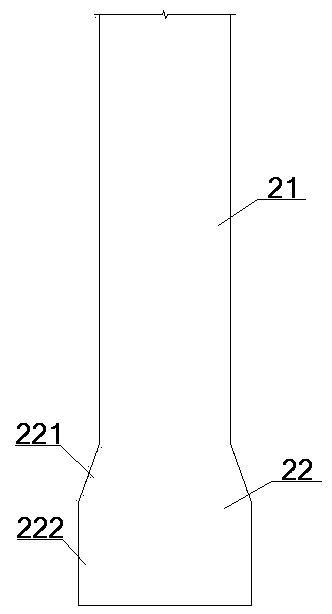

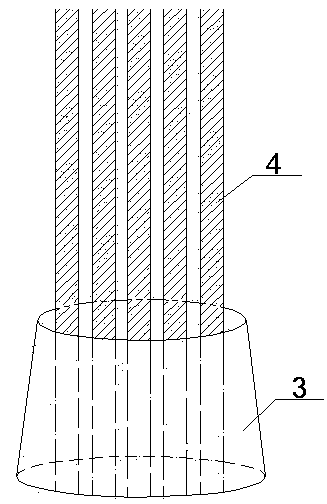

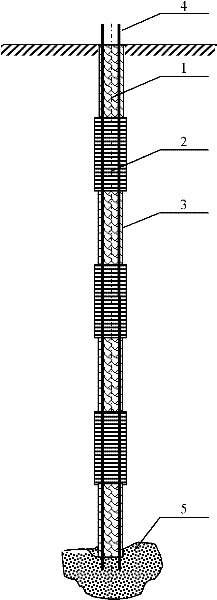

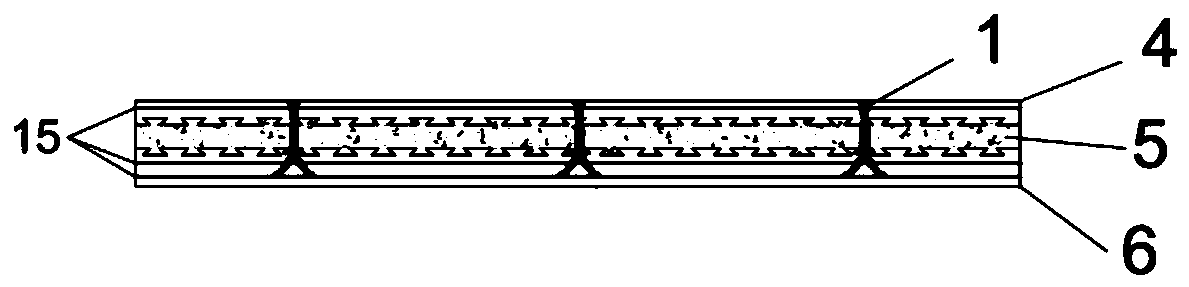

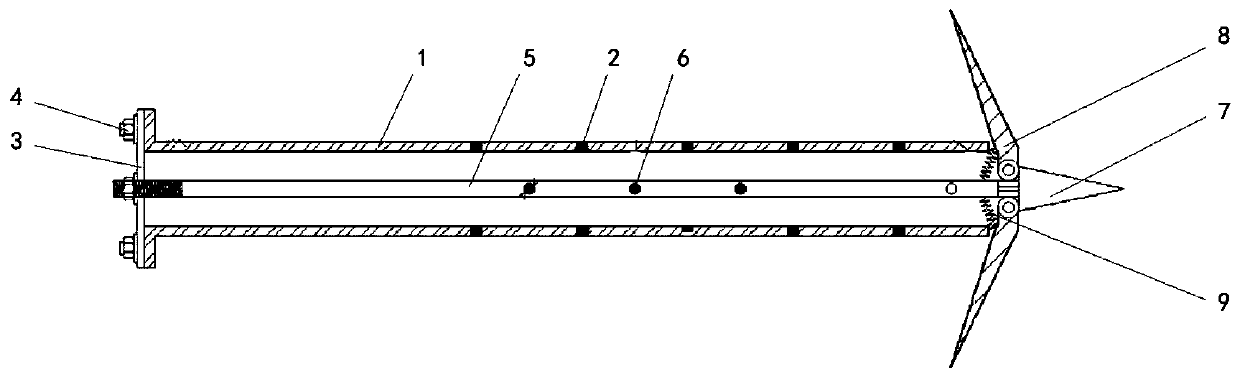

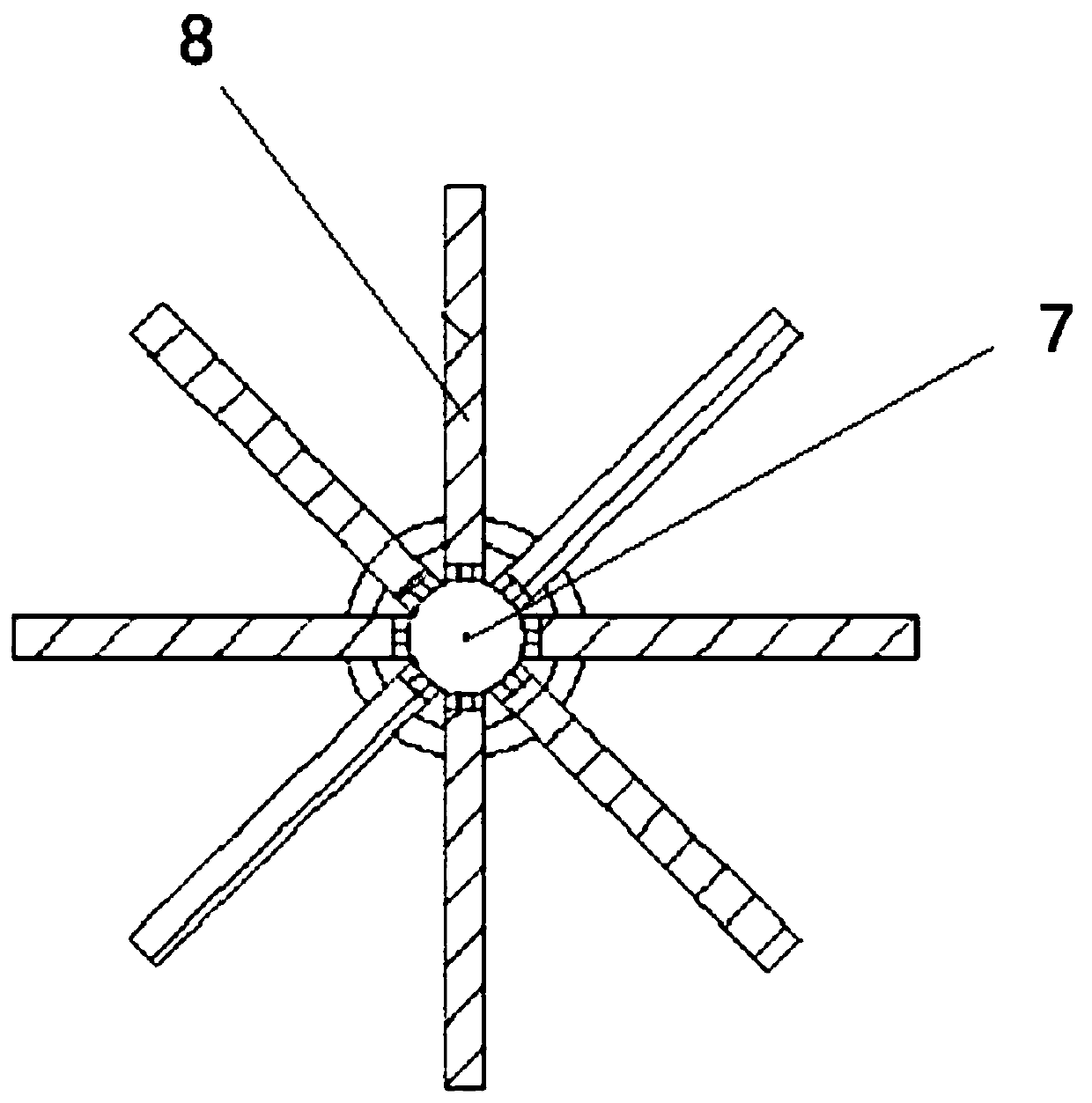

Rock reaming self-locking anchor cable comprising steel strands and manufacturing method of rock reaming self-locking anchor cable

ActiveCN104234052AAchieve mechanical fixationIncrease anchoring forceBulkheads/pilesChemical groutingCompound (substance)

The invention relates to a rock reaming self-locking anchor cable comprising steel strands. The rock reaming self-locking anchor cable comprising the steel strands comprises an outer hole, and an anchor cable, a locking head and a split circular pipe which are arranged in the outer hole, wherein the anchor cable is formed by a plurality of steel strands; the steel strands sequentially penetrate through inserting holes in the top part and the bottom part of the locking head, and then clamping pieces are installed for fixing; the top end of the lamelliform part in the split circular pipe is arranged higher than the top part of the locking head; the bottom end of the lamelliform part in the split circular pipe is arranged between the top part and the bottom part of the locking head, and is connected with a hole wall of a bottom reamed hole formed in the bottom part of the outer hole. During manufacturing, the outer hole is firstly formed; the steel strands and the locking head are then assembled and arranged in the outer hole; a pressurization sleeve pipe sleeves the steel strands so as to downwards press the split circular pipe until the front end of the scattered lamelliform part is connected with the hole wall of the bottom reamed hole and an effect of mechanical anchoring is realized; the pressurization sleeve pipe is taken away, and grouting and solidifying are carried out sequentially. The design not only has the chemical grouting anchoring force and mechanical anchoring force simultaneously, but also has strong aging resistance performance and fatigue resistance performance.

