Patents

Literature

145results about How to "Improve grip strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

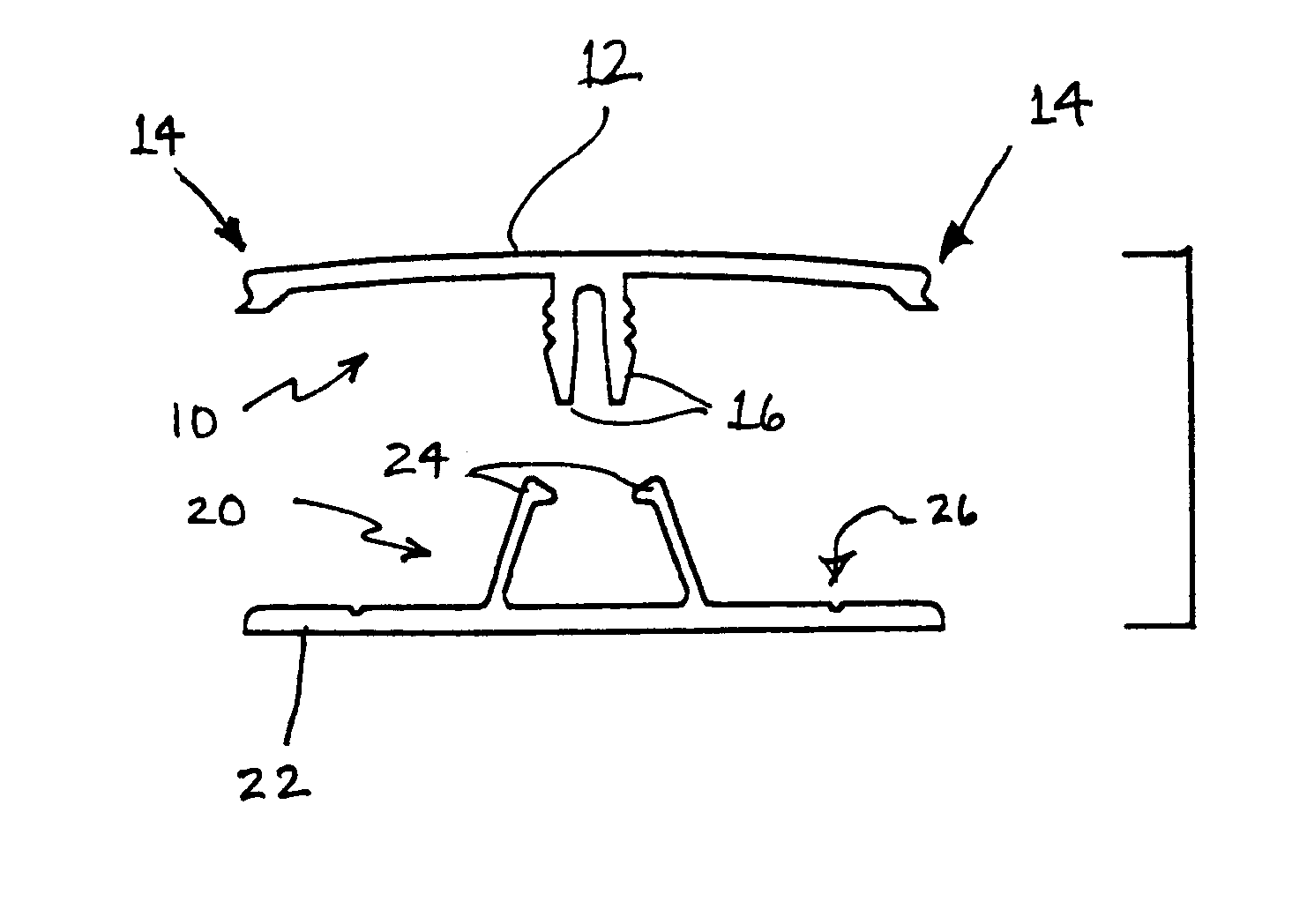

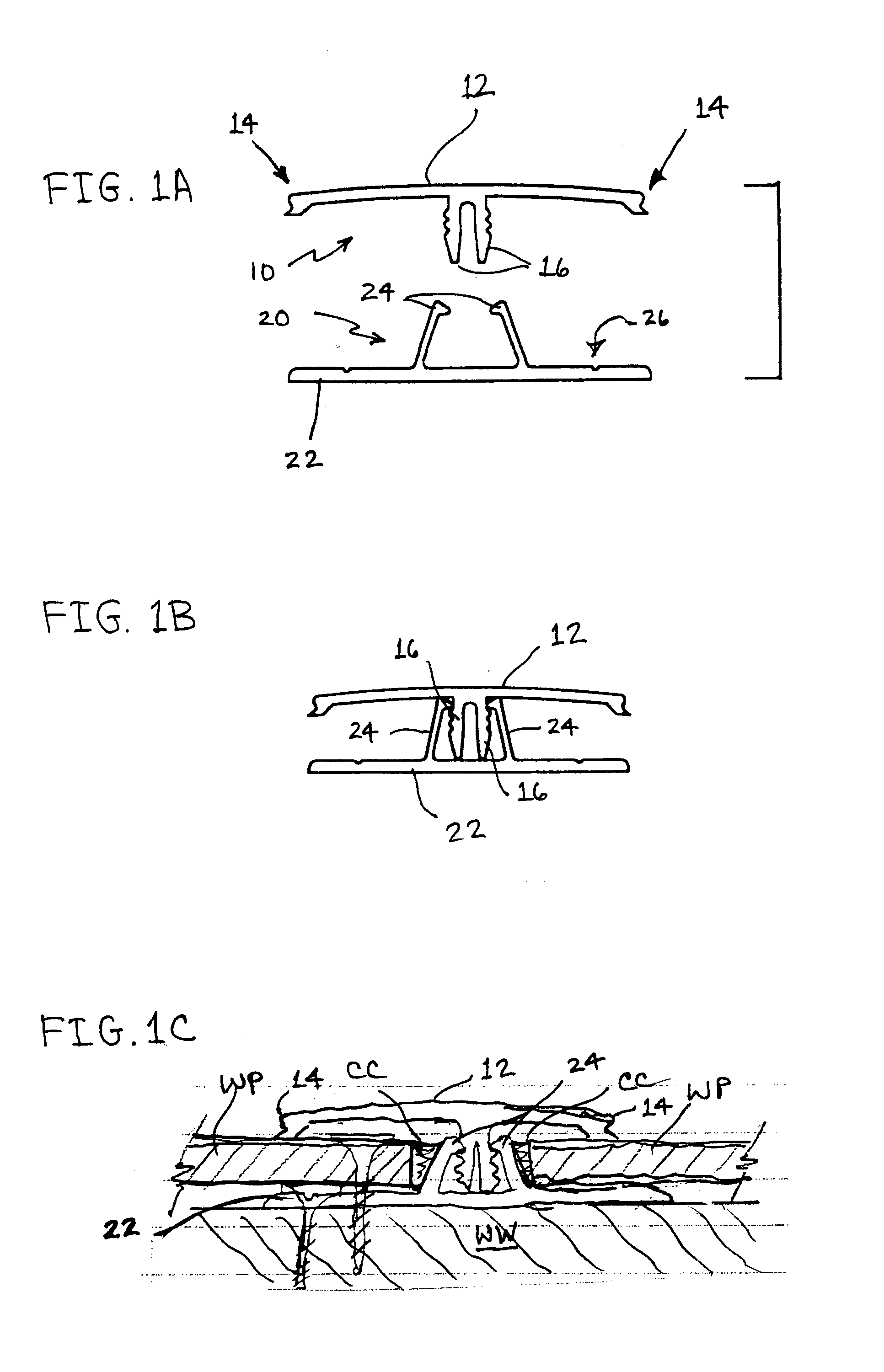

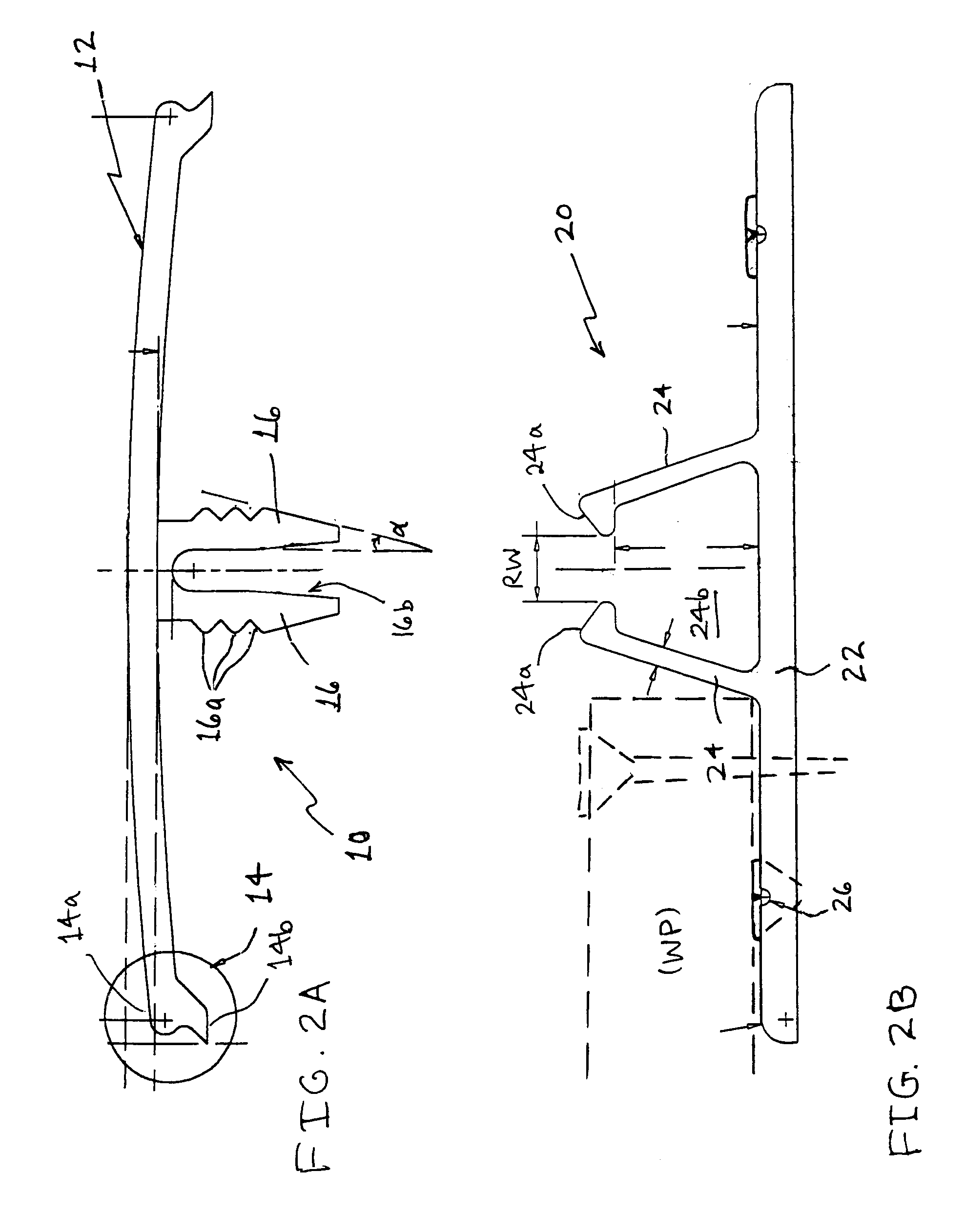

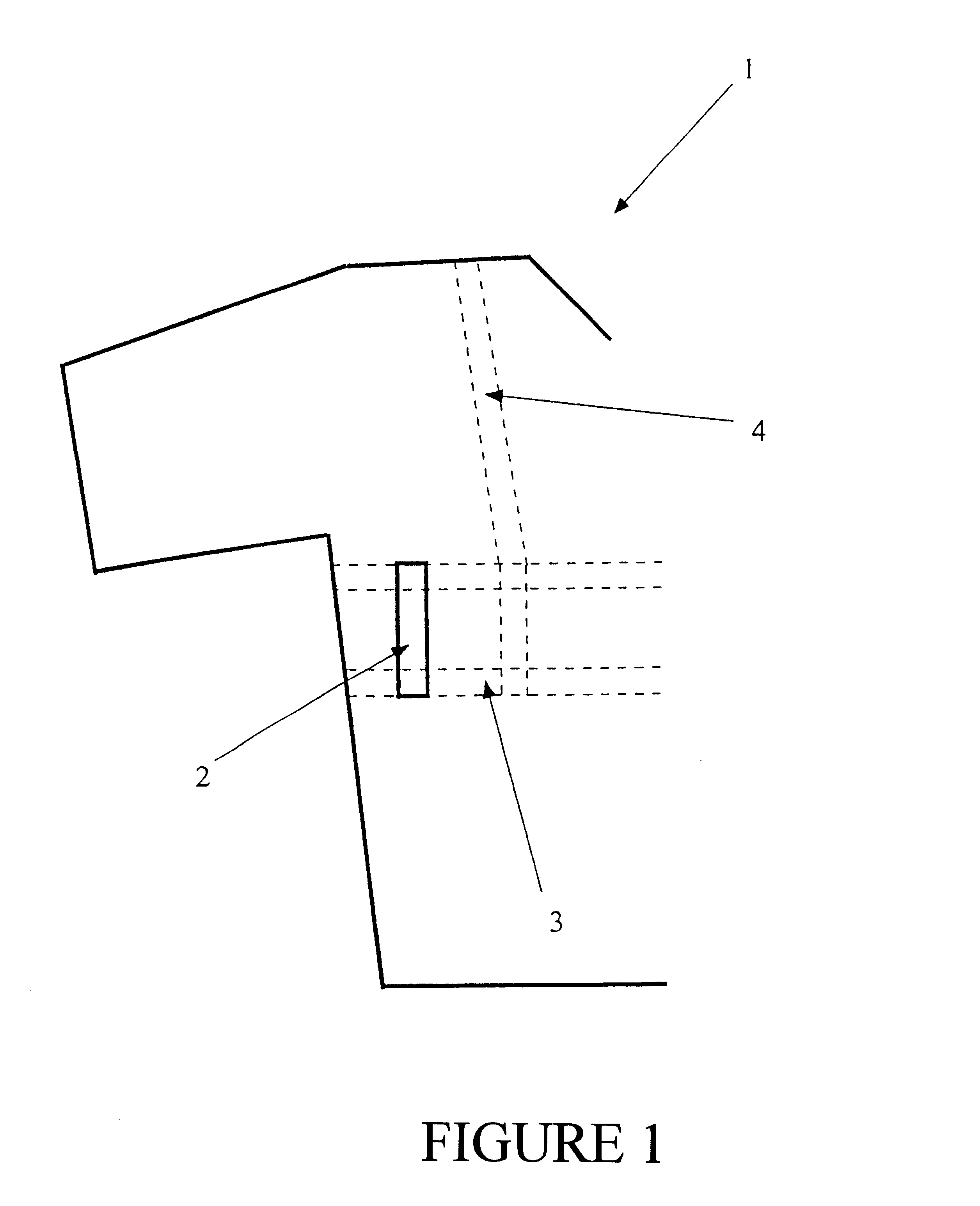

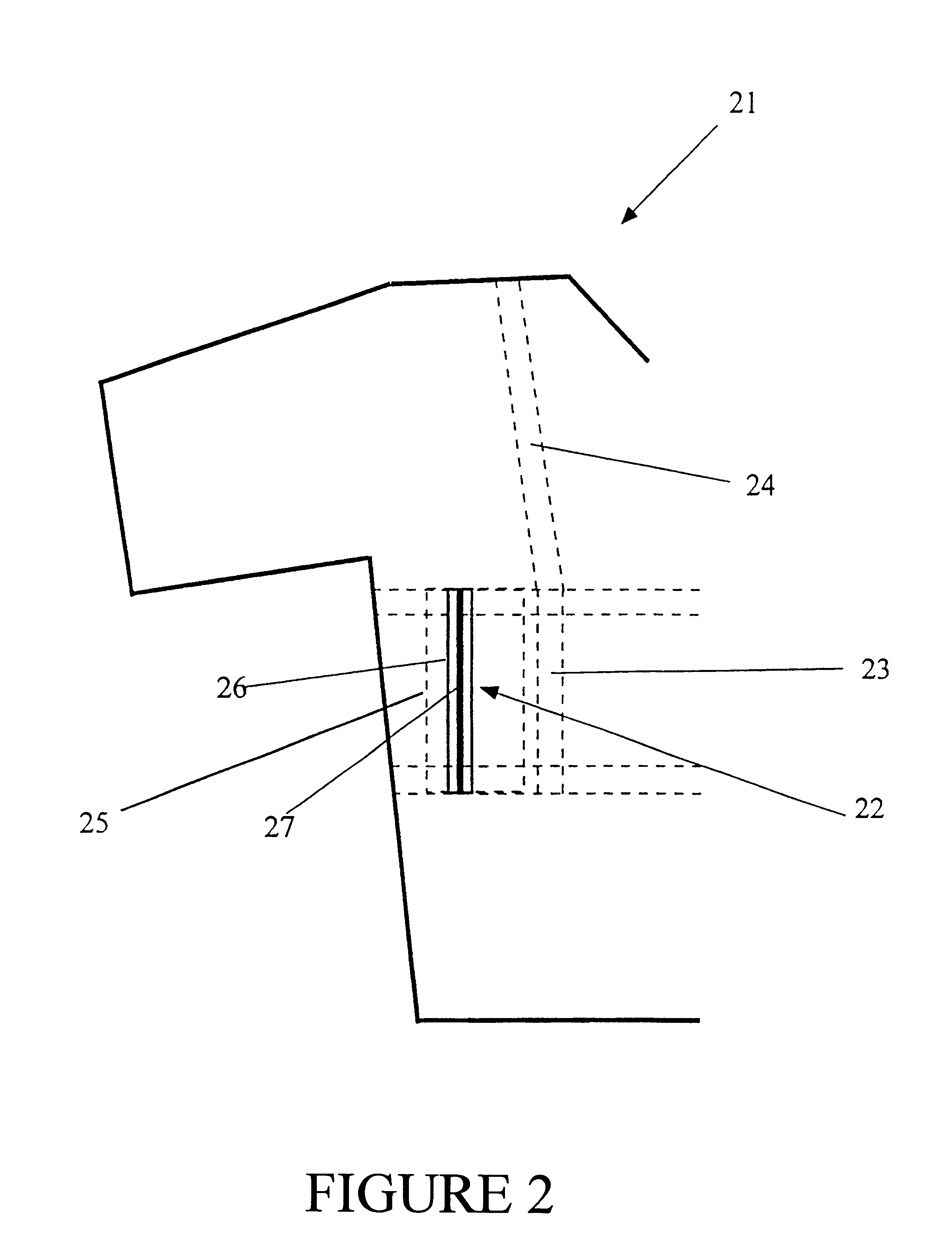

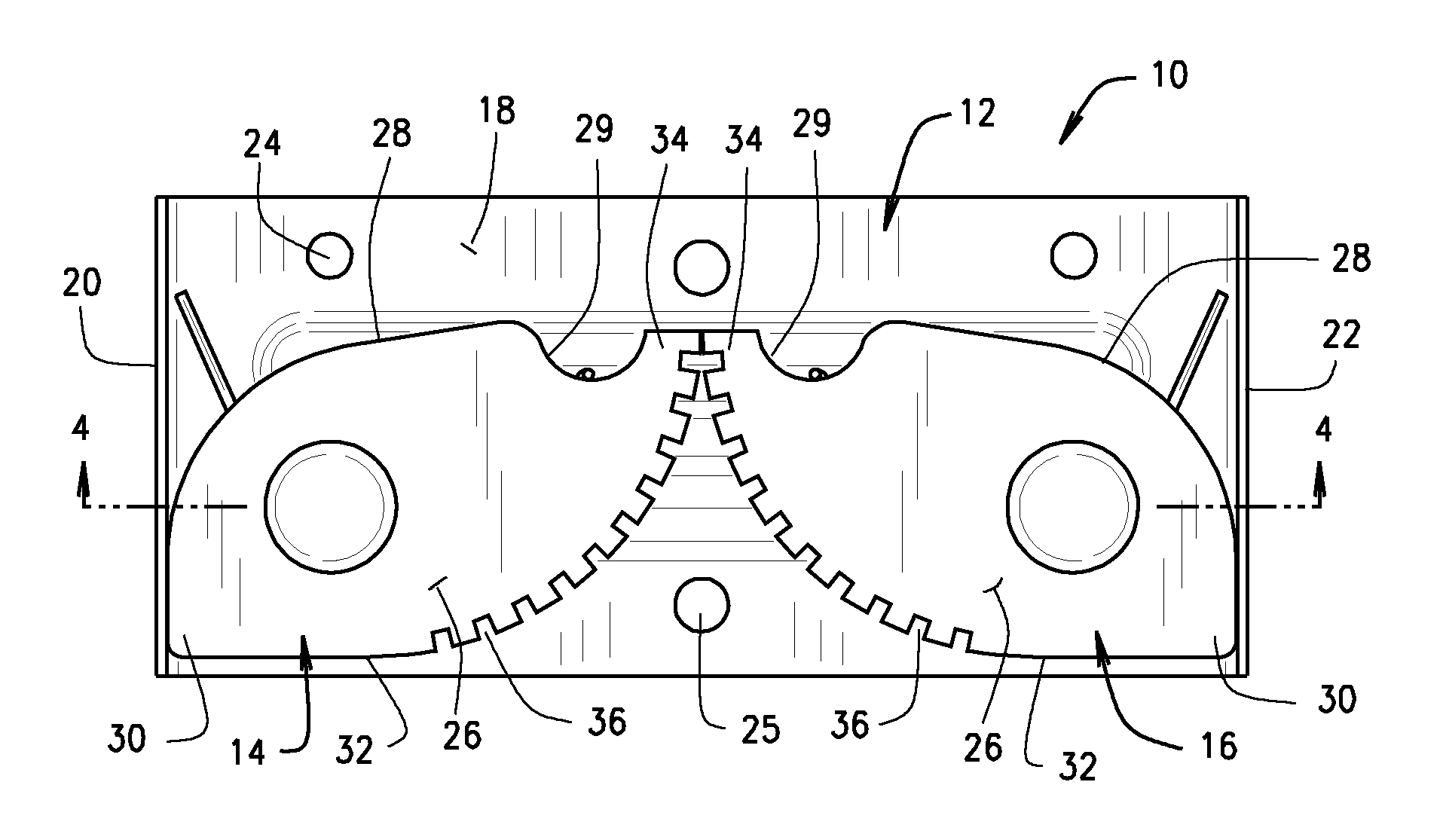

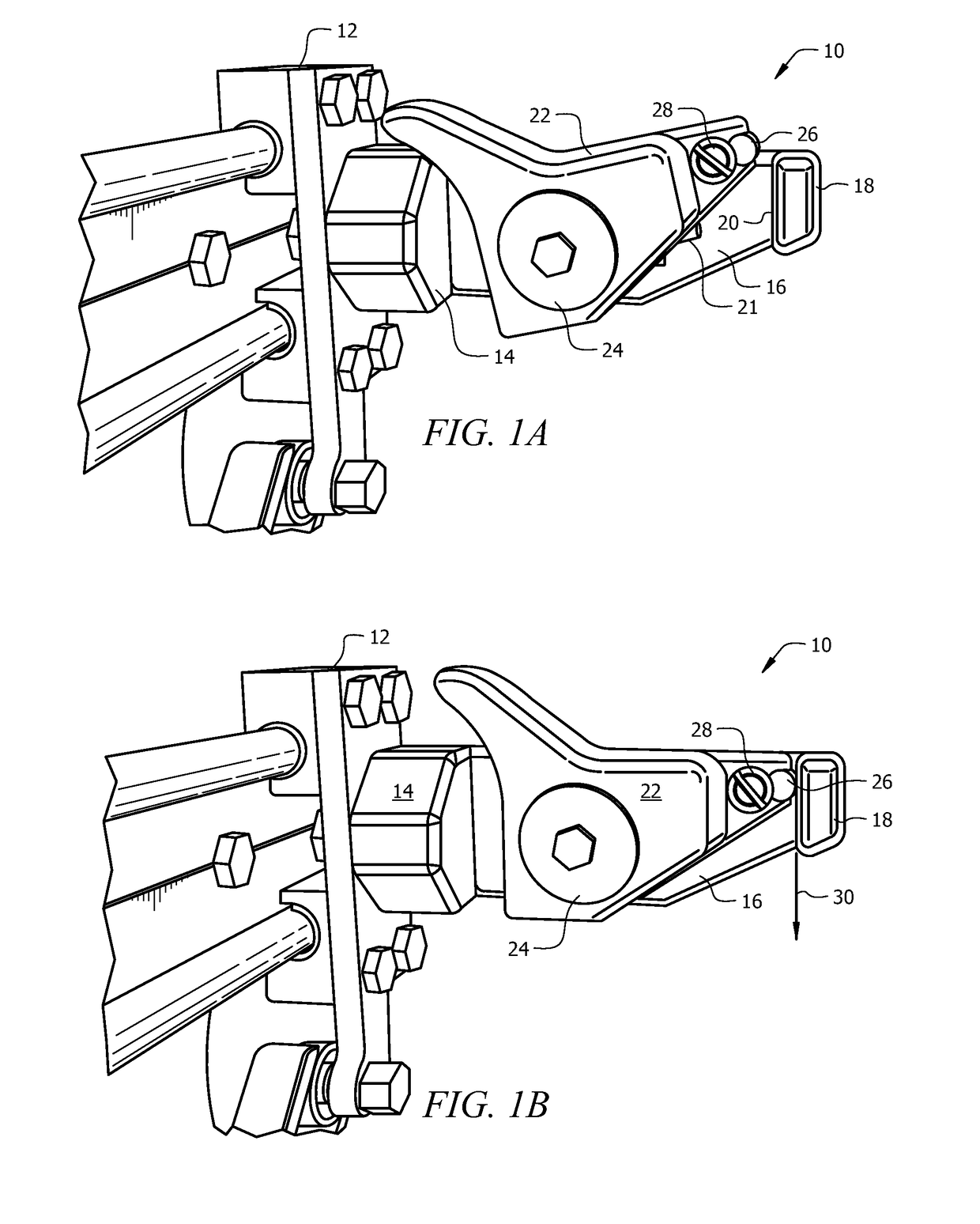

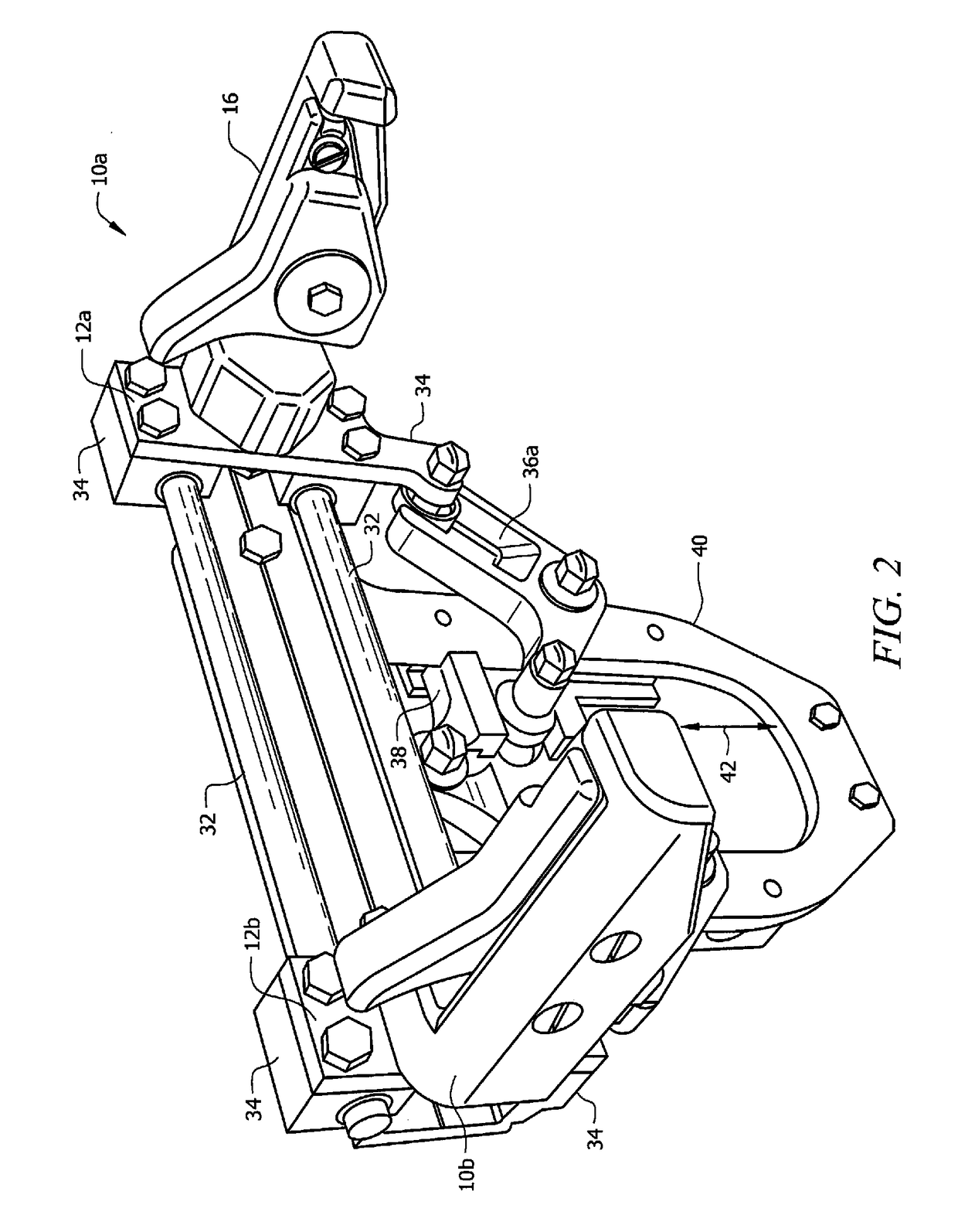

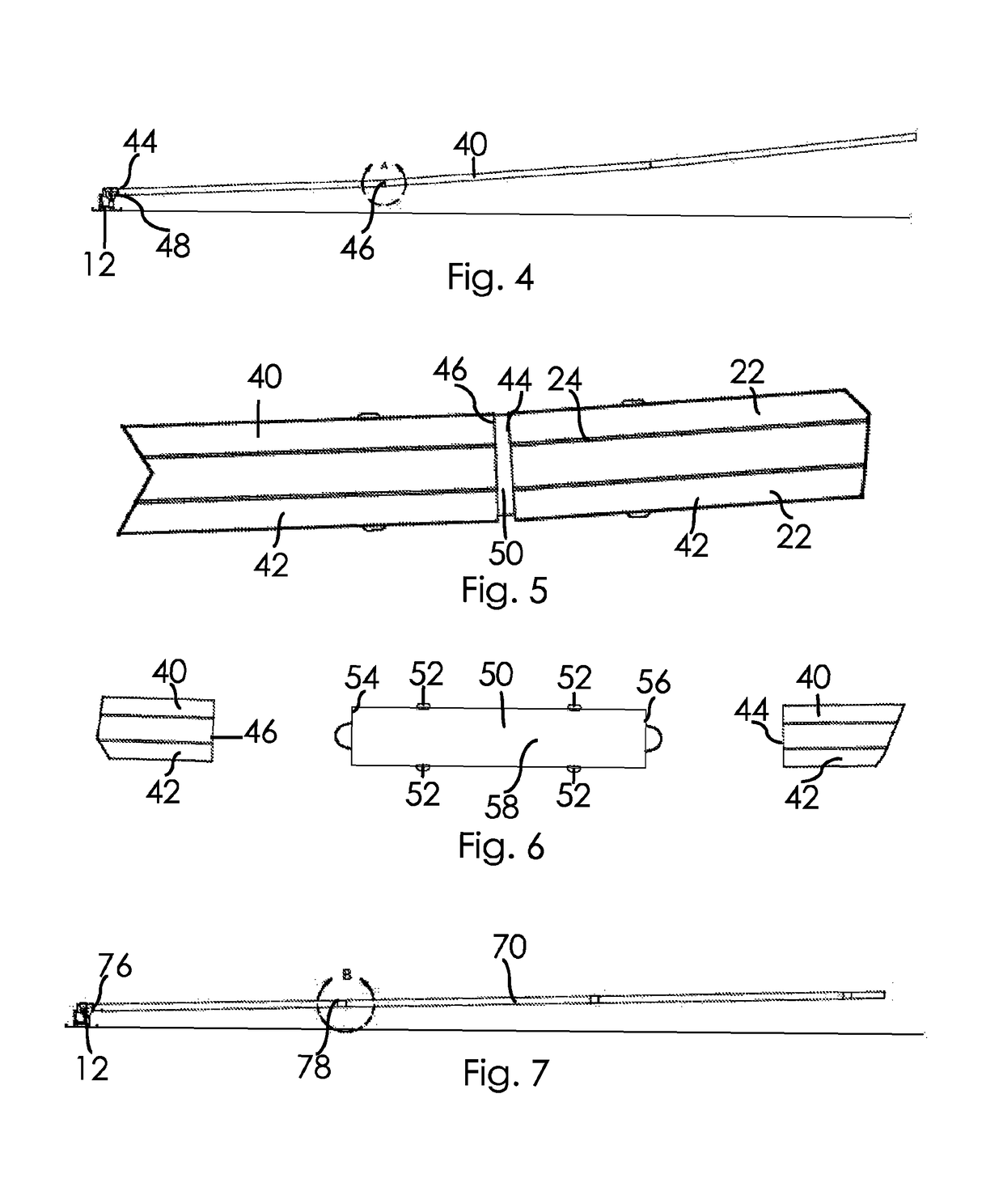

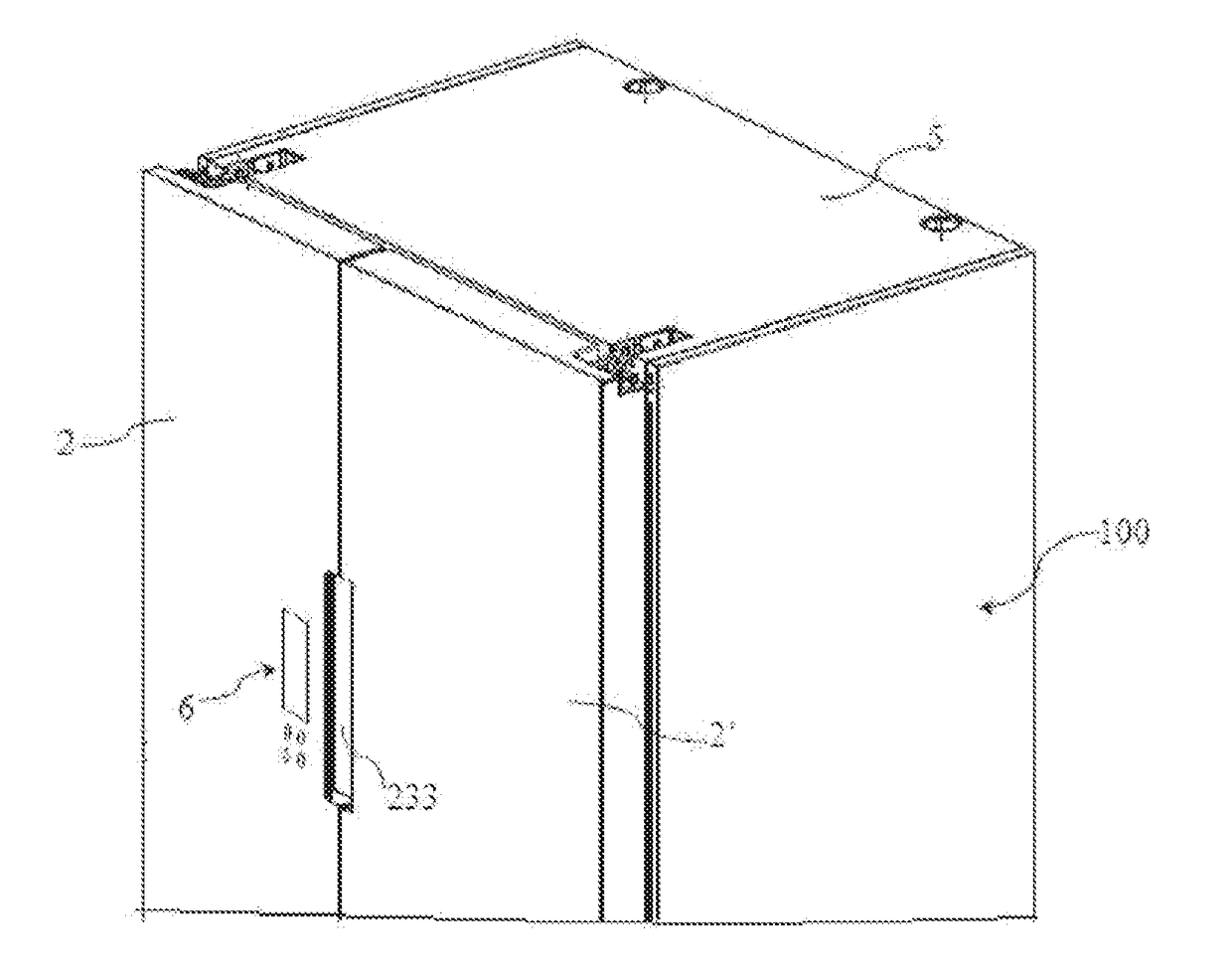

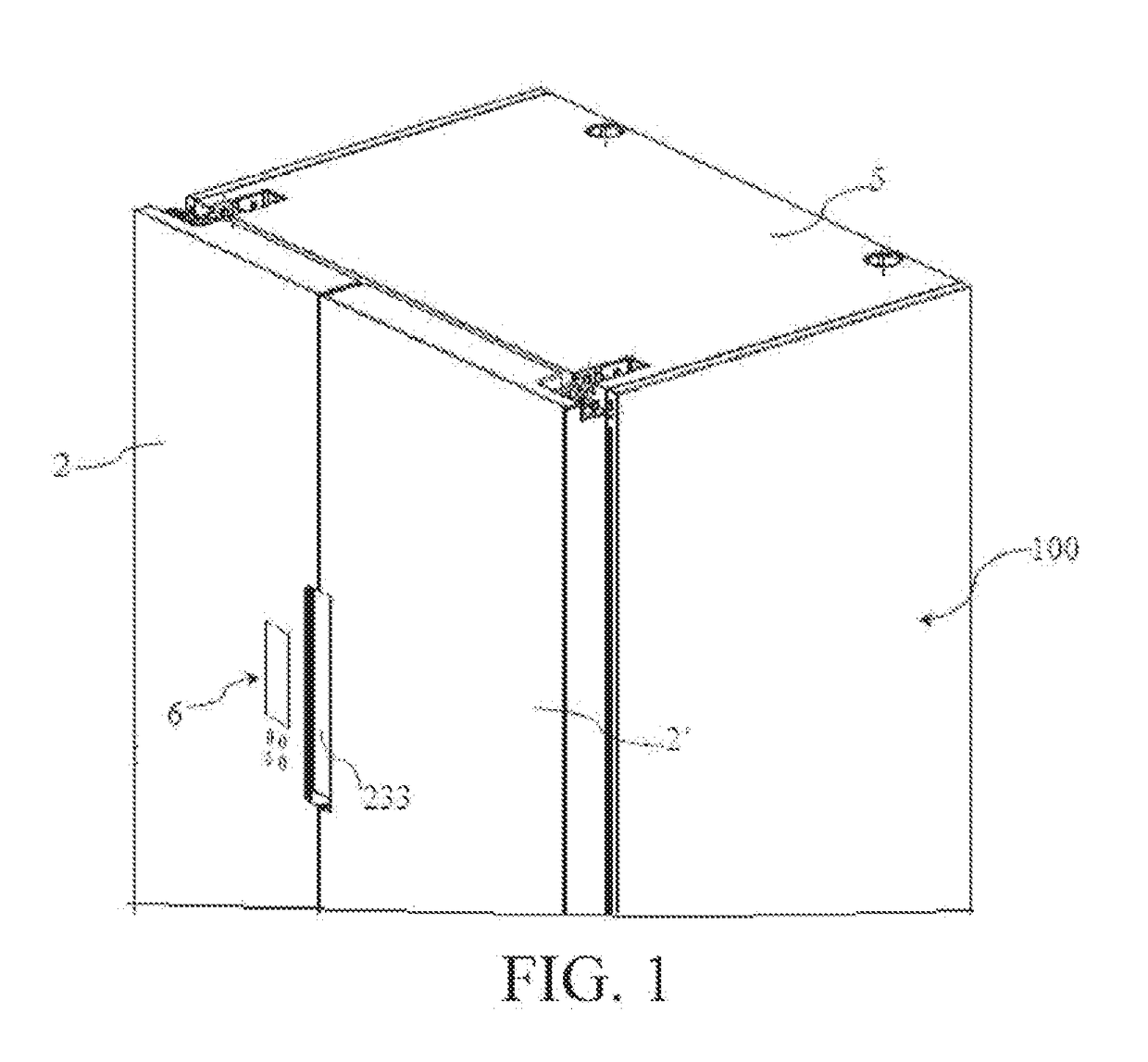

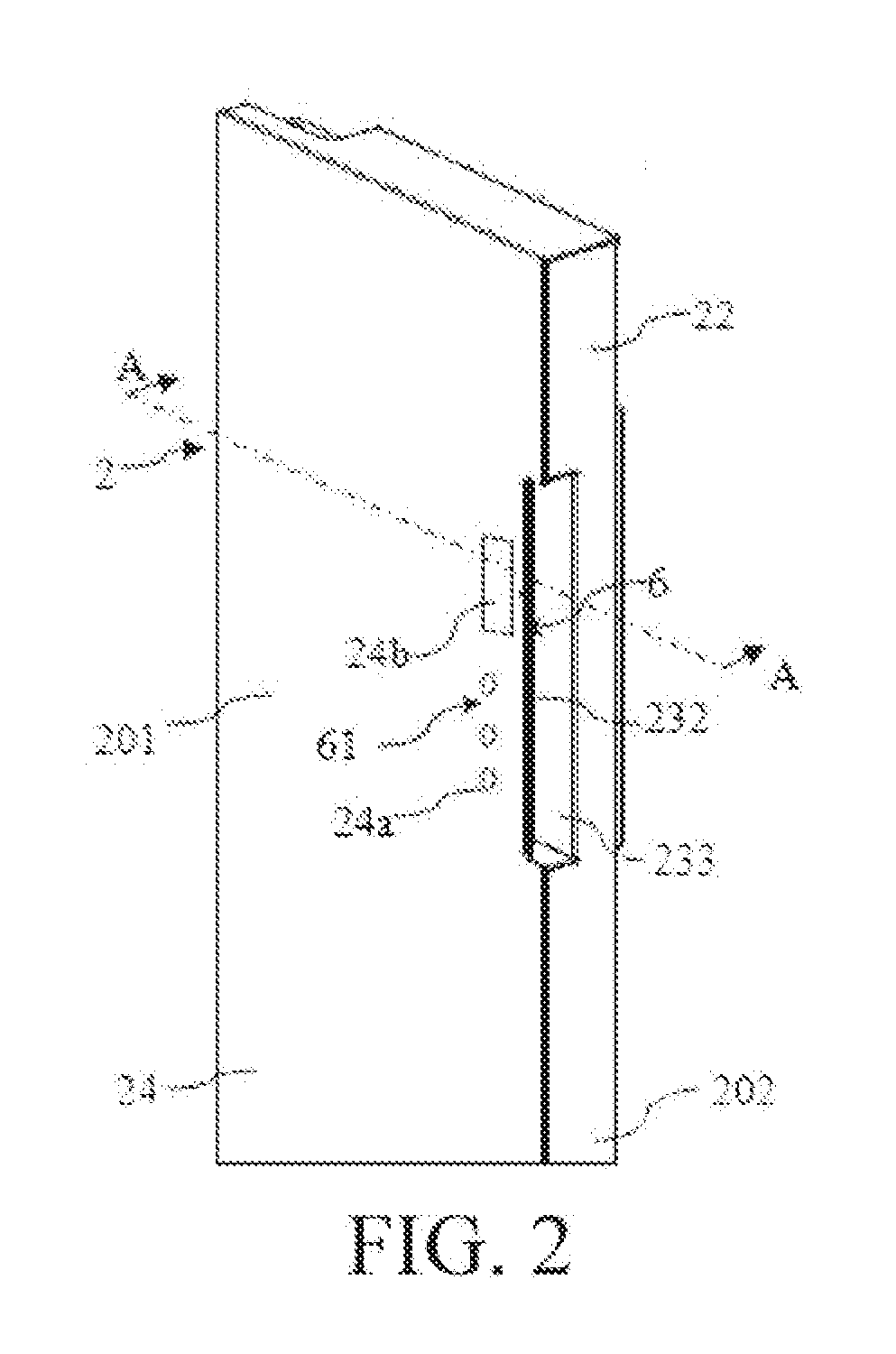

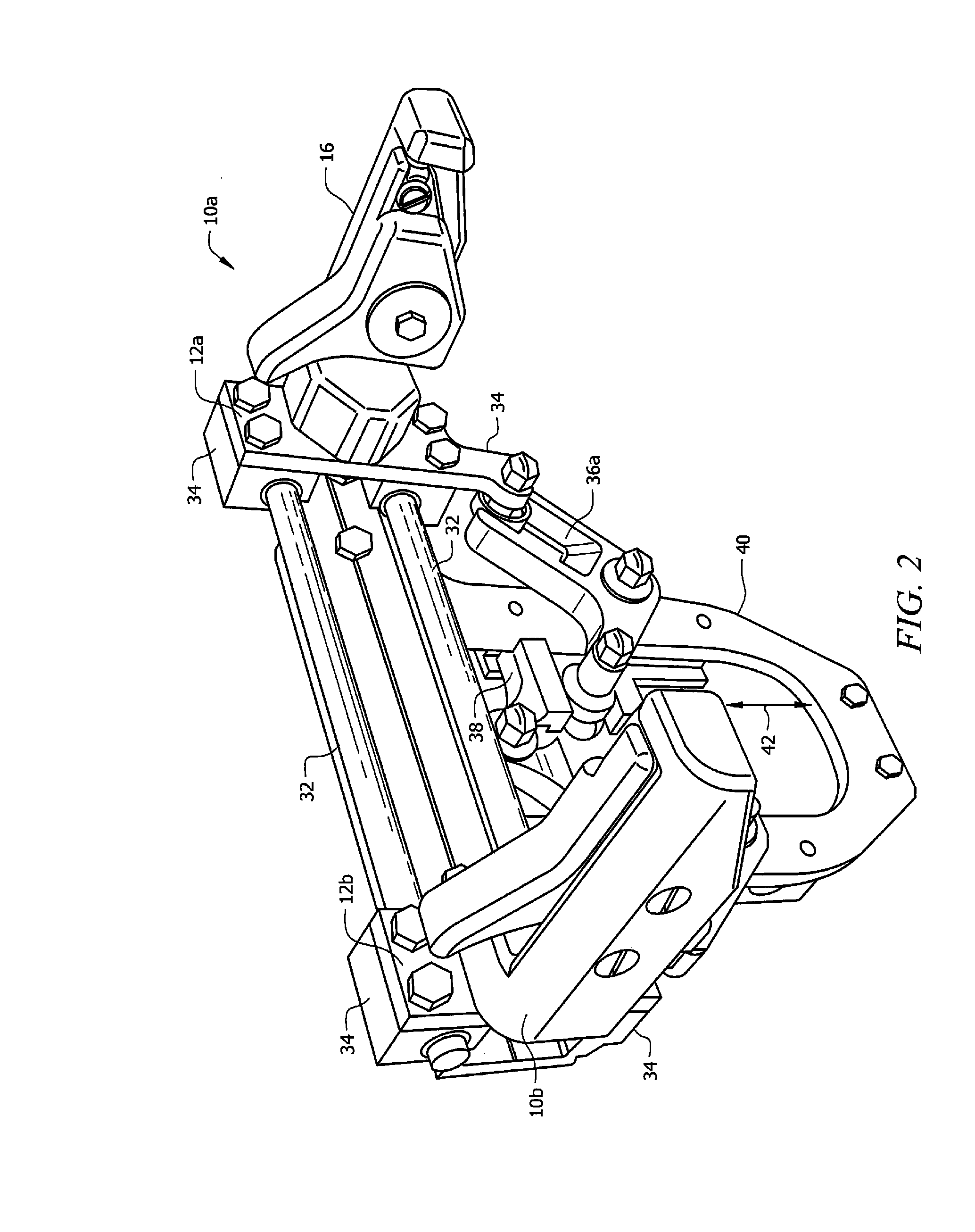

Extrusion devices for mounting wall panels

InactiveUS6588165B1Easy to insertImprove grip strengthCeilingsRoof covering using tiles/slatesEngineeringEdge space

An extrusion device for mounting a wall panel has an outer cap extending to an edge on at least one side which is positioned against an outer surface of a wall panel, having a pair of spaced-apart insertion fingers, and a receiver base having a planar mounting portion and a pair of angled receiver flanges projecting upwardly to receive the insertion fingers therein. The two-piece extrusion permits wall panels to be mounted or removed from the underlying wall structure in on-sequential order. The receiver base and cap can be provided on both sides to form an "H" type extrusion, or on only one side in a "J" type extrusion. Preferably, the outer cap is made of metal, and the tips of the insertion fingers are beveled at a slight angle of about 7° to 14° to allow easy insertion