Packing material

A packaging material and crease line technology, applied in the field of packaging materials with a support layer, can solve the problems of insufficient packaging container, low holding strength, poor molding effect, etc., and achieve the effect of enhancing holding strength and full appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0022] The first embodiment of a packaging material of the present invention comprises the outermost layer of thermoplastic material, the support layer, the middle layer of thermoplastic material, the barrier layer, the adhesive layer and the innermost layer of thermoplastic material in order from outside to inside, and the support layer faces the thermoplastic material Identification information is printed on one side of the outermost layer, wherein the support layer is a paper matrix layer, and the barrier layer is an aluminum foil layer.

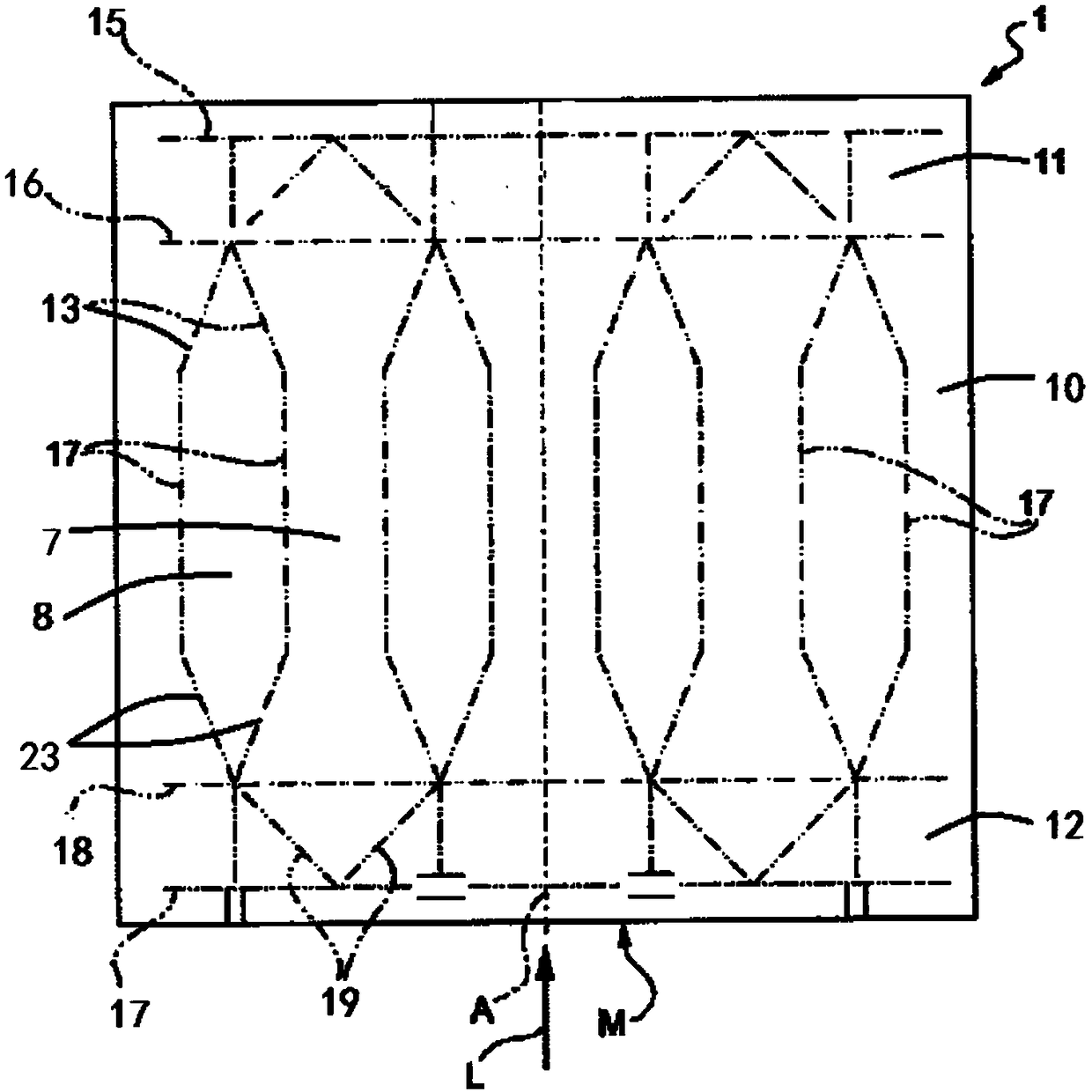

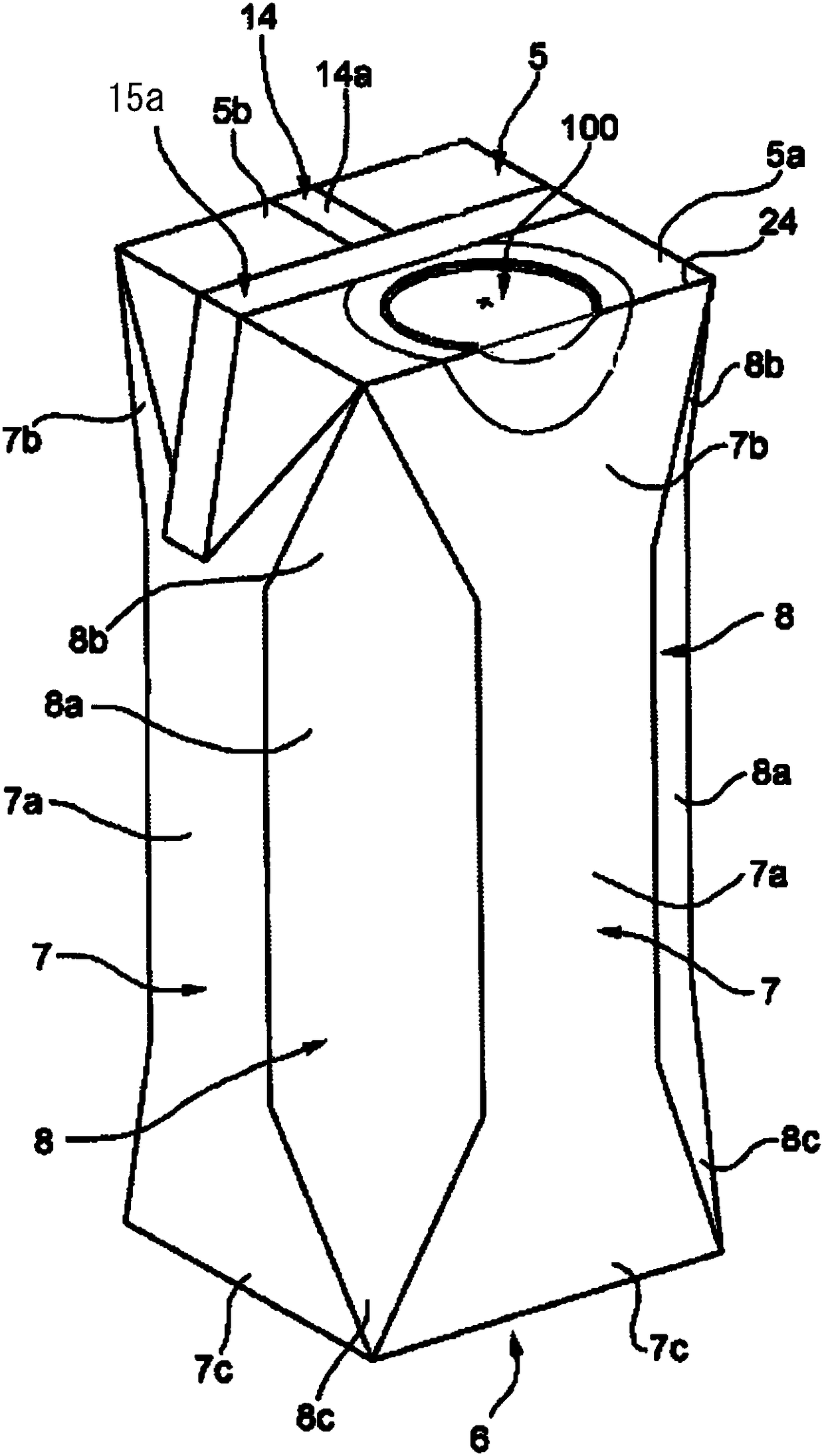

[0023] see figure 1 and figure 2 , the packaging material 1 has a top surface part 11, a main body part 10 and a bottom surface part 12; the left and right longitudinal edges 14 of the packaging material 1 are lapped and sealed to form a longitudinal sealing strip 14a, and the upper and lower ends are horizontally sealed (described below), and folded After the container is made, the top surface portion 11 is formed as the top wall 5 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com