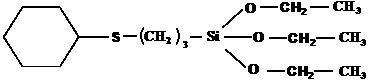

A kind of 3-cyclohexylthio-1-propyl-triethoxysilane and its preparation method and application

A technology of chloropropyl triethoxy silane and triethoxy silane, which is applied in the field of multifunctional rubber additives, can solve the problem of not improving the chemical bonding effect between silica and rubber matrix to a certain extent, and achieves synthesis The method is simple, the process flow is short, and the cost is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

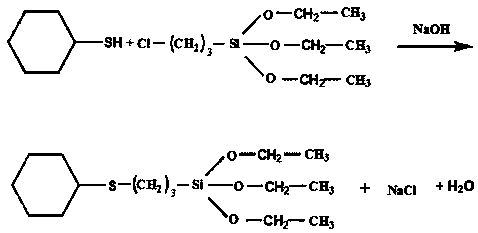

Method used

Image

Examples

Embodiment 1

[0025] Put 11.6g of cyclohexanethiol, 24g of 3-chloropropyltriethoxysilane, 4.1g of sodium hydroxide, and 200g of petroleum ether into a 1000mL three-necked flask, stir and react at 40°C for 2 hours, filter after reaction, and obtain a white Sodium chloride solid 4.7g, filtrate 208g, after filtrate is concentrated to dryness, obtain product 26.4g, measure by HPLC, 3-cyclohexylthio-1-propyl-triethoxysilane content is 95.1% in the product, yield The yield is 82.4%, and the calculation method of the yield is: the quality of the obtained product / theoretical quality of the product, the same below.

Embodiment 2

[0027] Put 11.6g of cyclohexanethiol, 28.9g of 3-chloropropyltriethoxysilane, 4.9g of sodium hydroxide, and 200g of toluene into a 1000mL three-neck flask, stir and react at 60°C for 2 hours, filter after reaction, and obtain a white Sodium chloride solid 4.9g, filtrate 209g, obtain product 27.1g after filtrate is concentrated to dryness, through HPLC measurement, 3-cyclohexylthio-1-propyl-triethoxysilane content is 95.9% in the product, yield The rate is 84.6%.

Embodiment 3

[0029] Put 11.6g cyclohexanethiol, 24g 3-chloropropyltriethoxysilane, 4.1g sodium hydroxide, 0.3g catalyst KI, 200g petroleum ether into a 1000mL three-necked flask, stir and react at 40°C for 2 hours, the reaction After filtration, obtain white sodium chloride solid 5.2g, filtrate 210g, obtain product 28.3g after filtrate is concentrated to dryness, through HPLC determination, 3-cyclohexylthio-1-propyl-triethoxysilane content in the product It was 95.7%, and the yield was 88.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com