A kind of sleeve grouting material for steel bar connection and preparation method thereof

A technology of sleeve grouting and steel reinforcement, which is applied in the field of building materials to achieve the effects of high grip strength, improved mechanical occlusal force and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

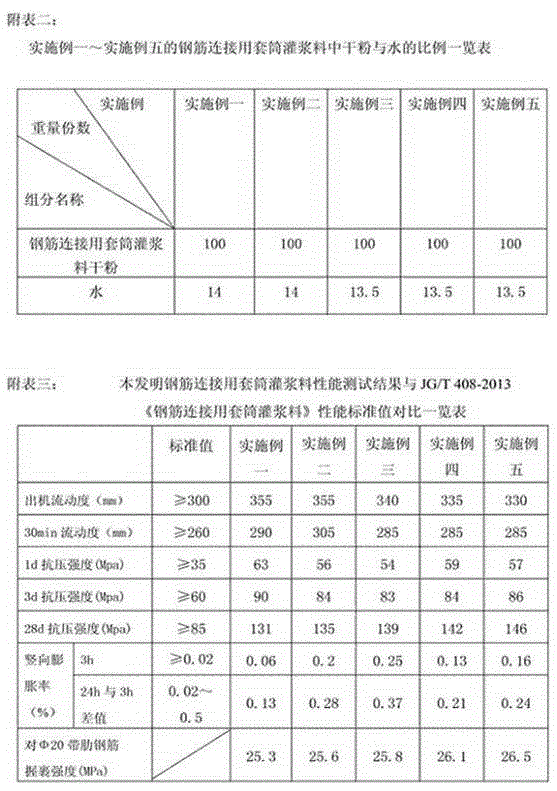

Examples

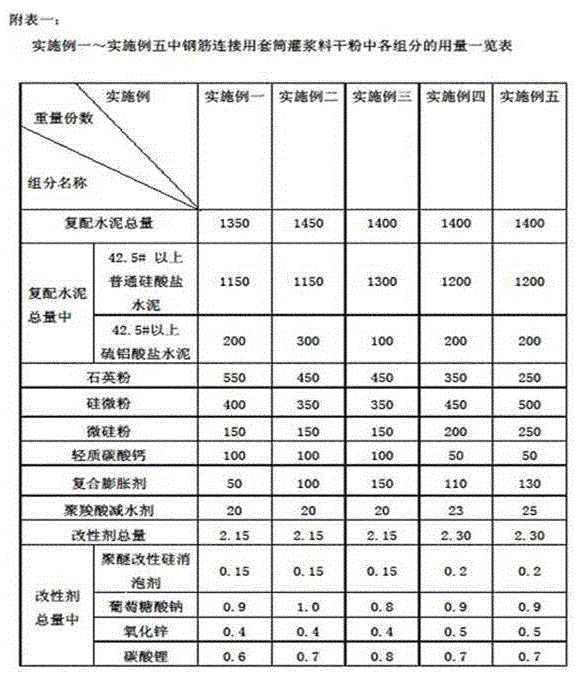

Embodiment 1

[0047] A sleeve grouting material for steel bar connection, which is formed by adding water to the dry powder of the sleeve grouting material for steel bar connection on site, and the dry powder of the sleeve grouting material for steel bar connection is a mixture composed of the following components. The content of each component is calculated in parts by weight as:

[0048] 1350 parts by weight of compound cement, which is a mixture of 1100 parts by weight of ordinary portland cement and 300 parts by weight of sulphoaluminate cement;

[0049] 550 parts by weight of quartz powder,

[0050] 400 parts by weight of microsilica powder, 150 parts by weight of microsilica powder,

[0051] 100 parts by weight of light calcium carbonate, composite expansion agent: 50 parts by weight,

[0052] 20 parts by weight of polycarboxylate water reducer,

[0053] Modifier 2.15 parts by weight;

[0054] Wherein: 0.15 parts by weight of polyether modified silicon defoamer, 0.9 parts by weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com