Owner:WUDA JUCHENG STRUCTURE CO LTD

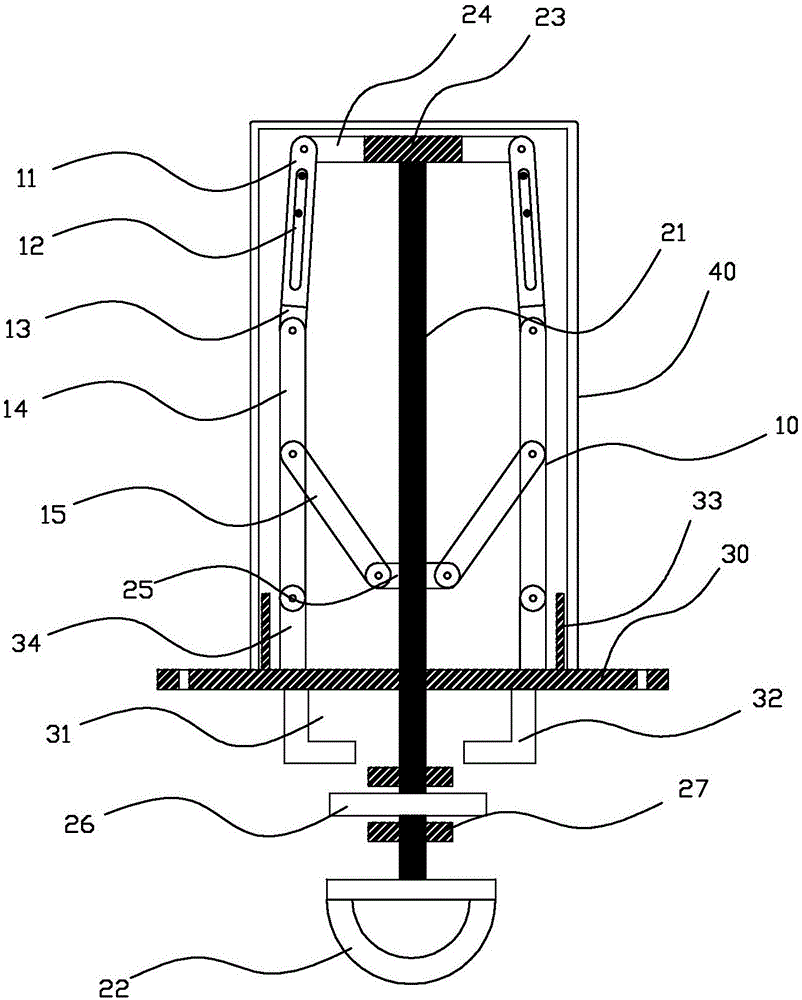

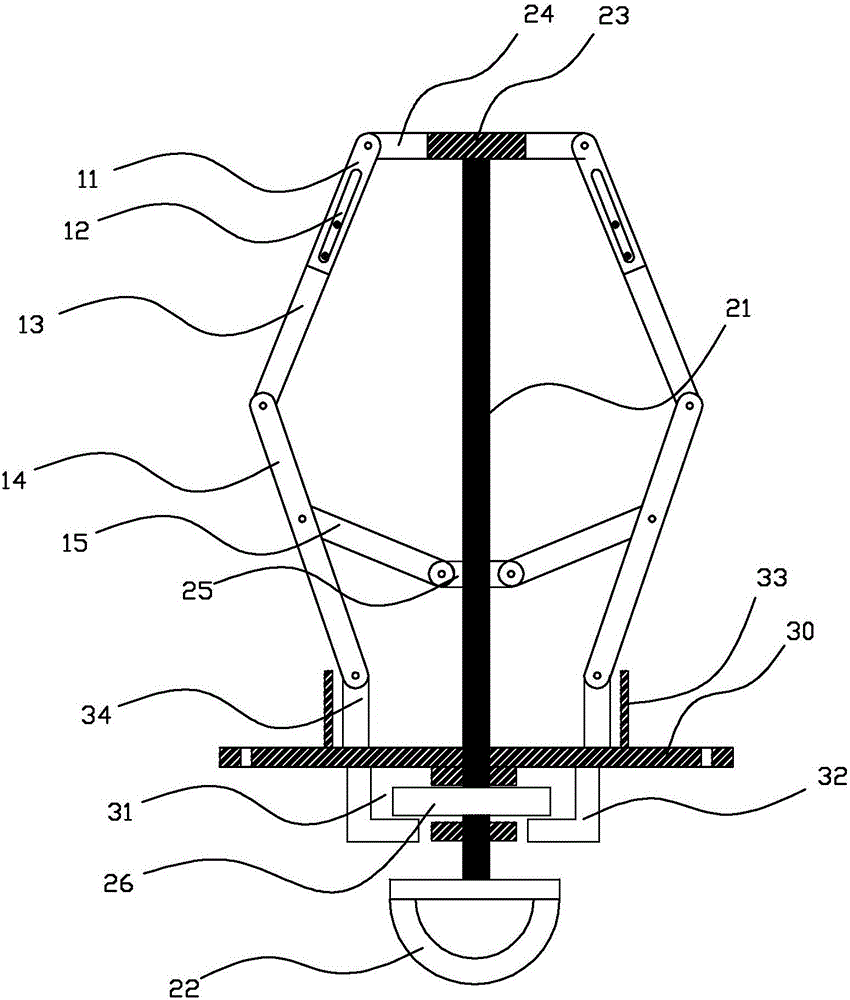

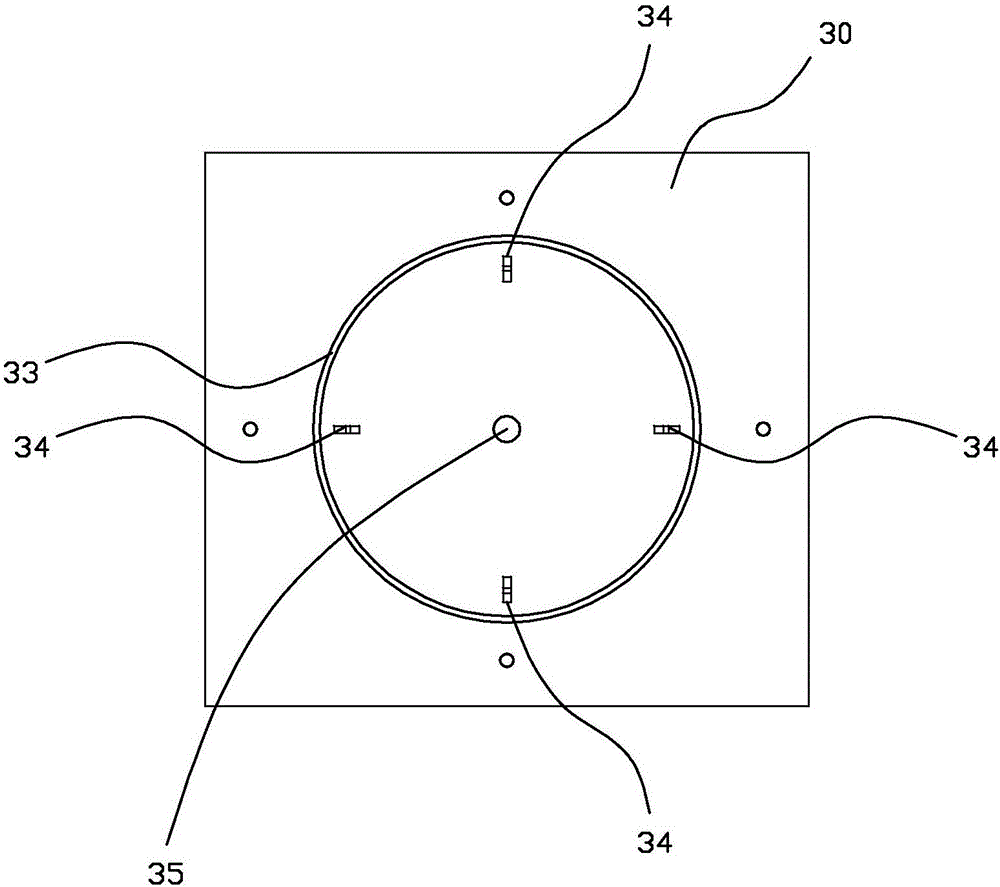

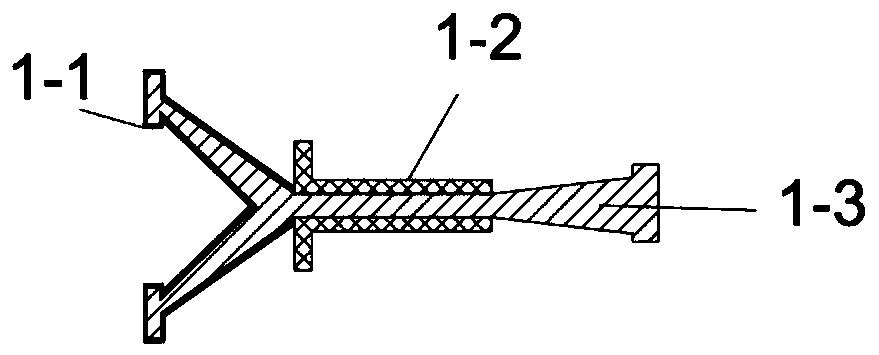

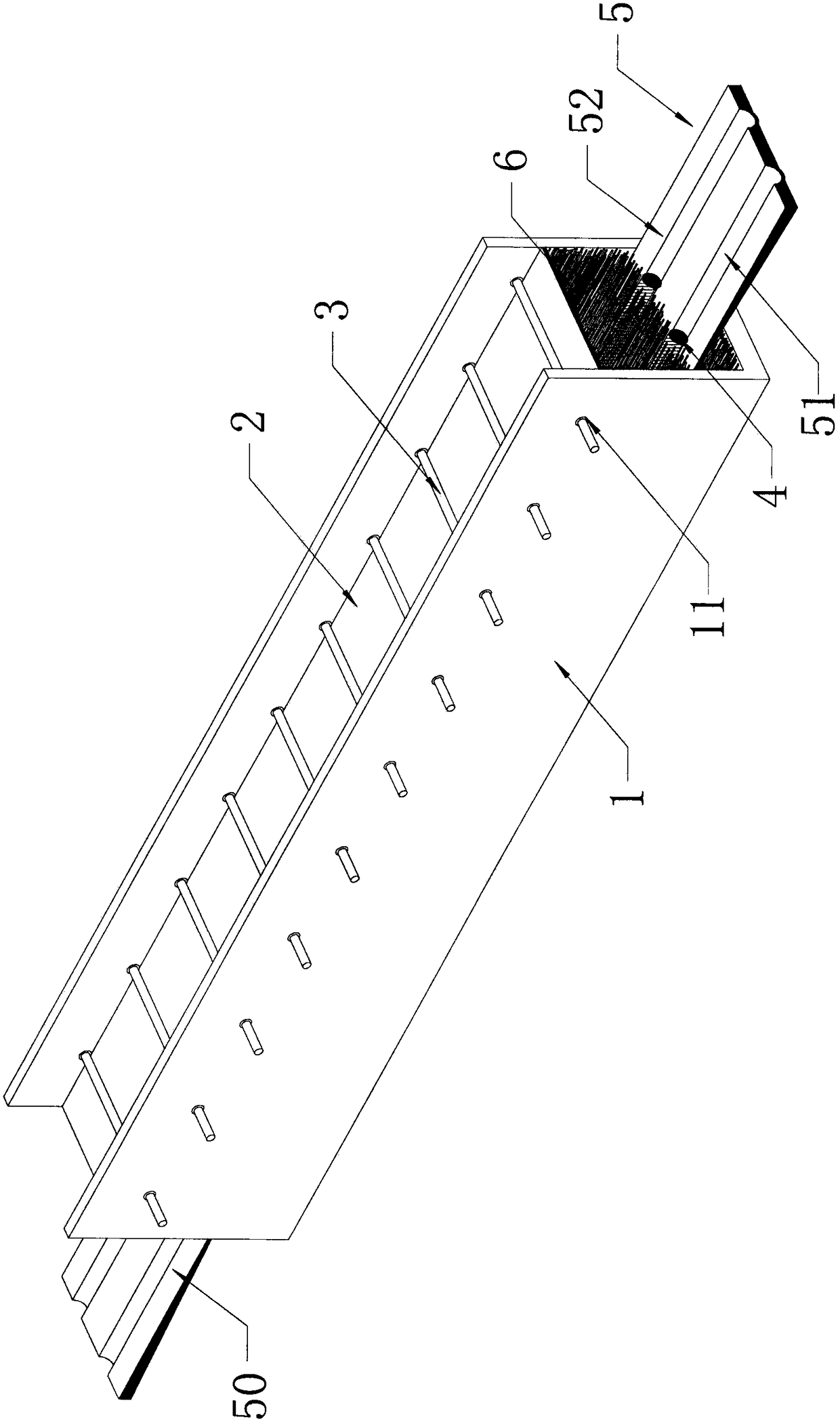

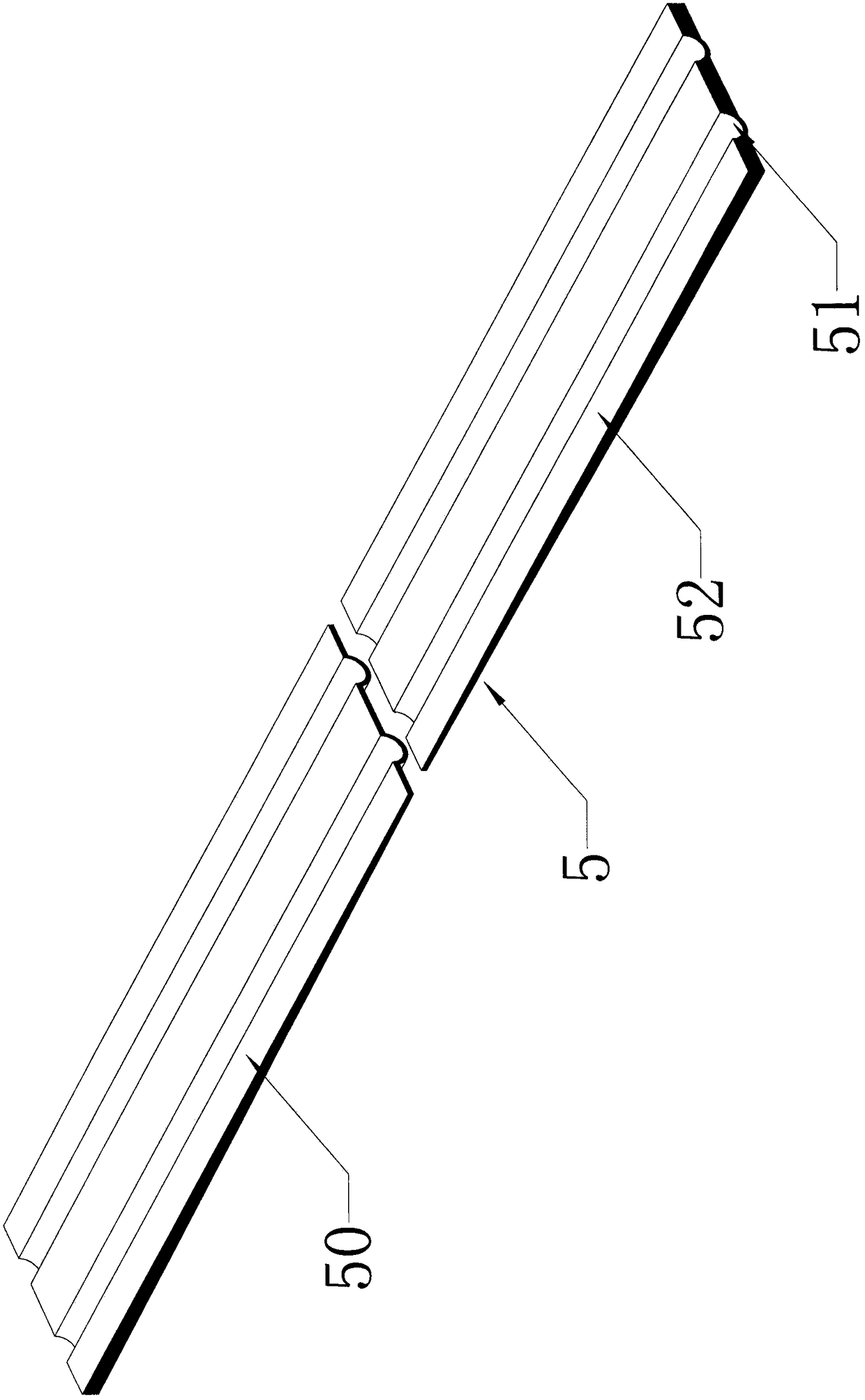

Device for forming diameter-expanded prefabricated hole

ActiveCN106545159AFirmly connectedIncrease mechanical bite forceForms/shuttering/falseworksSlurryMechanical engineering

The invention relates to a device for forming a diameter-expanded prefabricated hole. A diameter-expanded profile with the big middle and the small two ends can be formed through a expanding device, the device for forming the diameter-expanded prefabricated hole is mounted on the prefabricated hole position of a component before concrete is poured to the prefabricated component, after hardening, the expanding device contracts, a die is disassembled, the expanding device can be easily taken out from the cured prefabricated component, and the diameter-expanded prefabricated