into the receiver flanges. The cap has compound water-shedding edges formed with a rounded rain-drip edge spaced in close proximity to a sharply inclined knife edge. In another variation, a one-piece extrusion device has a rear base portion and a front cover portion forming a pocket therewith, and a ramp formed on the base portion within the width of the front cover portion for gradually forcing the edge of a wall panel inserted in the pocket toward the front cover portion clear of the heads of screws used to mount the base portion to the underlying wall structure. The base portion is formed with a hook indentation on a back side of the ramp on a rear surface of the base portion, and interconnects with a "Z" type extrusion having a hook end to form a right angle connection. The one-piece extrusion may be formed as a "J" (one-sided), "H" (two sided), "C" (corner), or other suitable types.

Owner:WRIGHT JOHN T

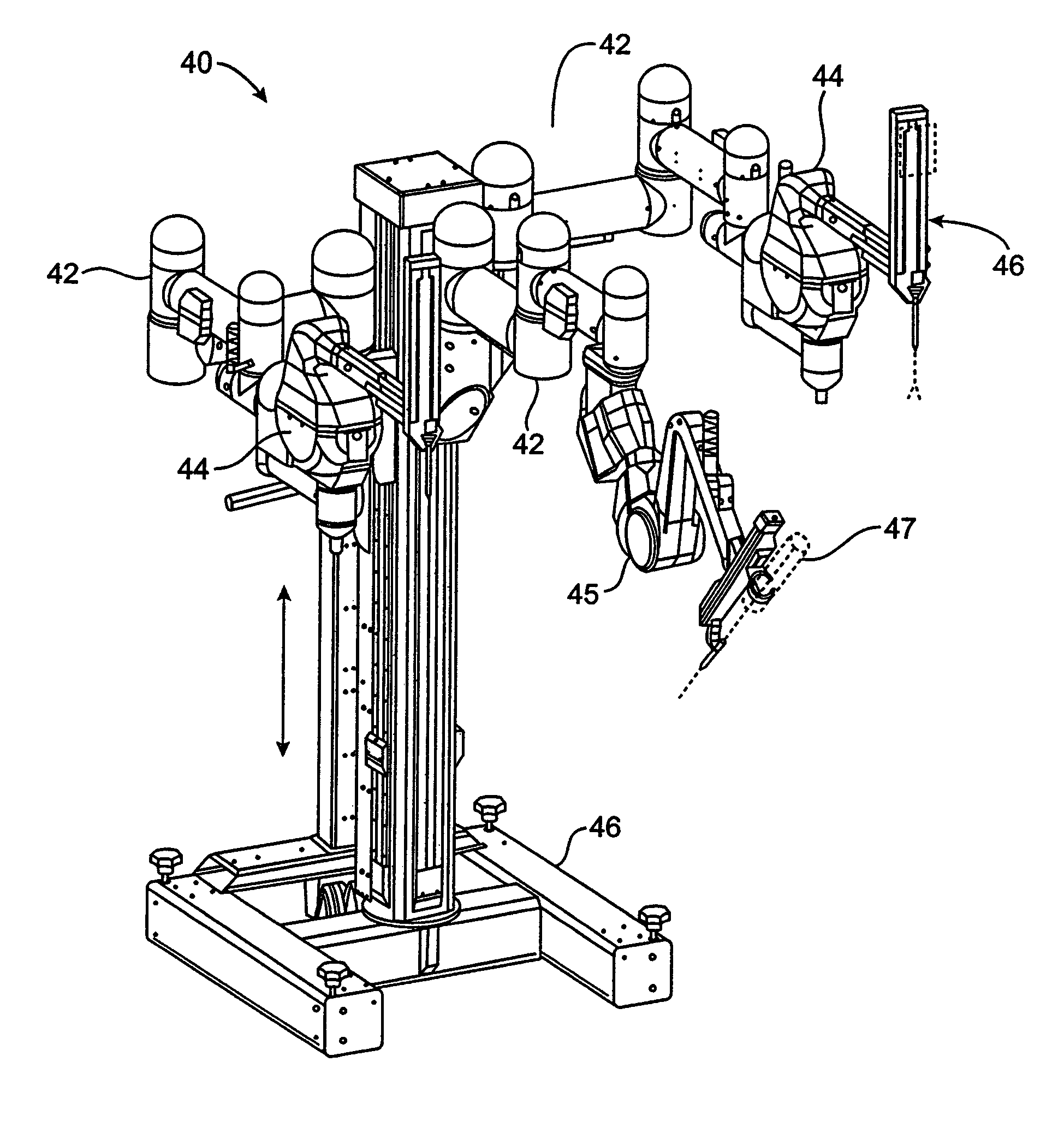

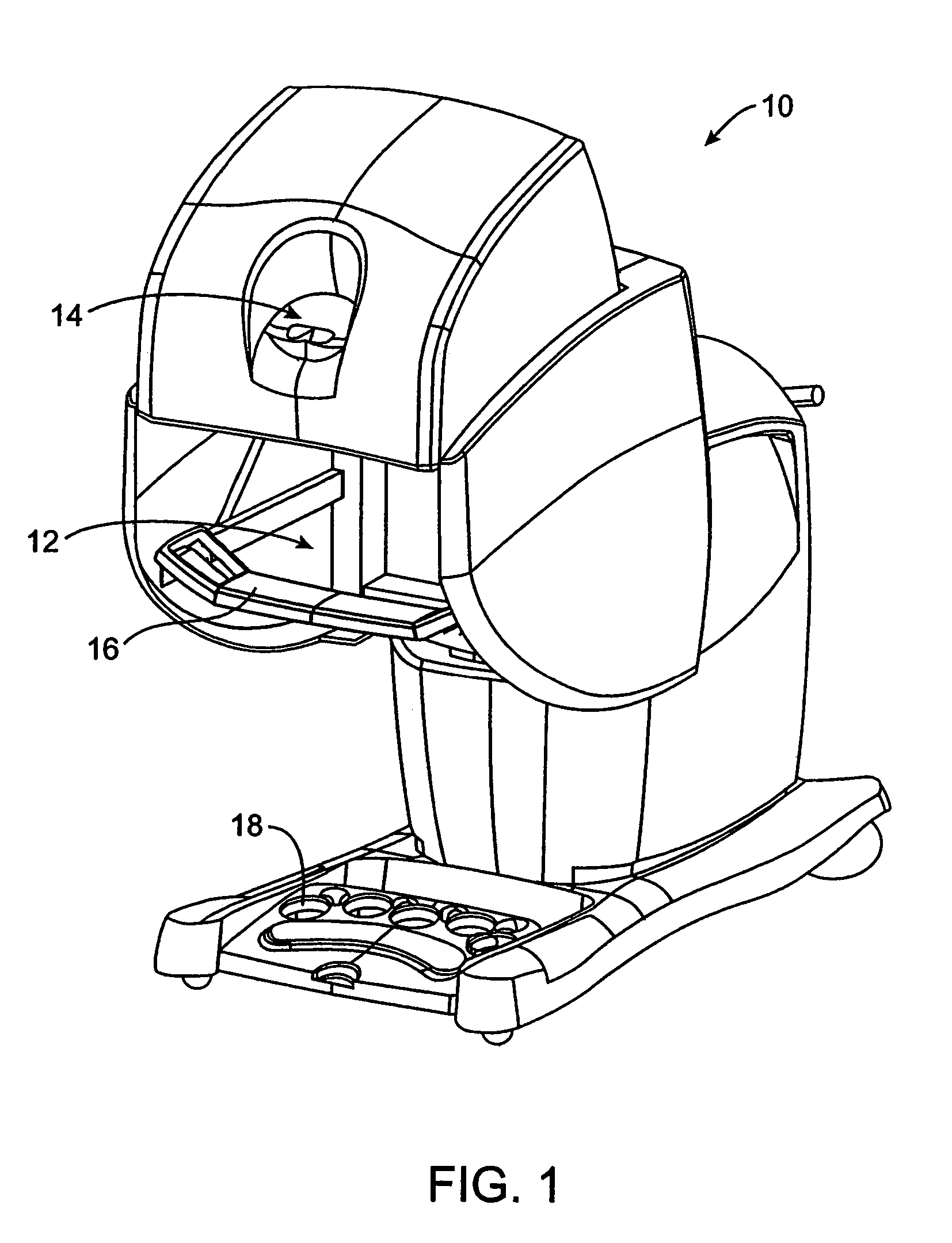

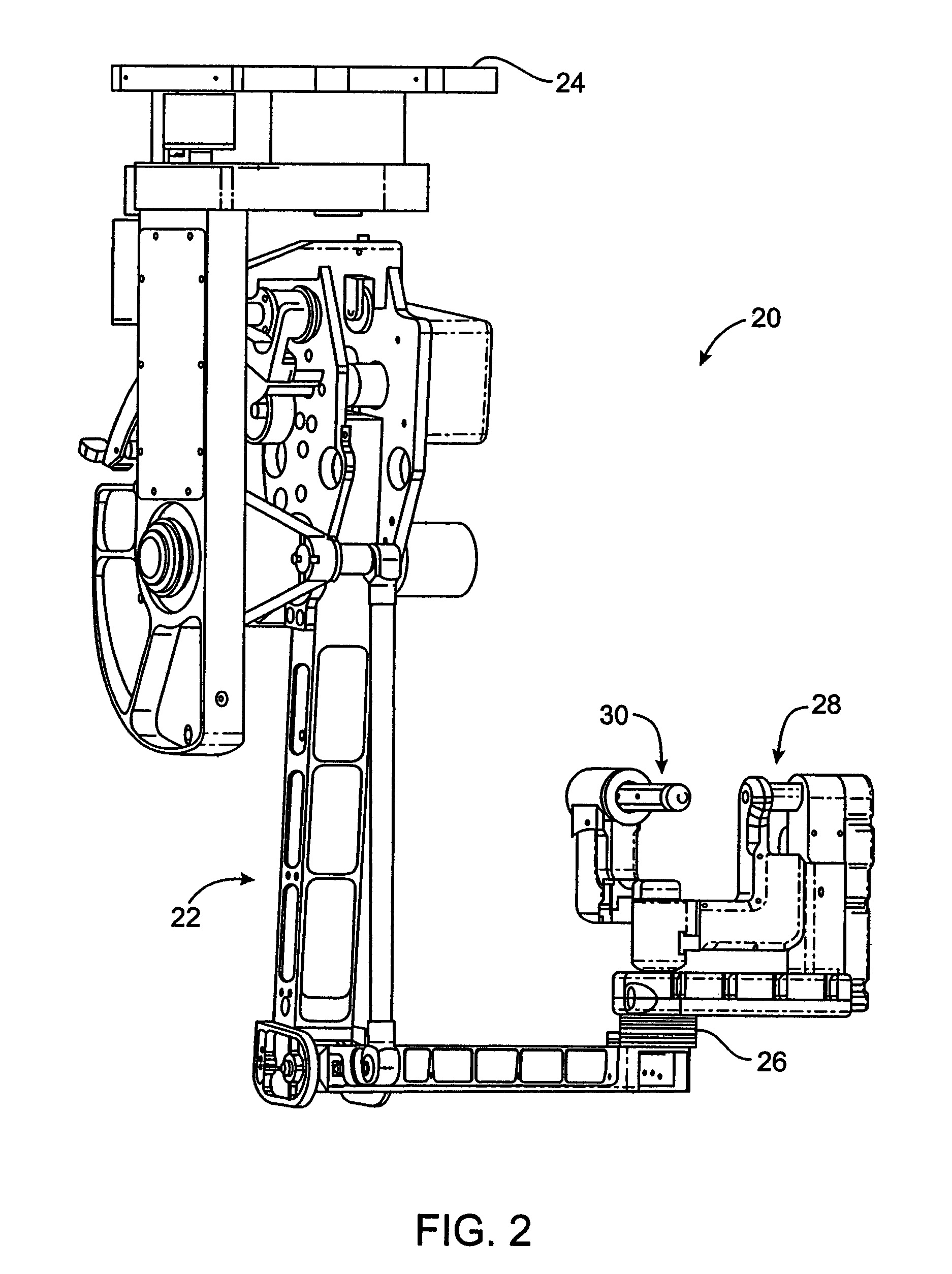

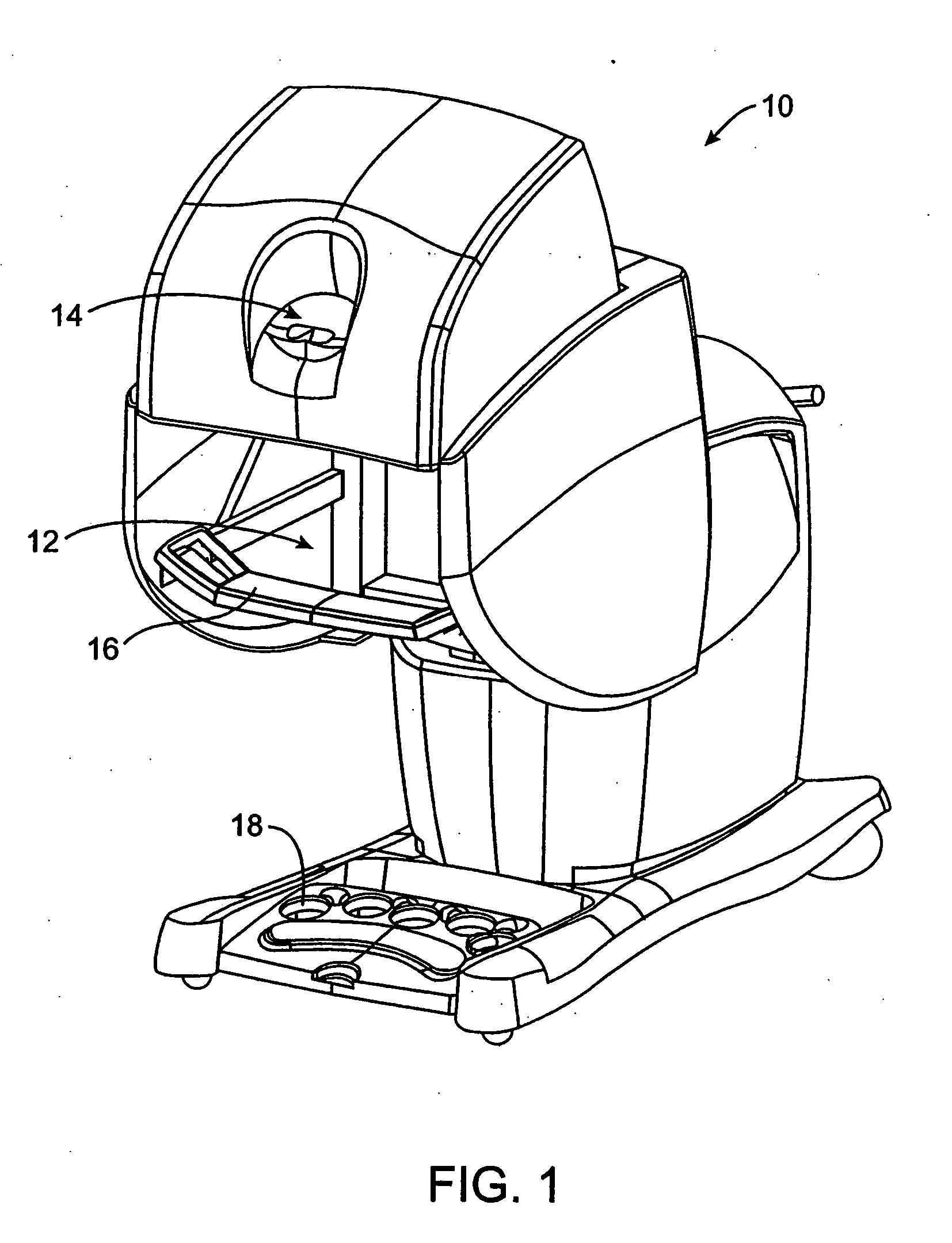

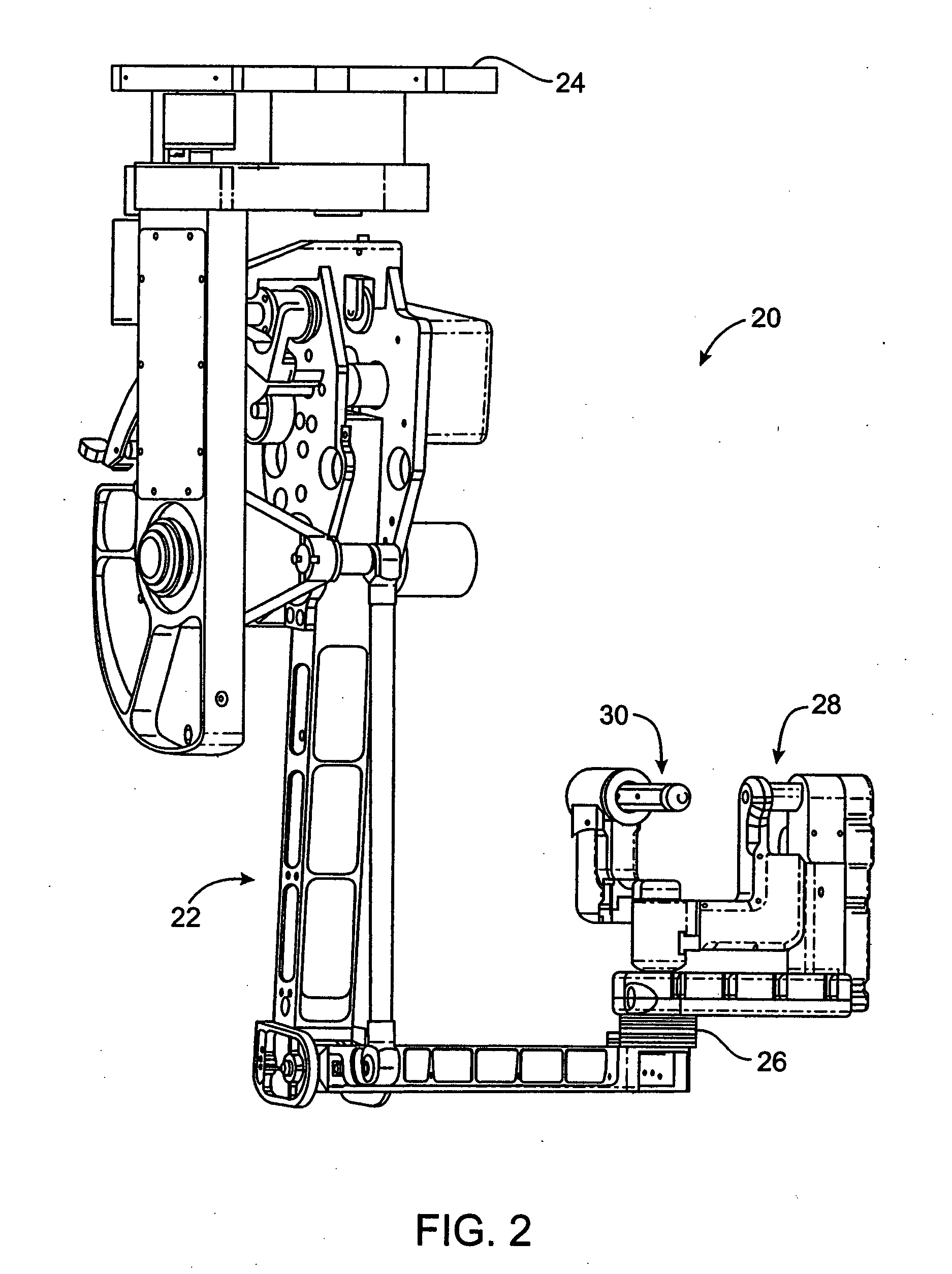

Grip strength with tactile feedback for robotic surgery

InactiveUS7373219B2Enhanced telepresenceImprove grip strengthProgramme-controlled manipulatorDigital data processing detailsSurgical robotEngineering

Surgical robots and other telepresence systems have enhanced grip actuation for manipulating tissues and objects with small sizes. A master / slave system is used in which an error signal or gain is artificially altered when grip members are near a closed configuration.

