Joint of carbon fiber composite core wire

A composite core and carbon fiber technology, which is applied in the installation of cables, cable terminals, electrical components, etc., can solve the problems of high requirements for construction technology, complex structure, and unfavorable wide-range application, so as to achieve convenient and reliable anchoring, and improve The effect of grip strength and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

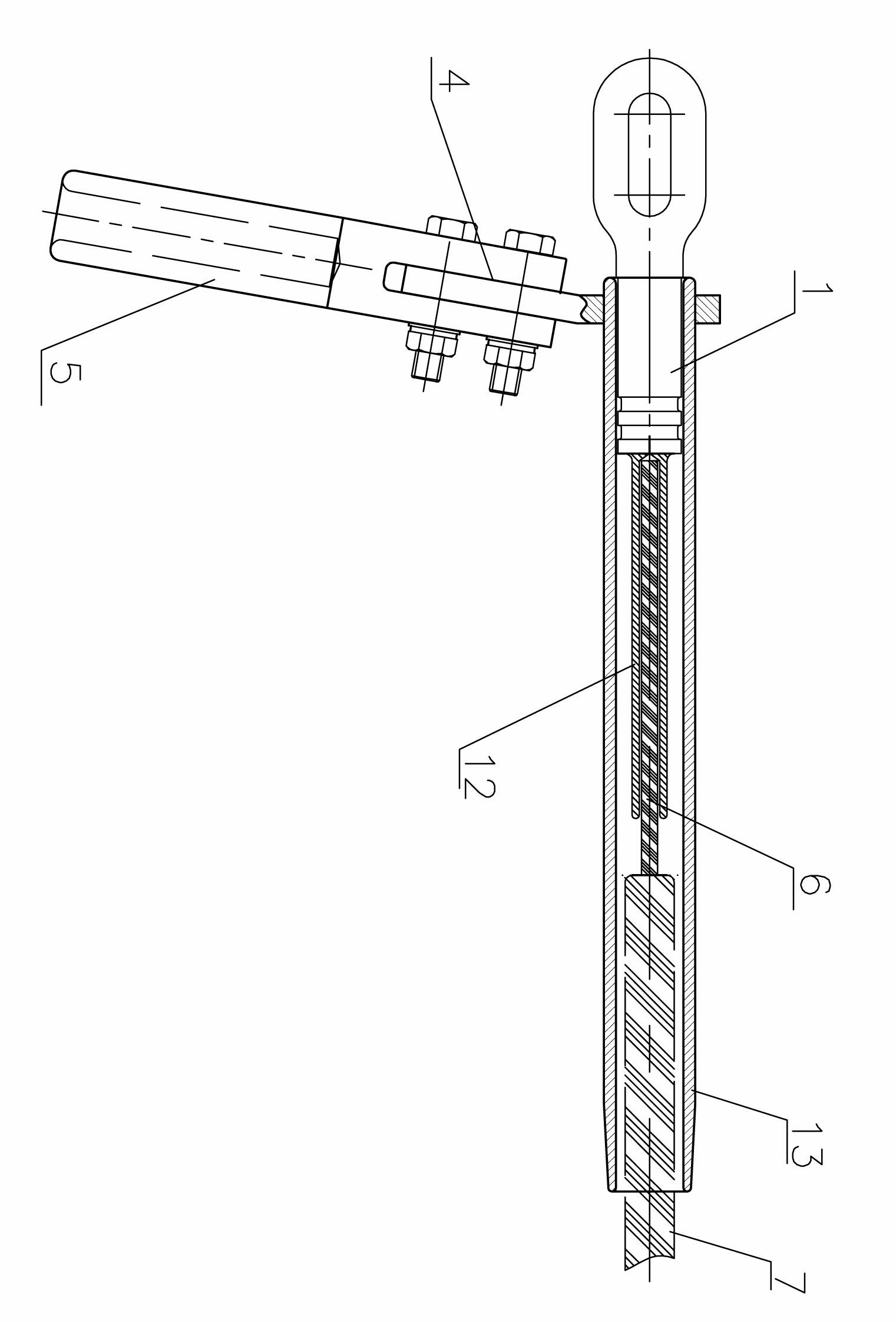

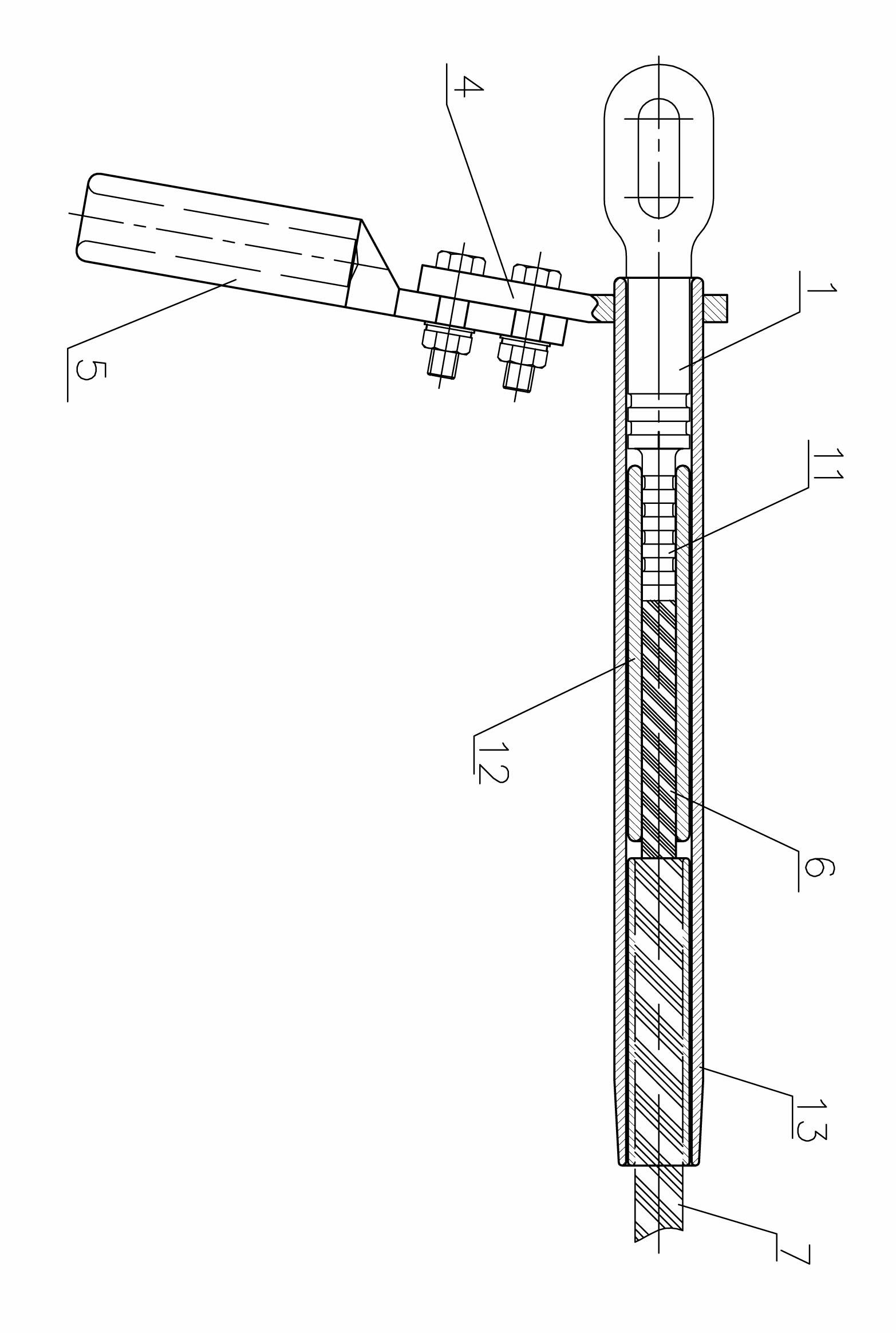

