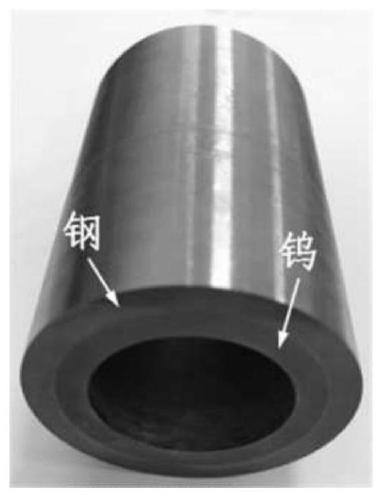

A hot isostatic pressing diffusion bonding method for tungsten/steel cylindrical structural parts

A technology of hot isostatic pressure diffusion and connection method, used in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of difficult surface treatment of cylindrical structures, large residual stress of welded joints, and easy generation of intermetallic compounds. , to achieve the effect of high sphericity, high production efficiency and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The tungsten cylinder is made of pure tungsten, and the steel cylinder is made of 316L stainless steel. The nickel-based alloy powder is prepared by plasma rotating electrode atomization powder technology. The obtained powder is sieved through a 300-mesh screen to obtain the powder intermediate connecting material. The powder composition is calculated by mass percentage: 70% nickel, 20% iron, 8% copper , 2% cobalt.

[0055] Place the tungsten cylinder and the steel cylinder on a milling machine for surface processing to make the surface roughness 1.6μm, and then immerse them in a nitric acid solution with a concentration of 50% for 20 minutes to obtain a combination of tungsten and steel To be welded.

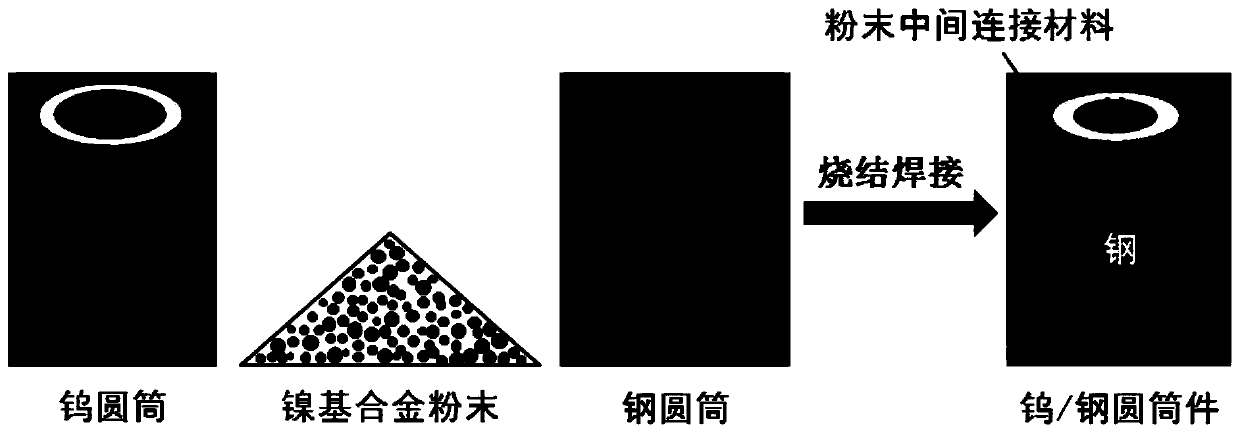

[0056] Place the welded parts of tungsten and steel according to the laminated structure of tungsten lining / steel jacket (the distance between the two is 5 mm), and then lay the powder intermediate connecting material between the welded parts of tungsten and steel, and the l...

Embodiment 2

[0061] The tungsten cylinder is made of tungsten-nickel-iron alloy, and its composition is calculated by mass percentage: 93% tungsten, 4.9% nickel, and 2.1% iron. The steel cylinder adopts 30Cr alloy structural steel. The nickel-based alloy powder is prepared by plasma rotating electrode atomization powder technology. The obtained powder is sieved through a 500-mesh screen to obtain the powder intermediate connecting material. The powder composition is calculated by mass percentage: 70% nickel, 25% iron, 5% cobalt .

[0062] The tungsten cylinder and the steel cylinder are placed on a grinder for surface processing to make the surface roughness 0.8 μm, and then placed in a nitric acid solution with a concentration of 30% for 30 min.

[0063] Place the welded parts of tungsten and steel in a stacked structure of tungsten lining / steel jacket (the distance between the two is 2 mm), and then lay the powder intermediate connecting material between the welded parts of tungsten and stee...

Embodiment 3

[0067] The tungsten cylinder is made of tungsten-nickel-iron alloy, and its composition is calculated by mass percentage: 90% tungsten, 7% nickel, and 3% iron. The steel cylinder adopts 30Cr alloy structural steel. The nickel-based alloy powder is prepared by plasma rotating electrode atomization powder technology. The obtained powder is sieved through a 500-mesh screen to obtain the powder intermediate connection material. The powder composition is calculated by mass percentage: 65% nickel, 20% iron, 10% copper , 5% cobalt.

[0068] The tungsten cylinder and the steel cylinder were placed on a milling machine for surface processing to make the surface roughness 1.6 μm, and then placed in a nitric acid solution with a concentration of 40% for 20 min.

[0069] Place the welded parts of tungsten and steel according to the laminated structure of tungsten lining / steel jacket (the distance between the two is 5 mm), and then lay the powder intermediate connecting material between the we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com