Owner:INTUITIVE SURGICAL OPERATIONS INC

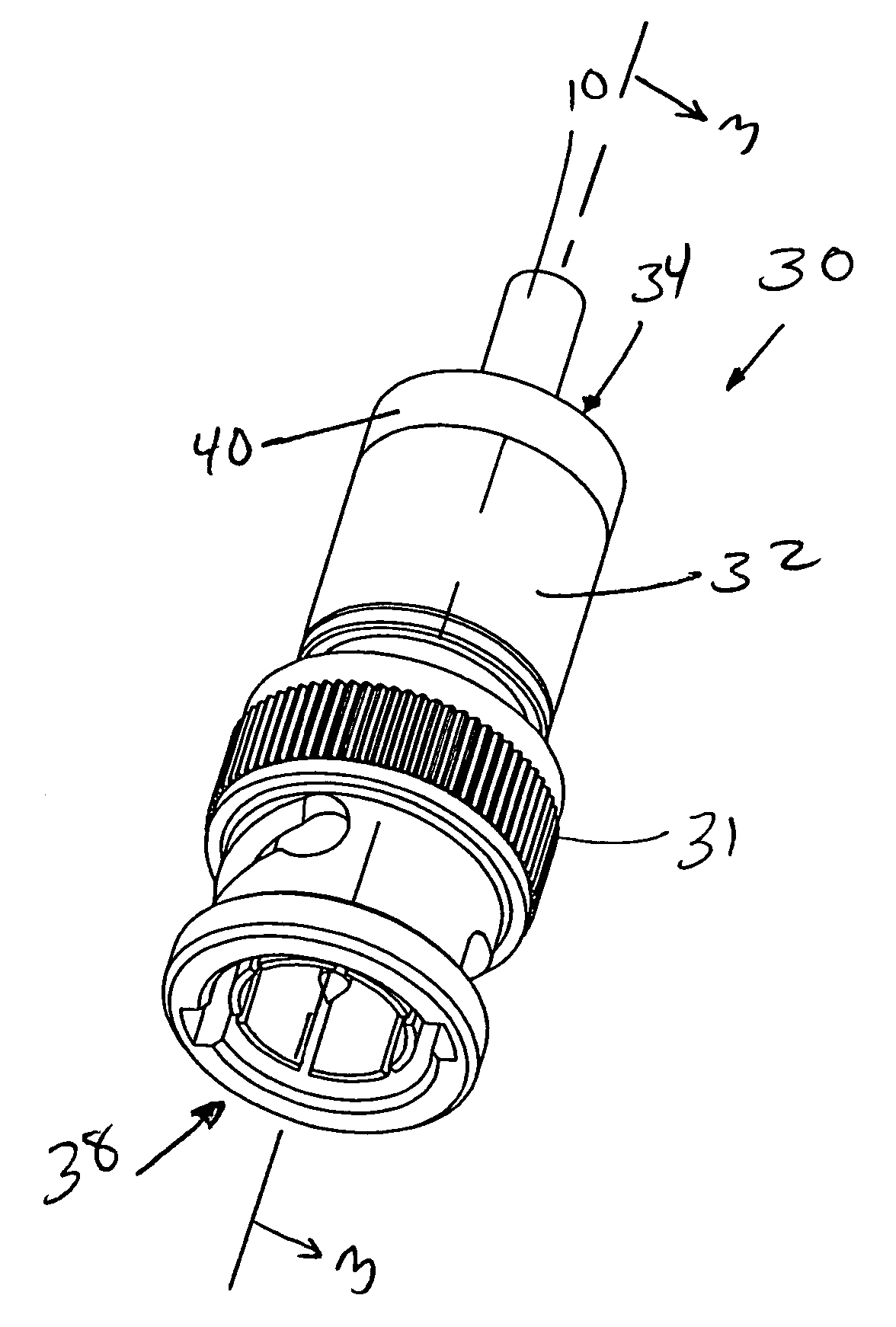

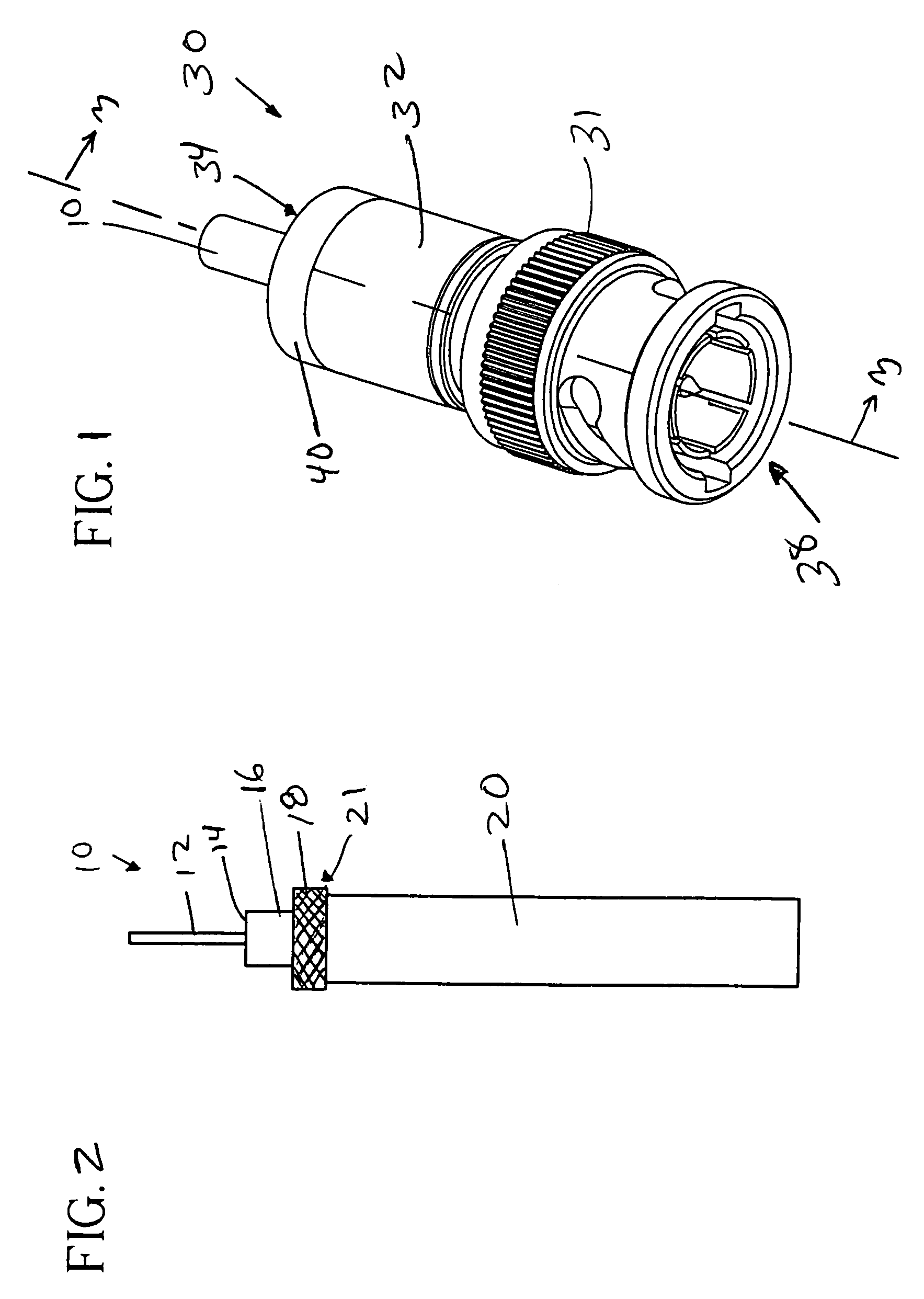

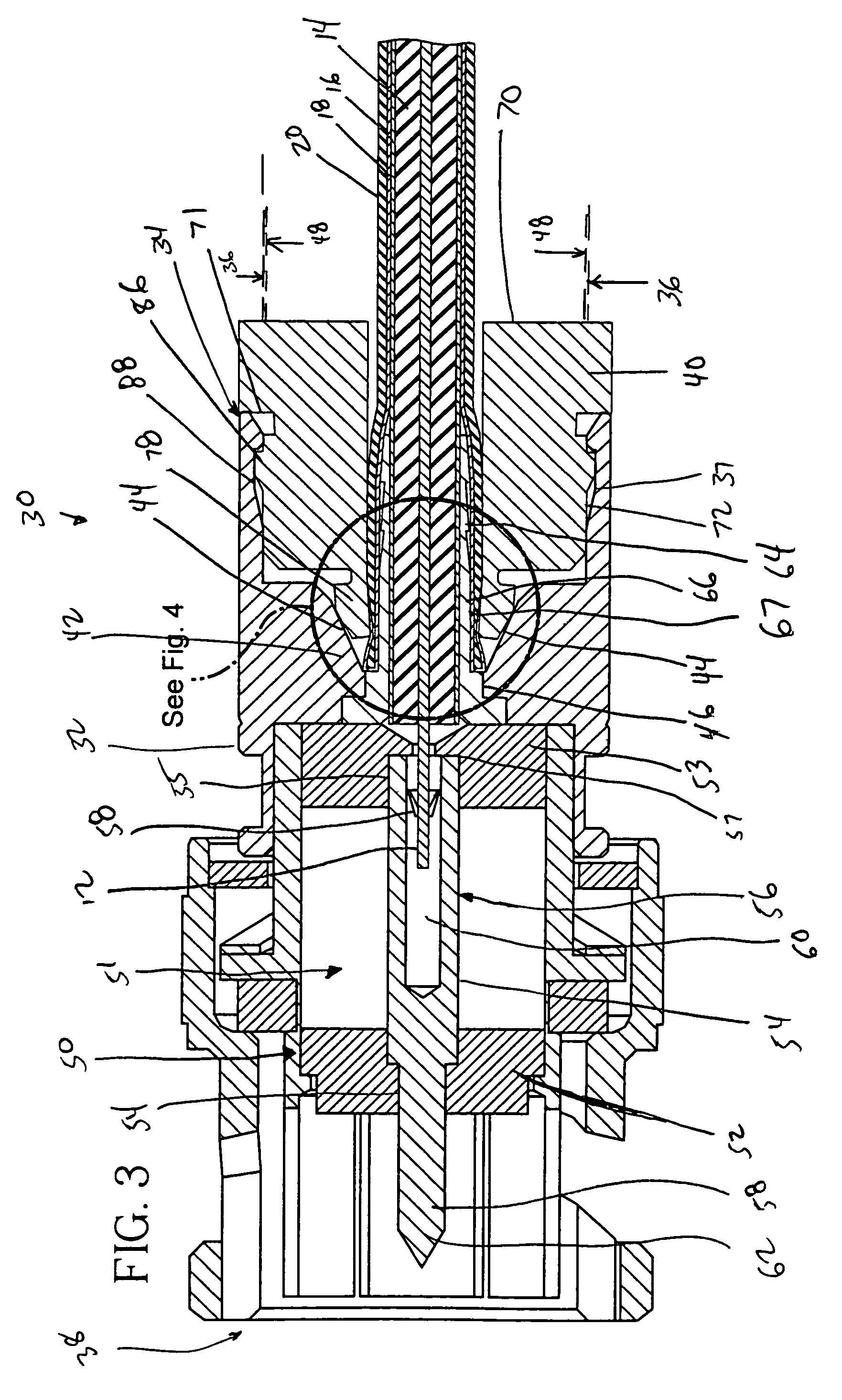

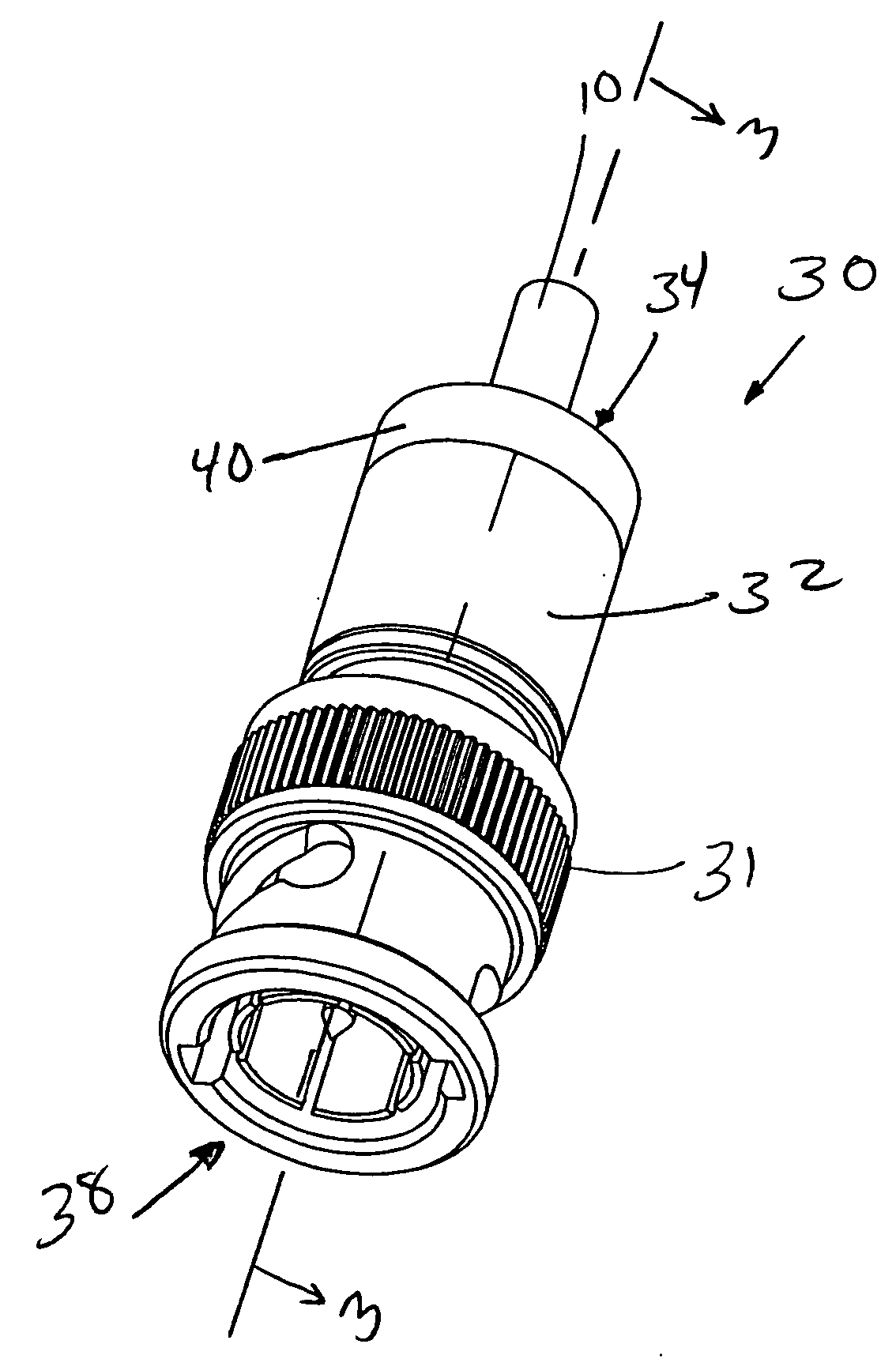

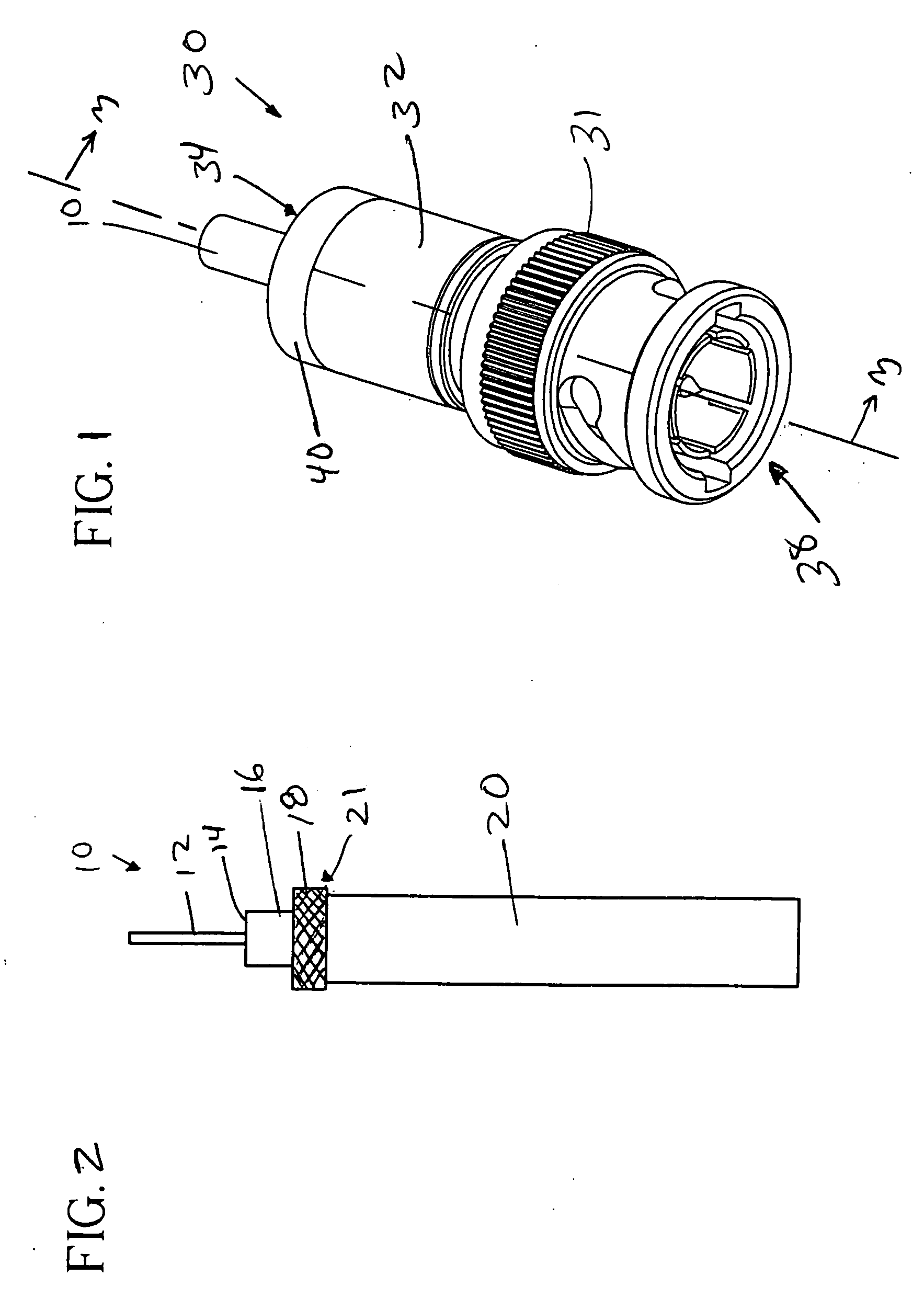

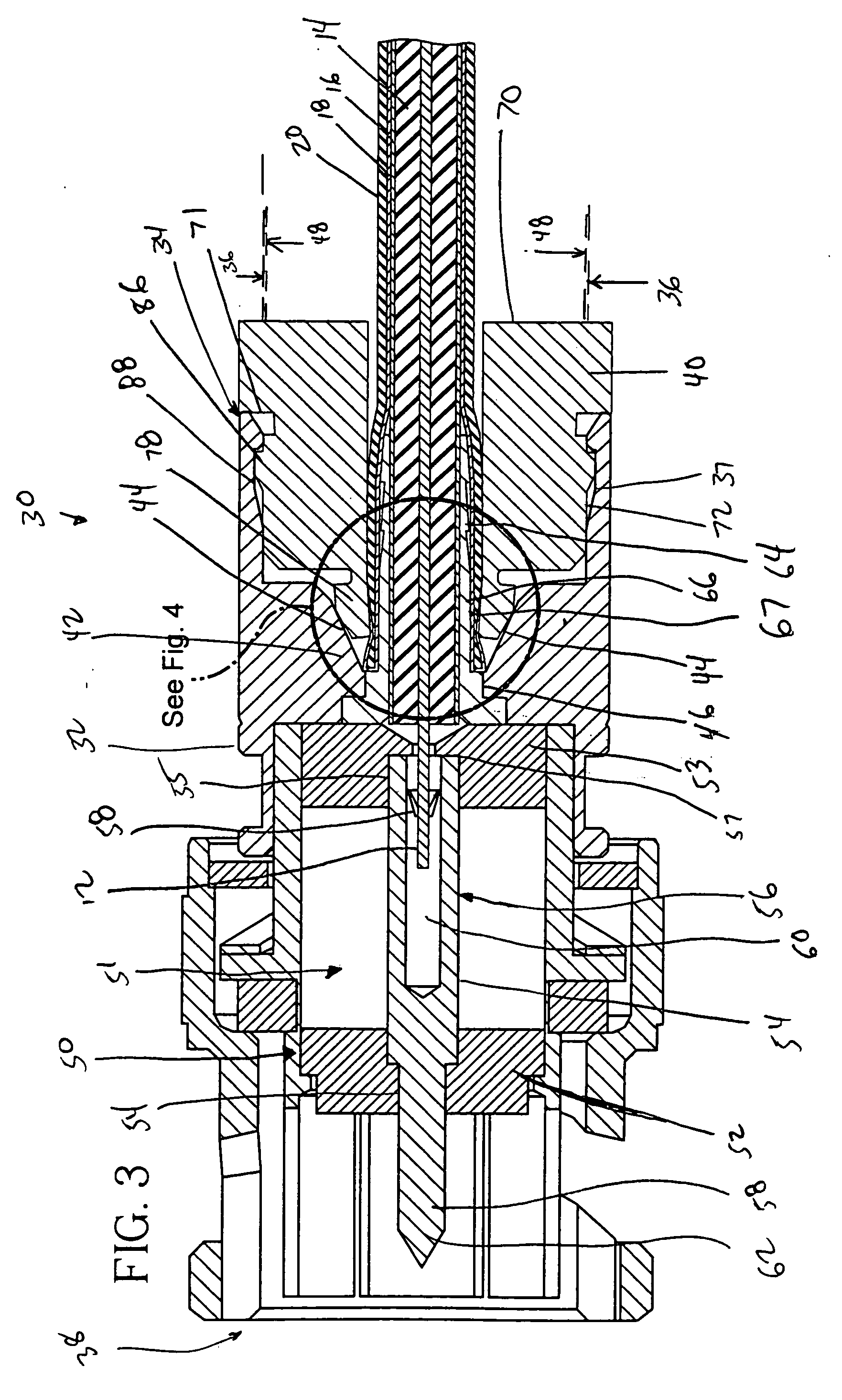

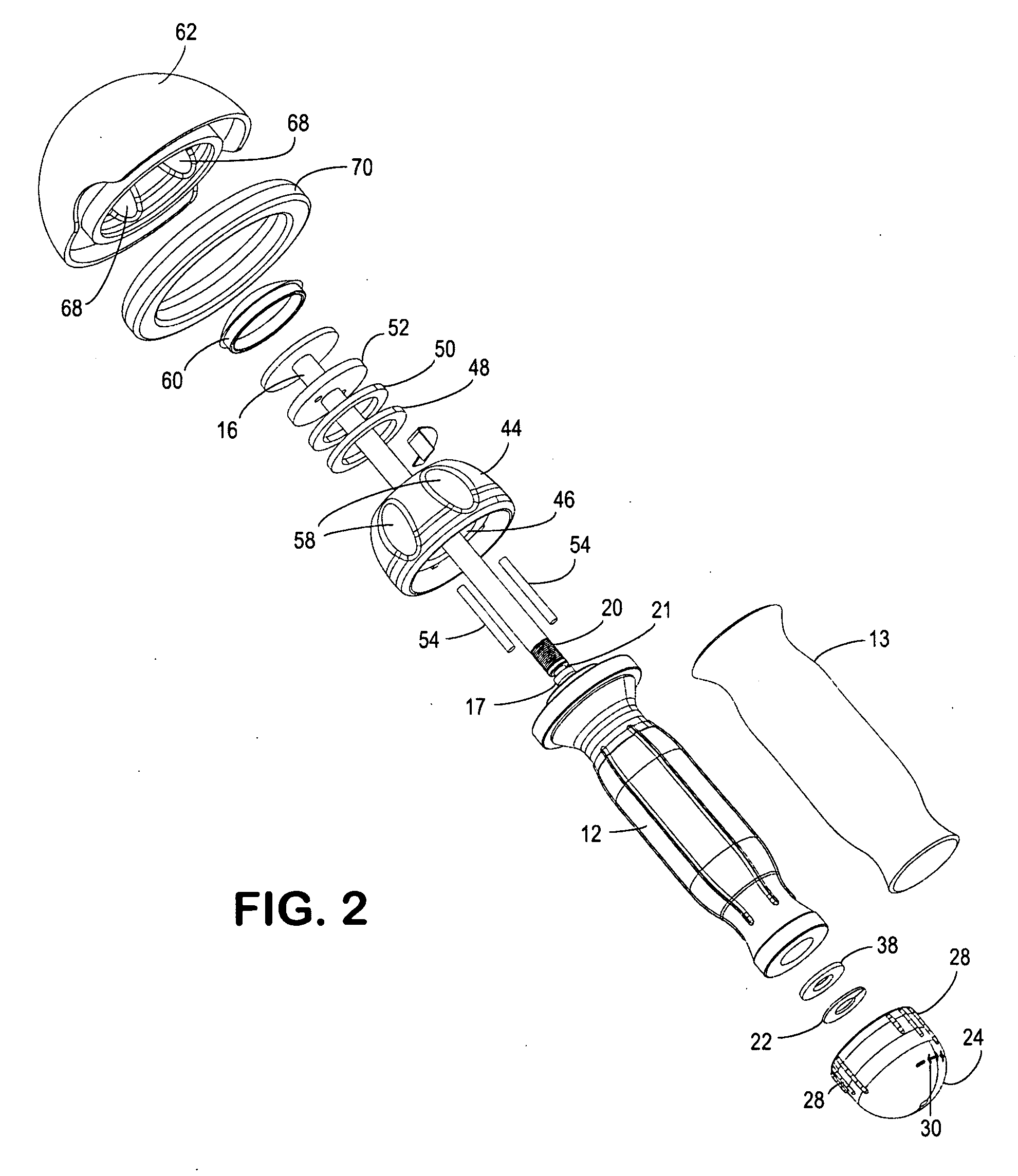

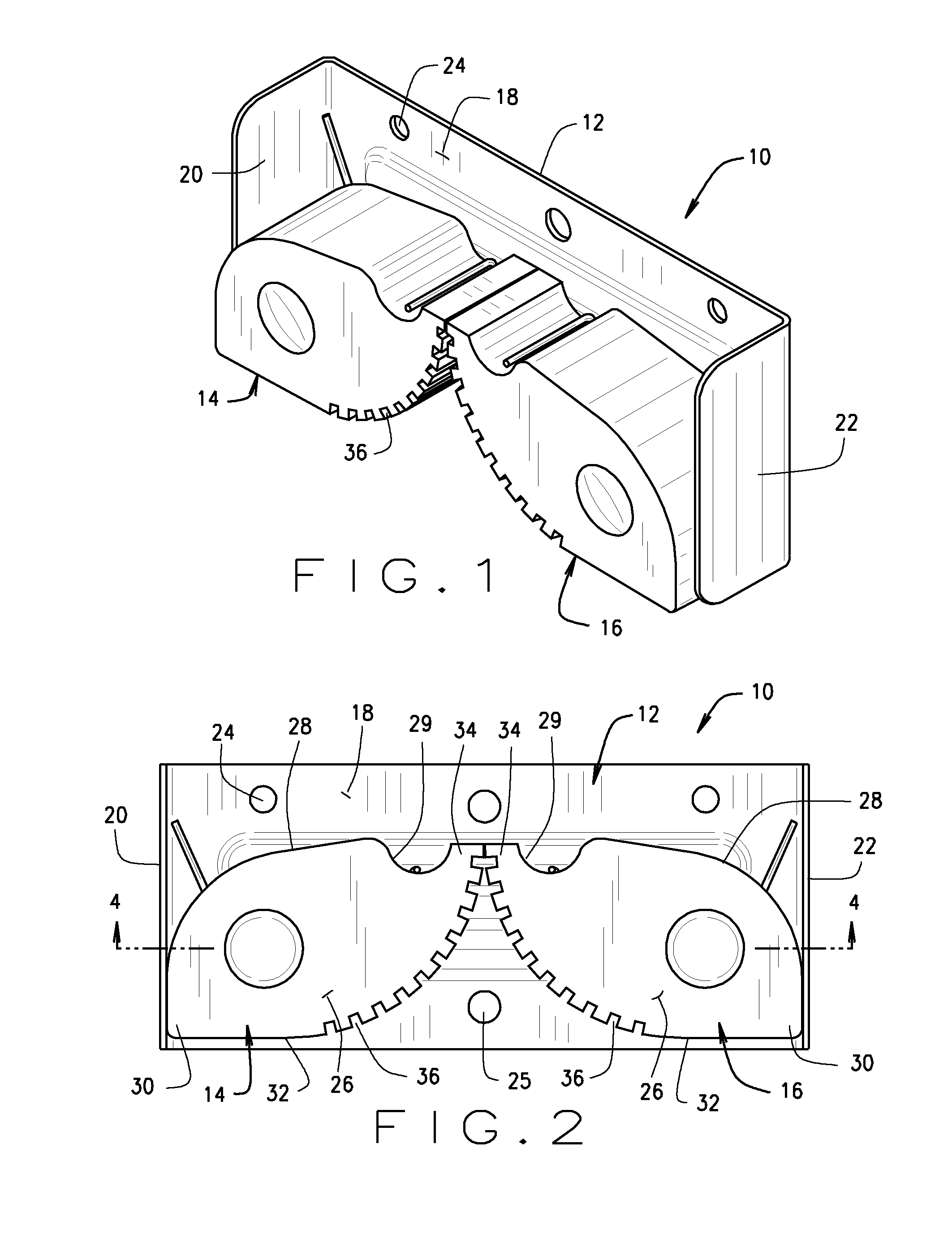

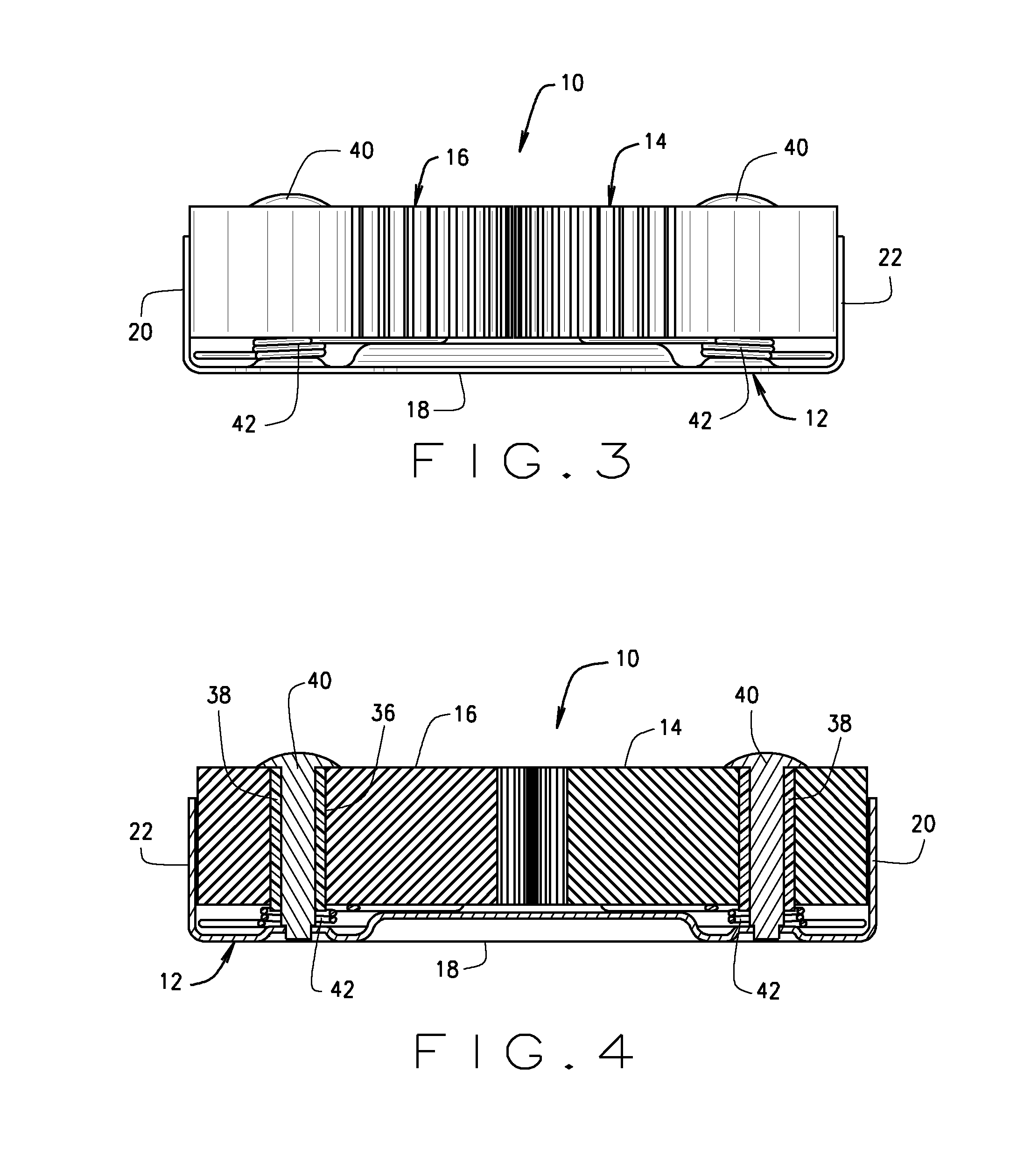

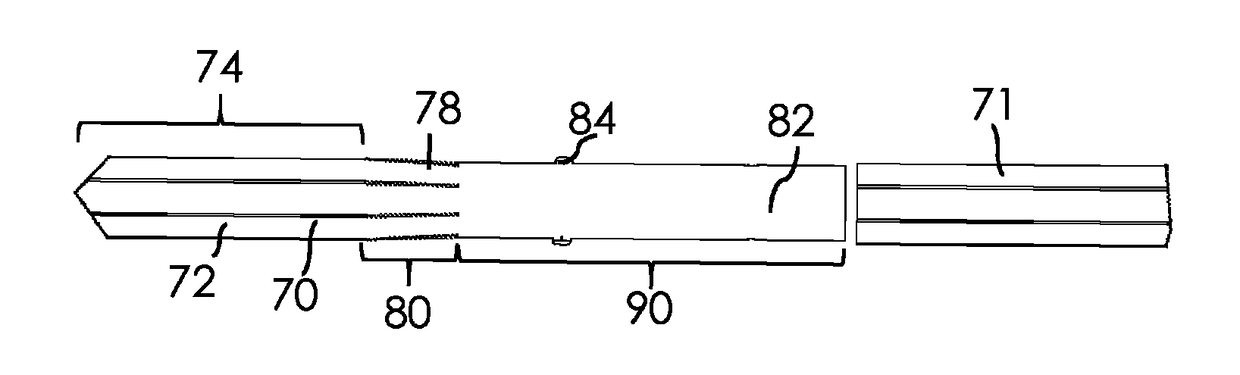

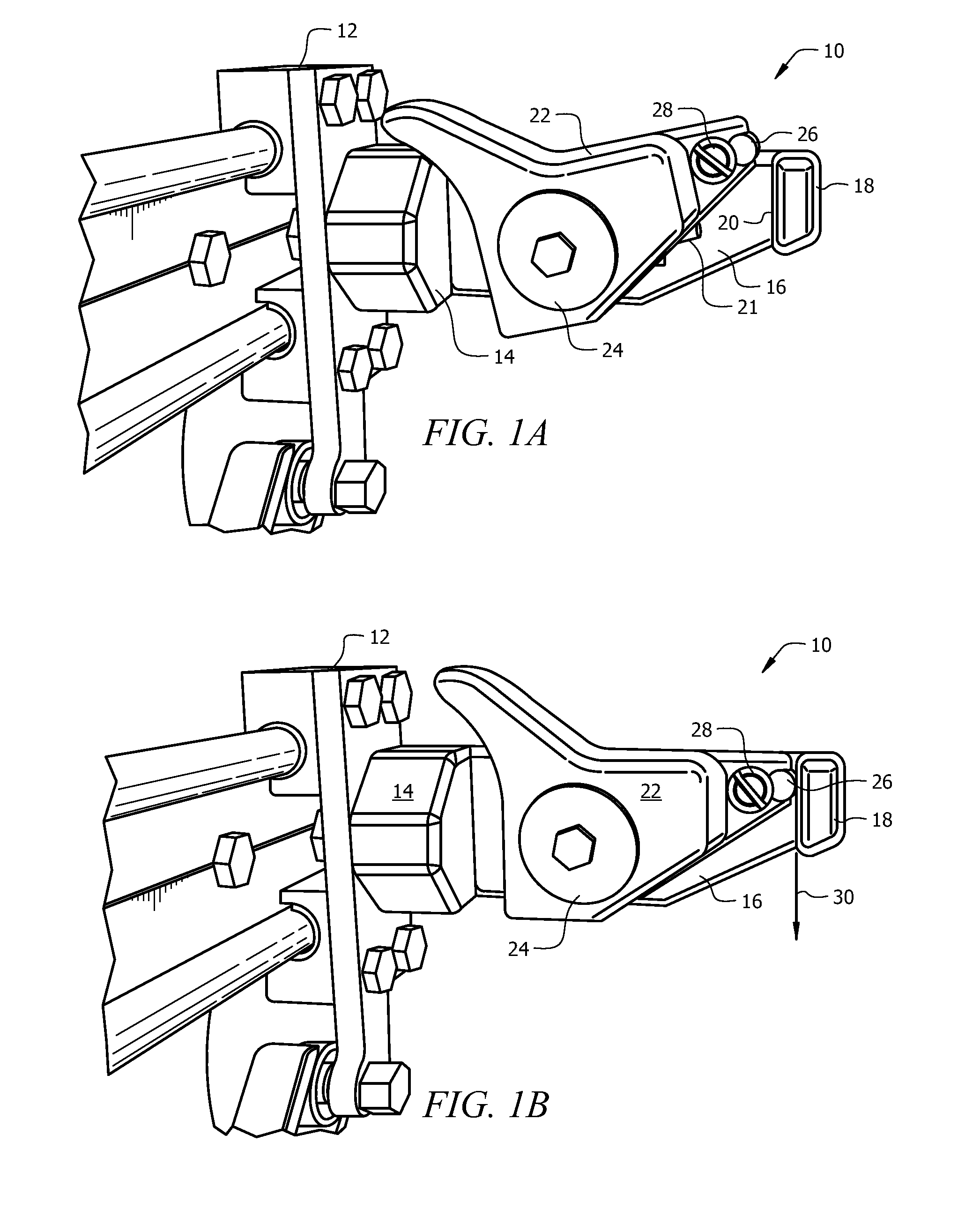

Coaxial connector with a cable gripping feature

ActiveUS7309255B2Improve gripIncrease flexibilityEngagement/disengagement of coupling partsTwo-part coupling devicesCoaxial cableEngineering

A coaxial cable connector including a connector body having a rearward sleeve receiving end and an inner engagement surface and an axially movable locking sleeve seated in the rearward sleeve receiving end of the connector body is disclosed. The locking sleeve has a rearward cable receiving end and an opposite forward connector insertion end. The forward connector insertion end is formed with at least one flexible finger for gripping a cable inserted in the sleeve when the locking sleeve is moved from a first position to a second position.

Owner:PPC BROADBAND INC

Coaxial connector with a cable gripping feature

ActiveUS20060205272A1Improve gripIncrease cable retentionElectrically conductive connectionsCoupling device detailsCoaxial cableEngineering

A coaxial cable connector including a connector body having a rearward sleeve receiving end and an inner engagement surface and an axially movable locking sleeve seated in the rearward sleeve receiving end of the connector body is disclosed. The locking sleeve has a rearward cable receiving end and an opposite forward connector insertion end. The forward connector insertion end is formed with at least one flexible finger for gripping a cable inserted in the sleeve when the locking sleeve is moved from a first position to a second position.

Owner:PPC BROADBAND INC

Grip strength with tactile feedback for robotic surgery

InactiveUS20060030840A1Enhanced telepresenceImprove grip strengthProgramme-controlled manipulatorDigital data processing detailsSurgical robotEngineering

Owner:INTUITIVE SURGICAL OPERATIONS INC

Garments

Owner:TE KANAWA KOHI

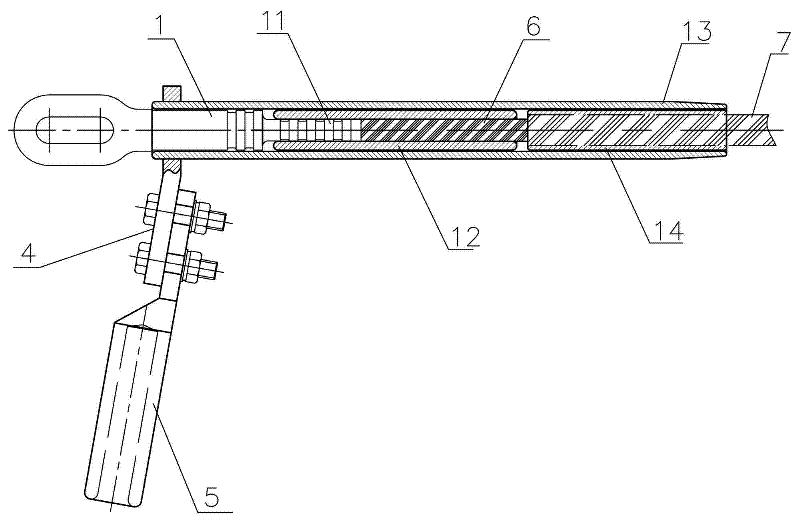

Universal multidirectional exerciser for exercising hand, wrist and forearm in multiple planes of motion with adjustable resistance

InactiveUS20100267523A1Increasing finger strengthImprove grip strengthDumb-bellsFrictional force resistorsElectrical resistance and conductanceEngineering

The present invention provides a multidirectional exerciser for hand, wrist and forearm comprising a handle having an axial opening through which a bolt extends. A spring means is around one end of the bolt disposed against an adjustment ring. A resistance knob is mounted on the adjustment ring. A pressure plate is mounted at the opposite end of the handle between the handle and the head of the bolt. At least one clutch disc is disposed against the pressure plate. A knob is mounted around the pressure plate and clutch disc, mounted for relative rotational movement with respect to the handle. The wrists and hands are exercised by holding the handle in one hand and the knob / grip member in the other hand, and repetitively twisting the handle and knob / grip member in opposite directions. A detachable grip member is mounted over said knob and the detachable grip member further comprises a gyro ring and a squeeze grip strengthener.

