Contact reaction brazing process for connecting TZM alloy and graphite through pure zirconium layer

A technology of contact reaction and brazing process, which is applied in the direction of metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of low joint strength, failure of adhesive connection, and use of difficult structural materials, etc., to achieve environmental protection and workpiece surface Low requirements, increased mechanical occlusal force, and easy compaction under pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

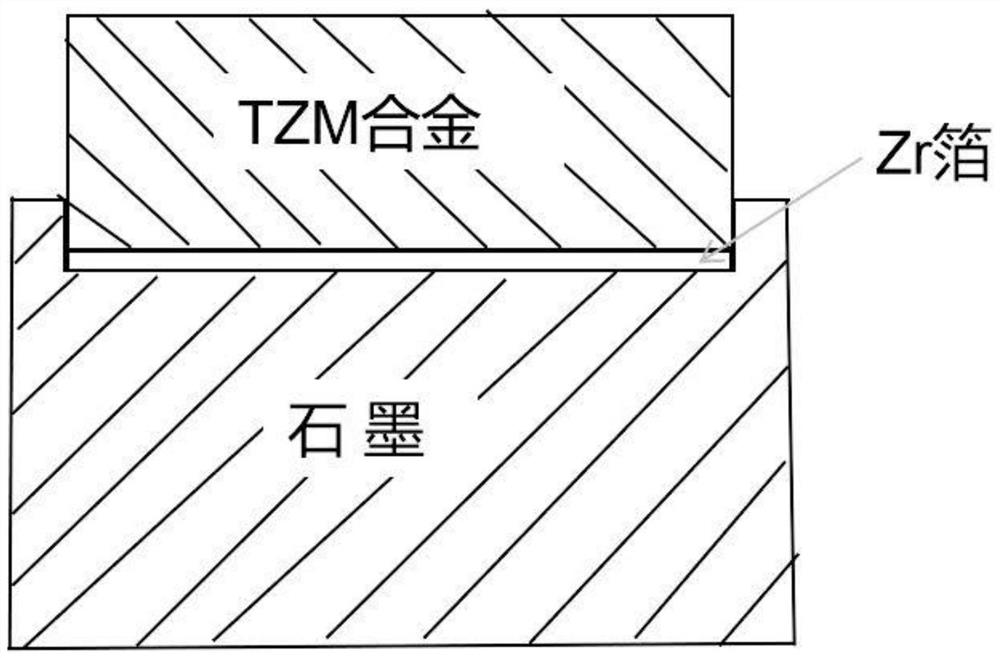

[0044]Take the TZM alloy, graphite and 200um zirconium foil samples to be welded, and use 120 mesh and 1000 mesh metallographic sandpaper to polish the TZM alloy and graphite welding surfaces in sequence, and finally clean all the samples ultrasonically in acetone for 30 minutes. The treated samples are assembled in the order of graphite, 200um zirconium foil, and TZM alloy from bottom to top. The specific assembly method is as follows: figure 1 As shown, according to the above assembly method, the misalignment of the sample can be prevented. Put the assembled workpiece into the furnace cavity of the air pressure sintering furnace, and evacuate it to less than 1*10 -3 Pa, after filling with argon gas, make the pressure in the furnace reach 0.5MPa, and maintain the pressure in the furnace, raise the vacuum pressure furnace from 20°C to 1000°C at a rate of 20°C / min, and then keep it for 20 minutes to make the temperature in the furnace uniform , preventing the existence of temp...

Embodiment 2

[0046] Take the TZM alloy, graphite and 200um zirconium foil samples to be welded, use 120-mesh, 1000-mesh metallographic sandpaper to polish the TZM alloy and graphite welding surfaces in turn, and finally clean the samples in acetone ultrasonically for 30 minutes. The processed samples are assembled in the order of graphite / 200um zirconium foil / TZM alloy from bottom to top, the specific assembly method is as follows figure 1 As shown, according to the above assembly method, the misalignment of the sample can be prevented. Put the assembled workpiece into the furnace cavity of the air pressure sintering furnace, and evacuate it to less than 1*10 -3 Pa. Fill with argon to make the pressure in the furnace reach 0.1 MPa, and maintain the pressure in the furnace. Raise the vacuum pressure furnace from 20°C to 1000°C at a rate of 20°C / min, and then keep it warm for 20 minutes to make the temperature in the furnace uniform and prevent the existence of temperature gradients. Then...

Embodiment 3

[0048] Take the TZM alloy, graphite and 200um zirconium foil samples to be welded, and use 120 mesh and 1000 mesh metallographic sandpaper to polish the TZM alloy and graphite welding surfaces in sequence, and finally clean all the samples ultrasonically in acetone for 30 minutes. The processed samples are assembled in the order of graphite / 200um zirconium foil / TZM alloy from bottom to top, the specific assembly method is as follows figure 1 As shown, according to the above assembly method, the misalignment of the sample can be prevented. Put the assembled workpiece into the furnace cavity of the vacuum pressure furnace, and evacuate it to less than 1*10 -3 Pa. Fill with argon to make the pressure in the furnace reach 1 MPa and maintain the pressure in the furnace. Raise the vacuum hot pressing furnace from 20°C to 1000°C at a rate of 20°C / min, and then keep it warm for 20 minutes to make the temperature in the furnace uniform and prevent the existence of temperature gradien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com