hole is manufactured; and the connecting performance between a later grouting material and the hole wall can be enhanced, the mechanical bite force between the grouting material and the prefabricated hole is enhanced, and the shear resistance and the anchor performance after the prefabricated slurry anchor component is connected are enhanced. According to the device for forming the diameter-expanded prefabricated hole, the slope of rhombus inclined edges obtained after the prefabricated hole is formed is controlled by adjusting the position and the length of a fixing arm or the length of a sliding groove, and the device has the beneficial effects of being convenient and fast to mount and high in control accuracy and is especially suitable for being used in mass production in a factory.

Owner:HUAQIAO UNIVERSITY

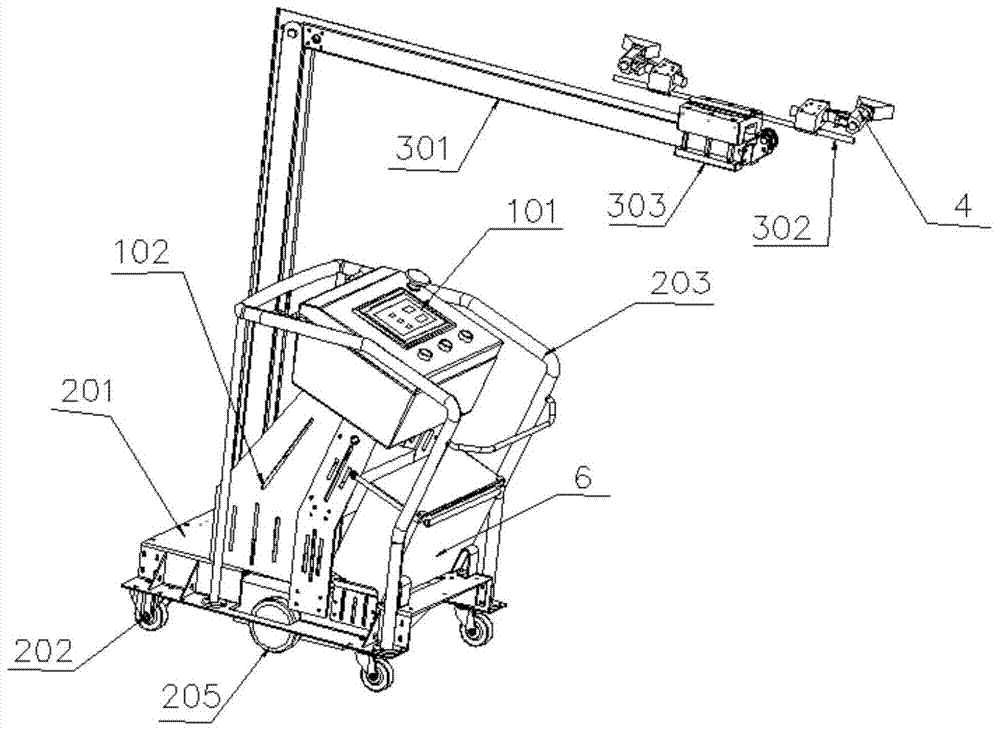

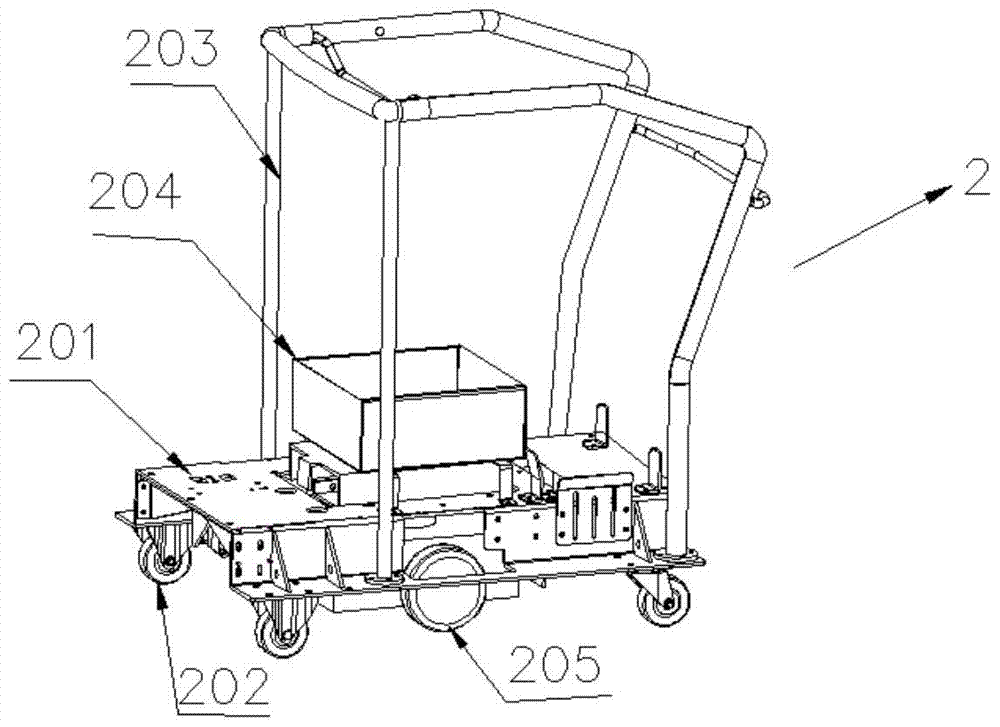

automatic spraying machine

InactiveCN105507565BSimple structureSmall footprintBuilding constructionsDistribution controlControl system

