Preparation method of high-performance gyromagnet ferrite material

A spinning ferrite, high-performance technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of poor compactness, high coercive force, and low crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

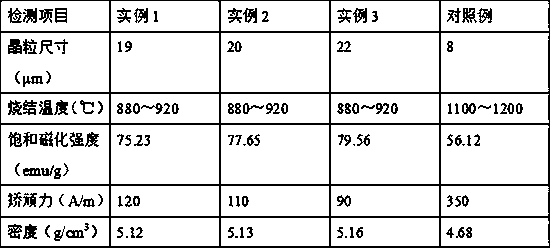

Examples

example 1

[0022] Digging and building a square cultivation field with a side length of 50m, selecting the aloe with a plant height of 20cm and planting it in the cultivation field, the concentration of 1mol / L naphthalene acetic acid solution and the concentration of 0.5mol / L indolebutyric acid solution Ratio mixed to obtain root-promoting liquid, press 500mL / m 2 Sprinkle the root-promoting liquid into the cultivation field, and cultivate it statically for 10 days; after the static cultivation, bismuth nitrate, zinc sulfate, aluminum nitrate and water Mix to obtain a metal salt solution, and then mix the metal salt solution at 1L / m 2 Sprinkle the amount of spraying into the cultivation field, continue to stand and cultivate for 20 days, and collect the cultivated aloe; cut off the cultivated aloe roots, and mix the aloe roots and rice husks in a mass ratio of 5:1 to obtain Fermentation substrate, put the fermentation substrate into a fermentation tank, then add yeast powder with 5% of t...

example 2

[0024] Digging and building a square cultivation field with a side length of 50m, selecting an aloe with a plant height of 25cm and planting it in the cultivation field, adding a concentration of 1mol / L naphthalene acetic acid solution and a concentration of 0.5mol / L indolebutyric acid solution Ratio mixed to obtain root-promoting liquid, press 500mL / m 2 Sprinkle the root-promoting liquid into the cultivation field, and cultivate it statically for 13 days; after the static cultivation ends, bismuth nitrate, zinc sulfate, aluminum nitrate and water Mix to obtain a metal salt solution, and then mix the metal salt solution at 1L / m 2 Sprinkle the amount of spraying into the cultivation field, continue to stand for 25 days, and collect the cultivated aloe; cut off the cultivated aloe root, and mix the aloe root and rice husk in a mass ratio of 5:1 to obtain Fermentation substrate, put the fermentation substrate into a fermentation tank, then add yeast powder with 5% of the ferment...

example 3

[0026] Digging and building a square cultivation field with a side length of 50m, selecting the aloe with a plant height of 30cm and planting it in the cultivation field, the concentration of 1mol / L naphthalene acetic acid solution and the concentration of 0.5mol / L indolebutyric acid solution Ratio mixed to obtain root-promoting liquid, press 500mL / m 2 Sprinkle the root-promoting liquid into the cultivation field, and cultivate it statically for 15 days; after the static cultivation, bismuth nitrate, zinc sulfate, aluminum nitrate and water Mix to obtain a metal salt solution, and then mix the metal salt solution at 1L / m 2 Sprinkle the amount of spraying into the cultivation field, continue to stand and cultivate for 30 days, and collect the cultivated aloe; cut off the cultivated aloe roots, and mix the aloe roots and rice husks in a mass ratio of 5:1 to obtain Fermentation substrate, put the fermentation substrate into a fermentation tank, then add yeast powder with 5% of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com