High-performance assembly-type combined externally-hung wallboard

An external wall panel, prefabricated technology, applied in the direction of walls, home walls, protective buildings/shelters, etc., can solve the problems of structural durability, poor thermal insulation performance, low tensile strength, etc., and achieve good integrity and safety, improve the anti-seepage and waterproof performance, and prevent the transfer of heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present application will be described in detail below in combination with specific embodiments and accompanying drawings.

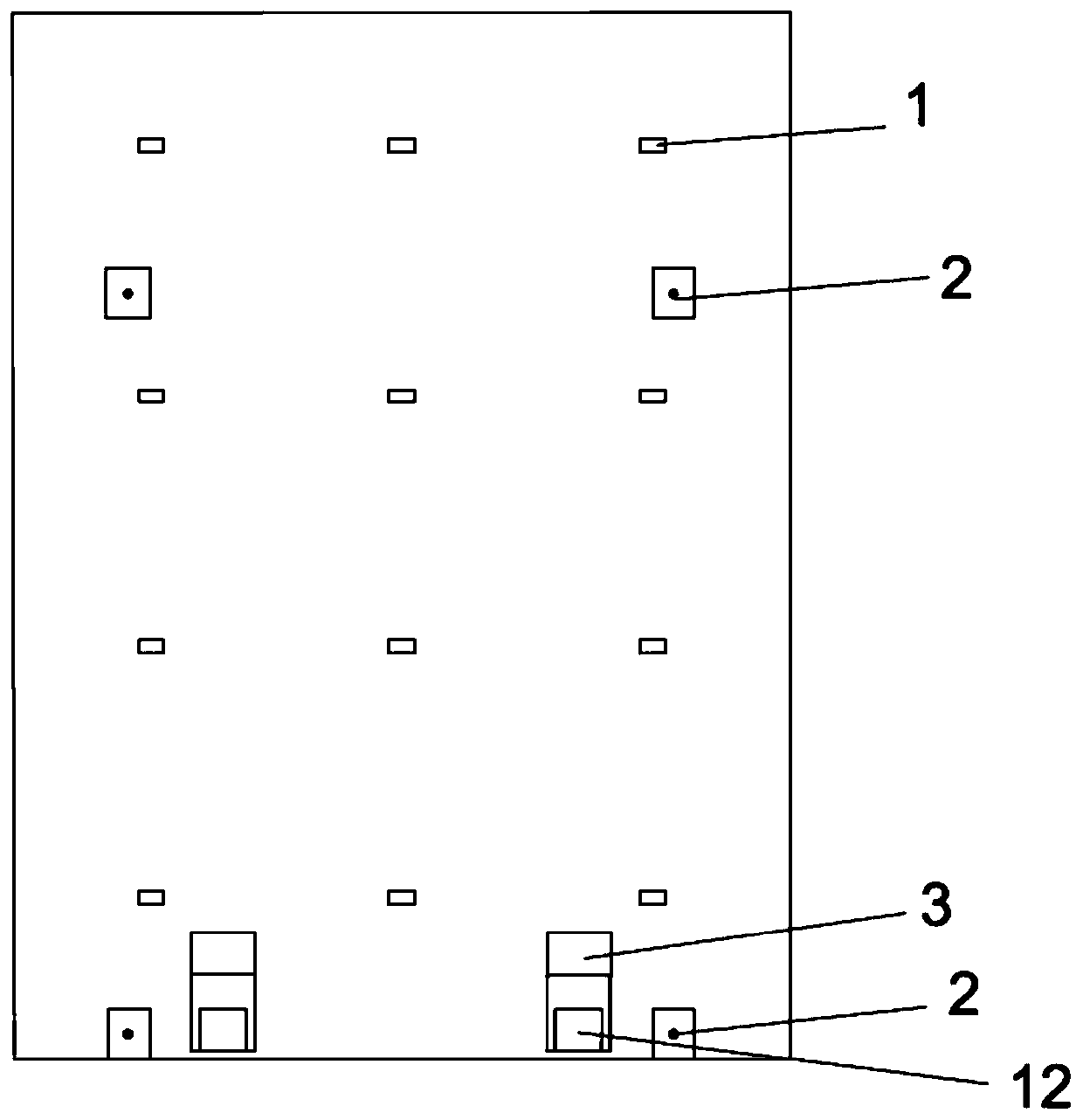

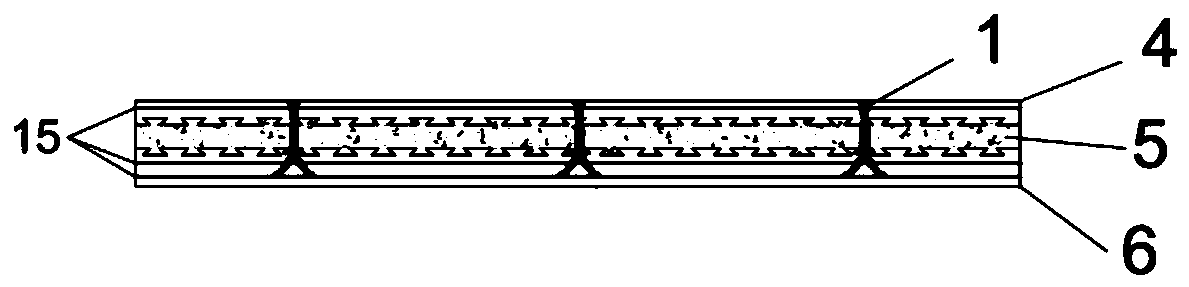

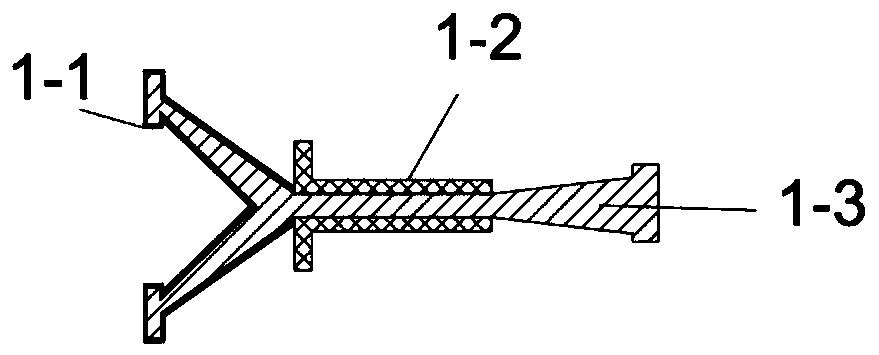

[0031] combine figure 1 and figure 2 An assembled high-performance composite external wall panel is shown, the main structure is divided into an internal structure layer 6, an insulation layer 5 and a decorative protective layer 4 that are arranged in sequence, wherein the decorative protective layer 4 is made of colored high-ductility cement-based composite materials , the insulation layer 5 is made of foamed concrete, the inner structure layer 6 is made of lightweight ceramsite concrete or non-fired lightweight aggregate concrete, and the three parts are connected to each other through the connecting piece 1 to form a whole. combine image 3 , the connecting piece 1 is pressed by Q235 steel plate, the two ends of the steel plate 1-3 are wide and the middle is narrow, and the two ends of the steel plate 1-3 have two protruding wing angles, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com