The invention relates to the field of spraying, in particular to an automatic spraying machine. The automatic spraying machine is characterized by comprising a control device, an automatic traveling trolley, a lifting device, spray guns, a feeding device and a power device, wherein the control device comprises a control box and a first distribution control cabinet, the automatic traveling trolley comprises a steering control system, a chassis, wheels and a protecting frame, the steering control system comprises a steering controller and a second distribution control cabinet, the lifting device comprises a first support, a second support, a slider, a tooth-shaped conveying belt and a driving motor, the lower end of the first support and the chassis are fixed, and the feeding device is connected with the spray guns through a guide pipe. The automatic spraying machine has the advantages of simple structure, high production flexibility, applicability to interior decoration and capabilities of reducing labor cost effectively and improving production efficiency and coating quality.

Owner:江苏恒嘉城市智能科技有限公司

Preparation method of epoxy resin-based electromagnetic shielding material

Owner:FOSHAN WANHE NEW ENERGY TECH CO LTD

Expansive concrete caisson pile and manufacturing method thereof, and concrete expanding agent

ActiveCN102162244BIncrease relative resistance to motionImprove bearing capacityBulkheads/pilesSlurryJoints types

The invention provides an expansive concrete caisson pile and a manufacturing method thereof, and a concrete expanding agent, and belongs to the technical field of engineering materials and construction of concrete pile foundation. The method comprises the following steps of: alternatively pouring common concrete and expansive concrete into a caisson pile hole sequentially so as to form bamboo joint type I-shaped pile; and pouring slurry at the pile end of the I-shaped pile or the expansive concrete pile so as to form a II-shaped pile or a III-shaped pile. The expanding agent is manufactured by pulverizing 40 to 80 percent of limestone and 20 to 60 percent of gypsum, calcining the powder in a rotary kiln at the high temperature of 1,300 to 1,500 DEG C, and pulverizing 20 to 80 weight percent of the calcined substance and 20 to 80 weight percent of calcium sulfoaluminate cement or alunite or calcium aluminate cement or a mixture of the calcium sulfoaluminate cement, the alunite and thecalcium aluminate cement until the specific surface area is 150 to 400 square meters per kilogram. By the method, the manufacturing cost of the expansive concrete caisson pile can be reduced obviously; and compared with the common expansive concrete caisson pile, the expansive concrete caisson pile has the advantage of obviously increasing the bearing capacity of a single caisson pile.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

High-performance assembly-type combined externally-hung wallboard

PendingCN110239157AExcellent deformability (uniaxial tensile strain reaches 2%-10%)Excellent crack control abilityCovering/liningsWallsThermal bridgeStructure function

The invention discloses a high-performance assembly-type combined externally-hung wallboard. A main body part of the high-performance assembly-type combined externally-hung wallboard can be divided into three layers, wherein a decorative layer is prepared of a colorful high-ductility cement-based composite material, a thermal insulation layer is prepared of foamed concrete, and a structure layer is prepared from lightweight ceramsite or baking-free light aggregate concrete, so that wallboard self weight is light. A wallboard and the main body part are connected through limit slippage nodes, so that influences of the main body part on the externally-hung wallboard in earthquake are reduced. The high-ductility cement-based composite material of the decorative protective layer is high in tensile strength, ductility, and is excellent in cracking controlling performance, and the color can be customized. Dovetail grooves are arranged at the interfaces of different layers, the layers of the wall body are connected through connecting components with forks and wings, so that wall body integral performance is improved. The connecting components are coated with FRP, so that wallboard heat bridge effect is reduced effectively. The high-performance assembly-type combined externally-hung wallboard possesses thermal insulation performance, energy saving performance, is high in weight, is high in strength, and is excellent in durability; wallboard decoration-thermal insulation-structure function combination is achieved; and the application prospect is promising.