Owner:WILKINSON WILLIAM T

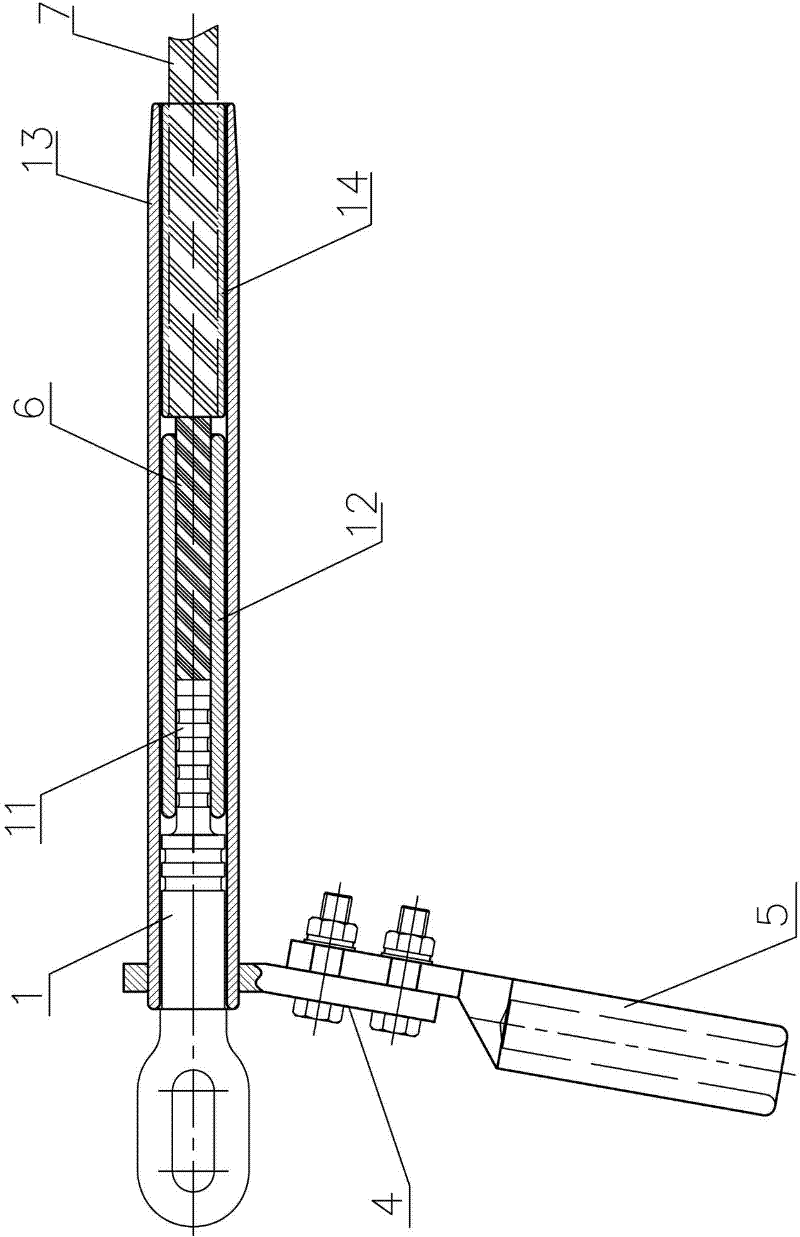

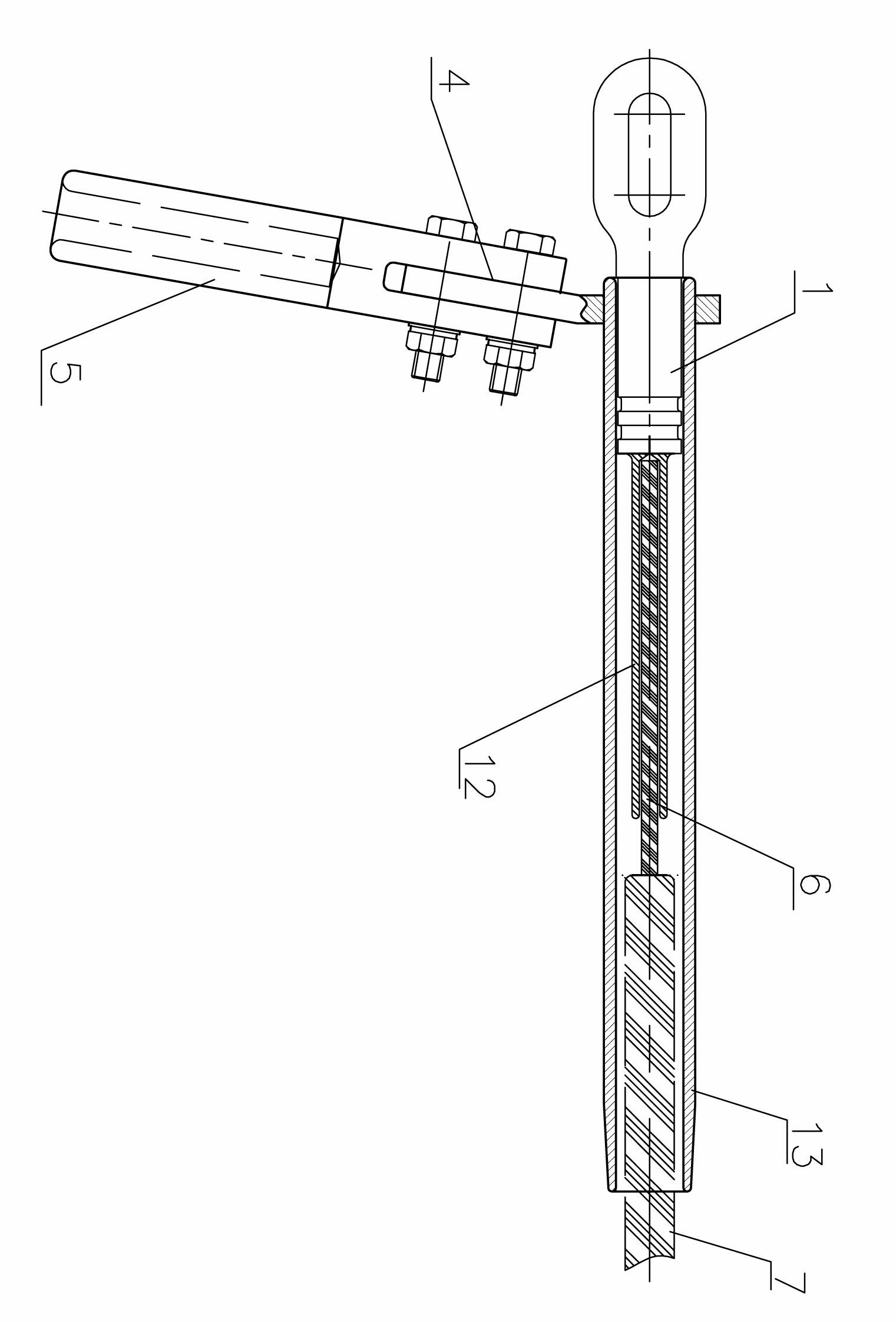

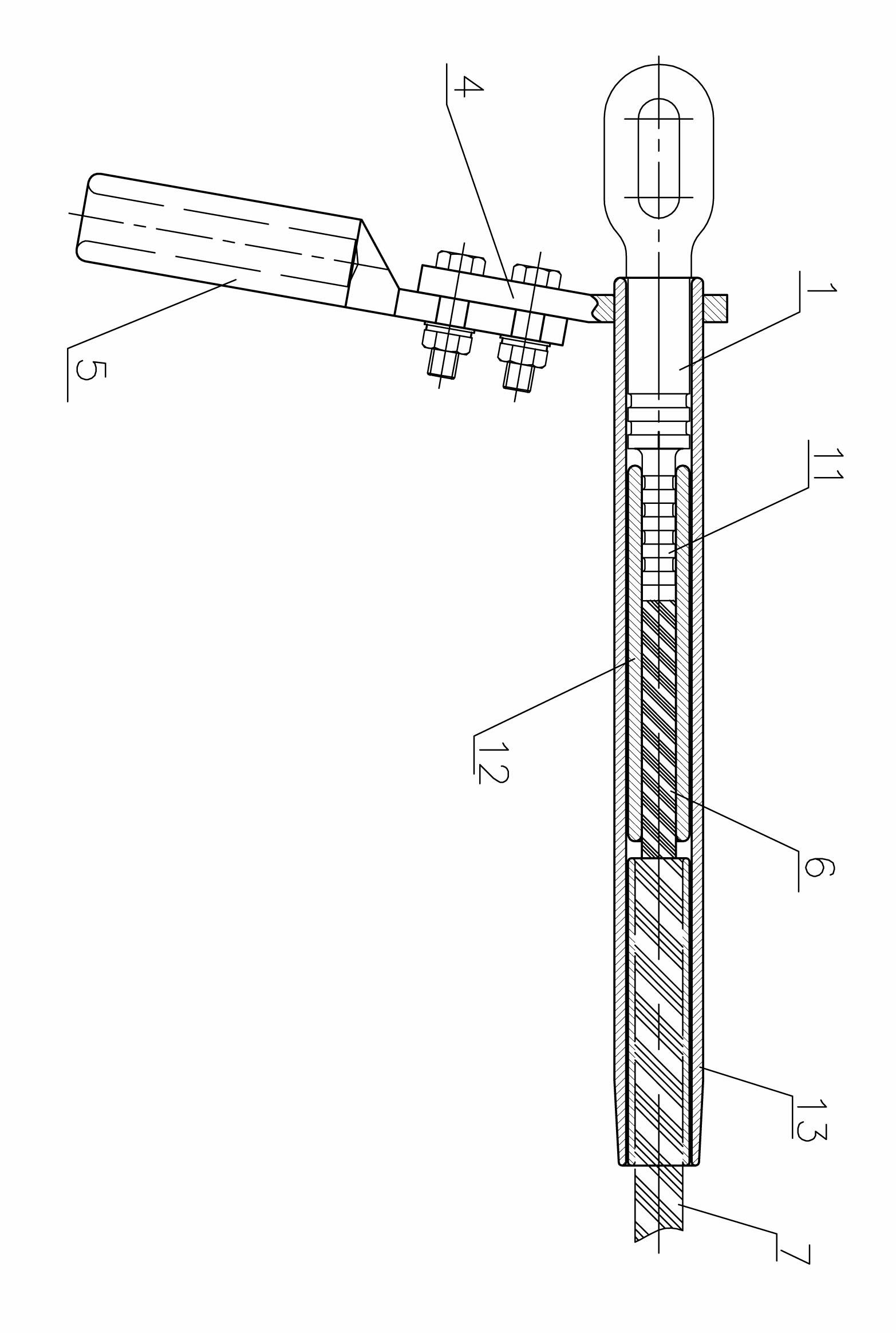

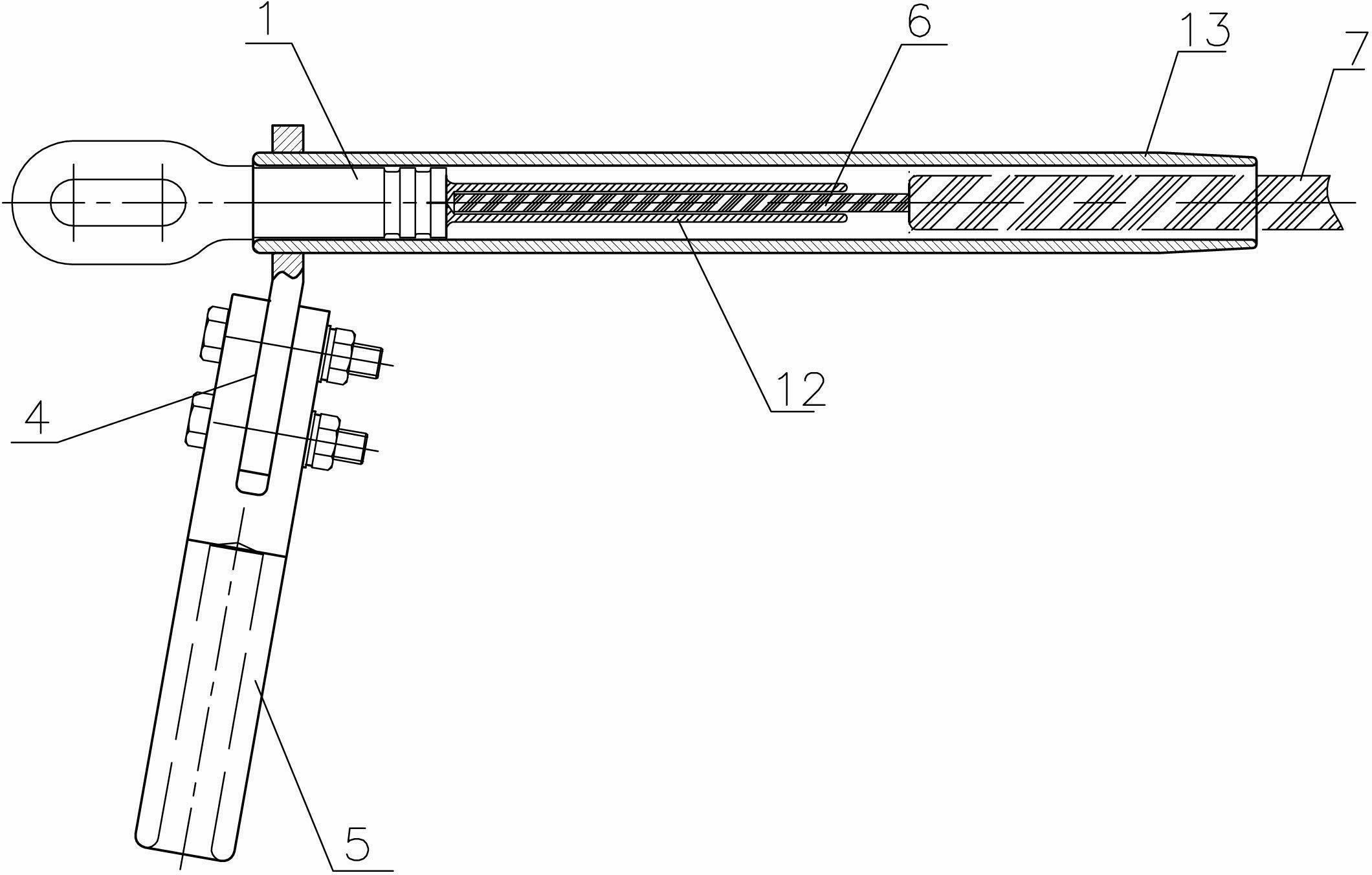

Strain clamp of aluminum alloy core aluminum stranded wire

InactiveCN102237660AGuaranteed uniformityImprove grip strengthAdjusting/maintaining mechanical tensionMaterials scienceAluminium alloy

The invention discloses a strain clamp of an aluminum alloy core aluminum stranded wire. The strain clamp comprises a steel anchor and a jumper clamp which is connected with the steel anchor, wherein an anchor head is connected with the rear end of the steel anchor; an external surface of the anchor head, from inside to outside, is sequentially sleeved with an inner-layer pressing connection pipe and an outer-layer sleeve; and a cavity into which an inner core of the aluminum alloy core aluminum stranded wire to be connected is embedded is formed in the inner-layer pressing connection pipe. By adding the inner-layer pressing connection pipe and the outer-layer sleeve which sleeves the inner-layer pressing connection pipe, when the aluminum alloy core aluminum stranded wire presses the strain clamp, a pressing force can be applied to a lead through two pipe walls, so the pressing force is dispersed to the forced steel anchor, the aluminum stranded wire can be forced uniformly, and the grip strength of the strain clamp on the aluminum stranded wire is improved. The strain clamp of the aluminum alloy core aluminum stranded wire is simple and reasonable in structure, convenient and reliable to anchor, reasonably stressed, and widely applicable to erection of a power transmission line of the aluminum alloy core aluminum stranded wire.

Owner:GUANGZHOU XYHY ELECTRIC POWER LINE EQUIP

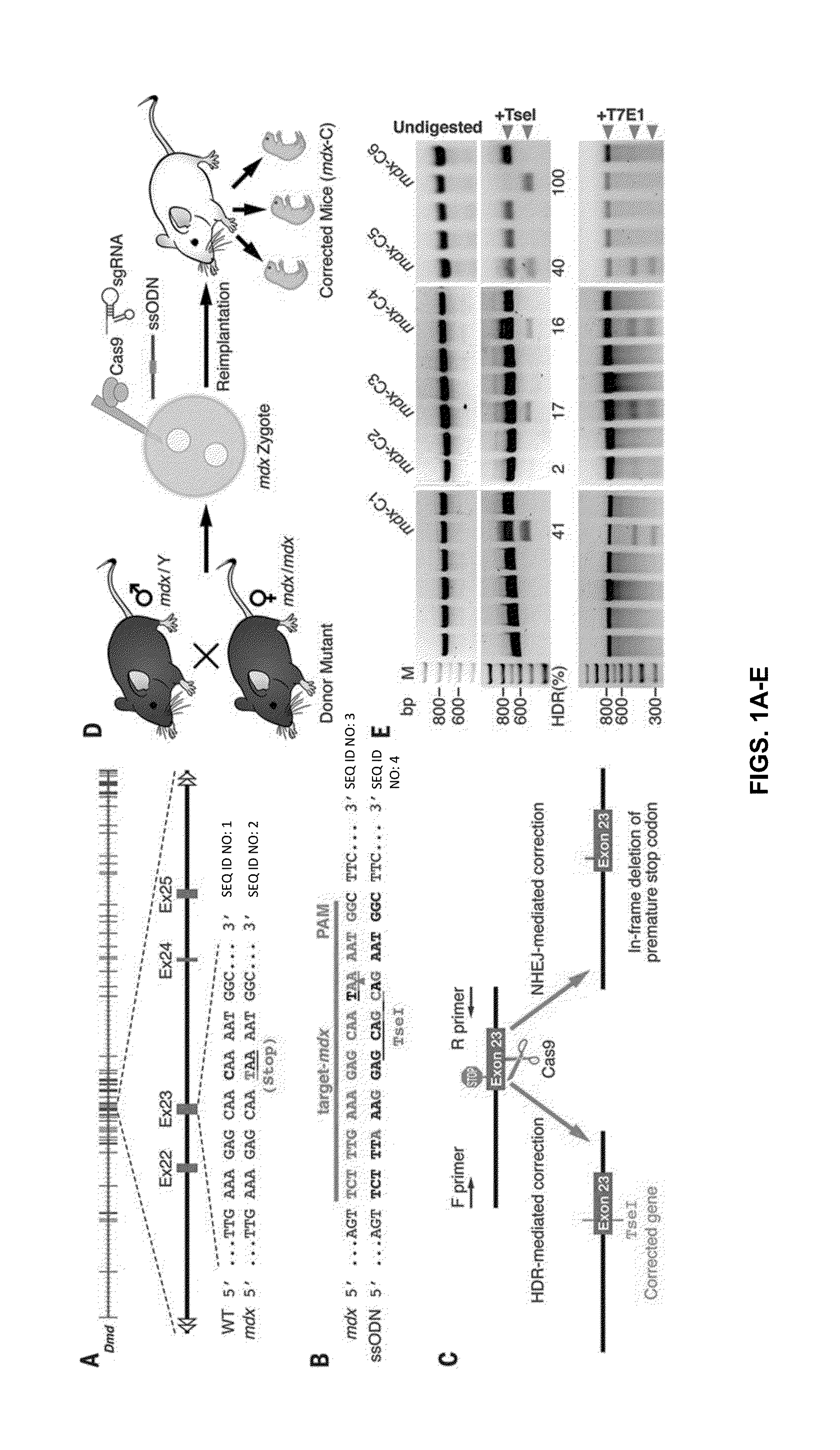

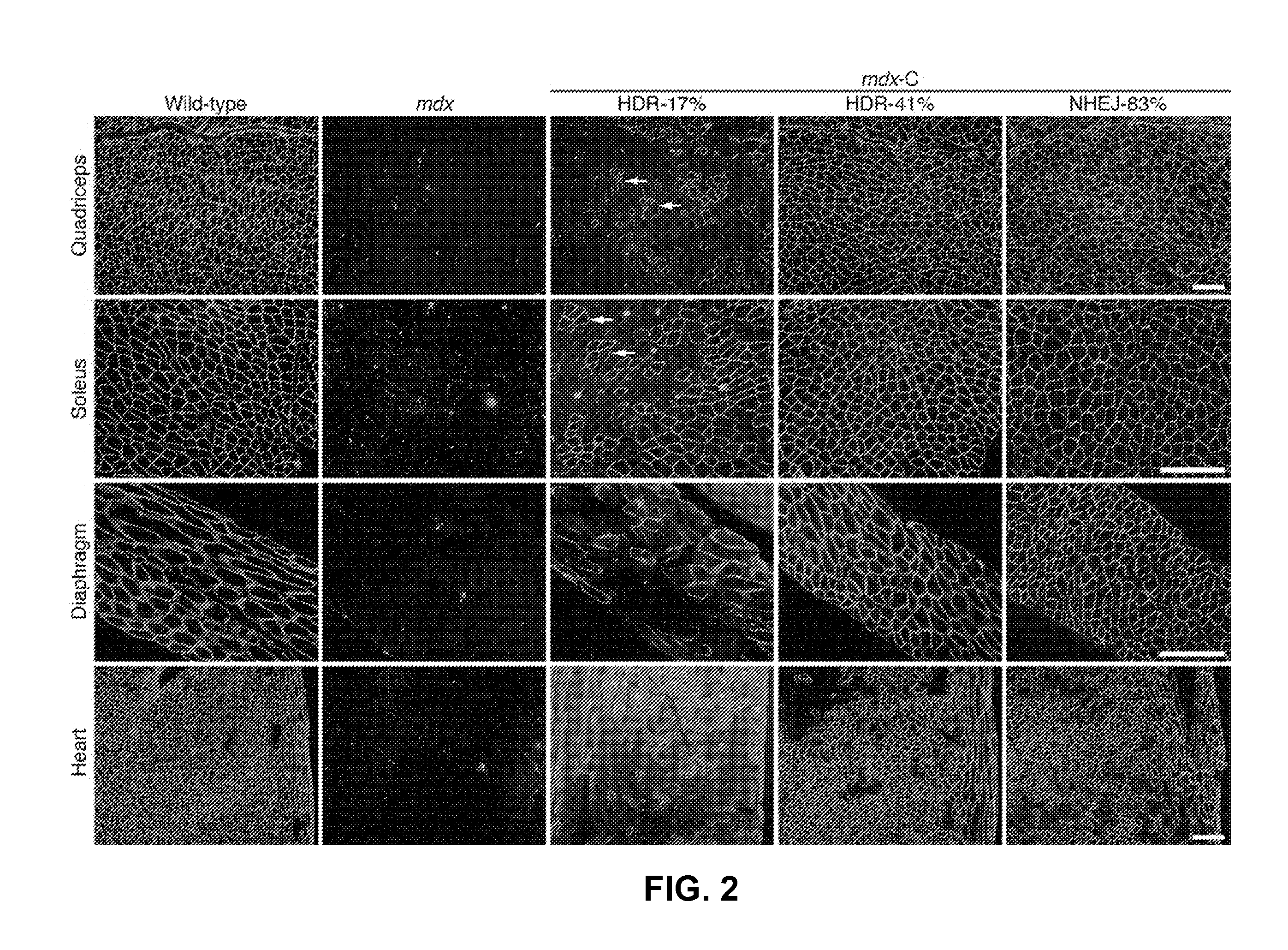

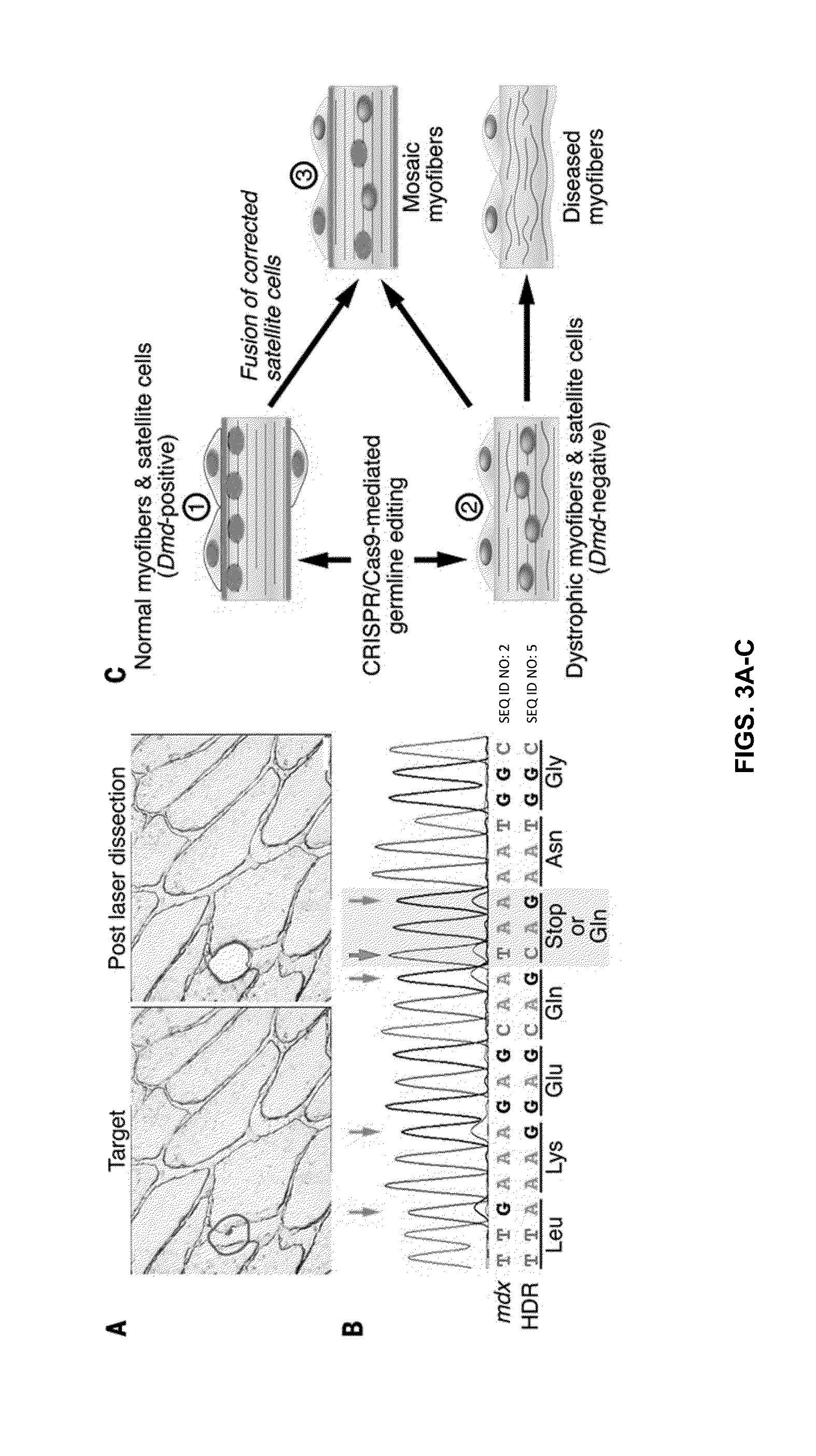

Prevention of muscular dystrophy by crispr/cas9-mediated gene editing

InactiveUS20160058889A1Lower Level RequirementsImprove grip strengthSplicing alterationPeptide/protein ingredientsDiseaseIn vivo

Duchenne muscular dystrophy (DMD) is an inherited X-linked disease caused by mutations in the gene encoding dystrophin, a protein required for muscle fiber integrity. The disclosure reports CRISPR / Cas9-mediated gene editing (Myo-editing) is effective at correcting the dystrophin gene mutation in the mdx mice, a model for DMD. Further, the disclosure reports optimization of germline editing of mdx mice by engineering the permanent skipping of mutant exon (exon 23) and extending exon skipping to also correct the disease by post-natal delivery of adeno-associate virus (AAV). AAV-mediated Myo-editing can efficiently rescue the reading frame of dystrophin in mdx mice in vivo. The disclosure reports means of Myo-editing-mediated exon skipping has been successfully advanced from somatic tissues in mice to human DMD patients-derived iPSCs (induced pluripotent stem cells). Custom Myo-editing was performed on iPSCs from patients with differing mutations and successfully restored dystrophin protein expression for all mutations in iPSCs-derived cardiomyocytes.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

