Strain clamp of aluminum alloy core aluminum stranded wire

A core aluminum stranded wire, tension clamp technology, applied in the direction of adjusting/maintaining mechanical tension, etc., can solve the problems of low product strength, difficult to meet, unable to hold, etc., to achieve convenient and reliable anchoring, simple and reasonable structure, Guaranteed uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

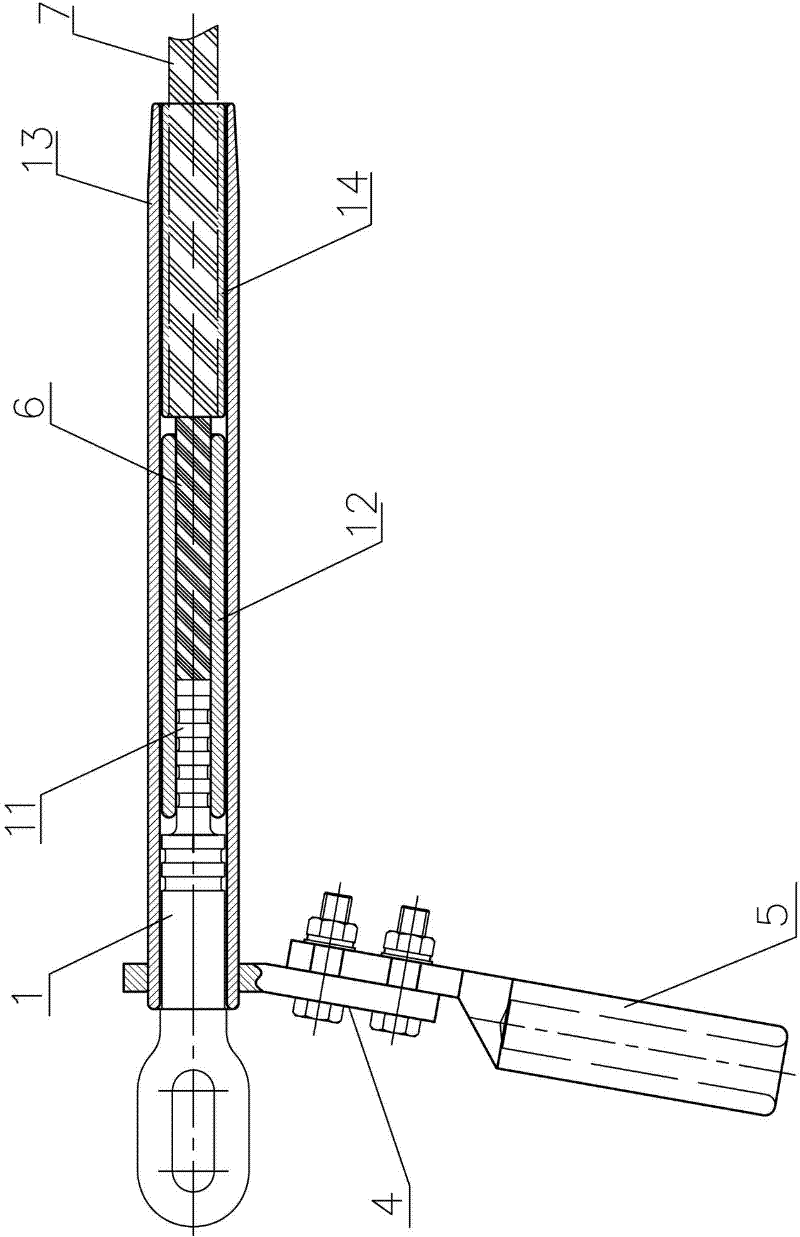

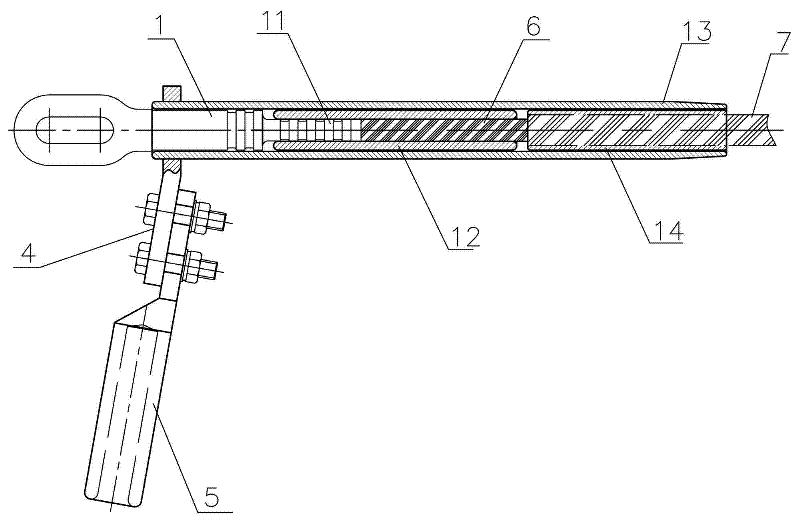

[0015] refer to figure 1 , a strain clamp of an aluminum alloy cored aluminum stranded wire, comprising a steel anchor 1 and a drainage clamp 5 connected with the steel anchor 1, the end of the steel anchor 1 is connected with an anchor head 11, the anchor head 11 The outer surface is covered with an inner layer crimping tube 12 and an outer layer sleeve 13 sequentially from the inside to the outside. The inner layer crimping tube 12 is provided with a cavity for accommodating the inner core of the aluminum alloy cored aluminum stranded wire to be connected. Specifically, the steel anchor 1 is integrated with the anchor head 11 , the steel anchor 1 is connected with the drain clamp 5 through the drain plate 4 , and the drain plate 4 and the body 13 are welded as a whole. When working, the inner core 6 of the aluminum alloy core aluminum stranded wire to be connected is located in the inner layer crimping tube 12, and the front end is against the anchor head 11. The mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com