Owner:南京彼卡斯建筑科技有限公司 +1

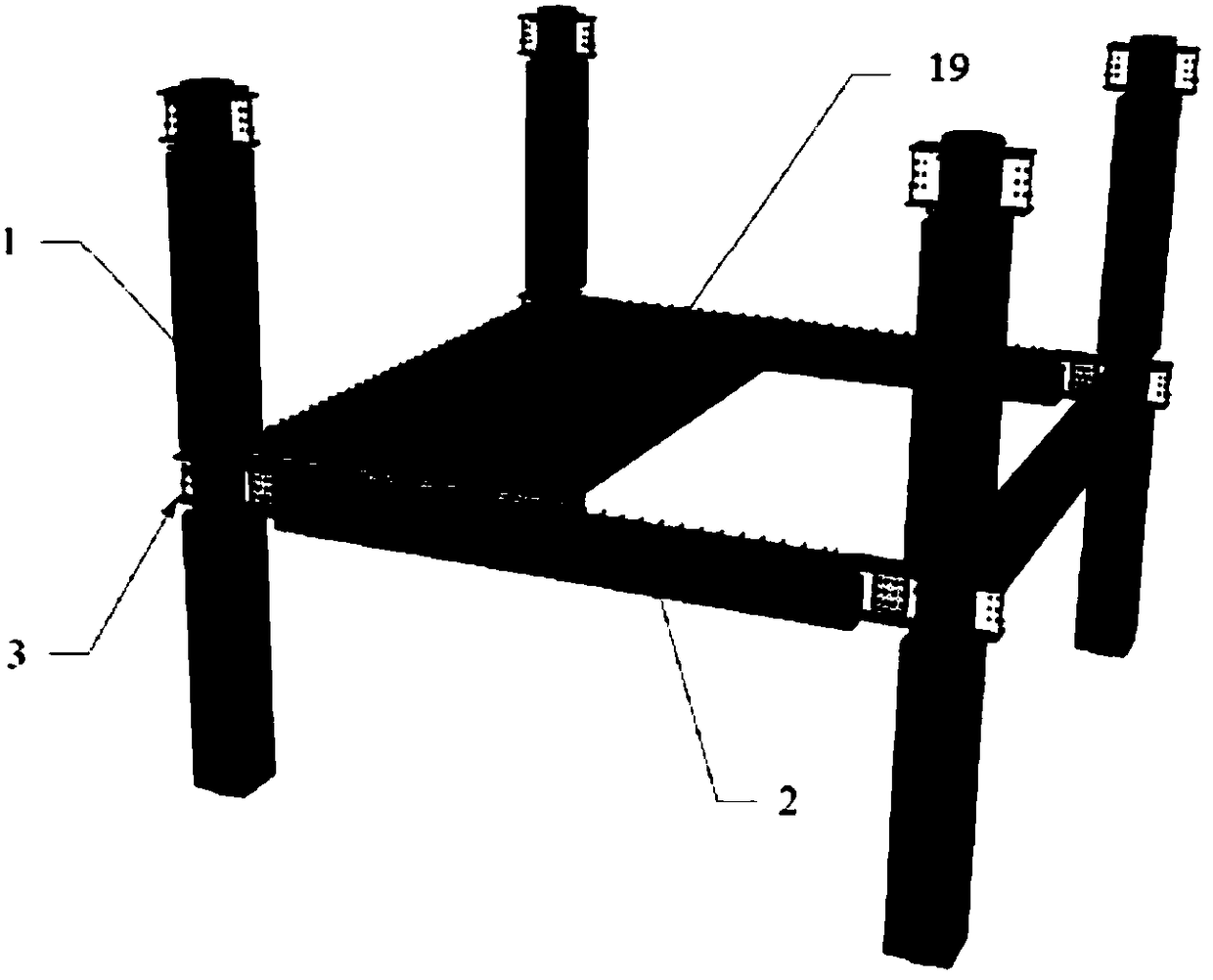

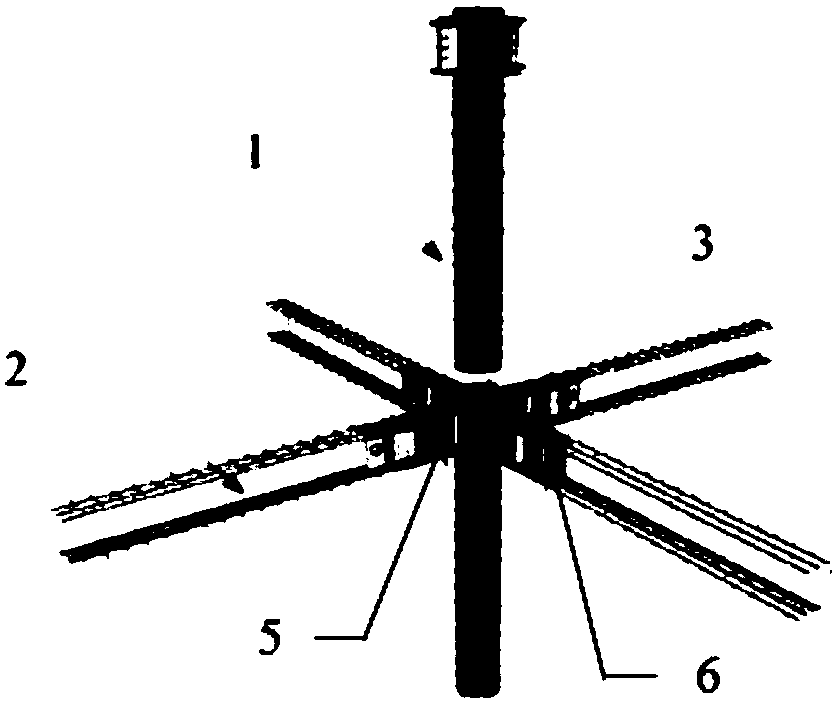

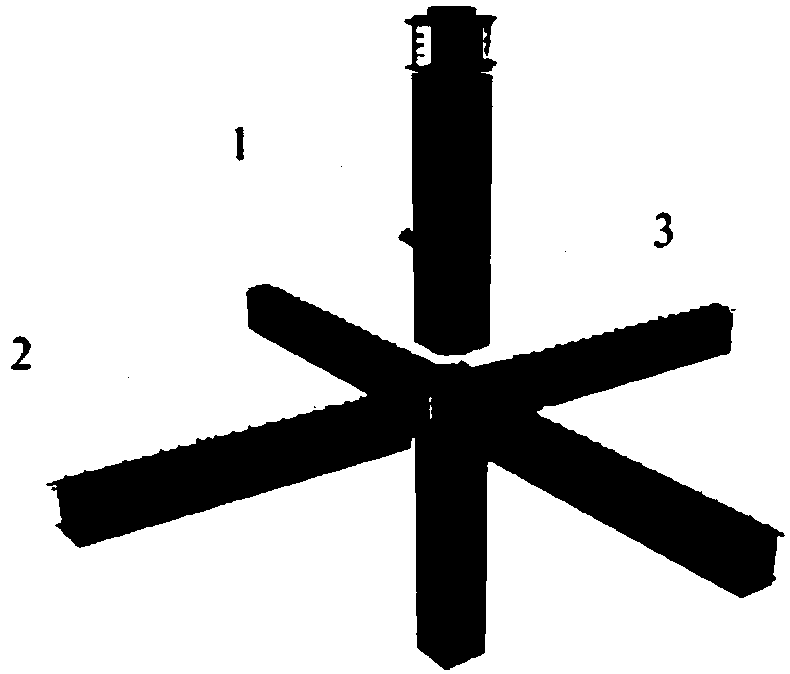

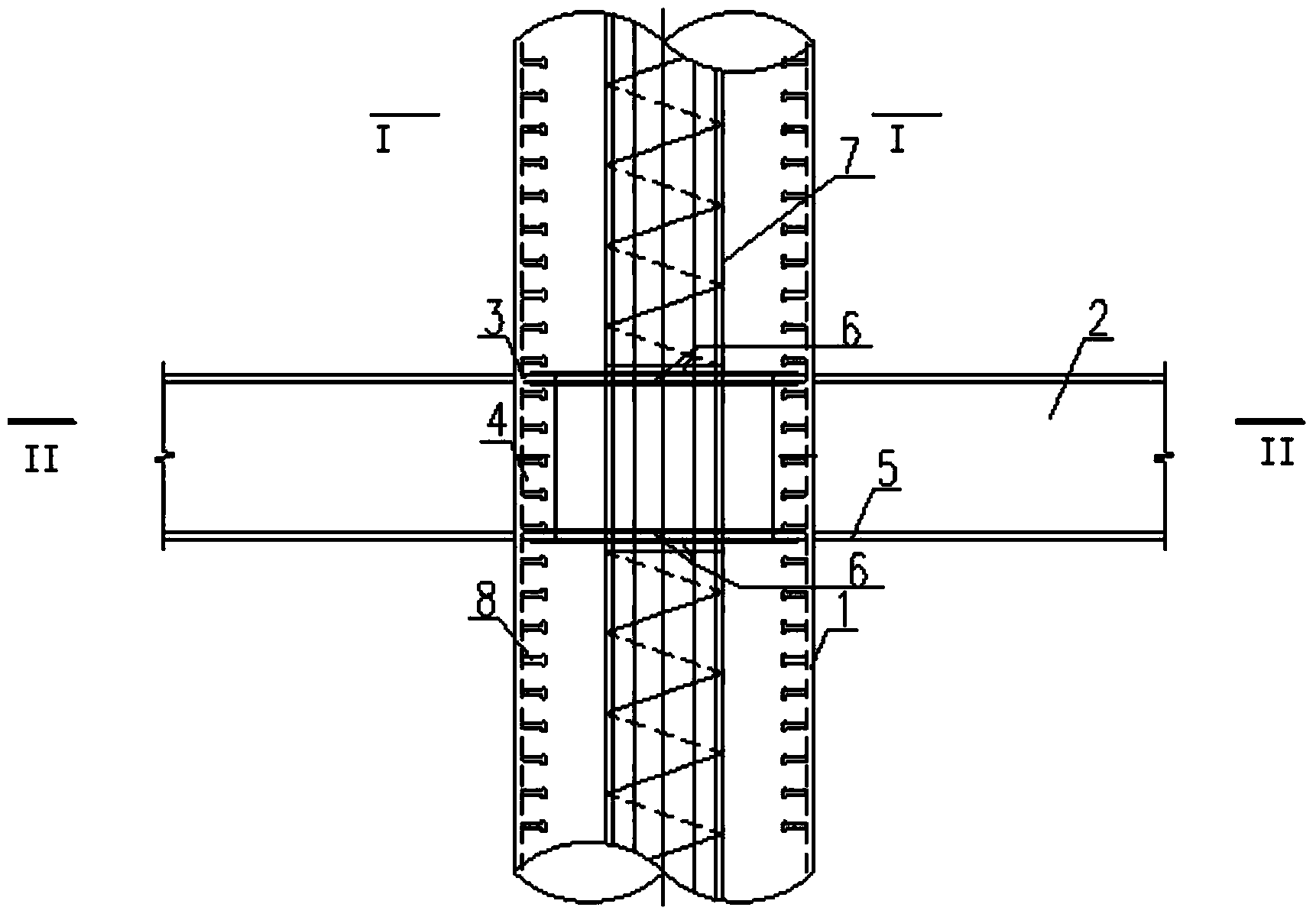

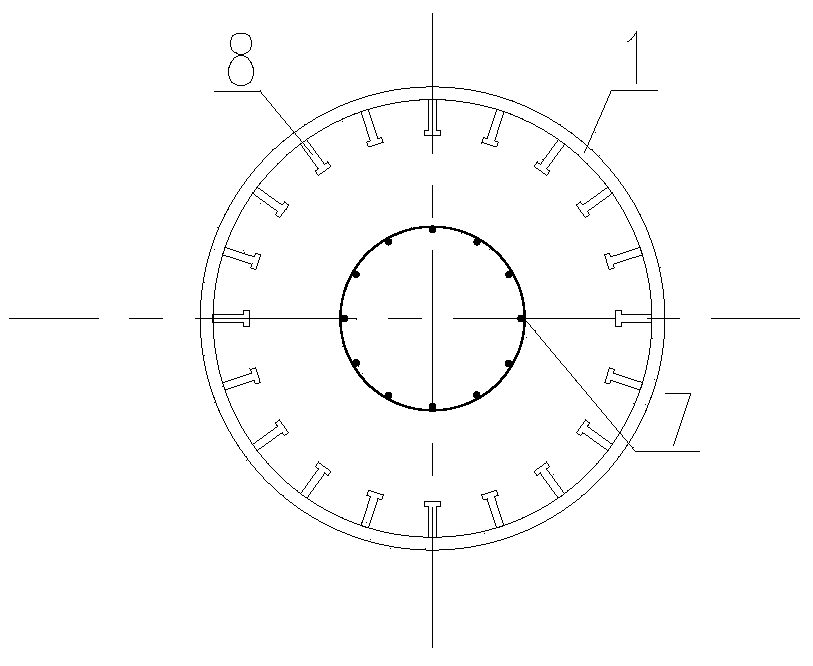

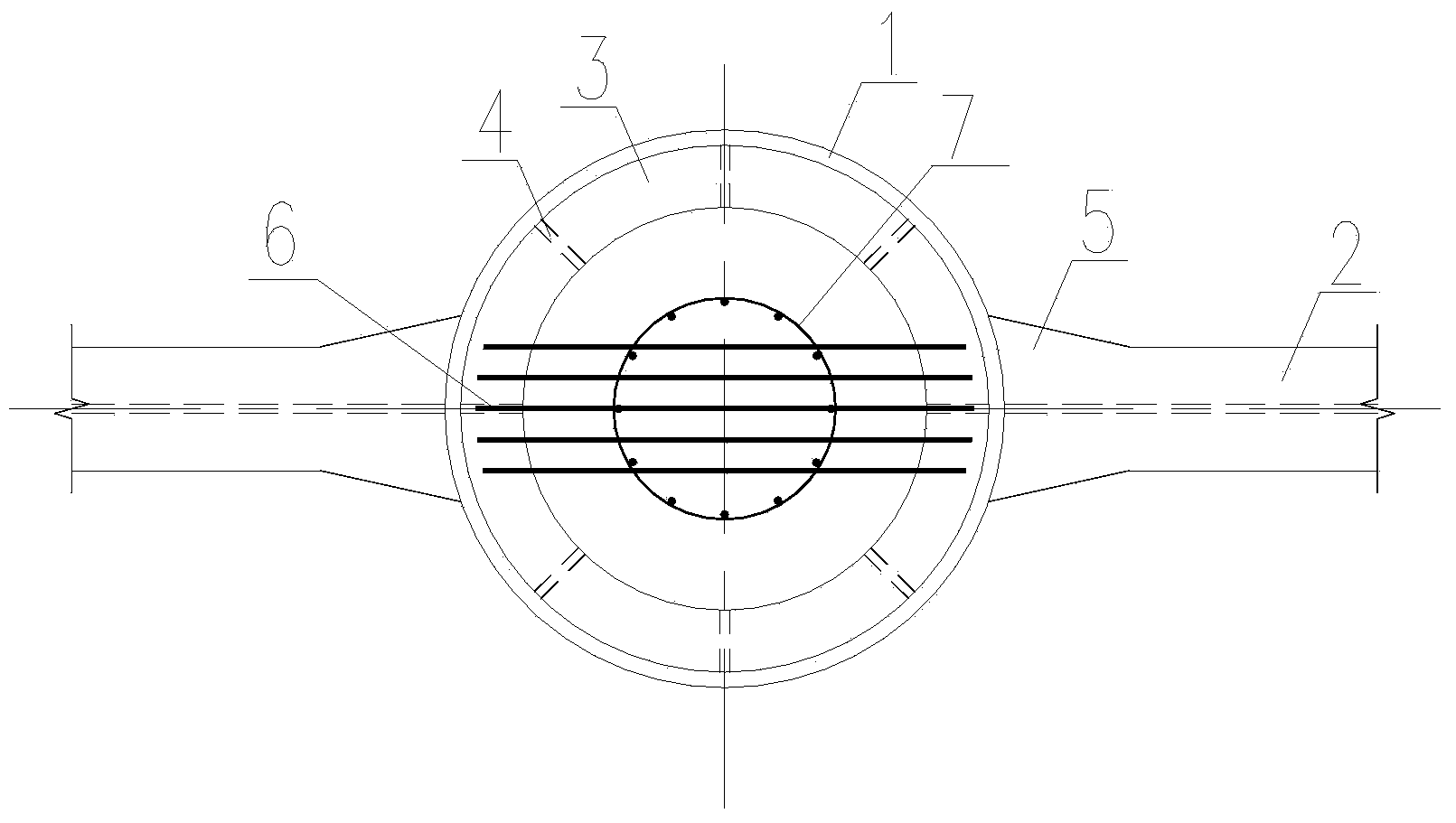

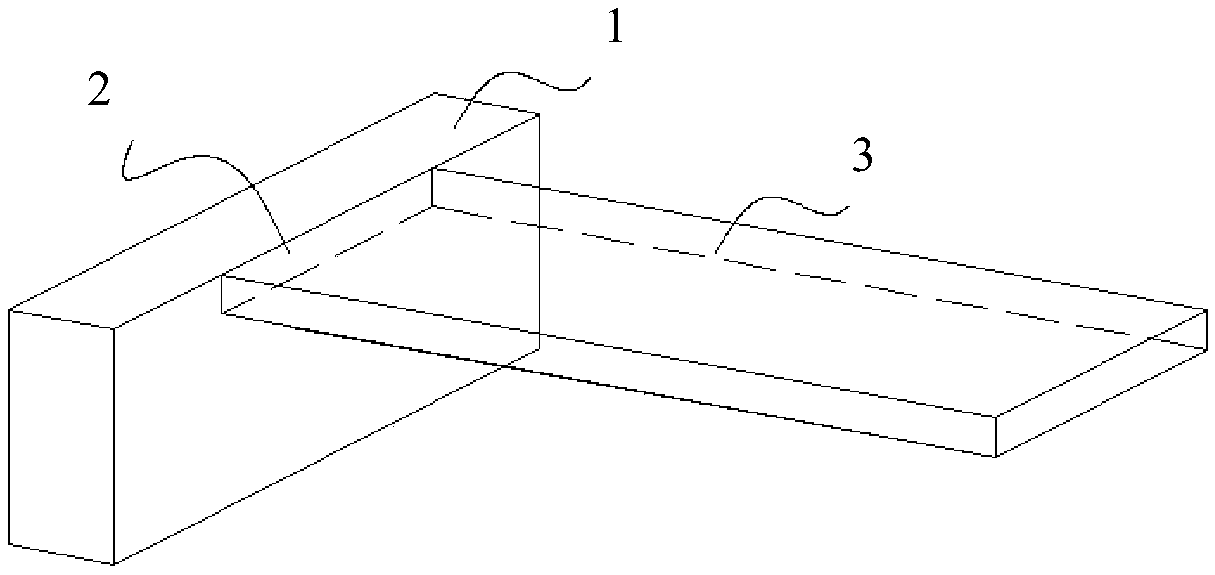

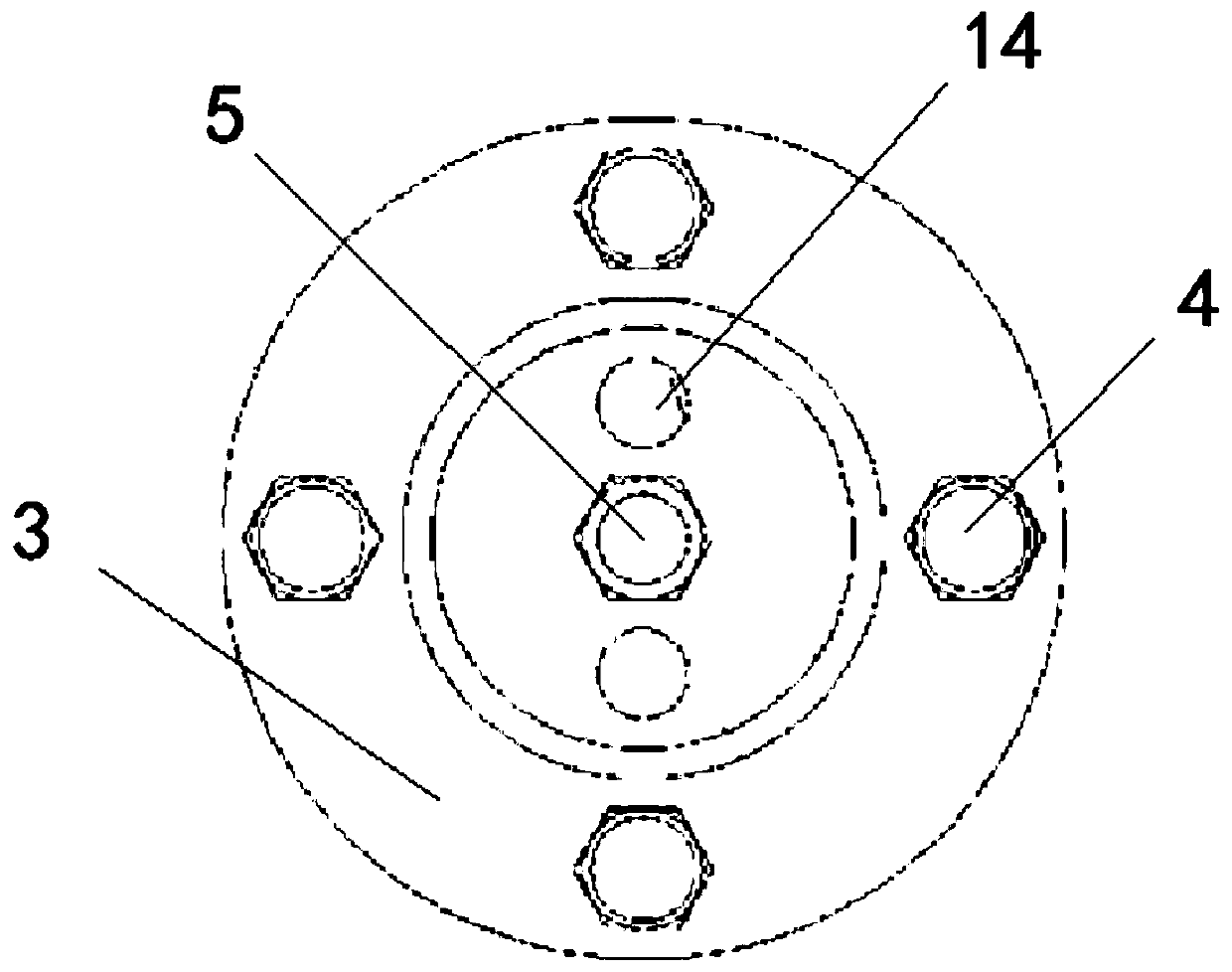

Joint of concrete-filled steel-tubular column and steel beam and architectural structure system

InactiveCN103993671APower transmission is clearImprove integrityBuilding constructionsRebarStructure system

The invention discloses a joint of a concrete-filled steel-tubular column and a steel beam. The steel beam is connected with a steel tube of the concrete-filled steel-tubular column at the joint, inner ring plates are arranged on the positions, corresponding to an upper flange and a lower flange of the steel beam, in the concrete-filled steel-tubular column respectively, the inner ring plates are fixedly connected to the inner wall of the steel tube of the concrete-filled steel-tubular column, and a plurality of steel bars are arranged on the inner ring plates in the direction of the steel beam. The invention further discloses an architectural structure system which comprises the joint of the concrete-filled steel-tubular column and the steel beam. Due to the fact that the multiple steel bars are arranged on the inner ring plates in the direction of the steel beam, the steel beam is clear in force transmission, high in integrality and good in ductility, joint quality is improved, mechanical bite force of the steel tube and the concrete is increased, and the problem of poor cooperativity of the steel tube of the concrete-filled steel-tubular column with the big diameter and the concrete is solved. The architectural structure system is safe and stable.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD

Old and new concrete interface beam and plate component connection structure and construction method thereof