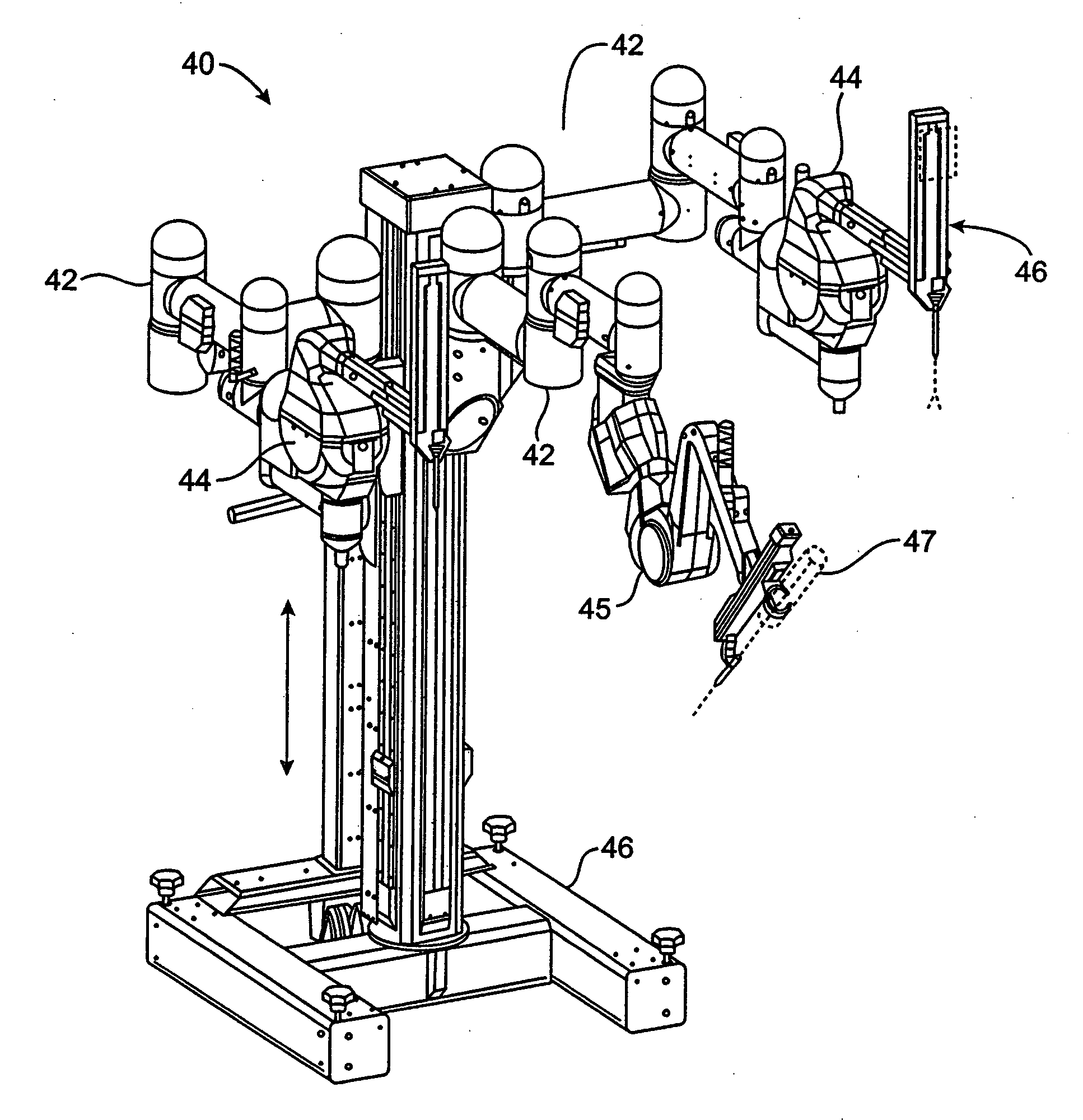

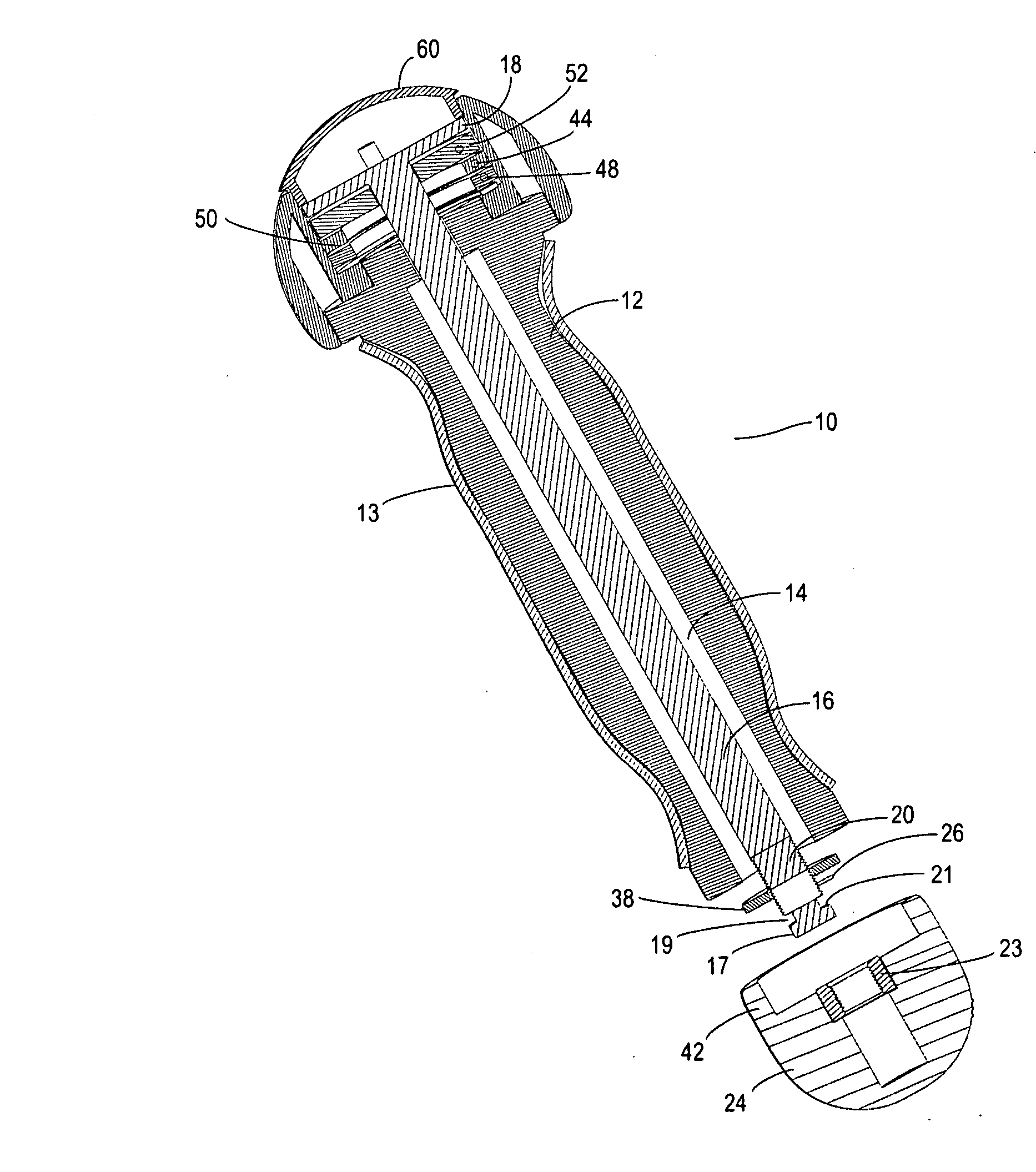

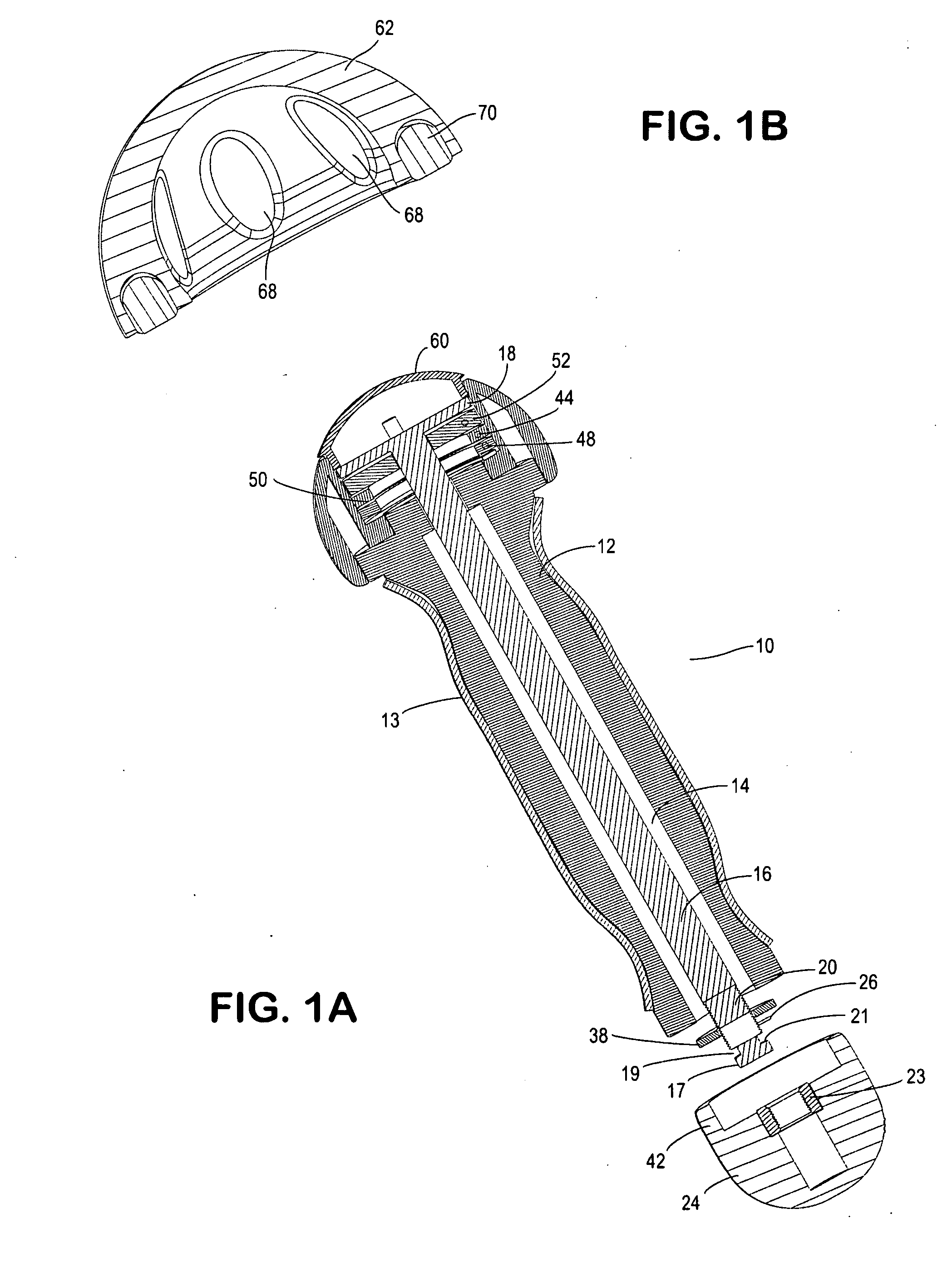

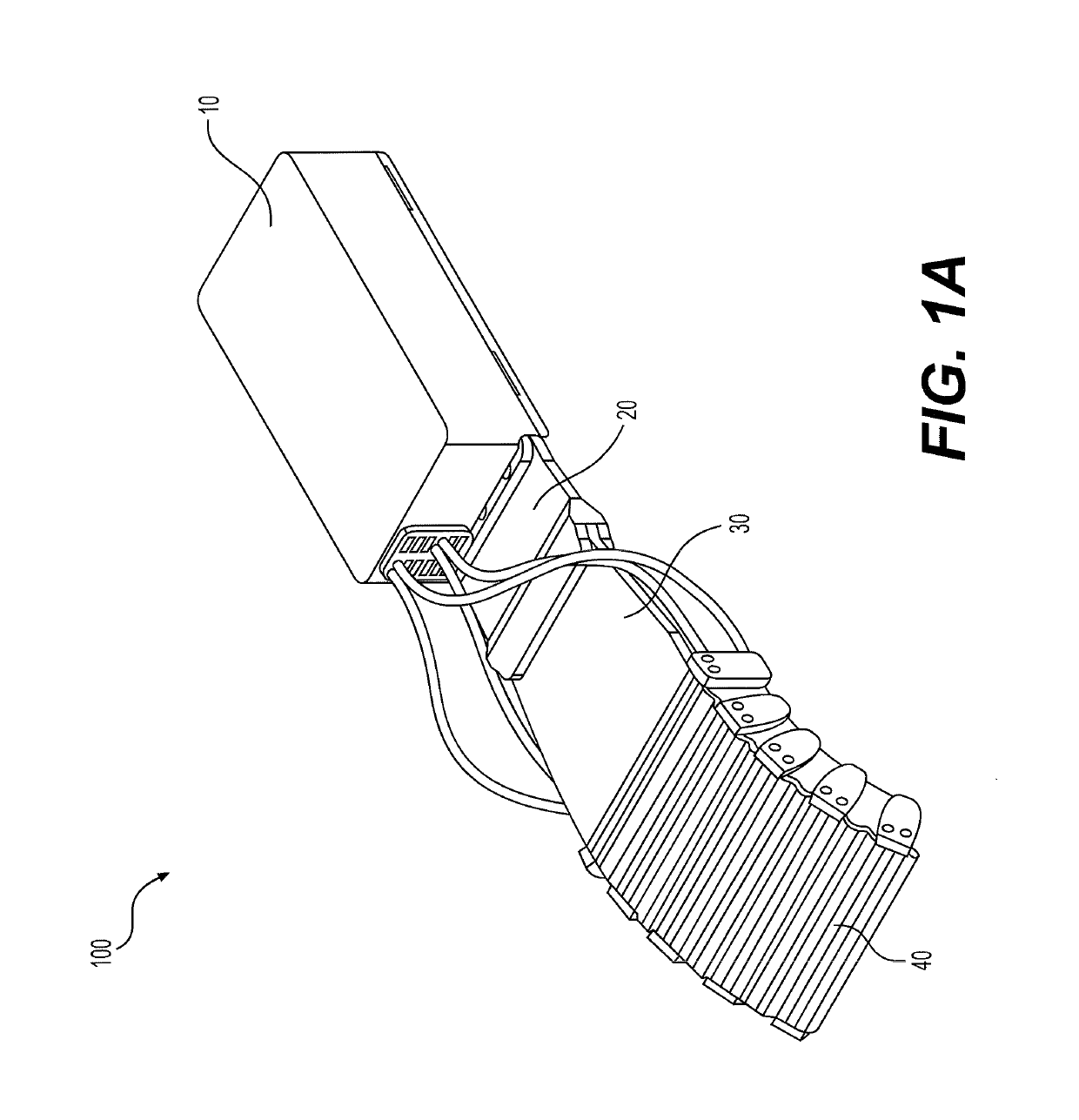

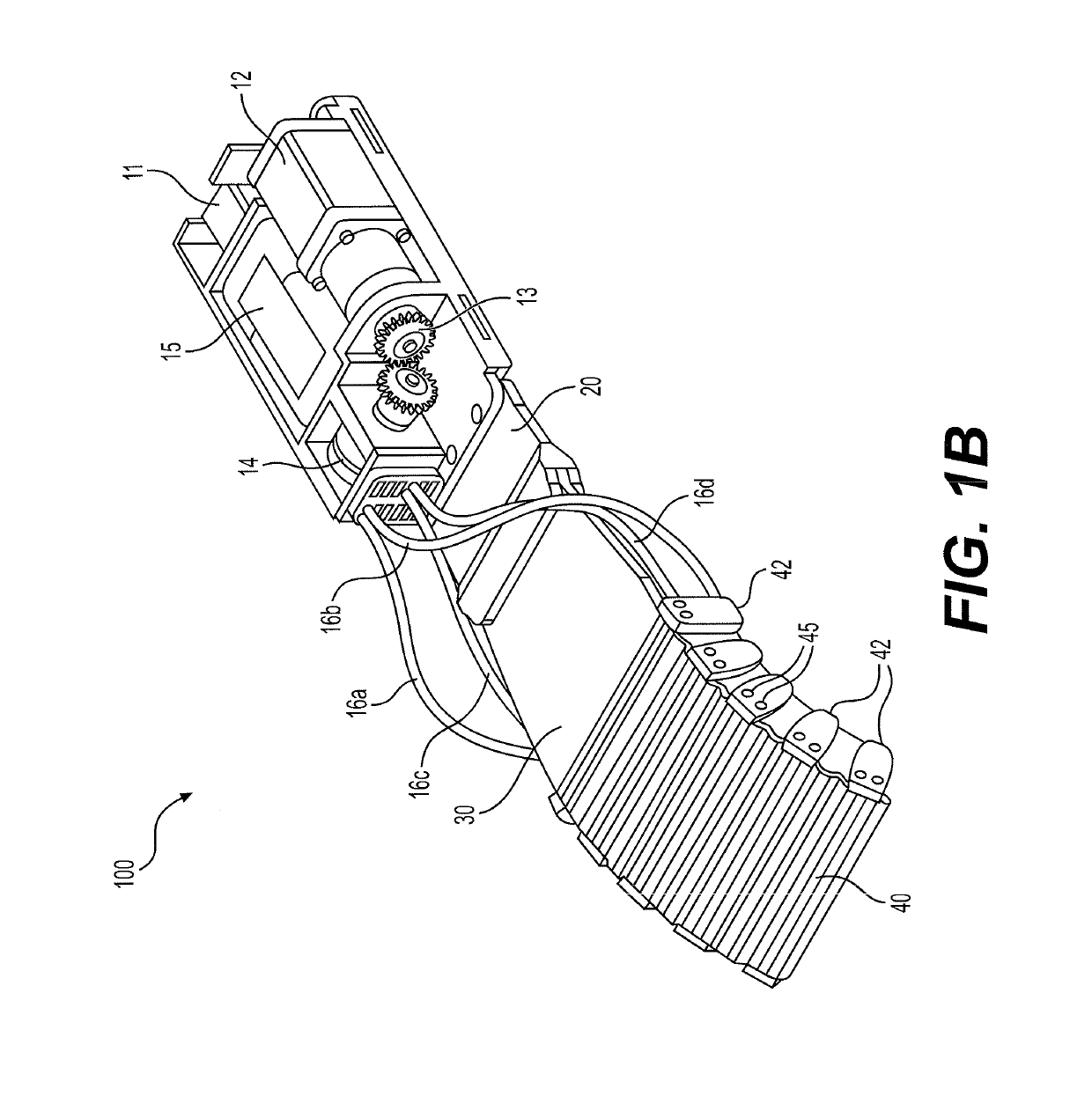

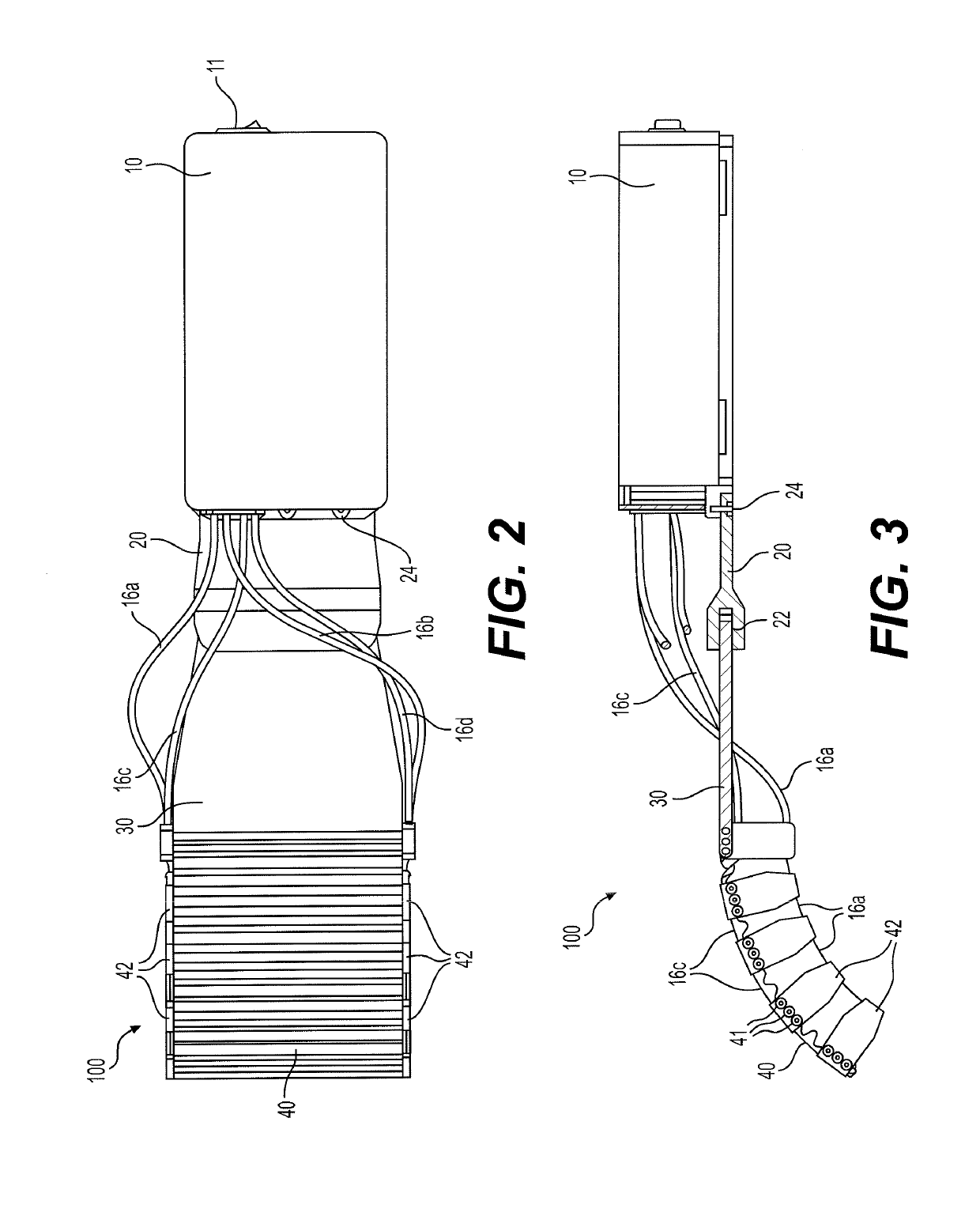

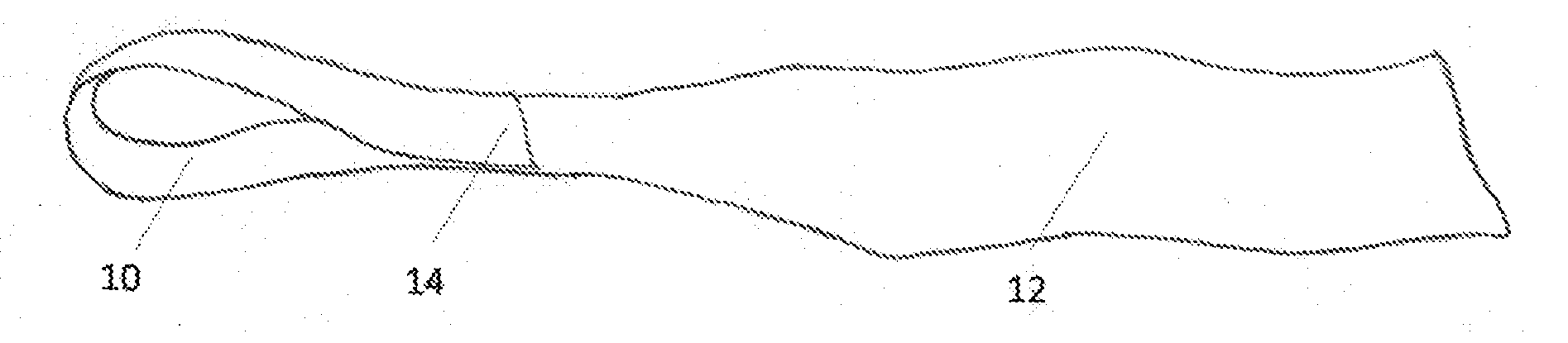

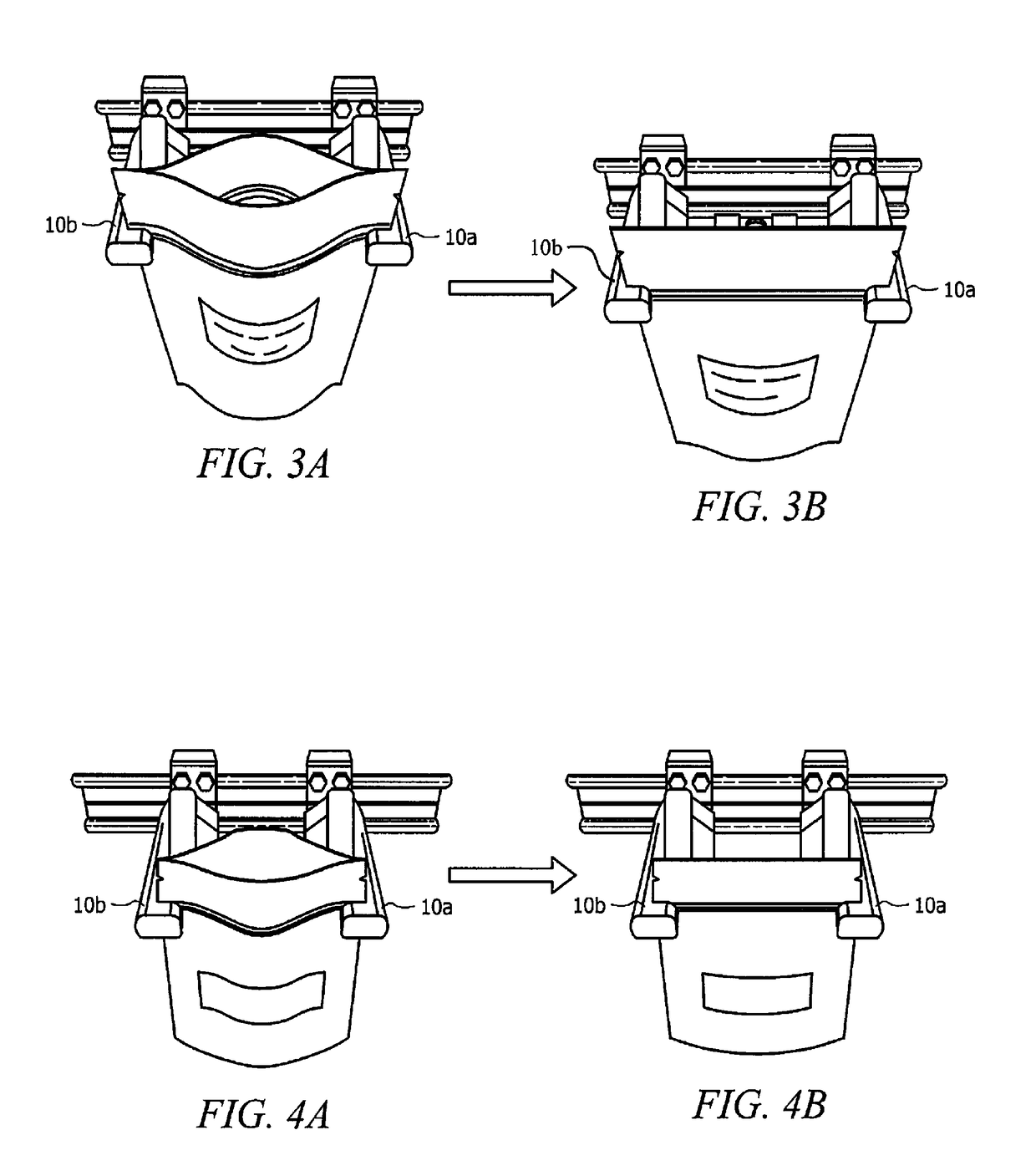

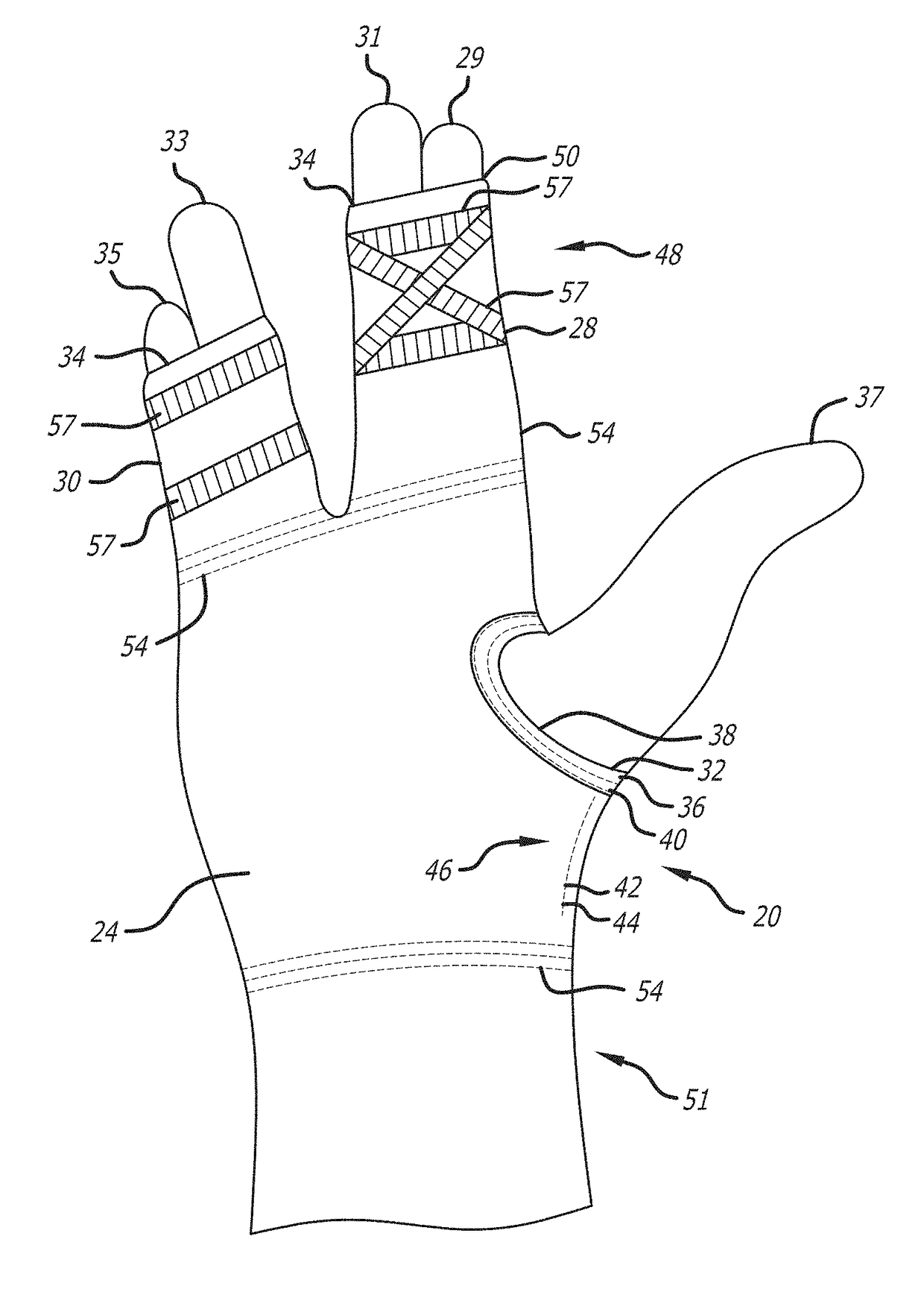

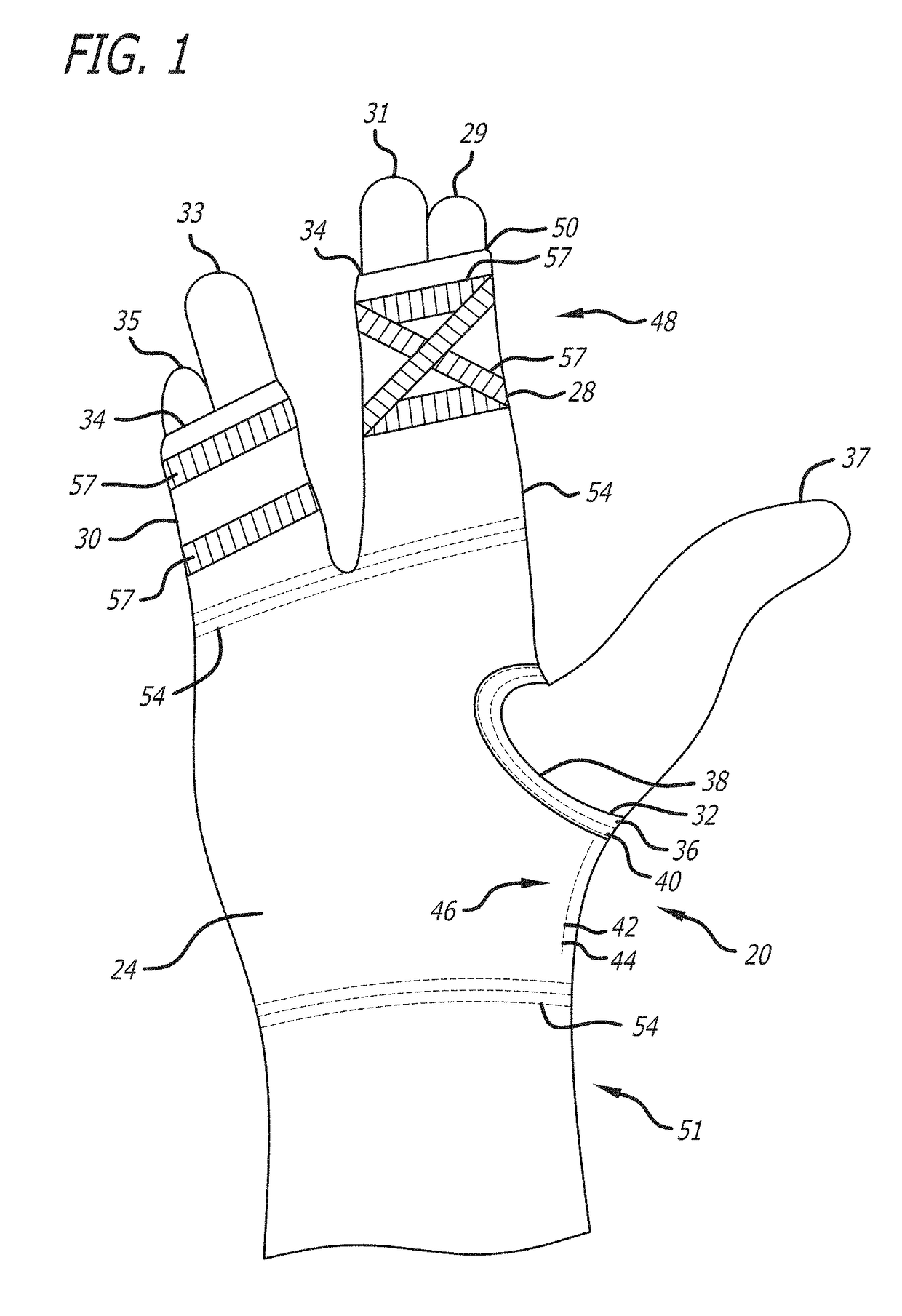

Robotic gripping assist

ActiveUS10449677B1Add grip strengthNormal functionProgramme-controlled manipulatorGarment special featuresGrip strengthEngineering

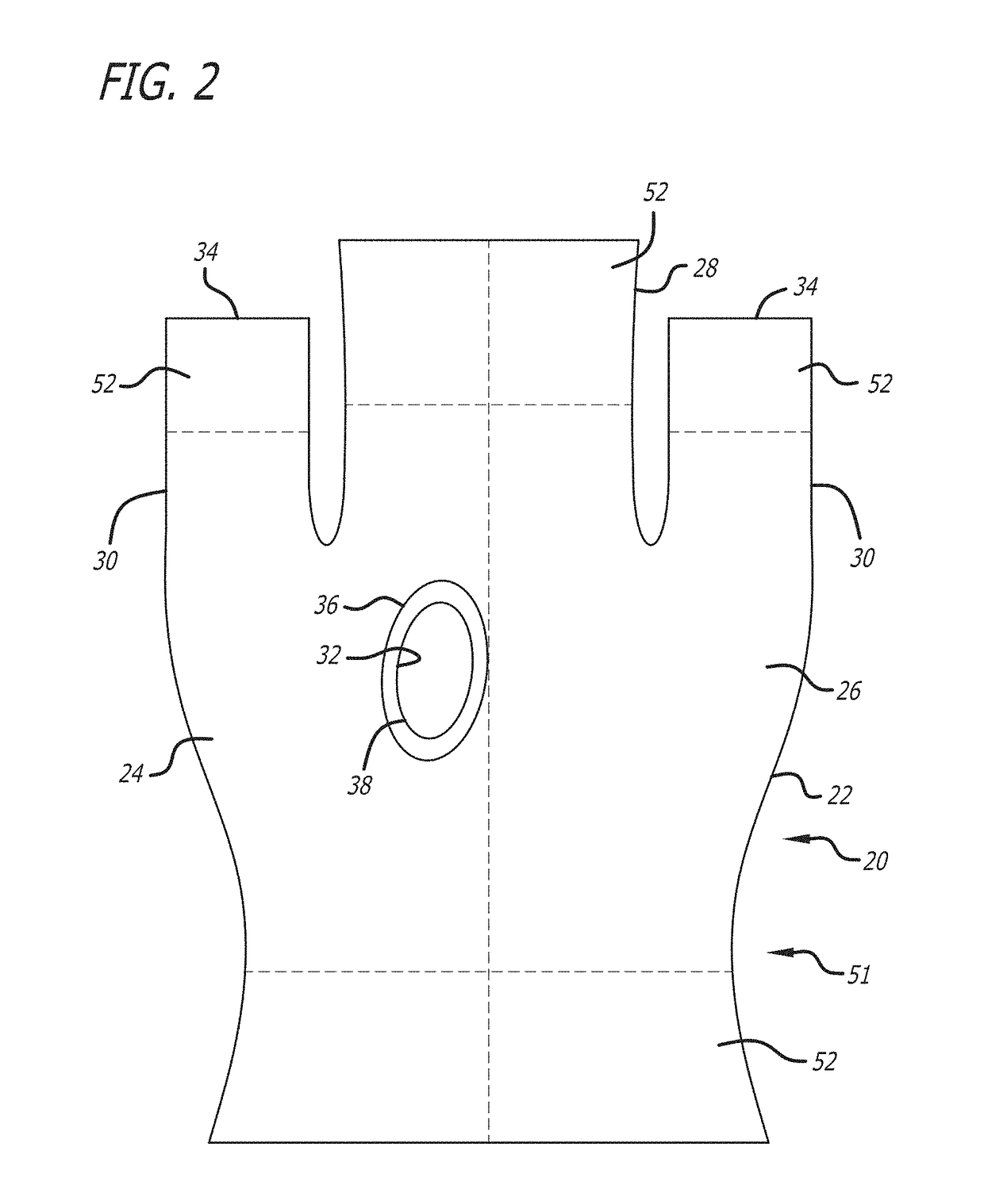

The robotic gripping assist (“RGA”) provides a user with additional grip strength by supporting and forcefully pushing a user's fingers and hand to a gripping position. A motor, controller, and power source are supported on a user's forearm and act as a source for the forced movement. A bending member is worn on the back of a user's hand. The motor draws in or lets out wires that cause the bending member to bend or straighten. By bending the bending member, through rotating the motor in a first direction, the attached fingers of the user are forced into a gripping position. The fingers are moved to a non-gripping position by rotating the motor in the opposite direction.

Owner:UNITED ARAB EMIRATES UNIVERSITY

Holder for variable sizes of tools and implements

InactiveUS20120049020A1Increase coefficient of frictionImprove grip strengthCandle holdersLighting support devicesEngineeringMirror image

A holder for securing objects having a plate for securing to a surface and a pair of opposed grippers rotatably mounted on the plate. The grippers are mirror images of each other and configured with a body, a heel on the butt end of the body and an upwardly arcing nose on the body opposite the heel with a curved gripping surface extending between the heel and the nose. The grippers are biased toward each other such that noses abut each other when there is no object between the grippers. An object to be secured is inserted between the grippers and the grippers rotate apart to accommodate the object and the biasing spring urges the grippers towards each other to secure the object between the grippers.

