Prestressed composite superimposed large-diameter tube pile and manufacturing method thereof

A technology of composite materials and large-diameter pipes, which is applied in the fields of bridge engineering, civil engineering, and port engineering pile foundations. It can solve problems such as cracking and pile durability, and achieve improved crack resistance, excellent impact resistance, and durability. The effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

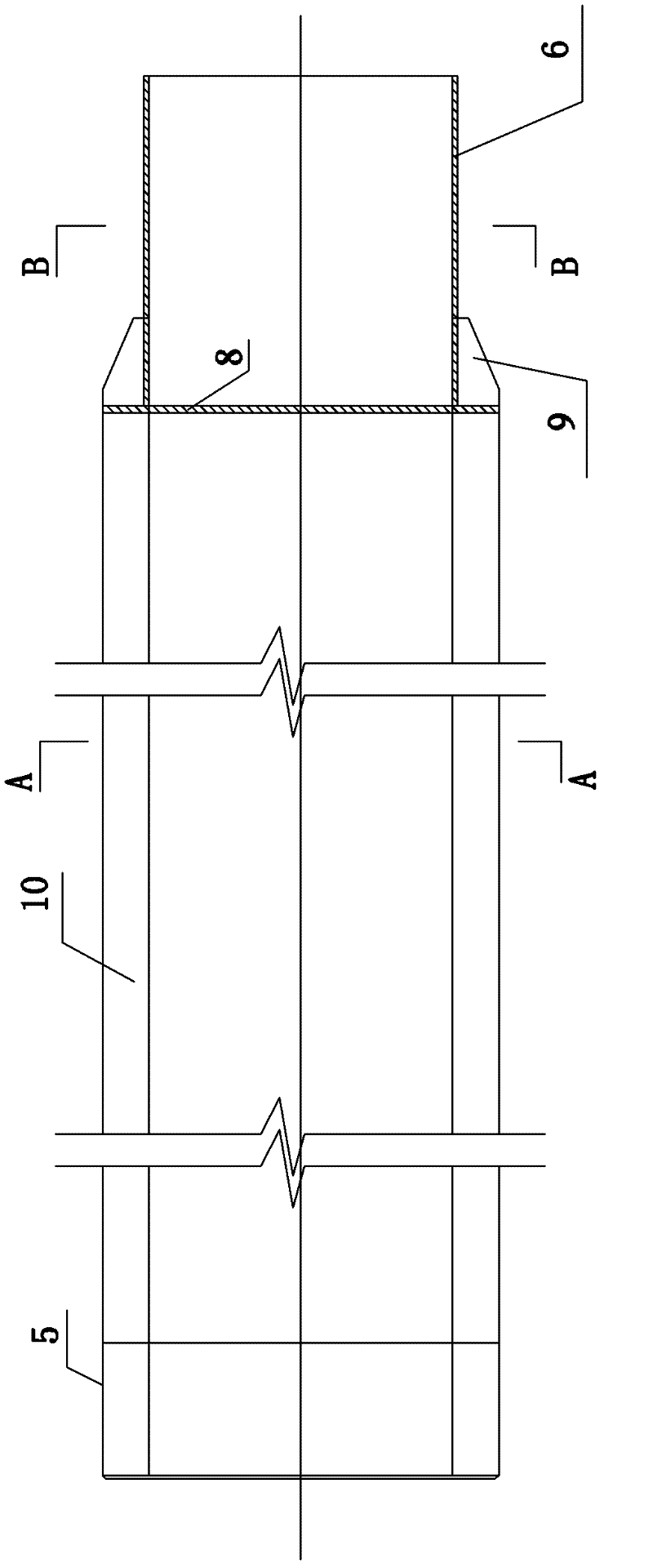

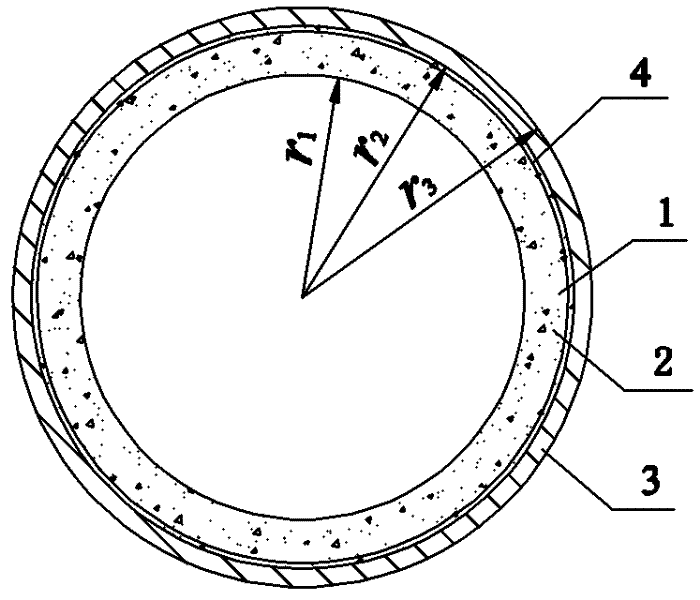

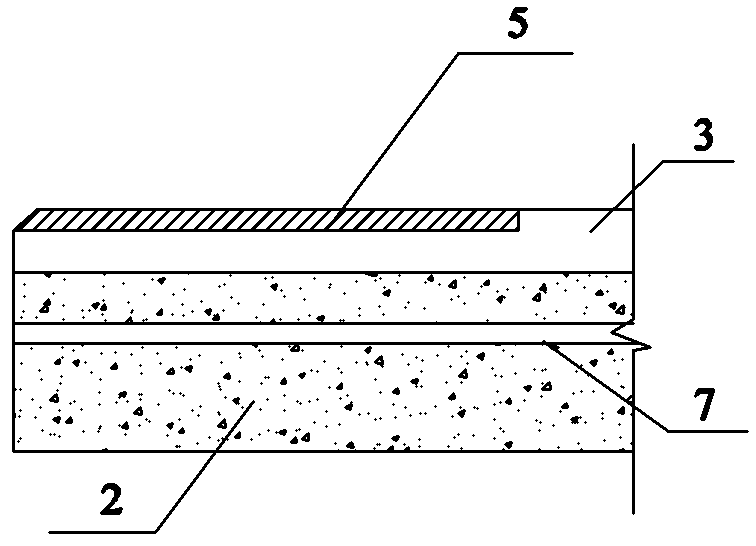

[0033] Refer to attached picture. A prestressed composite material superimposed large-diameter pipe pile provided by the present invention includes a steel pipe pile tip 6 and several pipe joints; wherein, each pipe joint adopts ultra-high-performance fiber-modified cement-based composite material UHPFRC as the matrix 2 , and an ultra-high toughness cement-based composite material UHTCC crack control protection layer 3 is provided on the outside of the matrix 2, a steel plate hoop 5 is provided on the top periphery of the pile top pipe joint, and a flange 8 is provided at the bottom of the pile bottom pipe joint. The wall is equipped with spiral stirrups 4, and a reserved channel 7 is set, and the pipe joints are spliced together by stretching the longitudinal prestressed tendons 1 passing through the reserved channel 7. 1. After the tensioning is completed, it is filled and compacted by injection of cement slurry. The steel pipe pile tip 6 and the pile bottom pipe joint fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com