PendingCN109372280AIncrease bonding areaIncrease mechanical bite forceBuilding repairsArchitectural engineeringRebar

The invention discloses an old and new concrete interface beam and plate component connection structure and a construction method thereof. The old and new concrete interface beam and plate component connection structure comprises an existing beam type component, a force transmission beam and a new built plate component. The force transmission beam is connected to the end portion of the new built plate component and is integrally poured with the new built plate component. The outer side face of the force transmission beam is fixed to an old and new concrete bonding face of the existing beam component, and chiselling treatment is carried out on the old and new concrete bonding face. An interface rebar is arranged between the force transmission beam and the existing beam type component, one end of the interface rebar is anchored into the force transmission beam, and the other end of the interface rebar penetrates through the old and new concrete bonding face to be embedded into the existing beam component. According to the old and new concrete interface beam and plate component connection structure and the construction method thereof, the force transmission beam is arranged between the existing beam component and the new built plate component, the bonding area of the old and new concrete interface is increased, the mechanical bite force, the van der waals force and other interfaceacting force of the old and new concrete interface are remarkably increased, the force transmission effect of the old and new concrete interface is improved, the construction quality is ensured, andconstruction is convenient. The interface rebar is arranged between the force transmission beam and the existing beam component, and the shear capacity of the interface is increased.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