Owner:STOCK DANIEL F

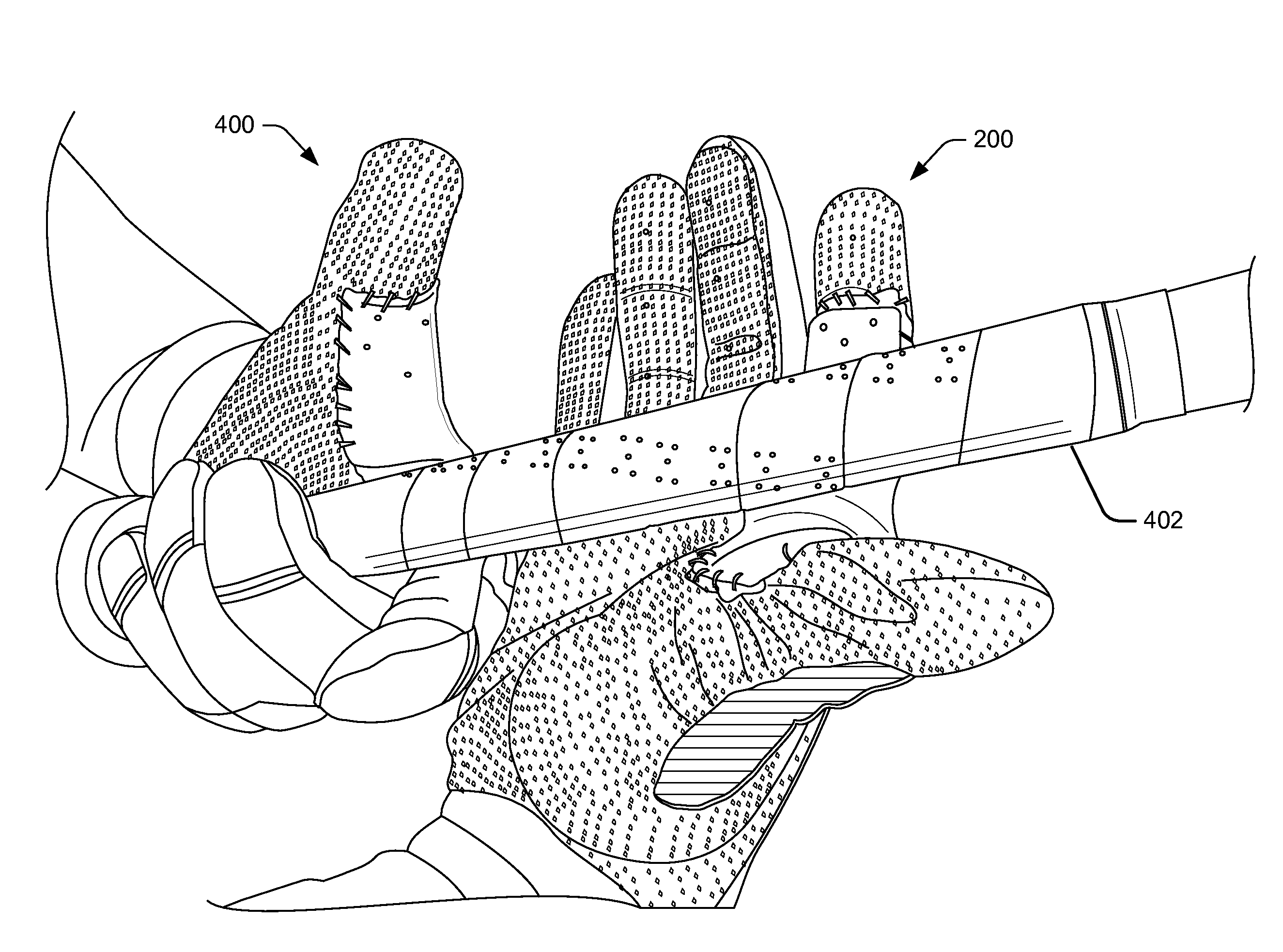

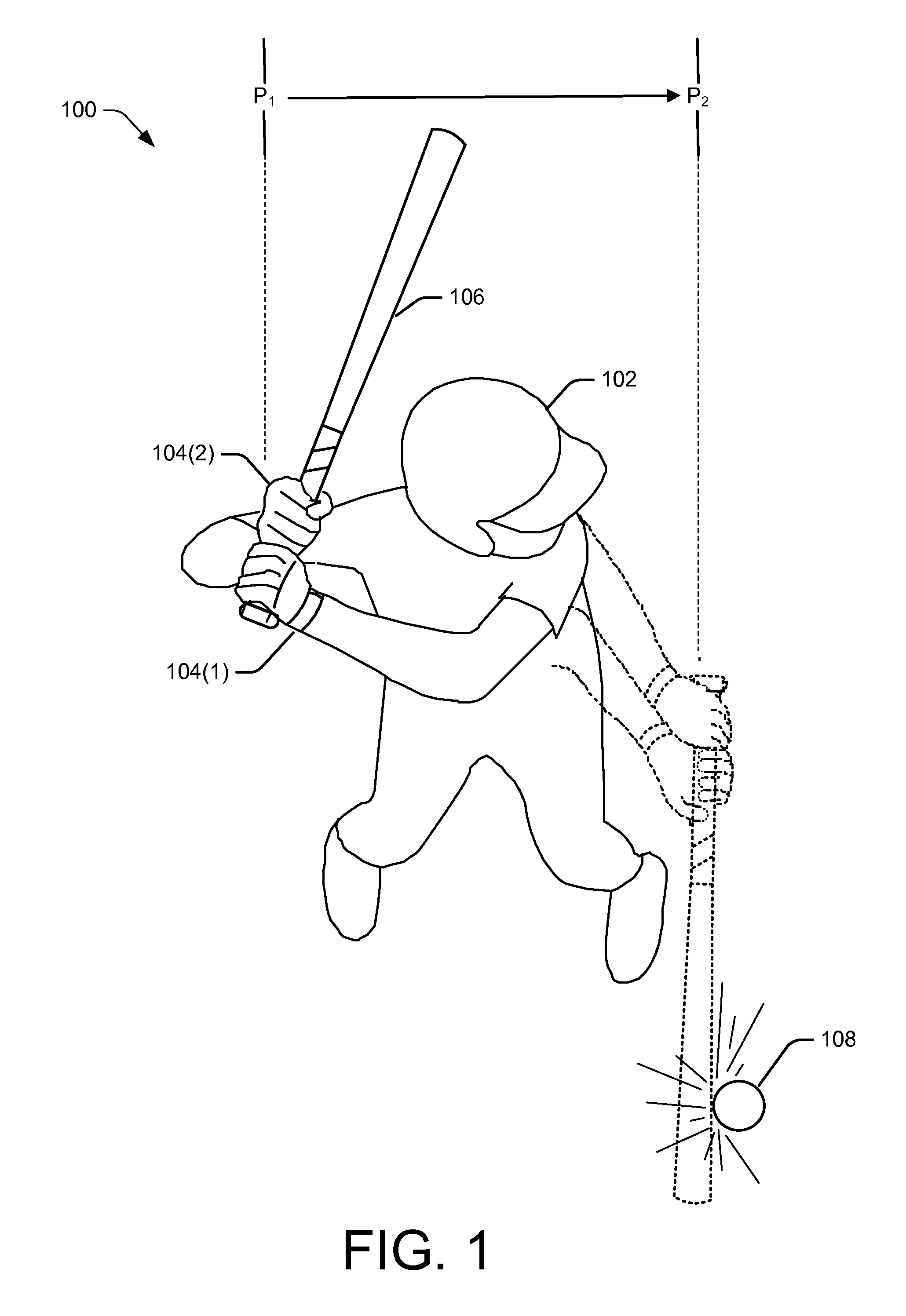

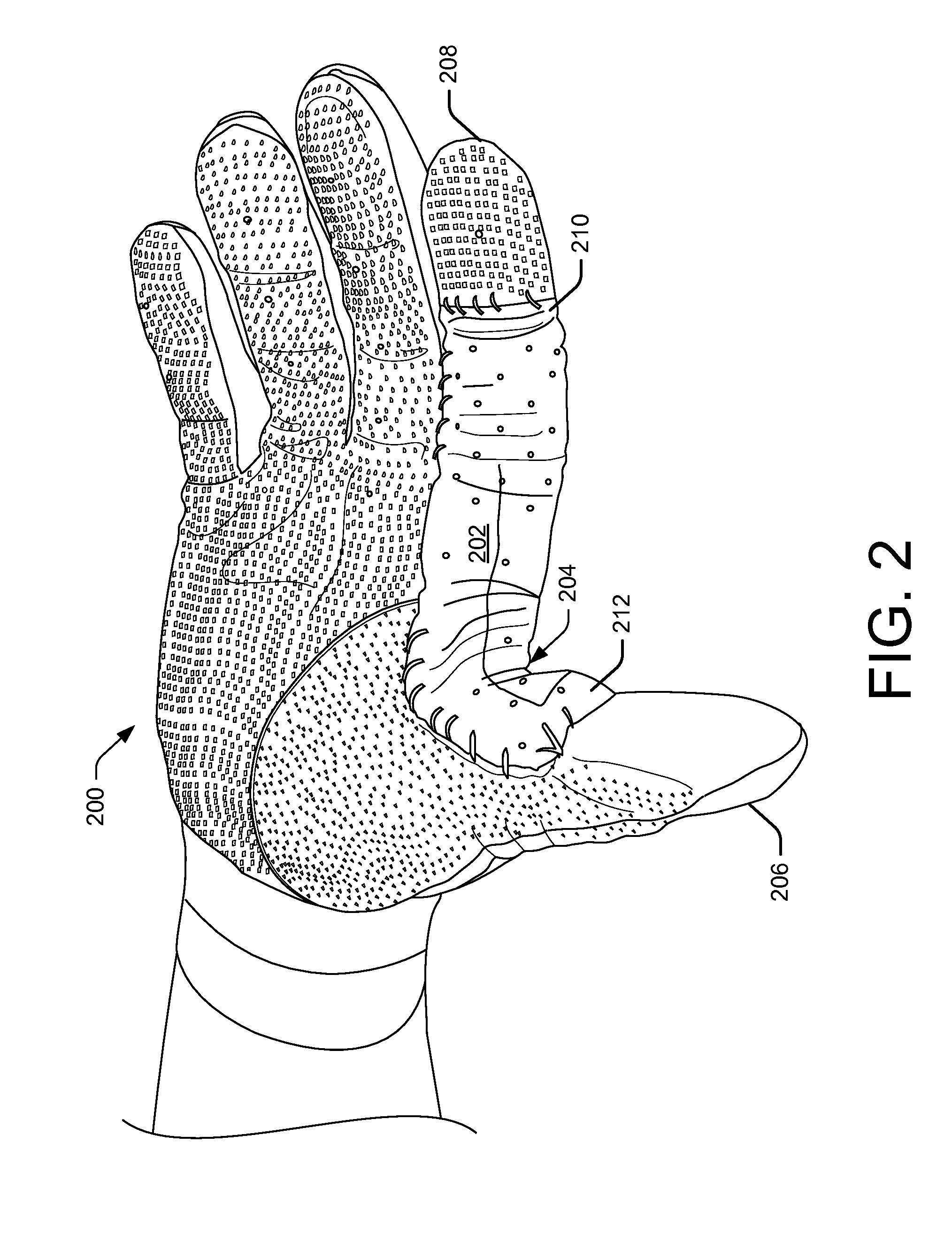

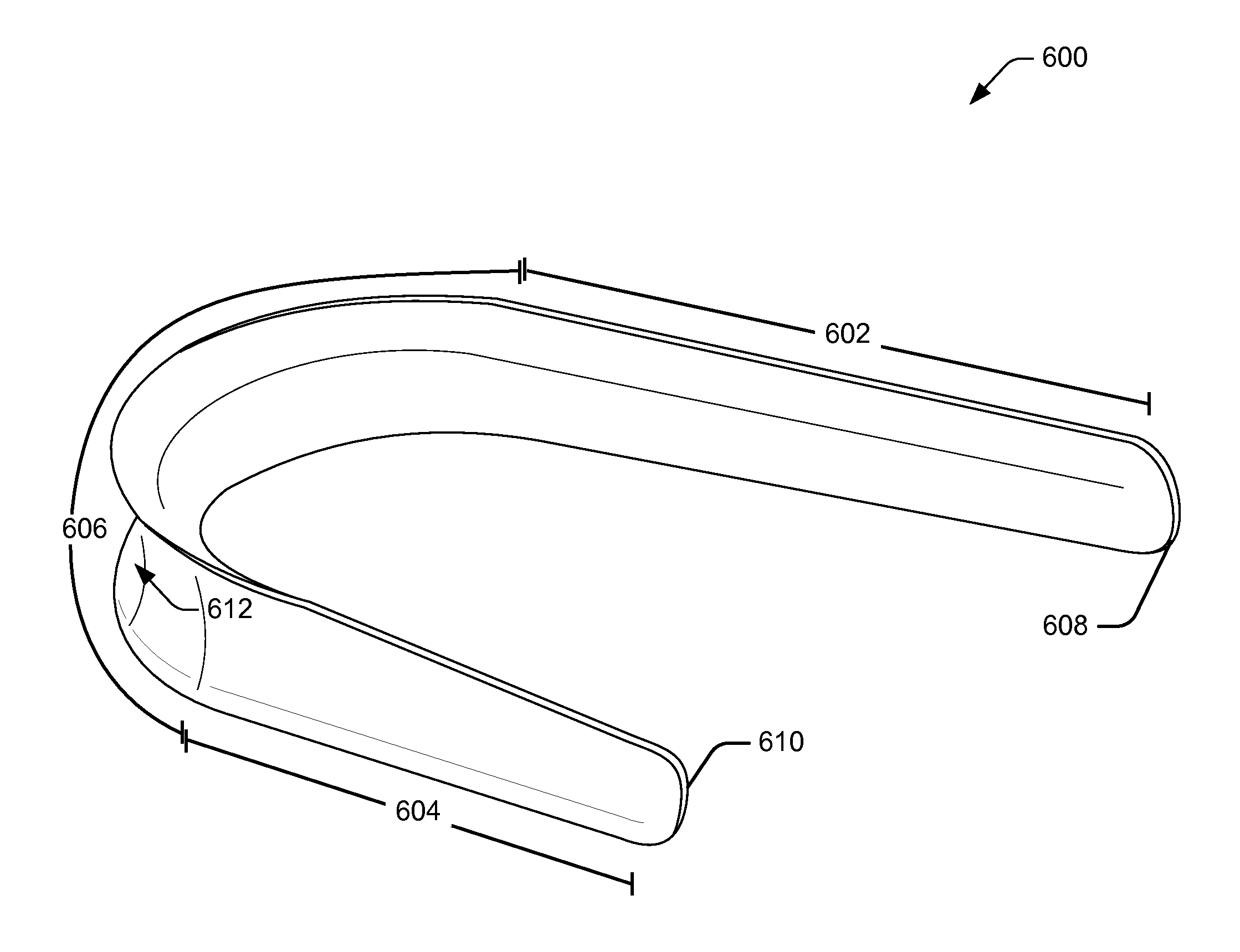

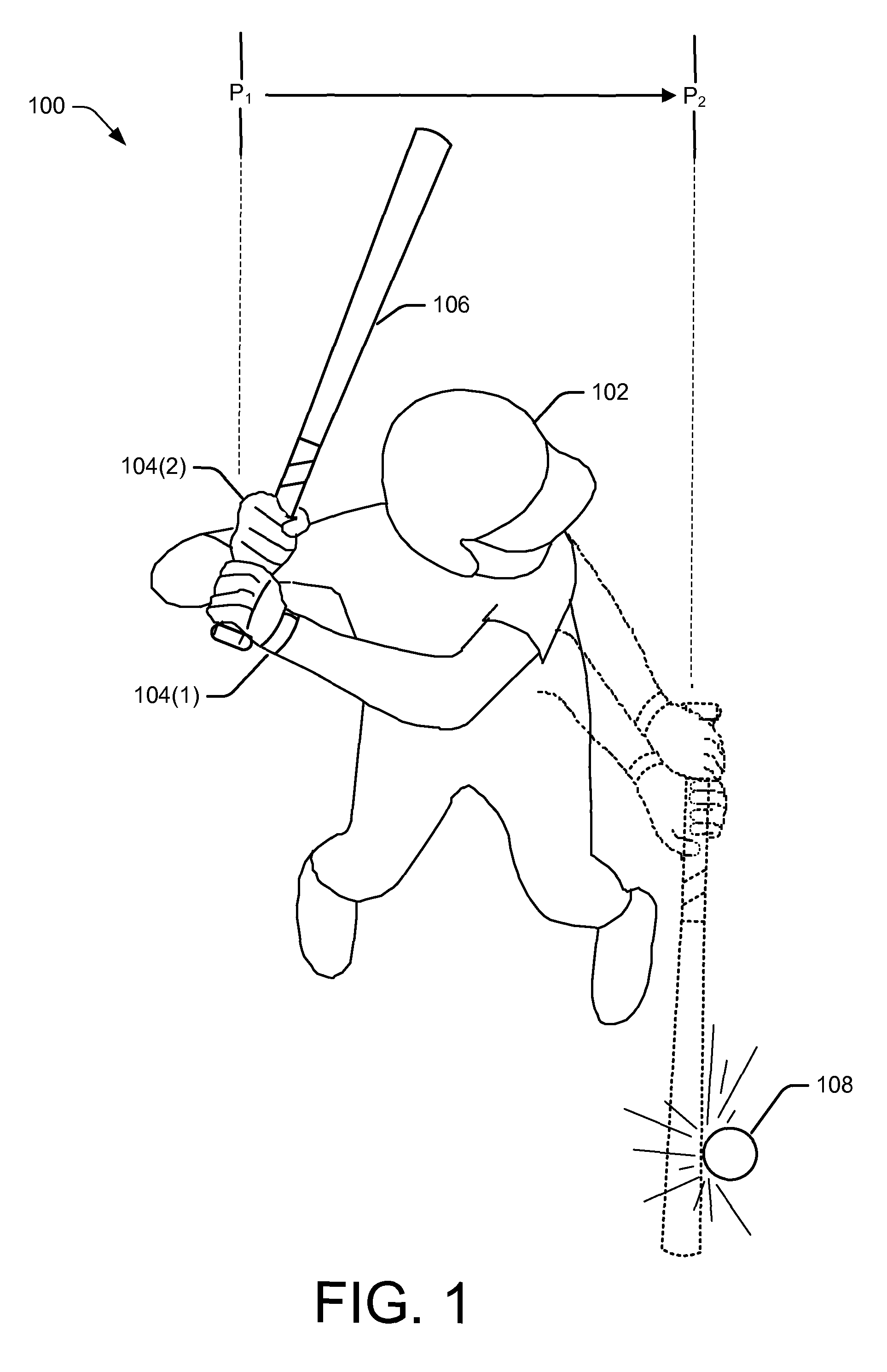

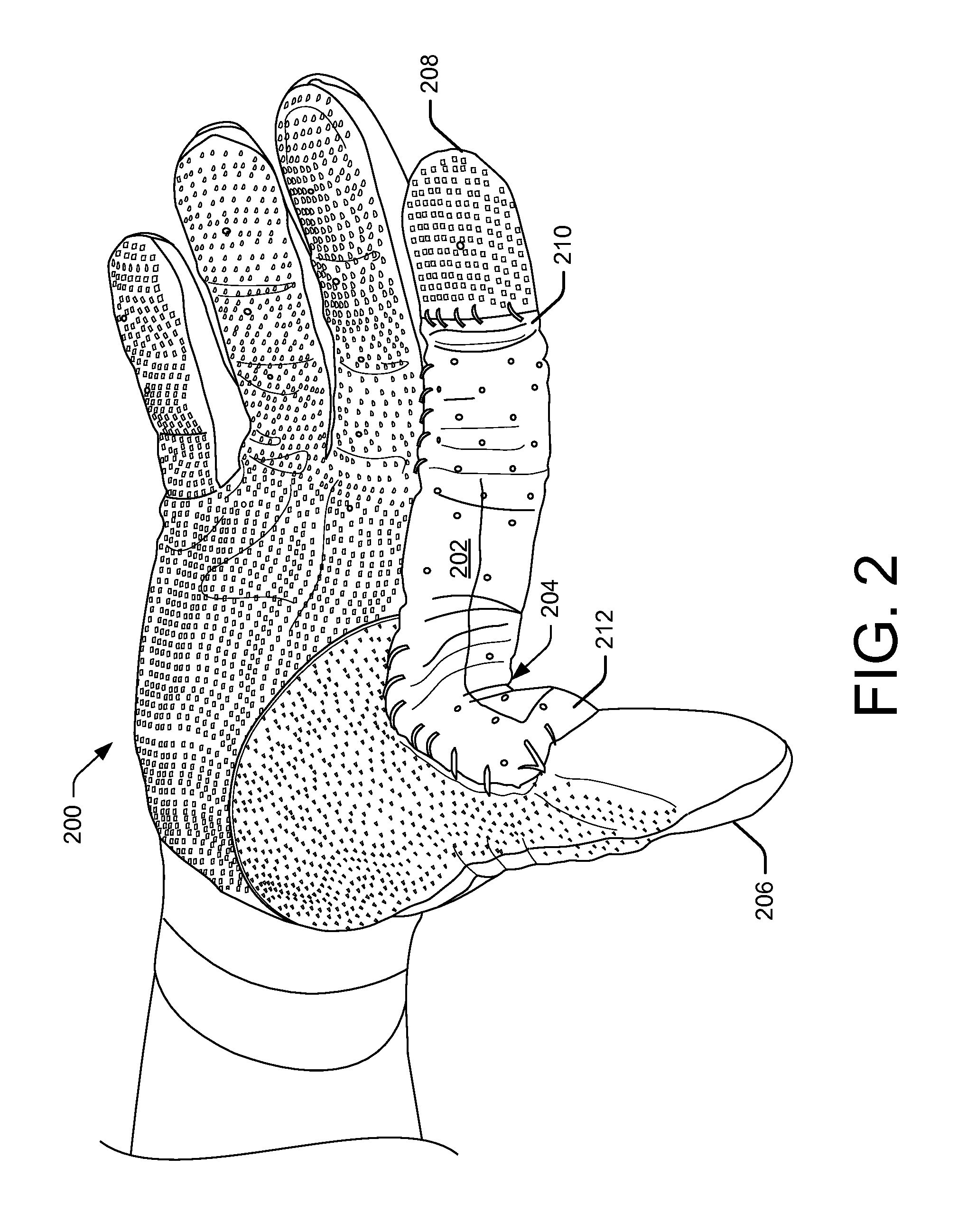

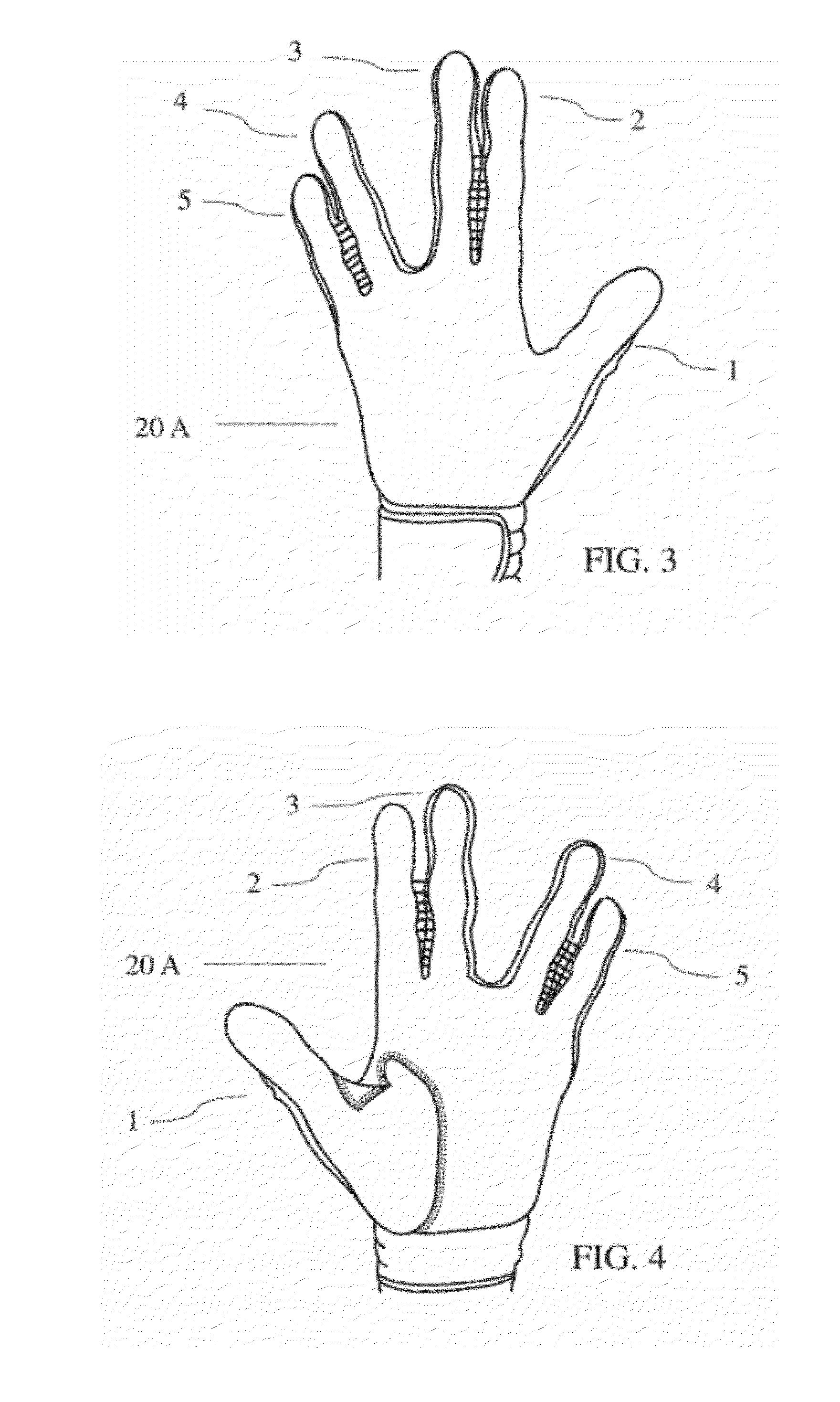

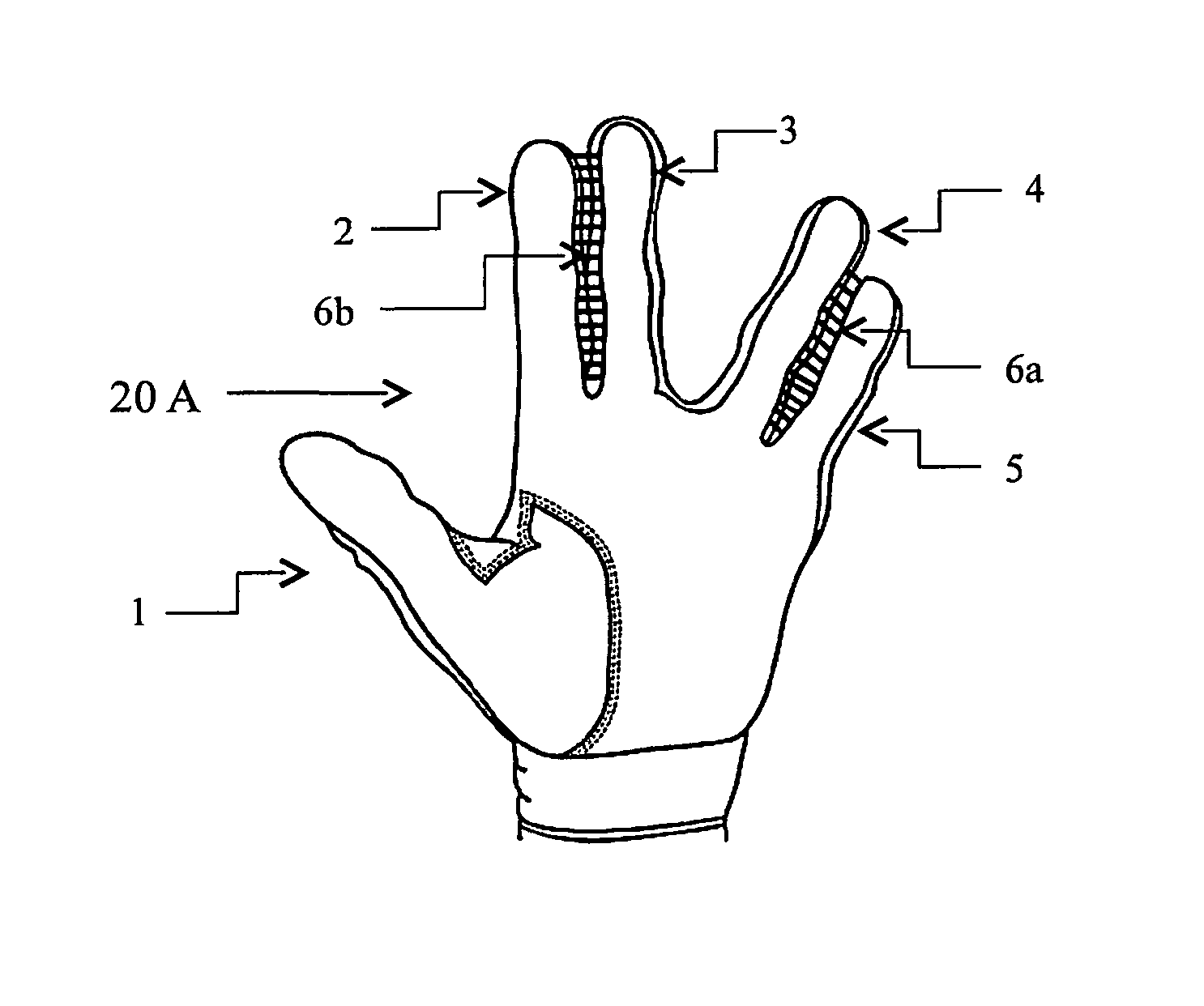

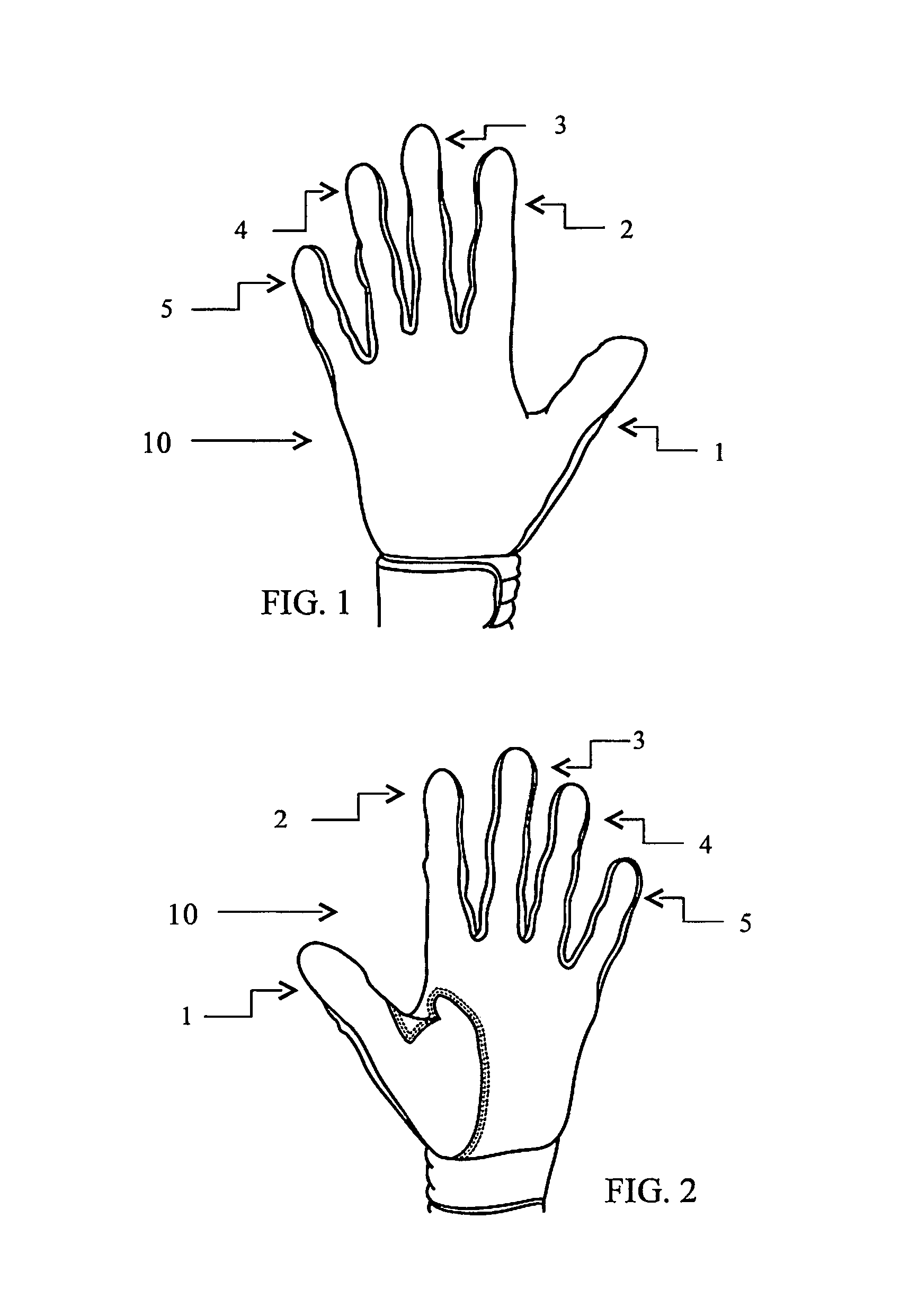

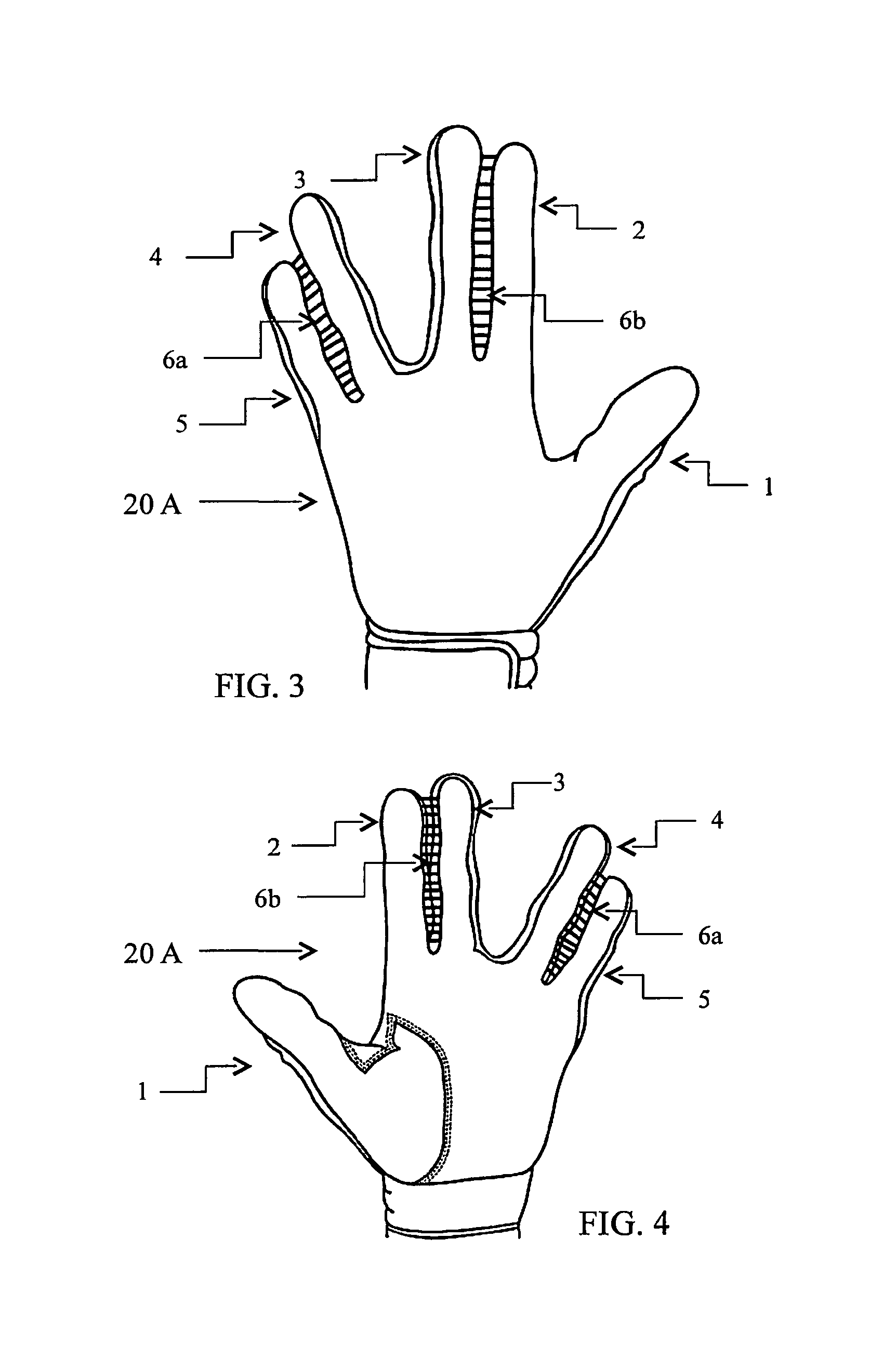

Gripping Glove

ActiveUS20150313298A1Improve gripEnhance biomechanical functionGarment special featuresGlovesEngineeringUltimate tensile strength

This disclosure describes a gripping glove with a gripping aid to increase the grip span of a user. In some implementations, the gripping aid may be composed of a crush resistant, flexible material and further include a crest or fulcrum to increase the speed, strength and / or torque of each swing of a tool (e.g., a baseball bat, sledge hammer, or the like). In some implementations, the gripping aid may also provide a reduction in vibrations and superficial hand traumas normally caused when the tool strikes an object.

Owner:BAILEY CLAIBORNE

Gripping glove

ActiveUS9549579B2Improve gripImprove rendering capabilitiesGarment special featuresGlovesEngineeringUltimate tensile strength

This disclosure describes a gripping glove with a gripping aid to increase the grip span of a user. In some implementations, the gripping aid may be composed of a crush resistant, flexible material and further include a crest or fulcrum to increase the speed, strength and / or torque of each swing of a tool (e.g., a baseball bat, sledge hammer, or the like). In some implementations, the gripping aid may also provide a reduction in vibrations and superficial hand traumas normally caused when the tool strikes an object.

Owner:BAILEY CLAIBORNE

Medicine for treating cervical disease and its preparation

Disclosed is a medicine for treating cervical disease and its preparation, wherein the medicine is prepared from Chinese medicinal herbs including prepared rehmannia root, gastrodia tuber, myrrh, homalomena rhizoma, frankincense, fleece-flower root, kudzu vine root, cassia twig, and musk through wine extraction, mixing with white spirit and musk.

Owner:吉林万通药业有限公司

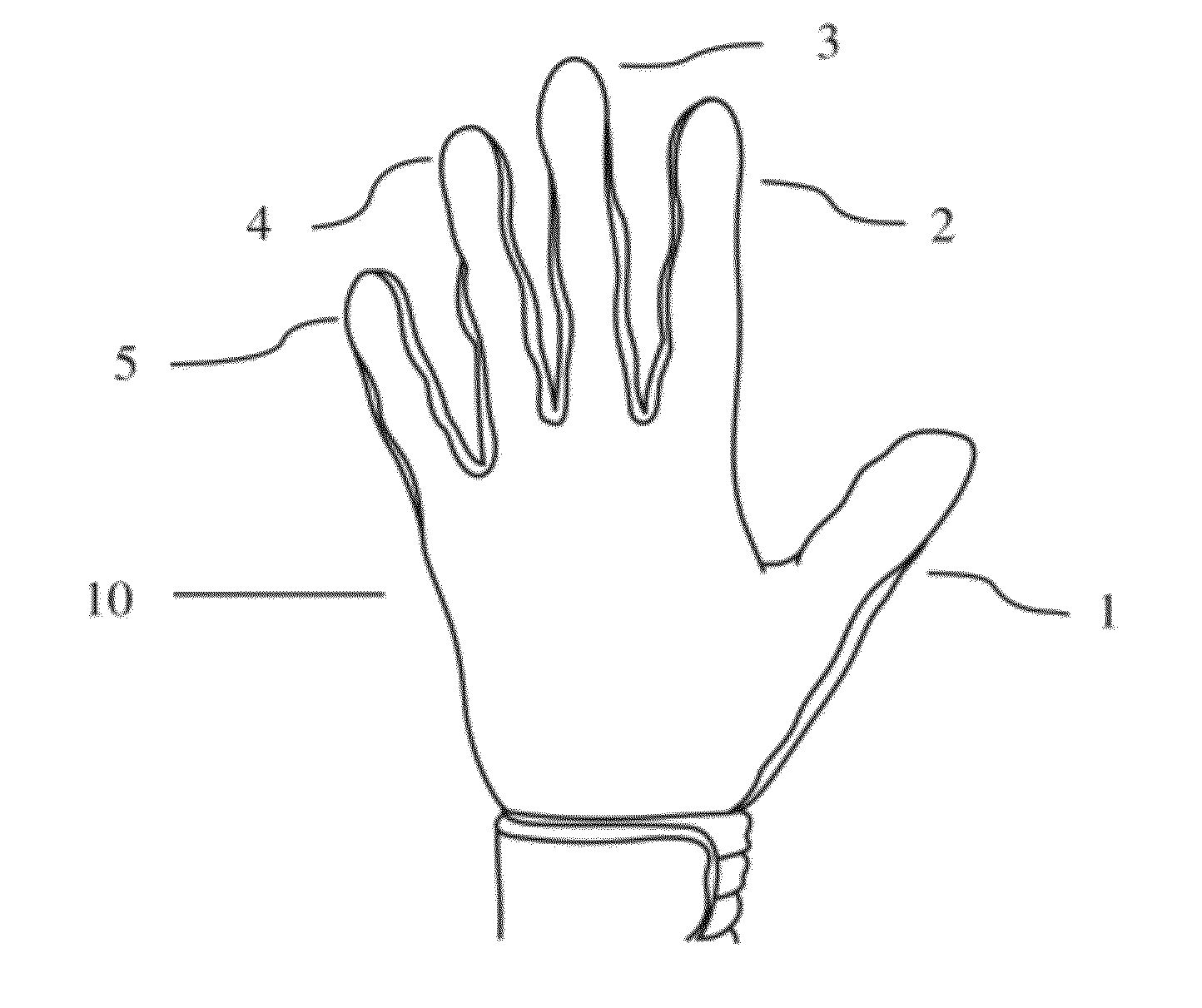

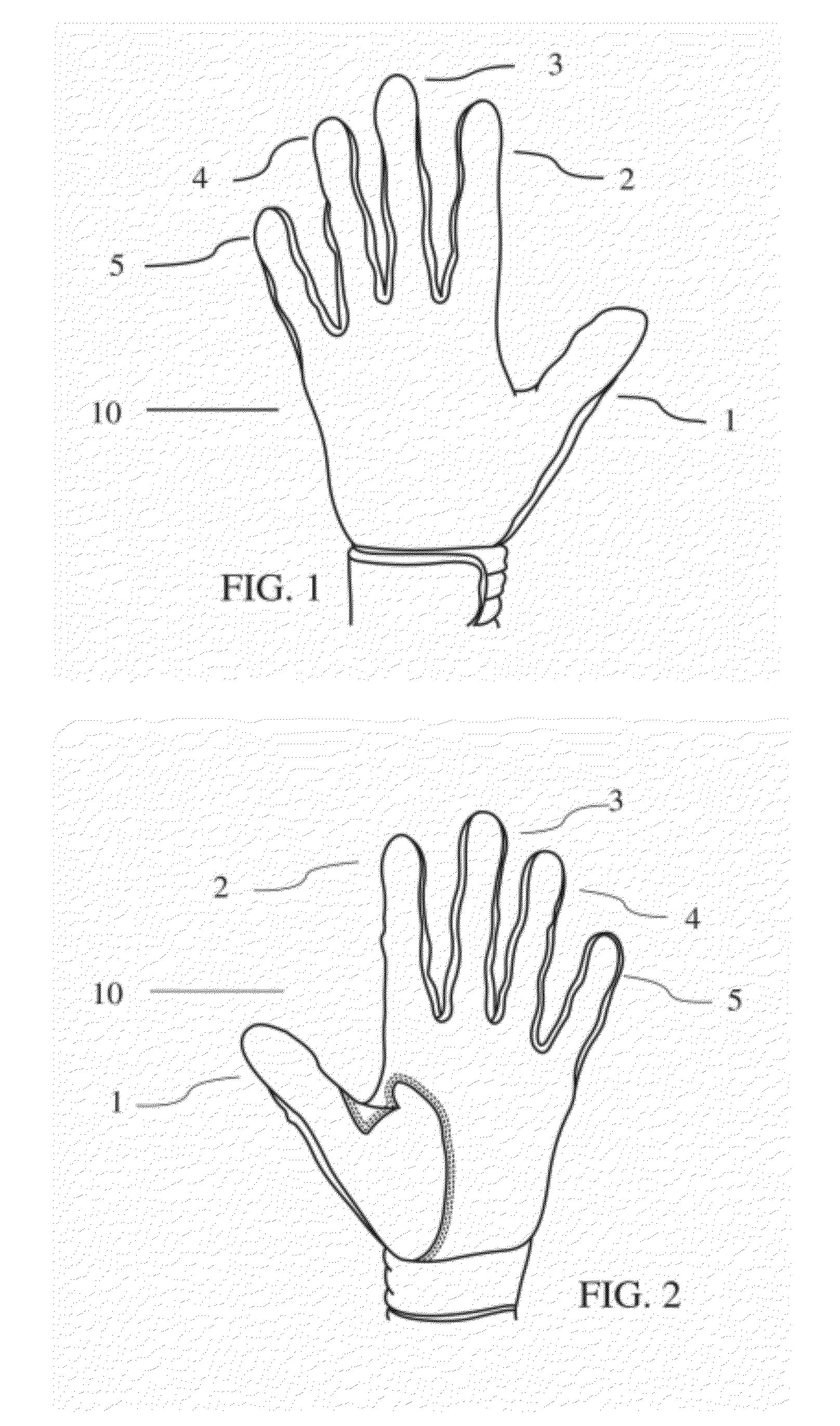

Sports glove with gripping power

InactiveUS20120204319A1Improve grip strengthImprove performanceGlovesSewing apparatusEngineeringUltimate tensile strength

A sports glove that increases grip strength to enhance an athlete's performance in any sport. The increase in grip strength generated by the Vpower sports glove of the invention is brought about by sewing the index finger and middle finger together and the ring finger and pinky finger together so that the pairs of fingers act as one finger. The Vpower glove forces the wearer to use the power of two fingers on every grip and immediately increases the gripping strength of the wearer without any additional effort and this increase in grip strength is permanent.

