Precise positioning reinforcing rib reconsolidated bamboo component production mould and manufacturing method

A technology for precise positioning and reinforcement of ribs, which is applied in the direction of manufacturing tools, wood processing appliances, and the joining of wooden veneers. Recombined bamboo components at a certain point in the cross-section, to achieve the effect of not easy to move, shorten the extraction stroke, and improve the rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

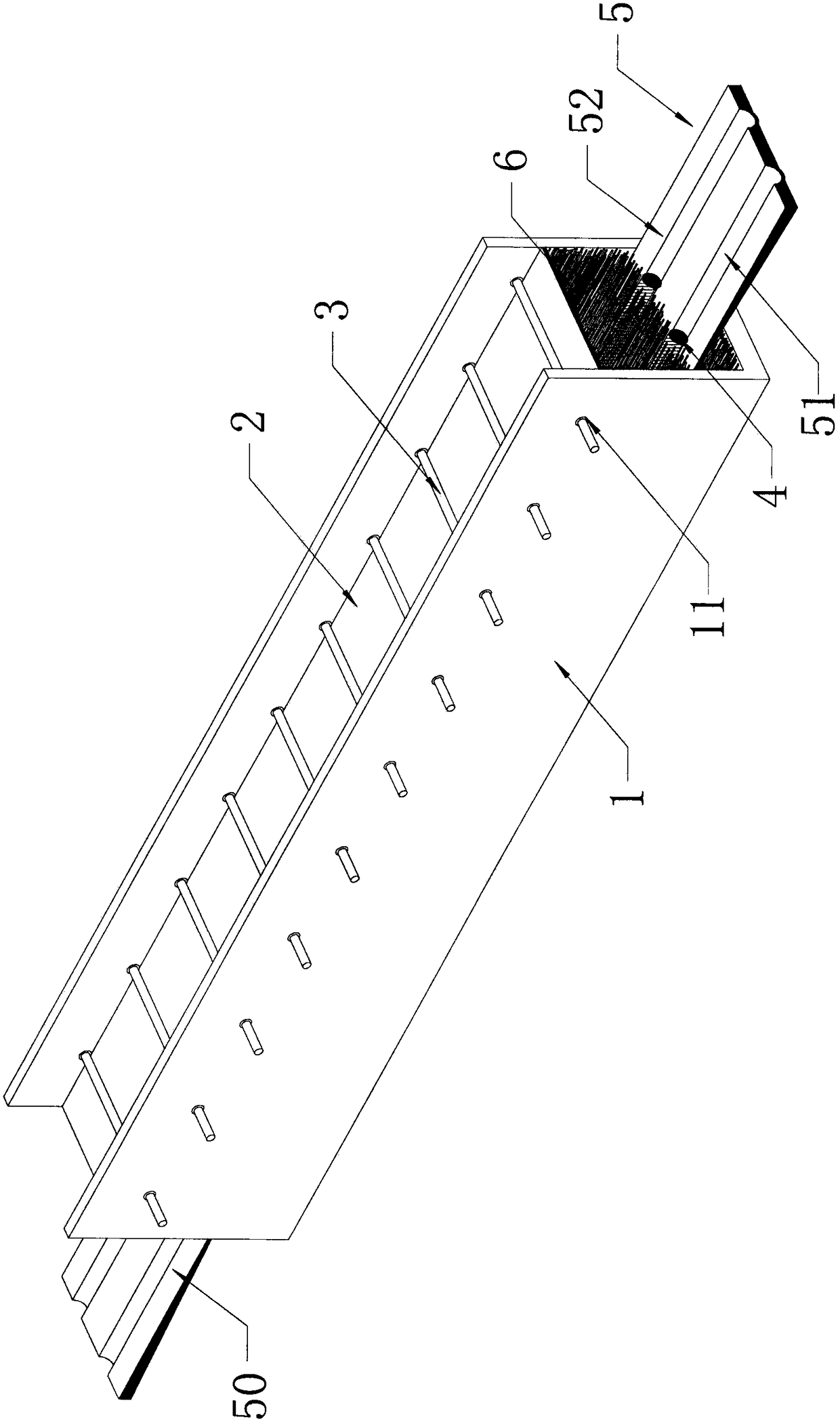

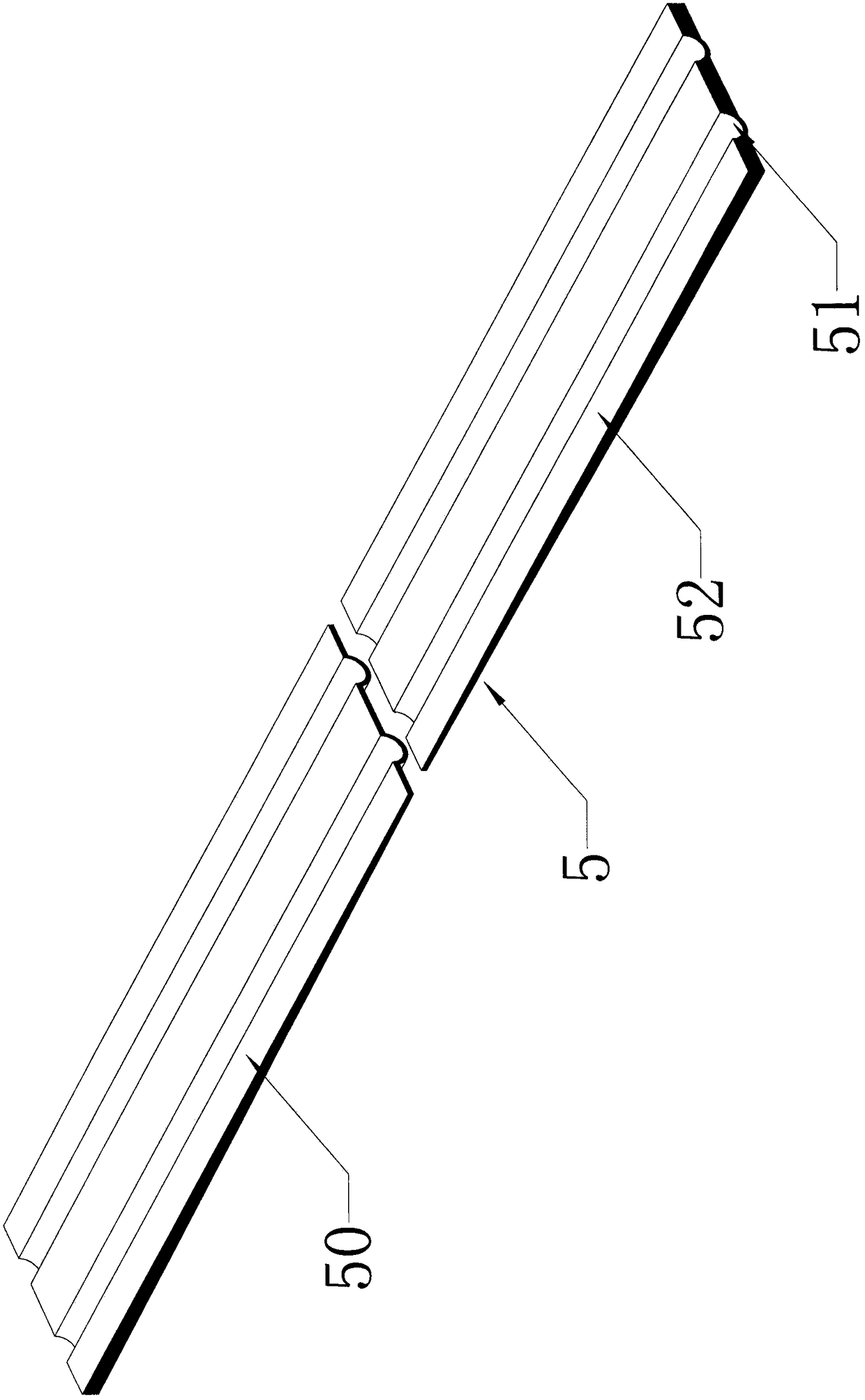

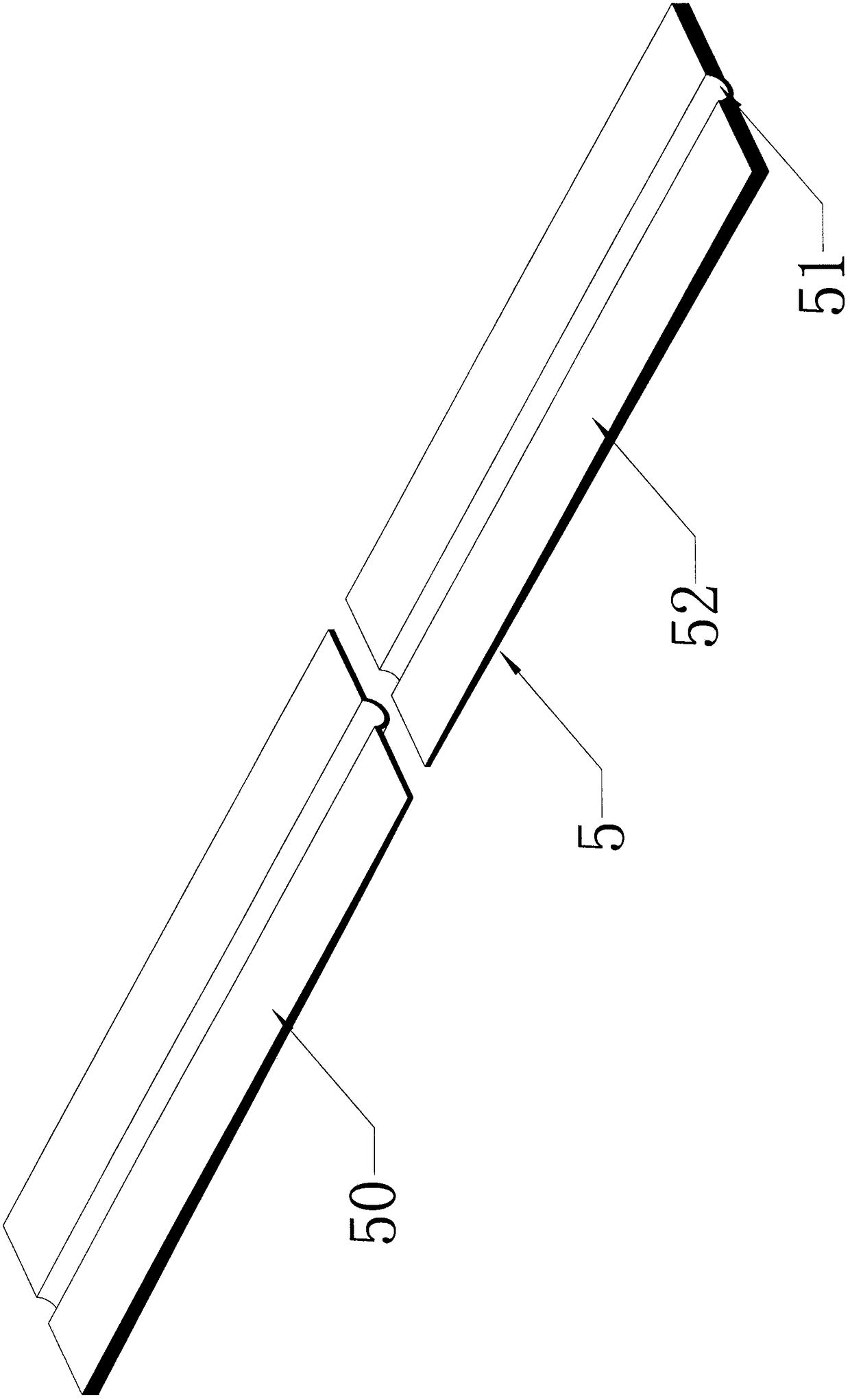

[0047] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. The present invention provides a mold for the production of recombined bamboo components with precise positioning and reinforced ribs, which includes a U-shaped mold 1, a top plate 2, a locking pin 3, a reinforced rib 4, and a reinforced rib positioning plate 5. It is characterized in that the U-shaped mold 1 is horizontal The cross-section is U-shaped, and two or more pairs of sockets 11 are symmetrically provided on the upper parts of the two side walls of the U-shaped mold 1. The reinforcing rib positioning plate 5 is composed of a left positioning plate 50 and a right positioning plate 52 with the same structure. The left positioning plate 50 and the right positioning plate The vertical section of the right positioning plate 52 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com