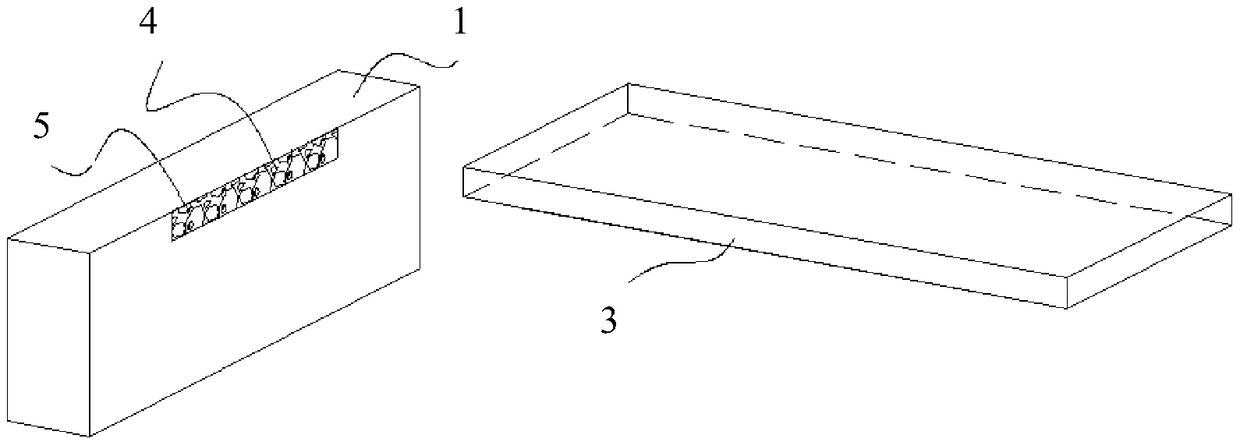

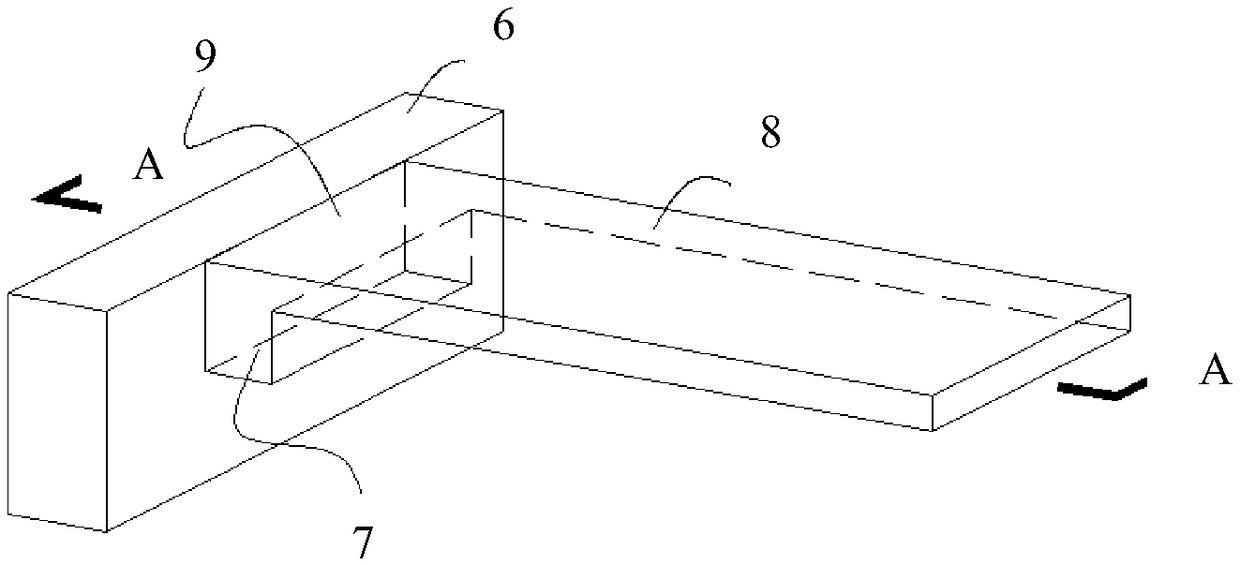

A kind of sleeve grouting material for steel bar connection and preparation method thereof

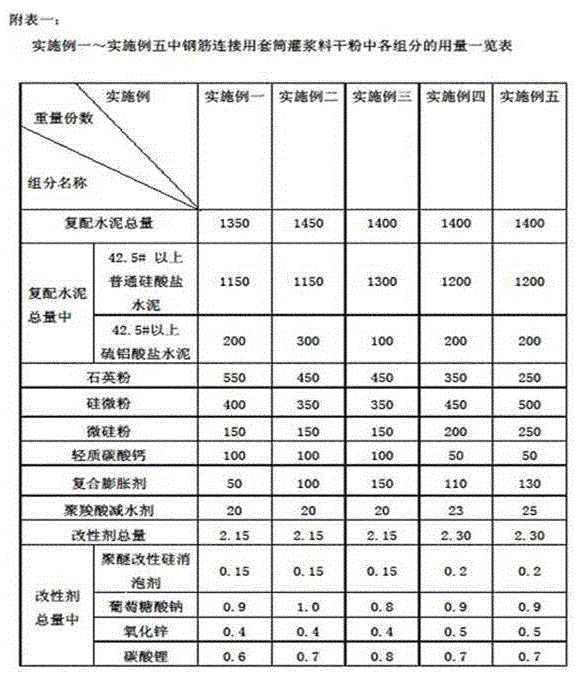

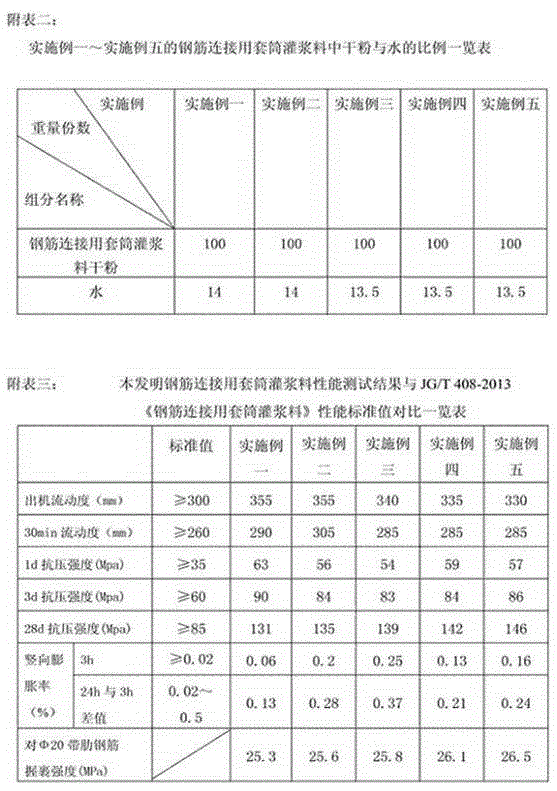

A sleeve grouting material for steel bar connection, which is prepared by mixing 100 parts by weight of dry powder with 13 to 14 parts by weight of water on site from the dry powder of sleeve grouting material for steel bar connection. The dry powder is a mixture composed of the following components and raw materials, The content of each component in the mixture is calculated in parts by weight: 1350-1450 parts of compound cement mixed with ordinary Portland cement and sulphoaluminate cement; 250-550 parts of quartz powder, 350-500 parts of silica powder , 150-250 parts of micro-silica fume, 50-100 parts of light calcium carbonate, 50-150 parts of composite expansion agent, 20-25 parts of polycarboxylate water reducer, 2.15-2.30 parts of modifier; the modified Agents include: 0.15-0.2 parts of polyether modified silicon defoamer, 0.8-1.0 parts of sodium gluconate, 0.4-0.5 parts of zinc oxide, 0.6-0.8 parts of lithium carbonate; the performance of the grout is stable and reliable, and its production method is simple and scientific .

Owner:LIUZHOU OVM MASCH CO LTD

Novel shield tunnel concrete pipe piece micro reinforcing pile

ActiveCN110593894AImprove mechanical propertiesImprove integrityUnderground chambersTunnel liningShield tunnelingPrecipitation

The invention relates to the technical field of civil engineering tunnel shield construction equipment, and discloses a novel shield tunnel concrete pipe piece micro reinforcing pile. The novel shieldtunnel concrete pipe piece micro reinforcing pile comprises a reinforcing pile main body; a pile body grouting port is formed in the external of the reinforcing pile main body; a cover plate is fixedly connected to the left side of the reinforcing pile main body; a cover body grouting port is formed in the cover plate; a pipe wall connecting bolt is fixedly connected to the left side of the coverplate; and a core rod is fixedly connected into the reinforcing pile main body. In the novel shield tunnel concrete pipe piece micro reinforcing pile, through use of the method and the device, the mechanical performance of soil around tunnels can be effectively improved; and a whole is formed through grouting, so that the load bearing capacity is improved, the lining and soil integrity is greatlyimproved, the stress range of the reinforcing pile main body is widened, the excessive precipitation deformation is effectively prevented, potential safety hazards in shield tunneling are greatly eliminated, and the shield method is used more safely.

Owner:CHONGQING UNIV

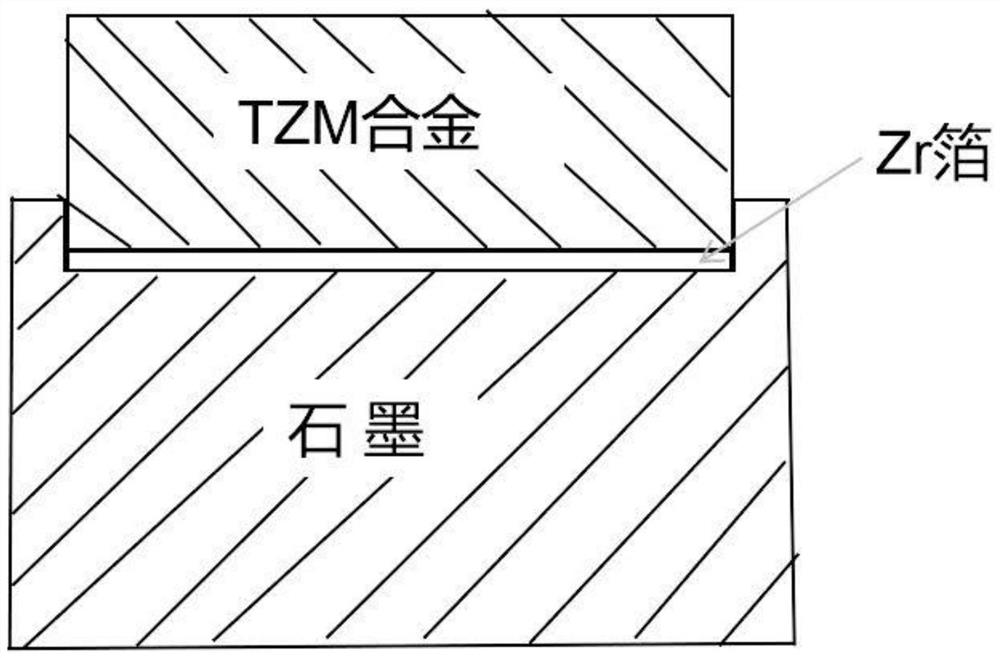

Contact reaction brazing process for connecting TZM alloy and graphite through pure zirconium layer

PendingCN114453693AReduced finish requirementsIncrease mechanical bite forceSoldering apparatusSand blastingGraphite

The invention relates to the technical field of brazing, and discloses a contact reaction brazing process for connecting TZM alloy and graphite through a pure zirconium layer, which comprises the following steps: step 1, taking TZM alloy, graphite and Zr foil to be welded, polishing the surfaces to be welded by using abrasive paper, and ultrasonically cleaning the sample in an organic solution for 30 minutes; and 2, grooving the surface of the graphite in the step 1, and then sequentially putting Zr foil and TZM alloy into the grooves in the surface of the graphite so as to prevent the sample from being misplaced and prevent brazing filler metal from flowing out. And (3) the workpiece assembled in the step (2) is put into a furnace cavity of a vacuum air pressure sintering furnace, the furnace cavity is vacuumized to be lower than 1 * 10 <-3 > Pa, then argon is filled into the furnace cavity to reach the set pressure, and the temperature is increased to 1000 DEG C from 20 DEG C at the speed of 50 DEG C / min. According to the method, the requirement for the smoothness of the welding surface can be lowered by adding the zirconium middle layer, and the welding surface can be subjected to various treatments such as polishing, sand blasting and machining according to the requirements so as to increase the mechanical occlusal force.