Owner:GAMBORDELLA TED

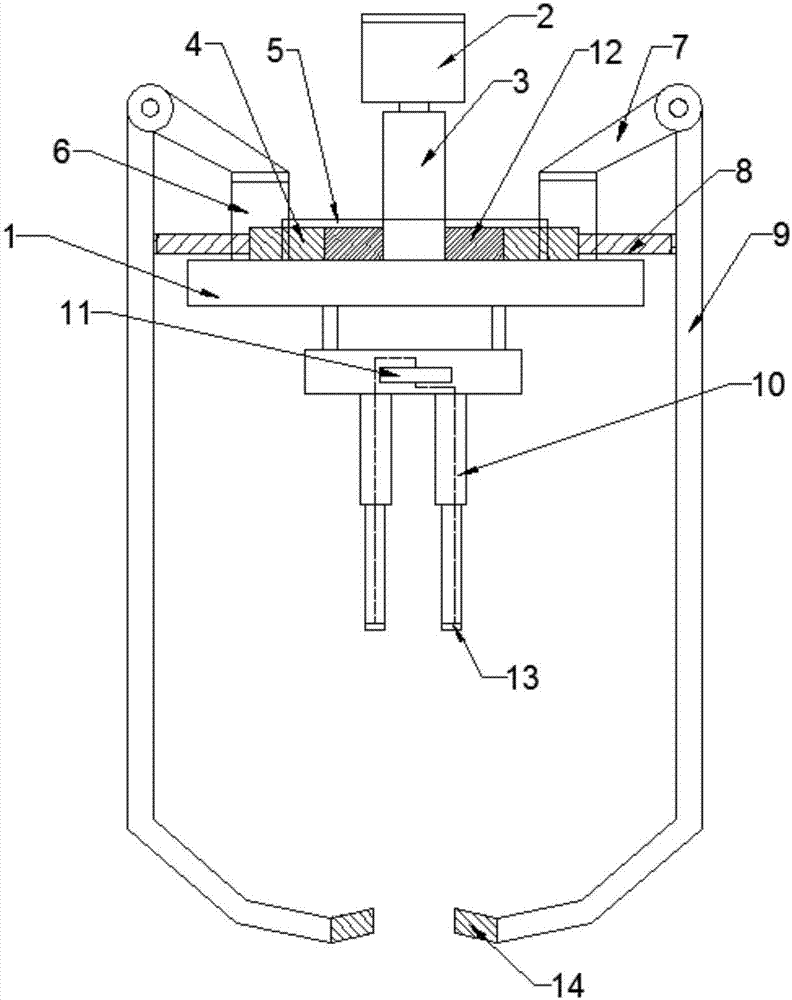

Unmanned aerial vehicle gripping device

InactiveCN106986031AEnhanced gripping powerWon't fallAircraft componentsLaunching weaponsClutchDrive motor

The invention discloses an unmanned aerial vehicle grabbing device, which relates to the field of unmanned aerial vehicles, and includes a driving device, a mechanical gripper and a fixing frame, the driving device is arranged above the fixing frame, and the driving device includes a driving motor and a longitudinal driving rod , a horizontal drive rod and a fixed plate, the drive motor drives the longitudinal drive rod through the drive gear, the horizontal drive rod is arranged at the lower end of the longitudinal drive rod, and is distributed in 4 mutually perpendicular directions at the lower end respectively, and the manipulator includes Hand grip mounting seat, connecting rod, push rod and hand grip arm, the grip mounting seat is welded to the periphery of the fixed plate, the connecting rods are respectively hinged to the grip mounting seat and the hand grip arm, and the push rod is respectively connected to the transverse drive rod And the upper part of the hand grab arm, the lower part of the fixed frame is also provided with an electric telescopic rod, and the electric telescopic rod is connected to a microprocessor. This kind of UAV grabbing device can realize a stable grabbing function through an improved driving device. It is worth promoting.

Owner:芜湖元一航空科技有限公司

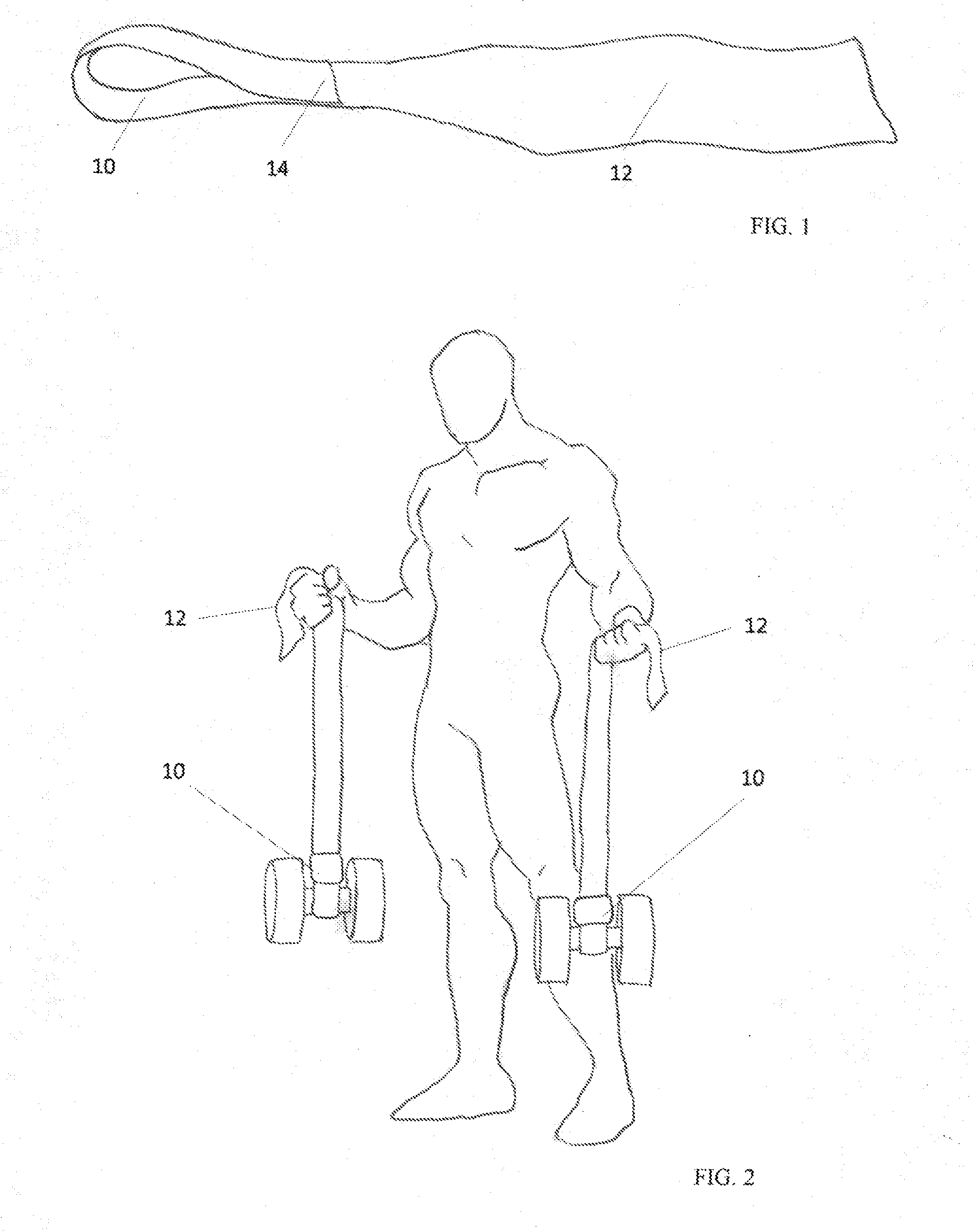

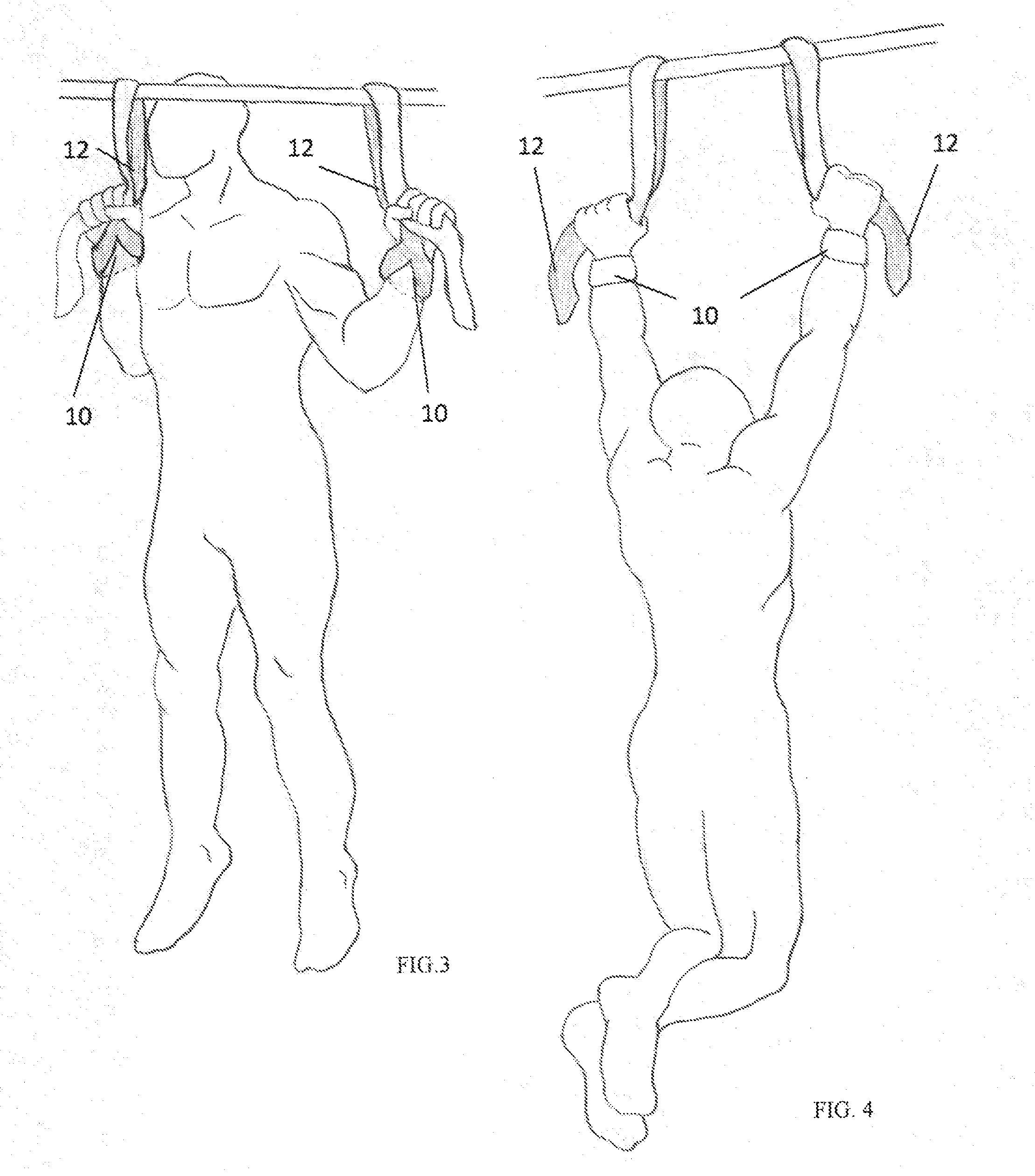

Exercise device including an inelastic sling strap

InactiveUS20120322626A1Improve grip strengthHigh strengthMuscle exercising devicesBody regionPhysical exercise

An exercise device having many advantageous features is described, including the ability to easily connect or anchor to a many different objects, structures, or body parts, the ability to use the device with many different workloads, forms of resistance, and exercise, the ability to provide a medium of an inconstant dynamic when controlling a workload or form of resistance, the ability to provide an emphasis for using and developing overall hand grip strength or an emphasis for relieving overall hand grip strain when exercising, and the ability to provide one or more users the ability to perform one or more exercises from many different positions with one or more device embodiments. The device includes and inelastic strap embodiment that has a flexible loop eye and an elongated tag-end.

Owner:MEIMAROGLOU CHRISTOS TASS

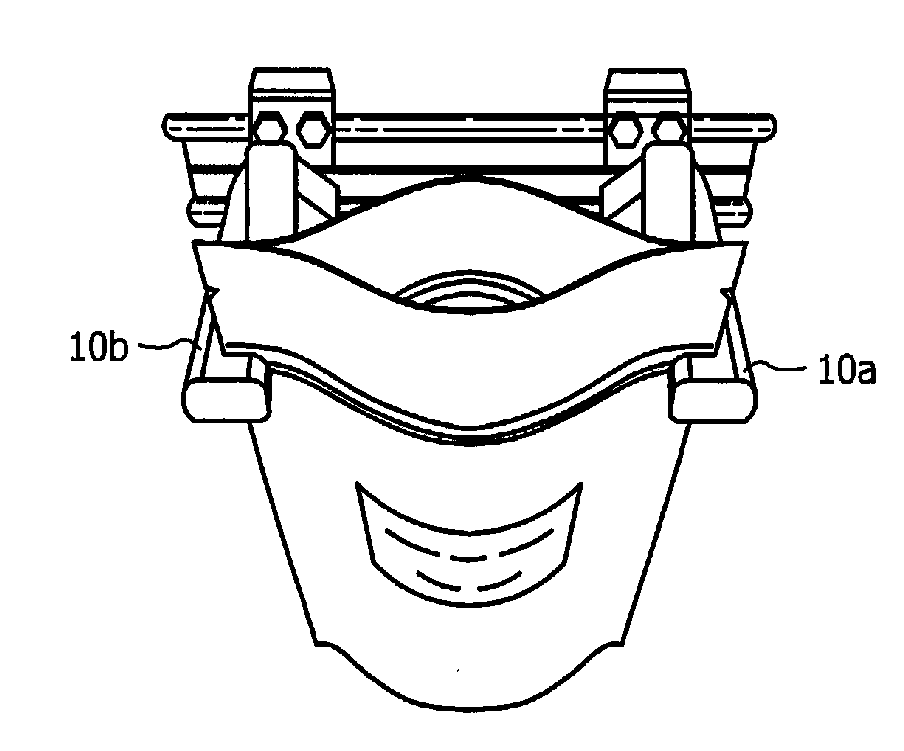

Pouch transport grippers

ActiveUS8468783B2Improve grip strengthIncrease costContainer making machineryEngineeringPressure increase

Owner:MAMATA ENTERPRISES

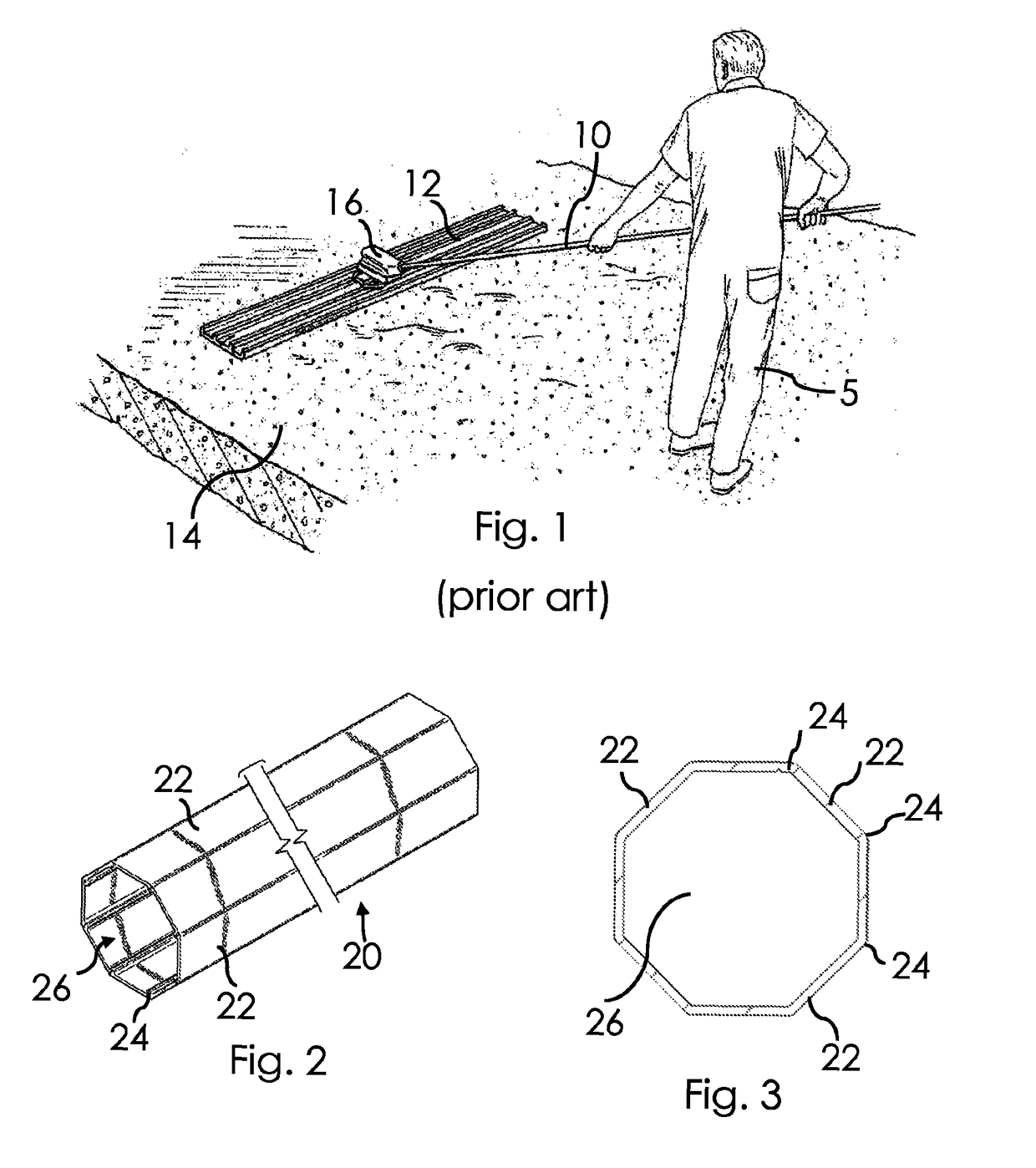

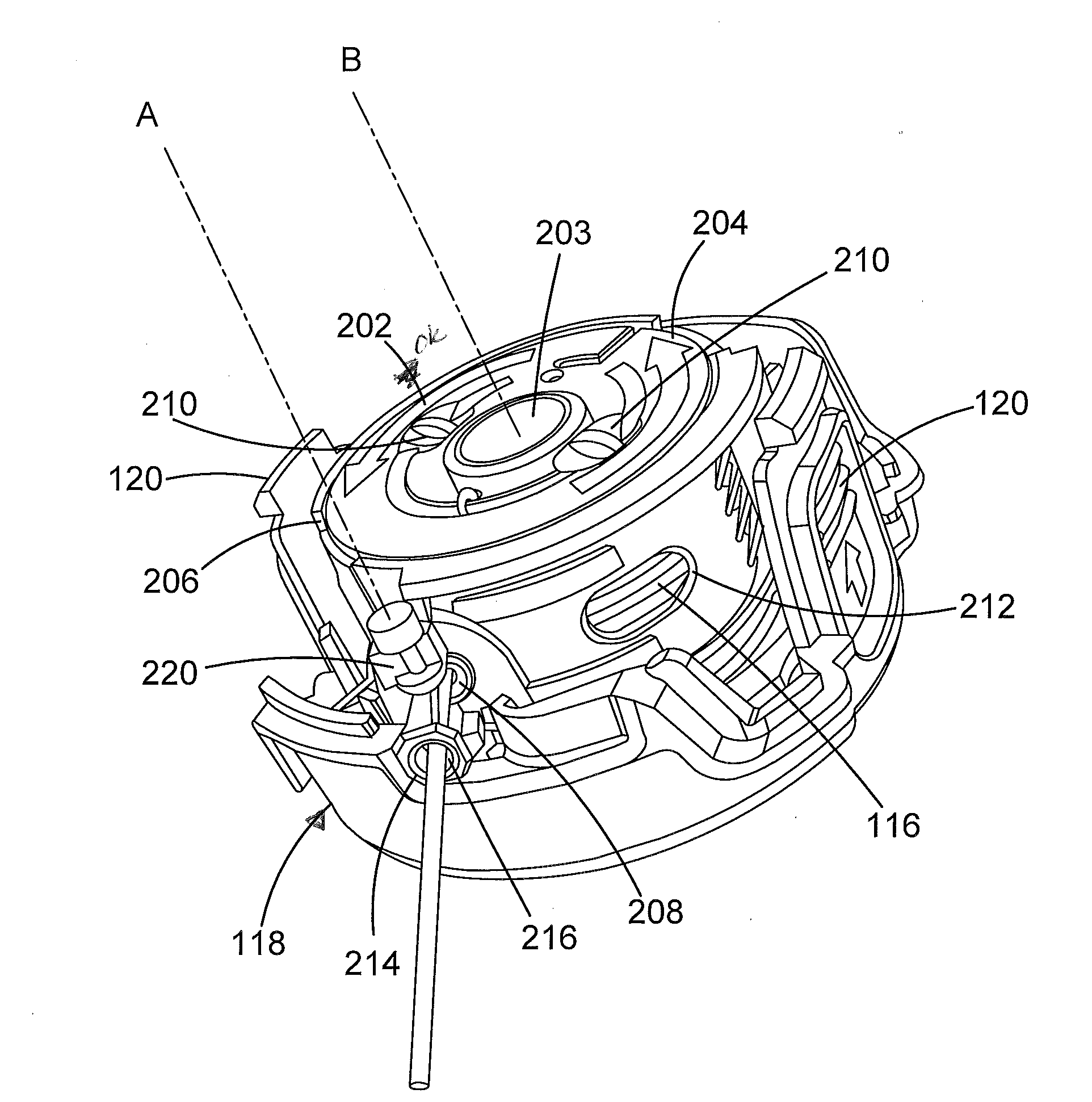

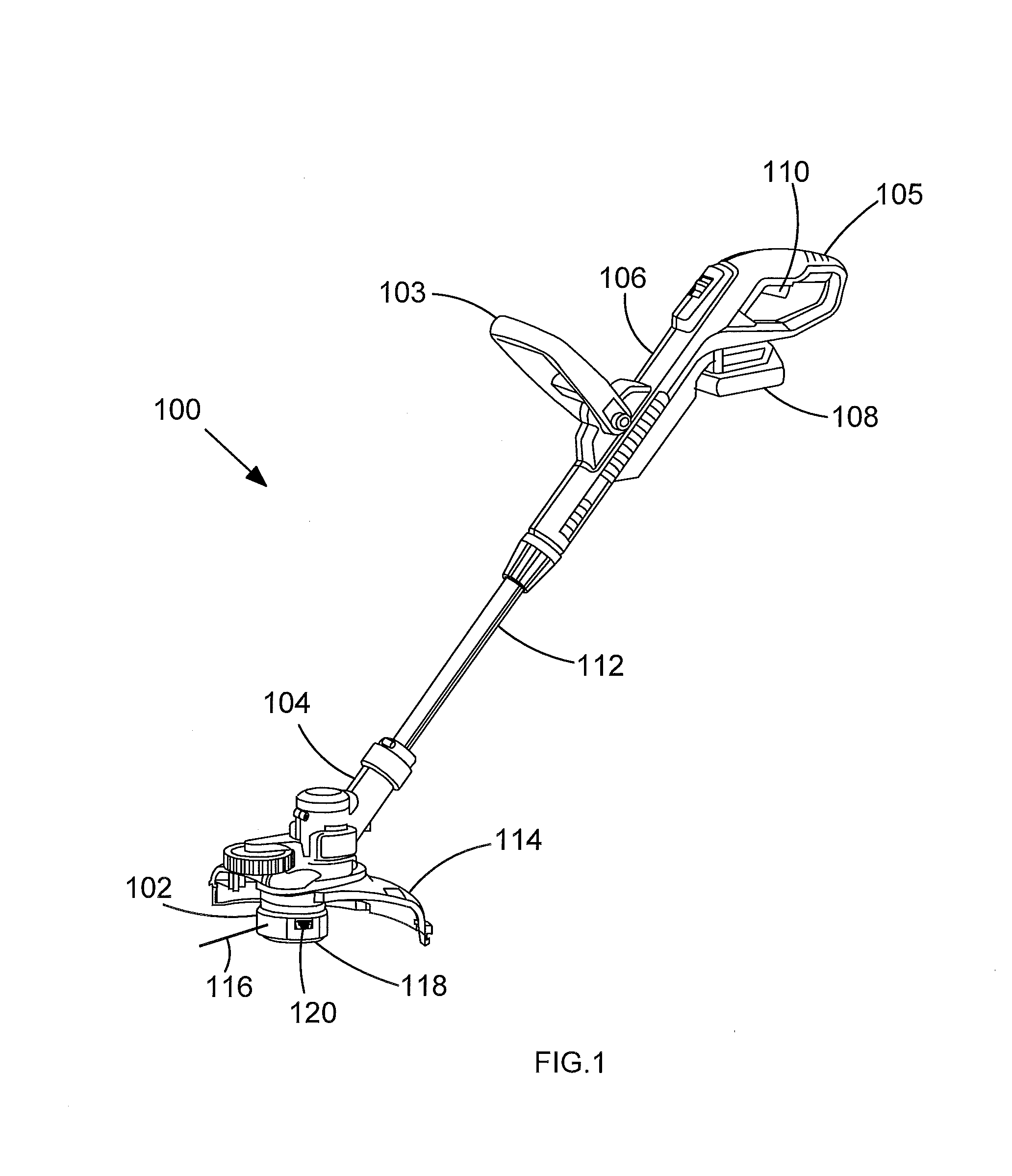

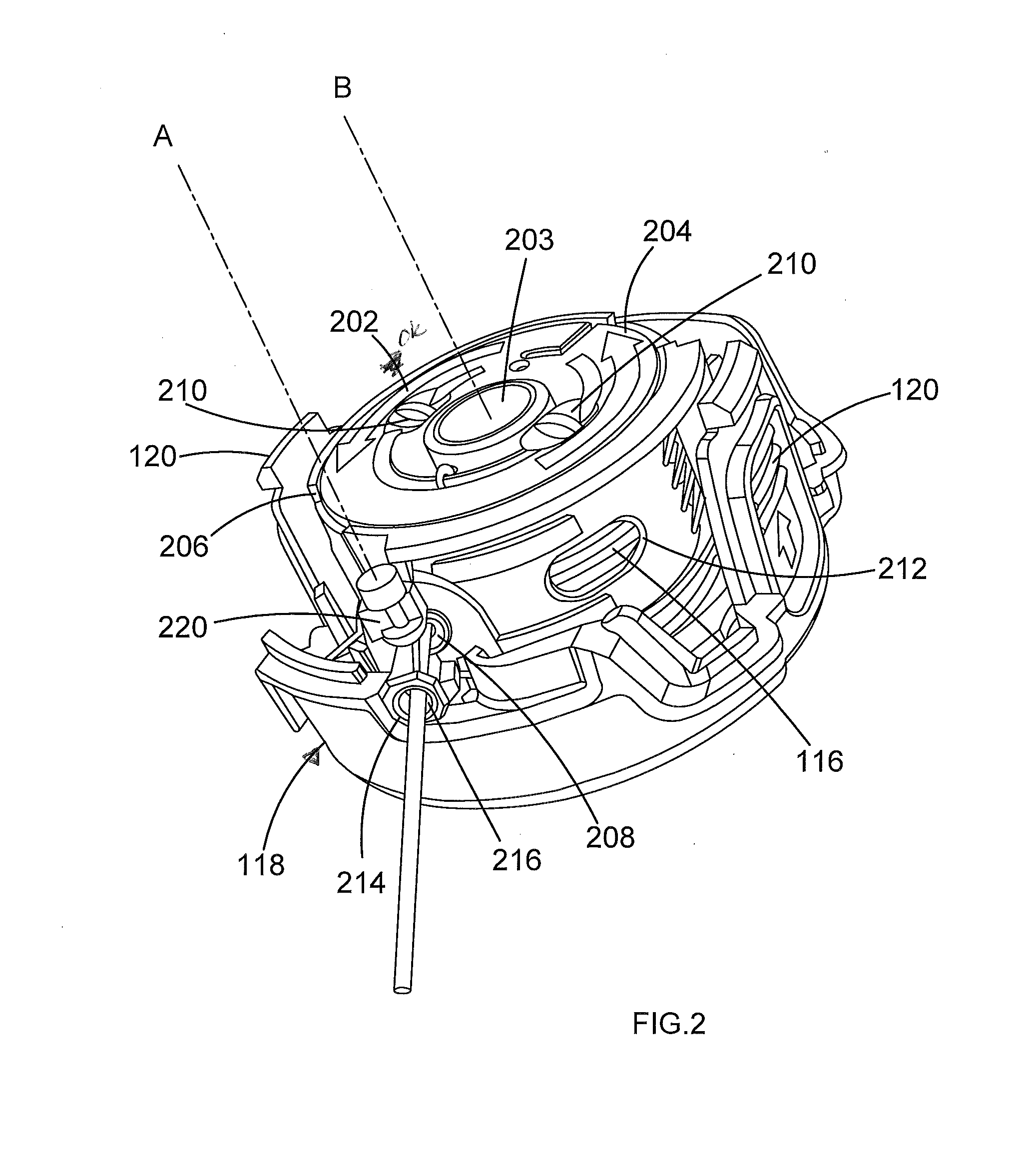

Vegetation cutting device

InactiveUS20140325850A1Prevent unwindingIncrease gripping strengthMowersMetal working apparatusEngineeringMechanical engineering

A spool accessory for a rotatable cutting head of a vegetation cutting device comprises: a spool configured to receive a cutting line wound thereon; and a spool sleeve mounted to the spool, the sleeve comprising a gripping arm moveable between a gripping position wherein the gripping arm grips the cutting line wound on the spool and a release position wherein the gripping arm does not engage the cutting line wound on the spool, wherein the gripping arm is configured to move from the gripping position to the release position when the cutting head rotates.

Owner:BLACK & DECKER INC

Refrigerator having a door

ActiveUS20170138658A1Reduce the possibilityImprove grip strengthLighting and heating apparatusCooling fluid circulationEngineeringMechanical engineering

A refrigerator includes a door having a handle groove, a grip portion located in front of the handle groove, and a front panel located in front of the grip portion. The grip portion is close to a rear surface of the front panel or is in contact with the rear surface of the front panel. The door includes at least a metal reinforcement member disposed in the grip portion.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

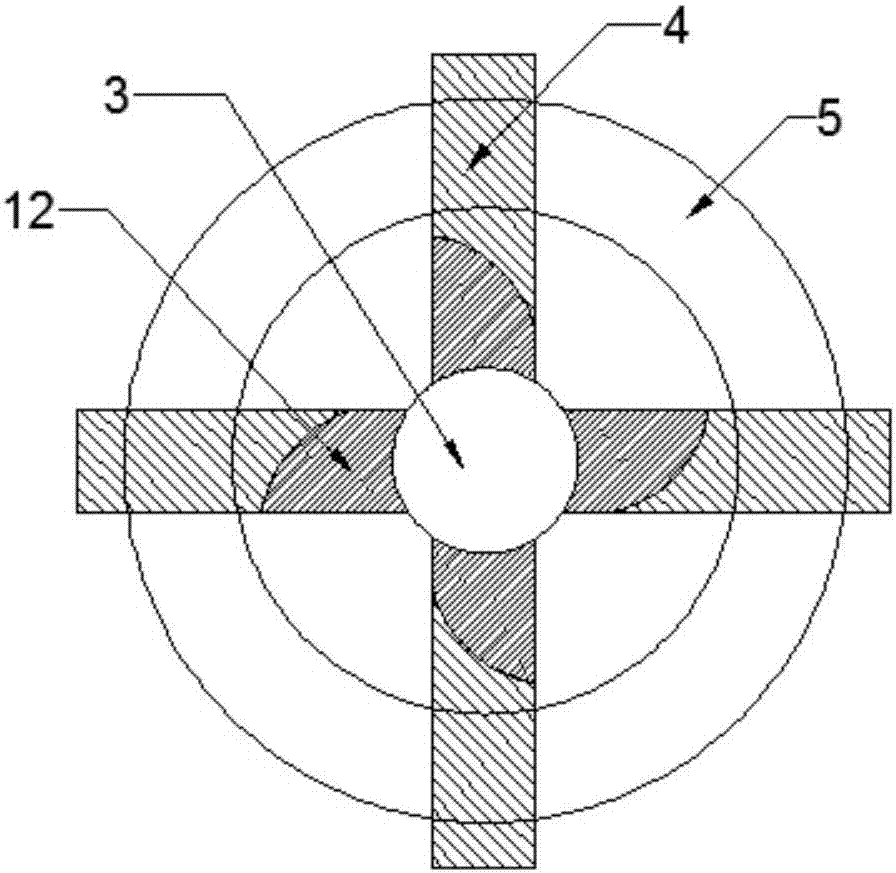

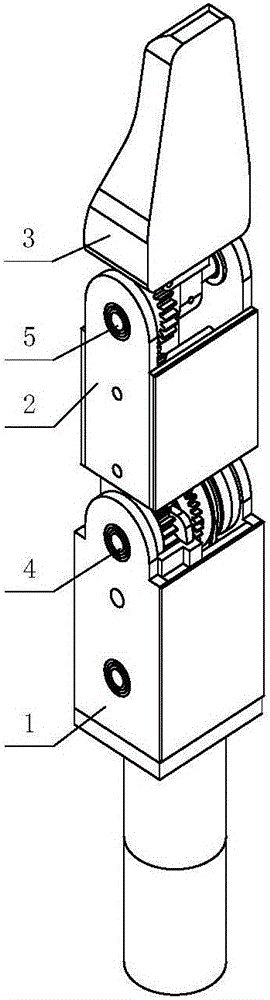

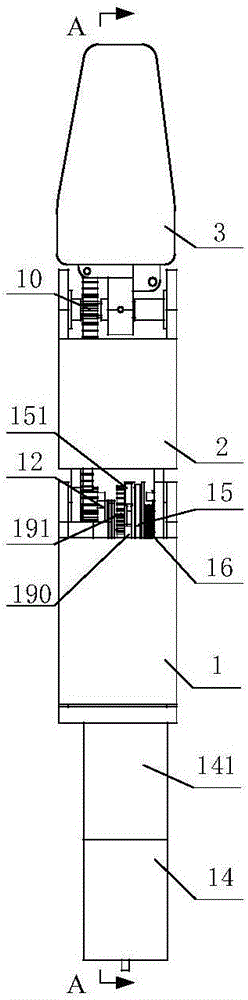

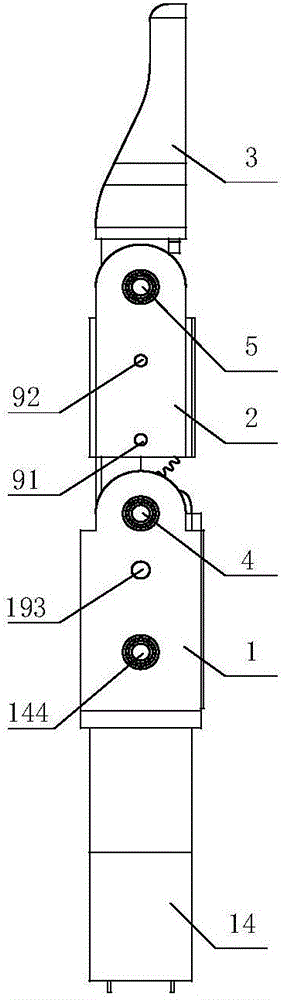

Idle stroke transmission gear coupling self-adaption robot finger device

InactiveCN106426239AHigh degree of anthropomorphismImprove grip strengthGripping headsReal-time Control SystemRobot hand

The invention discloses an idle stroke transmission gear coupling self-adaption robot finger device, and belongs to the technical field of robot hands. The device comprises a base, two finger sections, two joint shafts, a drive, multiple gears, a transition transmission mechanism, an intermediate transmission mechanism, a driving poking wheel, a driven poking wheel, a convex block poking disc, two springs, a limiting convex block and the like. The device realizes coupling and a self-adaption compound grabbing mode, can link two joints to hold an object by the tail ends to achieve high action personification degree, can rotate the second finger section to wrap the held object after rotating the first finger section to touch the object, is high in grabbing strength, achieves self-adaption grabbing effect of objects with different shape sizes, is stable and reliable in grabbing, drives two joints by using one drive without complex sensing and real-time control systems, and meanwhile, is simple in structure, small in size, light in weight, low in machining, assembly and maintenance costs and suitable for the robot hands.