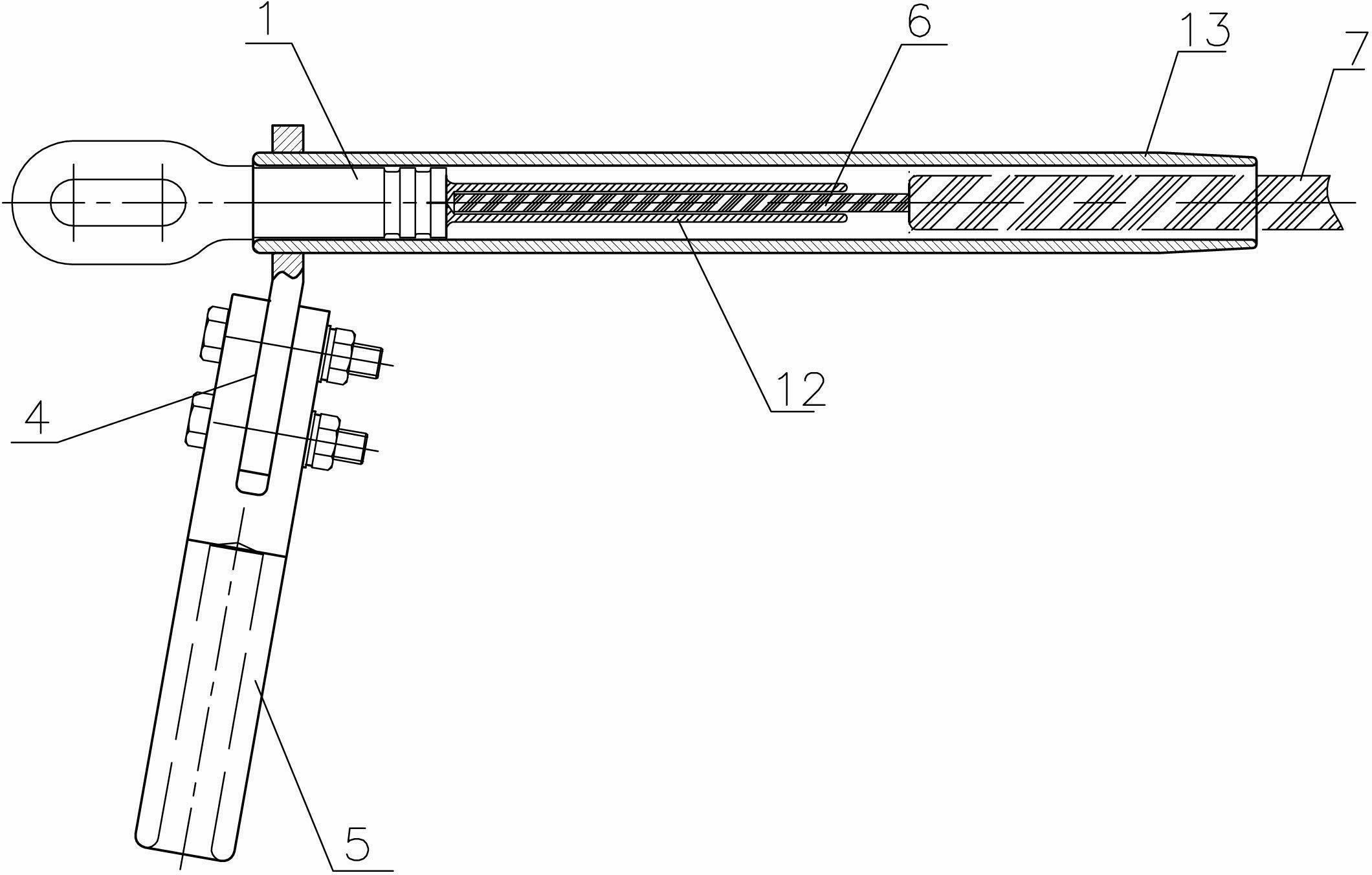

[0018] A joint for a carbon fiber composite core wire, comprising a steel anchor 1 and a drain clamp 5 connected to the steel anchor 1, the end of the steel anchor 1 is provided with an inner layer crimping tube 12, and the inner layer crimping tube 12 is covered with The outer casing 13, the inner crimping tube 12 is provided with a cavity for accommodating the inner core of the carbon fiber composite core wire to be connected.

[0019] For the first example, see figure 1 , a carbon fiber composite core wire joint, including a steel anchor 1 and a drain clamp 5 connected to the steel anchor 1, the end of the steel anchor 1 is directly connected to the inner crimping tube 12, and the two are connected into one body, the inner The laminated connecting tube 12 is covered with an outer layer sleeve 13, and the inner layer crimping tube 12 is provided with a cavity in which the inner core 6 of the carbon fiber composite core wire to be connected is embedded. The inner core 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com