Owner:HEFEI UNIV OF TECH

Precise positioning reinforcing rib reconsolidated bamboo component production mould and manufacturing method

ActiveCN108839146AIncrease stiffnessReduce deflectionBio-packagingCane mechanical workingEngineeringMechanical engineering

The invention discloses a precise positioning reinforcing rib reconsolidated bamboo component production mould. The mould comprises a U-shaped mould body, a top pressing plate, locking bolt pins, reinforcing ribs and a reinforcing rib positioning plate. The cross section of the U-shaped mould body is in a U shape. Two or more pairs of insert holes are symmetrically formed in the upper portions ofthe two side walls of the U-shaped mould body correspondingly. The reinforcing rib positioning plate is arranged inside the U-shaped mould body, and the two side surfaces of the reinforcing rib positioning plate are tightly attached to the U-shaped mould body and can slide up and down along the inner wall of the U-shaped mould body. The reinforcing ribs are arranged in grooves of the reinforcing rib positioning plate longitudinally. The reinforcing ribs and the grooves are matched in size. An upper space and a lower space which are defined by the reinforcing rib positioning plate and the U-shaped mould body are filled with bamboo wood, the top pressing plate blocks up an upper opening of the U-shaped mould body, and the locking bolt pins penetrate through the insert holes to fix and lock the top pressing plate. By means of the precise positioning reinforcing rib reconsolidated bamboo component production mould, reinforcing rib reconsolidated bamboo components are produced, the structure is simple, the reinforcing ribs are positioned precisely, and the rigidity and the bearing capacity of an ordinary reconsolidated bamboo bending component are improved.

Owner:NANJING FORESTRY UNIV

Preparation method of corrosion-resisting anti-rusting air conditioner bracket

InactiveCN107971189AHigh bonding strengthImprove adhesionPretreated surfacesAnti-corrosive paintsAbrasive blastingEngineering

The invention discloses a preparation method of a corrosion-resisting anti-rusting air conditioner bracket. The preparation method of the corrosion-resisting anti-rusting air conditioner bracket specifically comprises the following steps of (1) surface pretreatment, specifically, the surface of the air conditioner bracket is ground through abrasive paper, washed with clean water and alkali liquor,then dried, subjected to sandblasting roughing treatment, and then washed with clean water and alkali liquor; (2) spraying of a layer of binder on the surface of the air conditioner bracket and high-temperature bonding and compounding under the high pressure action; (3) spraying of a layer of corrosion-resisting coating on the surface sprayed with the binder; (4) solidifying; and (5) spraying ofa nano material solution on the surface of the corrosion-resisting coating, and drying. The corrosion-resisting anti-rusting air conditioner bracket is good in structure corrosion resistance and the service life is prolonged.

Owner:SUZHOU NIUDONG PRECISION MFG TECH CO LTD

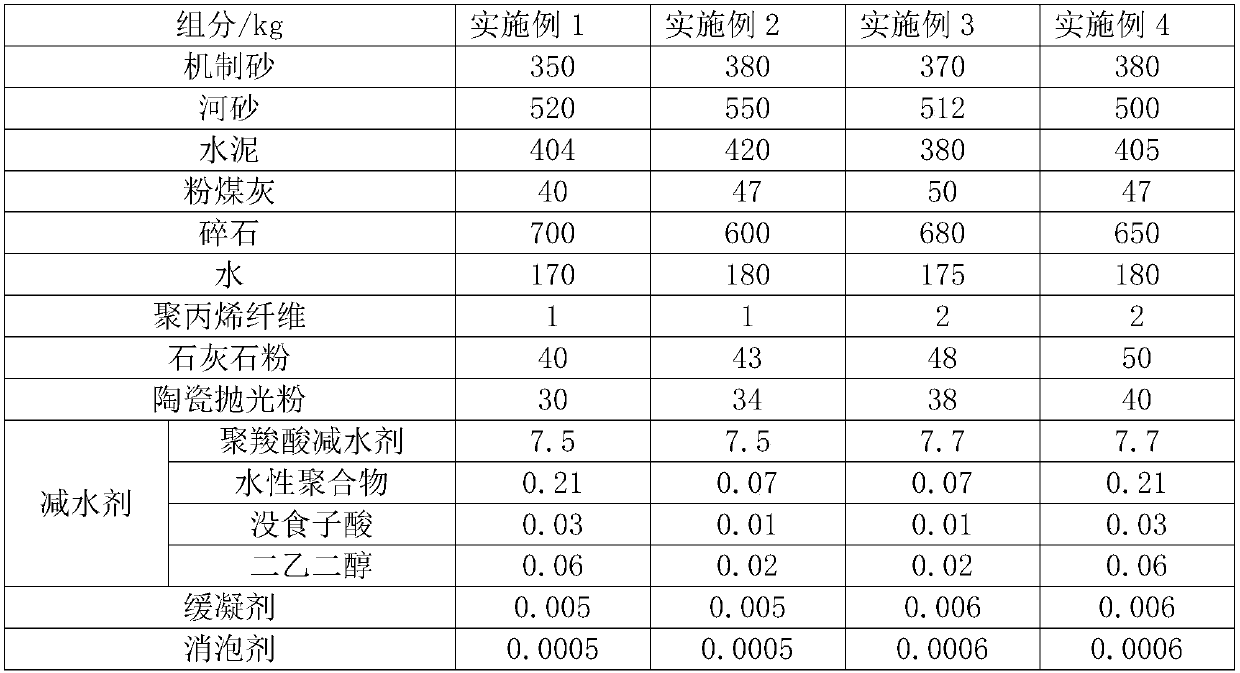

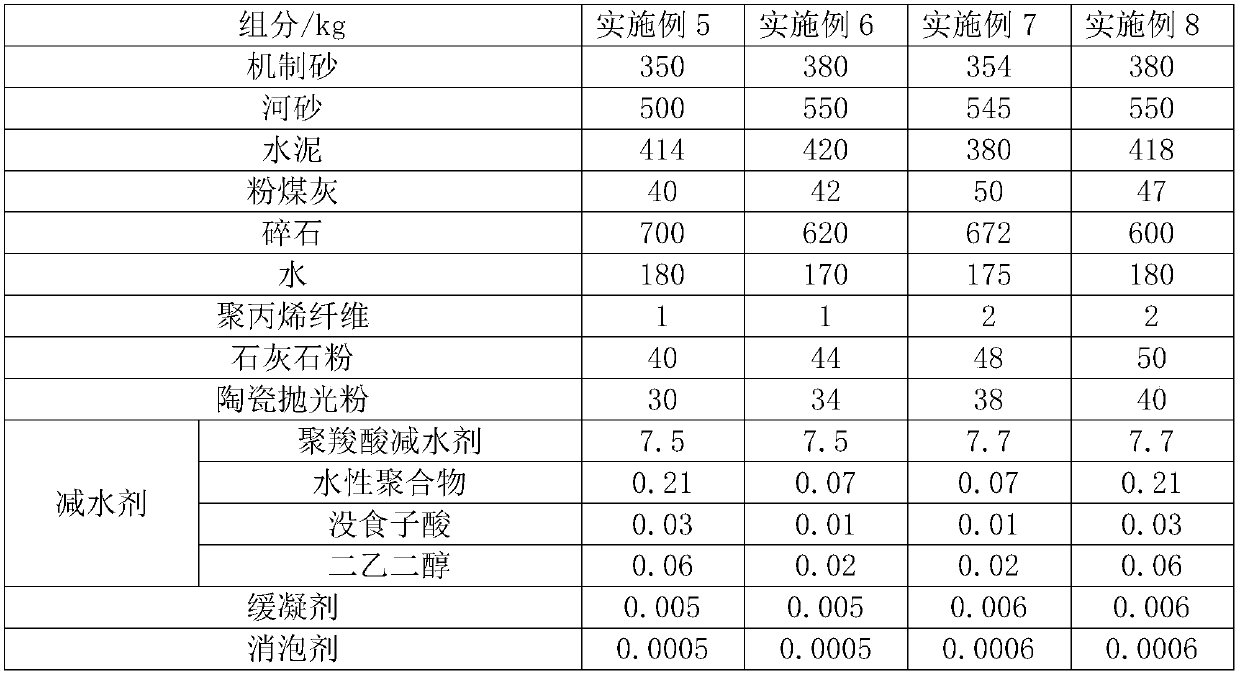

Machine-made sand concrete and preparation process thereof

InactiveCN109650803AImprove performanceImprove water retentionCrushed stoneUltimate tensile strength

The invention relates to machine-made sand concrete and a preparation process thereof. The preparation process comprises the following steps: step one, a first mixture is obtained after a water reducing agent and a retarder are first added into 50-80 parts of water and stirred uniformly, and then fly ash, cement, limestone powder and ceramic polishing powder are added and mixed uniformly; step two, a second mixture is obtained after river sand, machine-made sand, crushed stone, polypropylene fiber and residual water are added into the first mixture; step three, after the second mixture is stirred uniformly, a defoaming agent is added and stirred uniformly, and the machine-made sand concrete is made. The addition of polypropylene fiber in the components can improve the strength of the concrete. The limestone powder and the ceramic polishing powder can play a certain role in reducing water and improve the conditions that the content of stone powder in the machine-made sand is high and alarge amount of water is needed to a certain extent. In addition, the composite water reducing agent is selected as the water reducing agent, so that the dosage of the water reducing agent is reduced,the hydration of cement can be delayed, and the concrete has higher slump retention property.

Owner:陕西宏基混凝土构件有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com