Owner:TSINGHUA UNIV

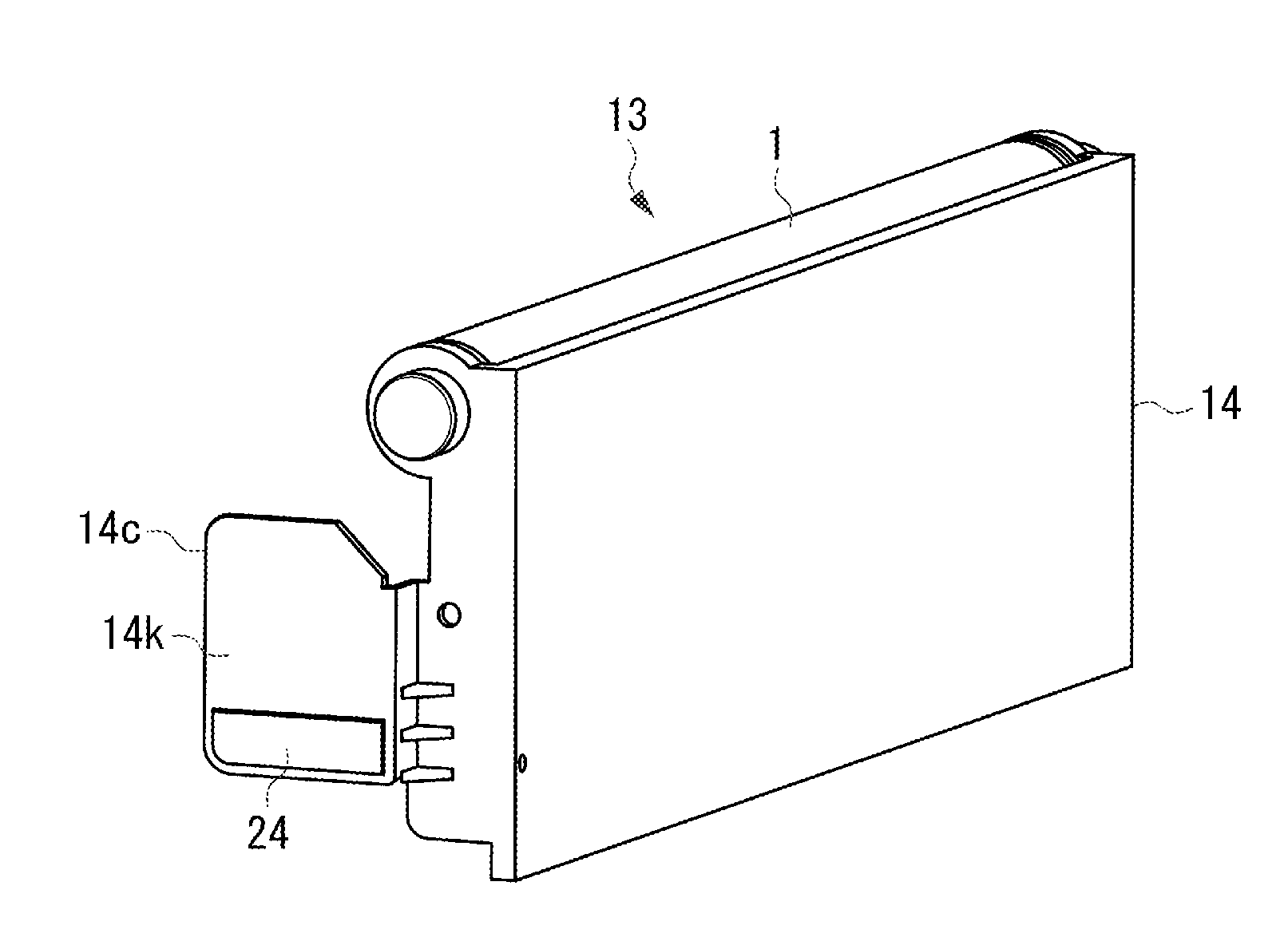

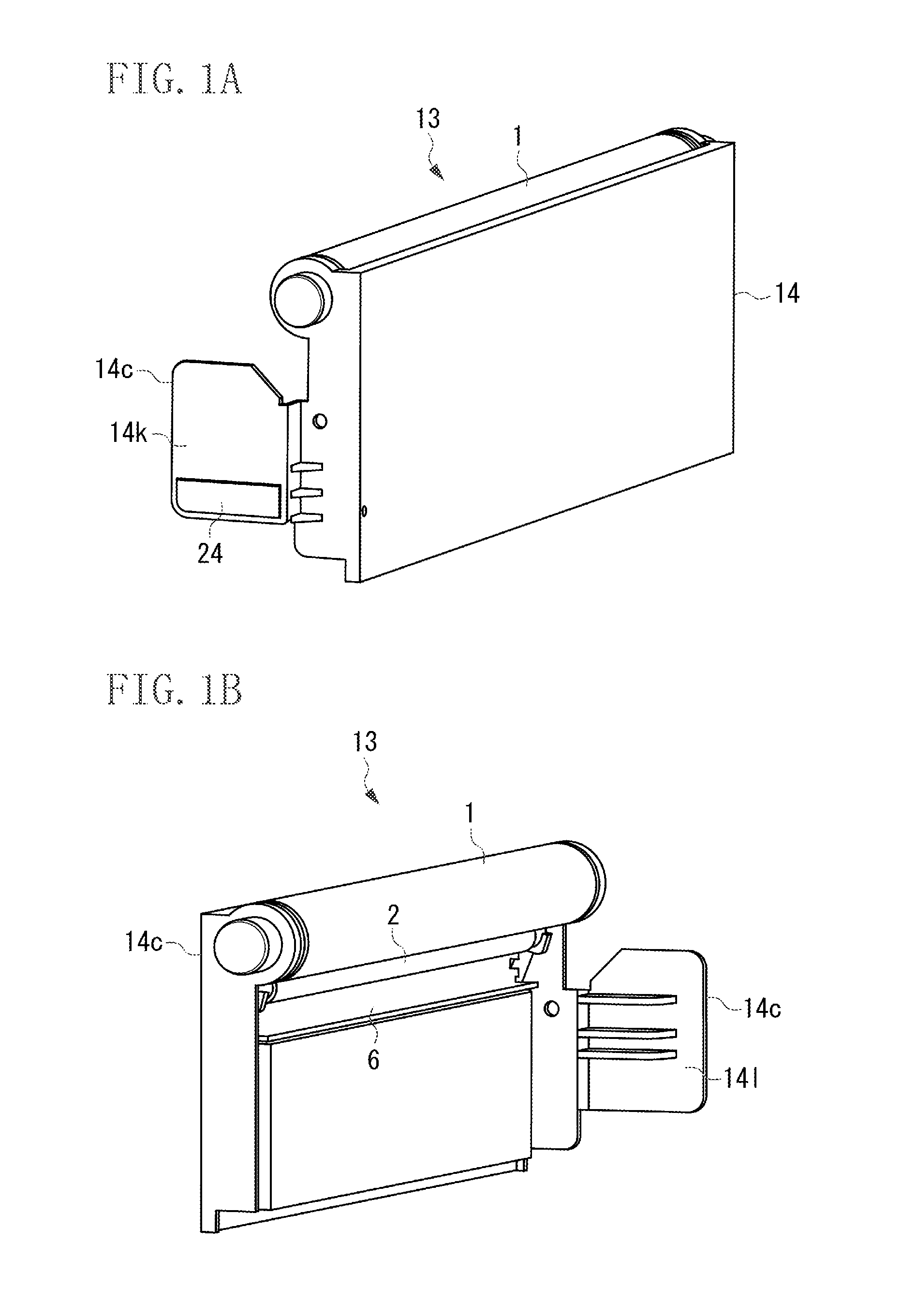

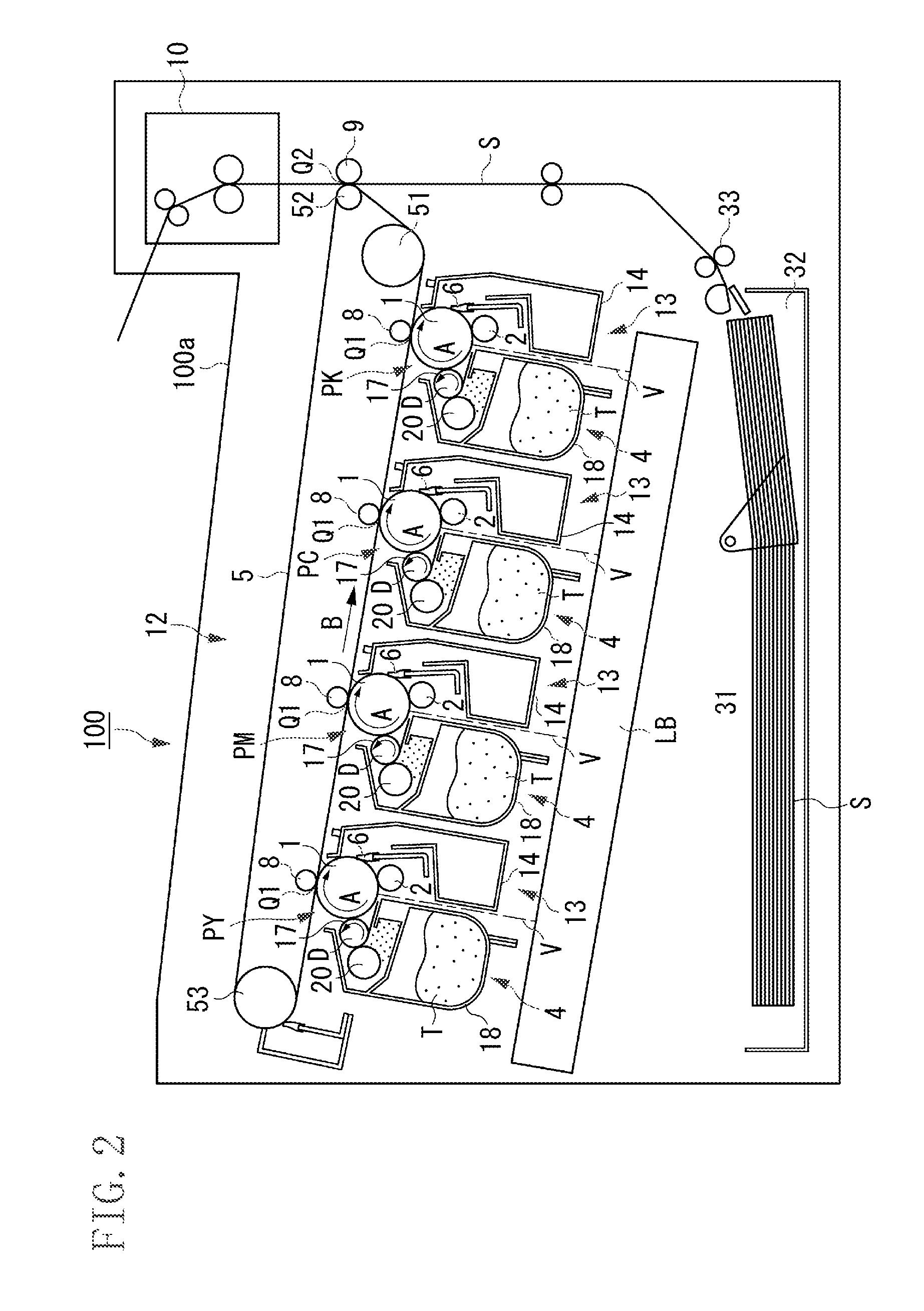

Cartridge

InactiveUS20140086629A1Improve grip strengthAvoid thickness thinningElectrography/magnetographyImaging equipmentMechanical engineering

A cartridge detachably mountable to an apparatus body of an image forming apparatus, includes a grip member that is provided on the frame member for gripping the cartridge when the cartridge is mounted on or dismounted from the apparatus body, the grip member including a first molded member that is integrally molded with the frame member, and a second molded member that is integrally molded on the first molded member with a second resin after the molding of the first molded member.

Owner:CANON KK

Joint of carbon fiber composite core wire

InactiveCN102570373AGuaranteed uniformityImprove grip strengthOverhead installationCable terminationsCarbon fiber compositeTransmission line

The invention discloses a joint of a carbon fiber composite core wire, which comprises a steel anchor and a jumper conductor clamper which is connected with the steel anchor. The terminal section of the steel anchor is provided with an inner layer press-connection pipe, an outer layer sleeve is coated outside the inner layer press-connection pipe, the inner layer press-connection pipe is provided with a hollow cavity, and the carbon fiber composite core wire inner core to be connected can be inserted into the hollow cavity. Due to the inner layer press-connection pipe and the outer layer sleeve coated outside the inner layer press-connection pipe, when the carbon fiber composite core wire is performed with clamping press fit, force of the press fit is pressed on the wire through two layers of pipe walls, so that the force of the press fit can be dispersed to the stressed steel anchor, uniformity of force loaded on the carbon fiber composite core wire is guaranteed, and grip strength of the joint on the carbon fiber composite core wire is improved. The structure of the joint is simple and reasonable, anchor connection is convenient and reliable, borne force is reasonable, and the joint is widely used for erecting transmission lines of the carbon fiber composite core wire.

Owner:GUANGZHOU XYHY ELECTRIC POWER LINE EQUIP

Sports glove with gripping power

InactiveUS9055774B2Improve grip strengthImprove performanceGlovesSport apparatusLittle fingerEngineering

A sports glove that increases grip strength to enhance an athlete's performance in any sport. The increase in grip strength generated by the Vpower sports glove of the invention is brought about by sewing the index finger and middle finger together and the ring finger and pinky finger together so that the pairs of fingers act as one finger. Another embodiment of the Vpower glove employs a hook and loop tape arrangement to bind the pairs of fingers together so that they act as one to increase the gripping power of the glove. The Vpower glove forces the wearer to use the power of two fingers on every grip and immediately increases the gripping strength of the wearer without any additional effort and this increase in grip strength is permanent.

Owner:GAMBORDELLA TED

Athletic support glove

A glove formed from a stretchable material for the purpose of increasing grip strength and protecting and supporting the wearers hand. The glove has a first finger stall, a second finger stall, and a thumb aperture, and is formed from a stretchable material that keeps the fingers in the first finger stall and the second finger stall tightly compressed to protect each from injury, and to increase the strength of two fingers being tightly compressed together. The thumb extends out of the thumb aperture and is free to move independently of the first finger stall and the second finger stall in order to allow the thumb freedom of movement and not be locked together with either of the finger stalls.

Owner:KOWALSKY JONATHAN

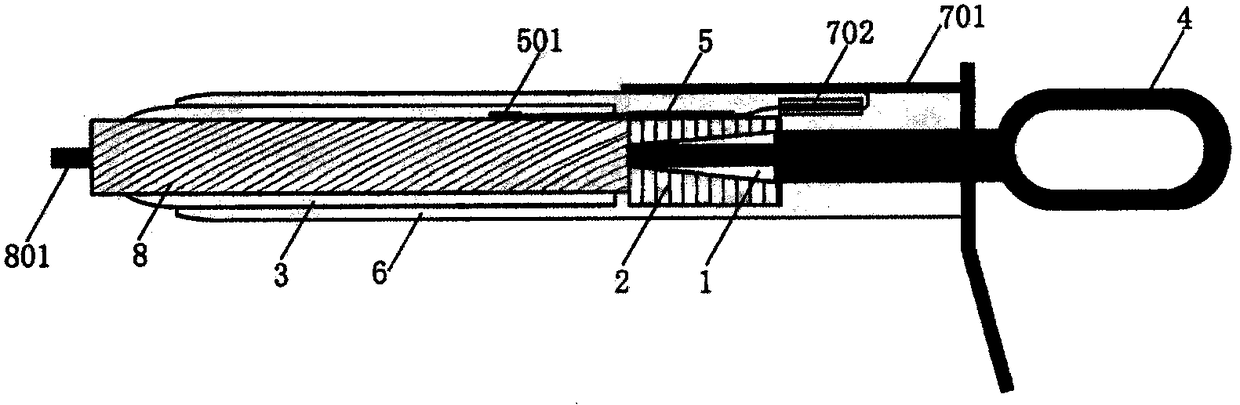

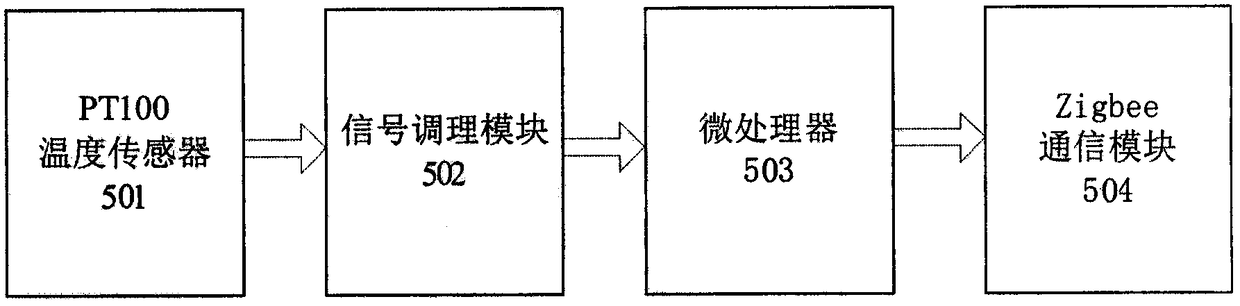

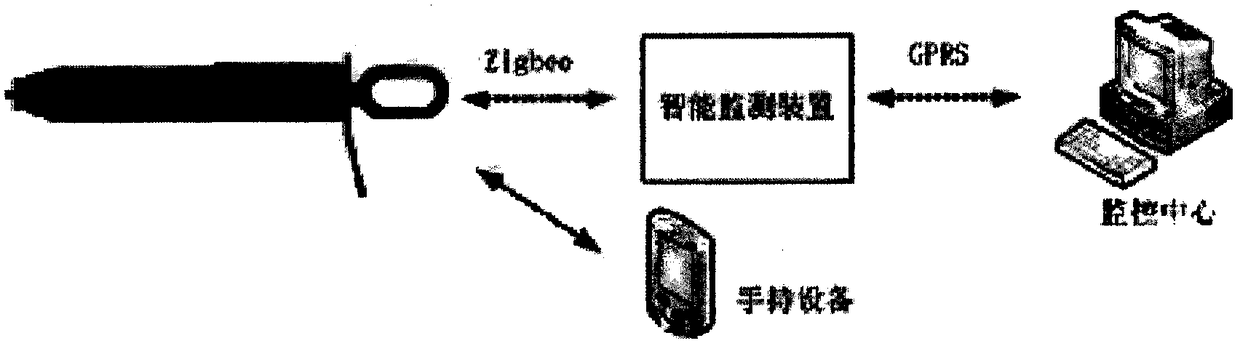

Power transmission line intelligent temperature measuring strain clamp

InactiveCN108631245AReduce the impact of temperature measurementsReduce volumeThermometer detailsBatteries circuit arrangementsSignal conditioningPower grid

The invention provides a power transmission line intelligent temperature measuring strain clamp comprising a wedge clamp head, a wedge clamp base, a lining pipe, a connecting ring, a wireless temperature measuring unit, a connecting sleeve and a solar power supply unit which are arranged from inside to outside. The wireless temperature measuring unit comprises a PT100 temperature sensor, a signalconditioning module, a microprocessor and a zigbee communication module which are connected in turn. The wireless temperature measuring unit is arranged on the internal wall of the lining pipe, and other modules are arranged between the wedge clamp base and the strain clamp connecting sleeve. A zigbee module antenna is arranged on the external surface of the strain clamp connecting sleeve. The solar power supply unit comprises two parts of a flexible solar cell panel and arc polymer cells. The solar cell panel wraps the external surface of the strain clamp connecting sleeve for charging the arc polymer cells. The arc polymer cells supply power to the wireless temperature measuring unit. According to the intelligent power grid strain clamp, the problems of low accuracy of the original leadtemperature measuring unit and inconvenient installation can be solved.

Owner:徐州宇飞电力科技有限公司

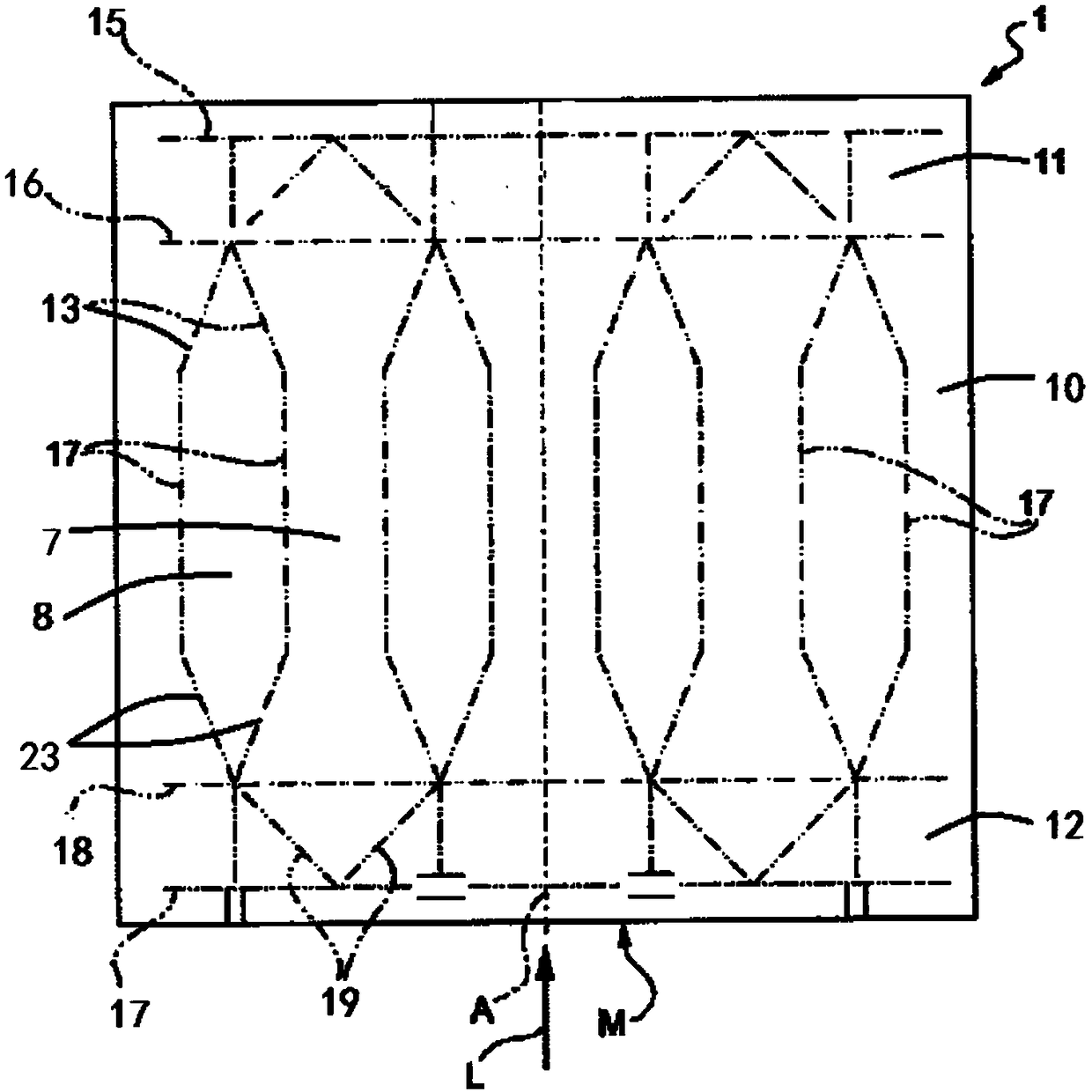

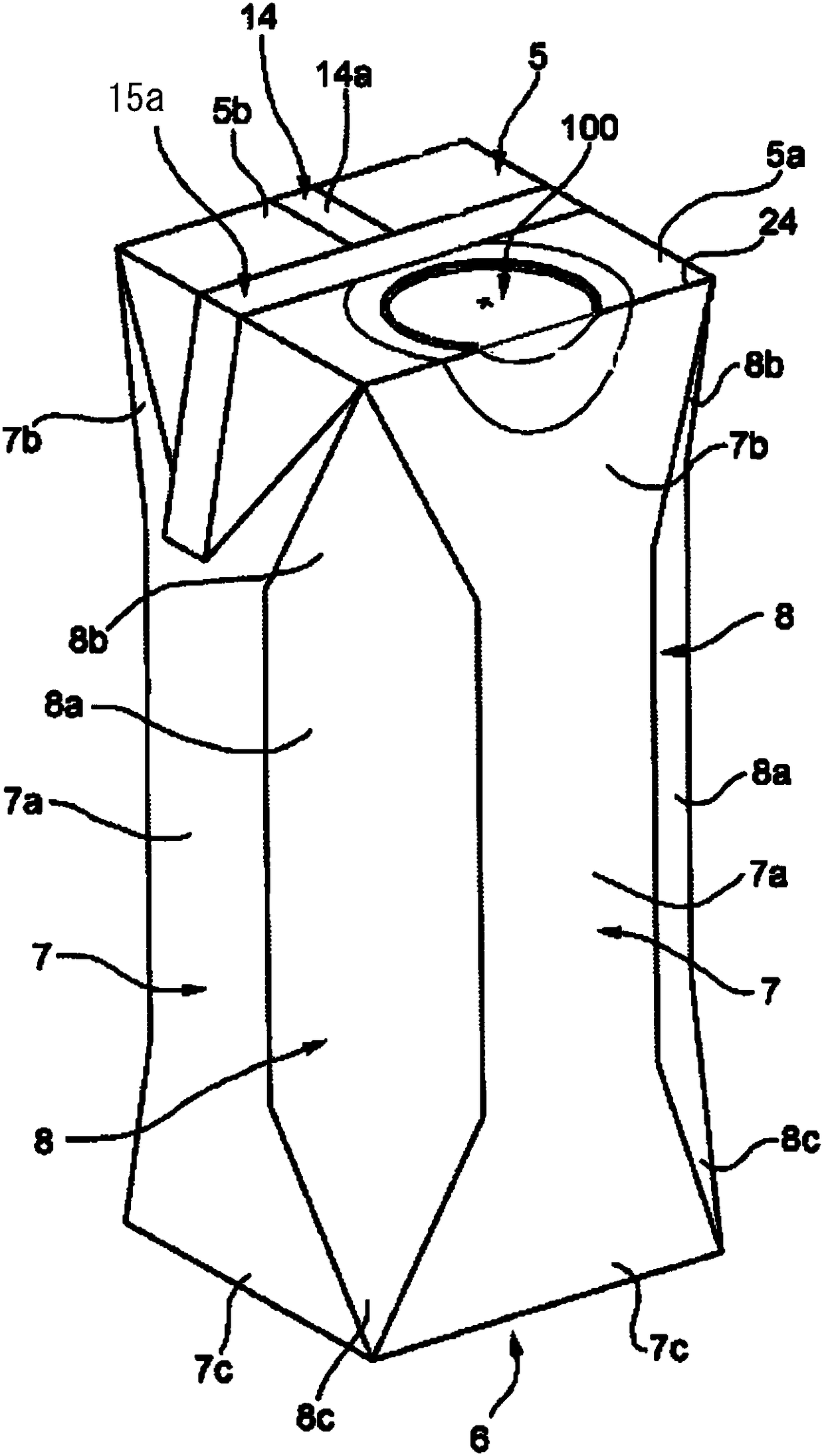

Packing material

InactiveCN108357749AFull appearanceImprove grip strengthRigid containersPack materialUltimate tensile strength

The invention relates to a packing material. The packing material comprises a top surface part, a main body part and a bottom surface part; a first transverse crease line is pressed between the top surface part and the main body part, and a second transverse crease line is pressed between the bottom surface part and the main body part; pairs of longitudinal crease lines are pressed on the main body part; first oblique crease lines are pressed between the longitudinal crease lines and the first transverse crease line, and second oblique crease lines are pressed between the longitudinal crease lines and the second transverse crease line; each pair of longitudinal crease lines and the first oblique crease line and the second oblique crease line at the two ends of the pair of longitudinal crease lines define an auxiliary wall plate; the first transverse crease line, the second transverse crease line, two longitudinal crease lines of corresponding adjacent pairs, and the first oblique crease lines and the second oblique crease lines at the two ends of the two longitudinal crease lines of adjacent pairs define a main wall plate; and the longitudinal crease lines, the first oblique creaselines and the second oblique crease lines are formed by pressing the inner side surfaces of a support layers downwards. The packing material has the advantages of being easy to form in the process ofbeing manufactured into a packing container, and the manufactured packing container is full in appearance and high in holding strength.

Owner:朱双海

Pouch transport grippers

ActiveUS20130025240A1Increases its gripping powerWeight increaseContainer making machineryPressure increaseGrippers

Owner:MAMATA ENTERPRISES

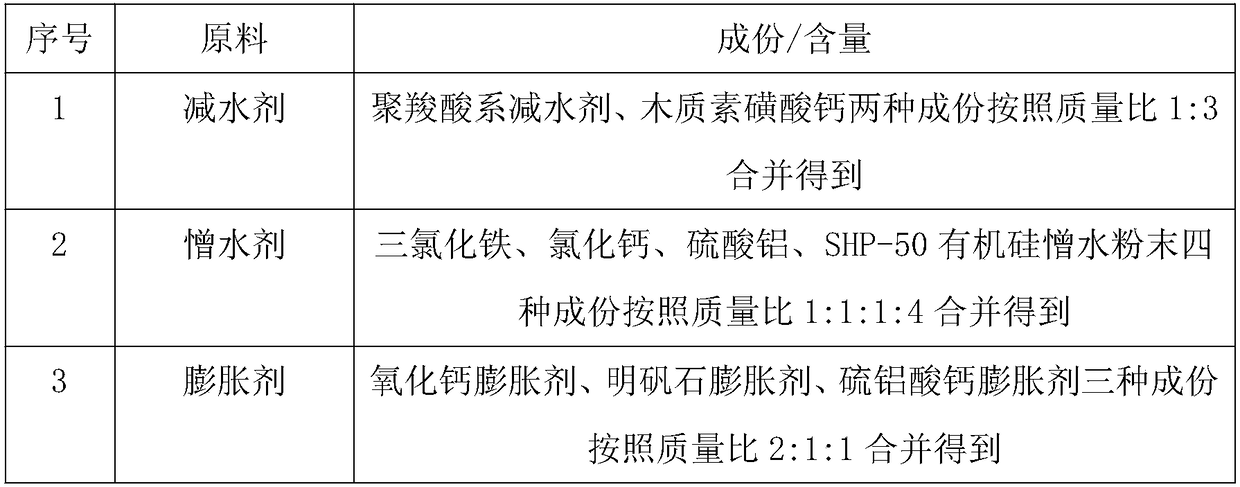

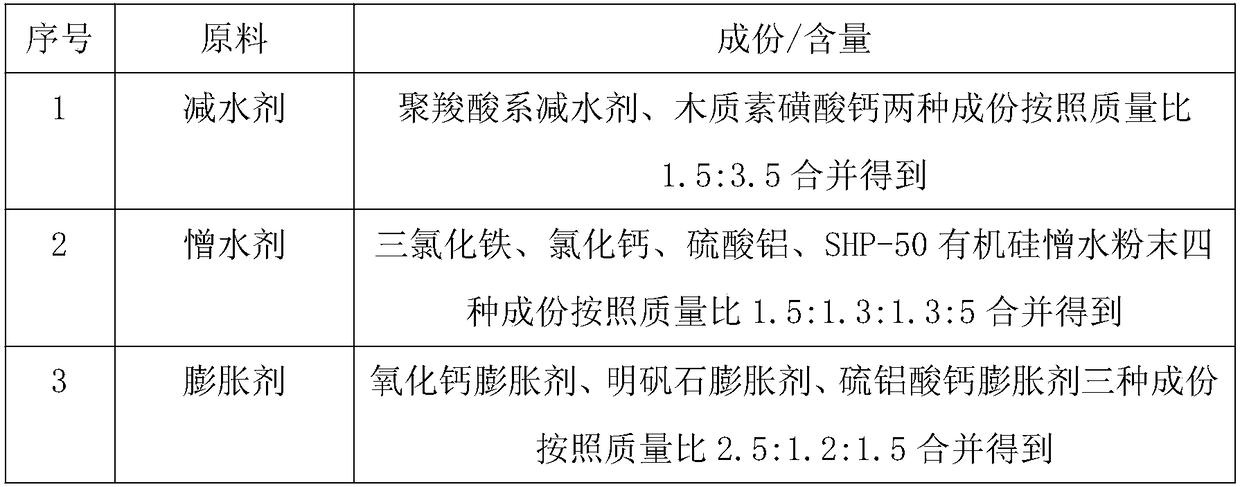

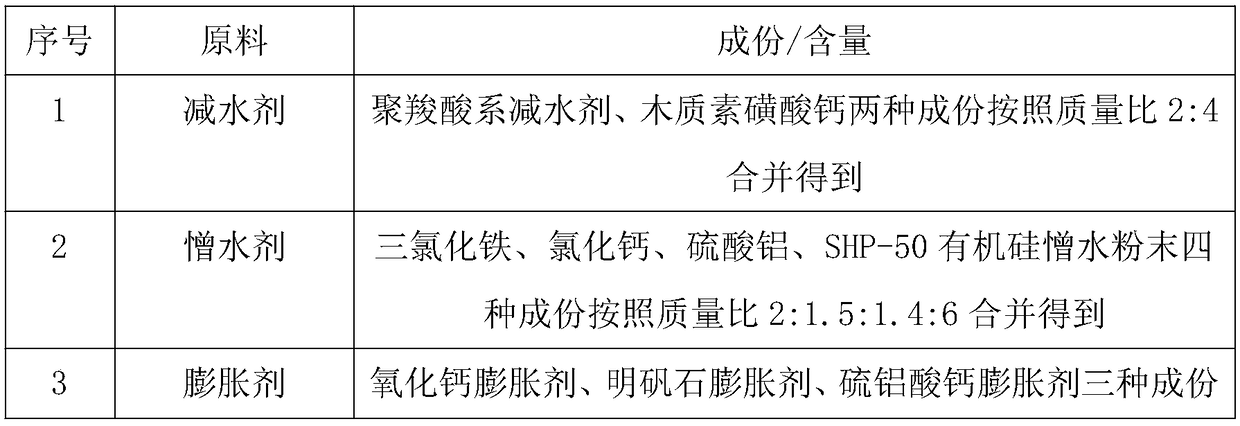

High-temperature-resistant non-shrink early-strength grouting material and application thereof

The invention discloses a high-temperature-resistant non-shrink early-strength grouting material and application thereof, and relates to the technical field of grouting materials. The high-temperature-resistant non-shrink early-strength grouting material comprises volcanic ash silicate cement 32.5R, perovskite flotation tailing, illite powder, shell powder, shale pottery sand, Swf-05 gelatin powder, water reducing agents, water repellents, expansive agents, rare-earth coupling agents and magnetized water. The high-temperature-resistant non-shrink early-strength grouting material and the application have the advantage that the high-temperature-resistant non-shrink early-strength grouting material is comprehensively obviously enhanced in the aspects of the physical properties, the frost resistance, the high-temperature resistance, the flowability, the mechanical strength and the like, is obviously progressed as compared with the prior art, and is good in applicability and long in servicelife.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com