Patents

Literature

56results about How to "Solving Assembly Challenges" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

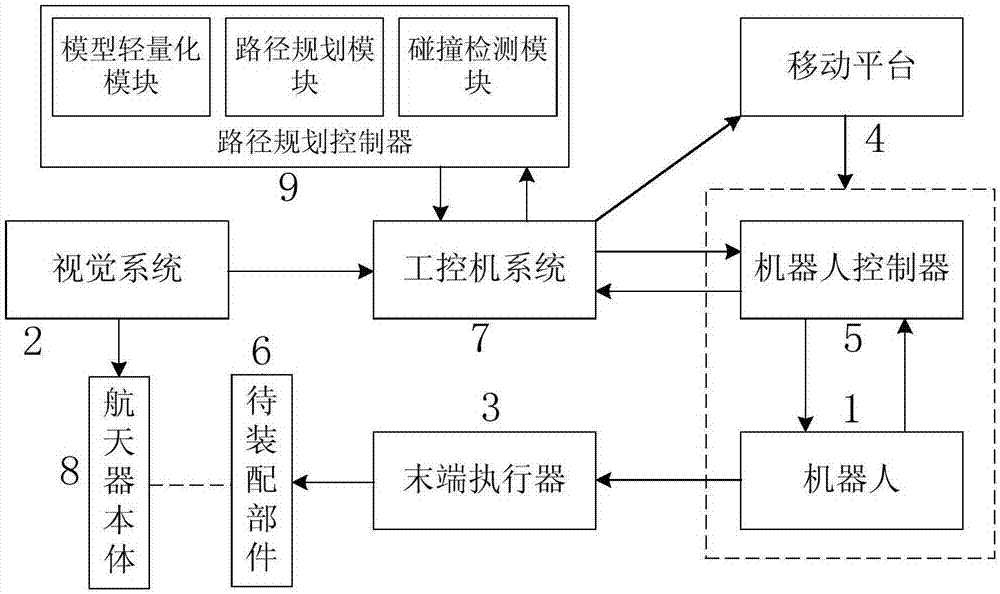

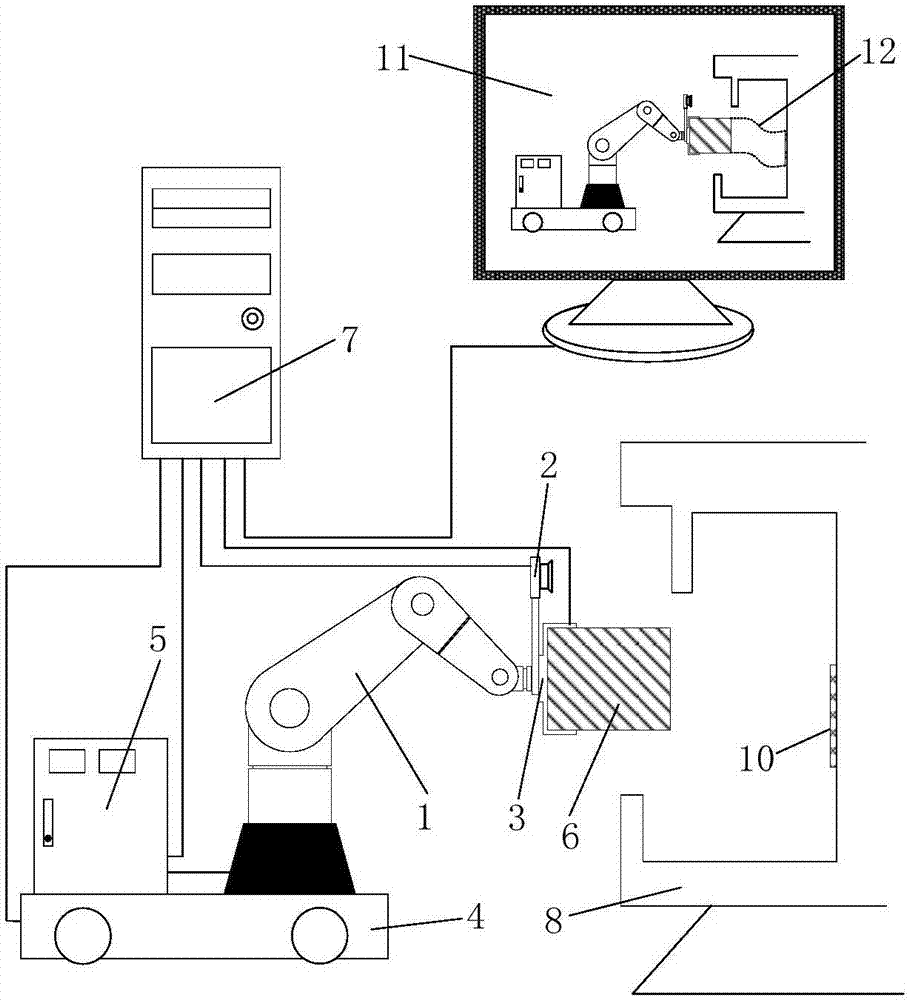

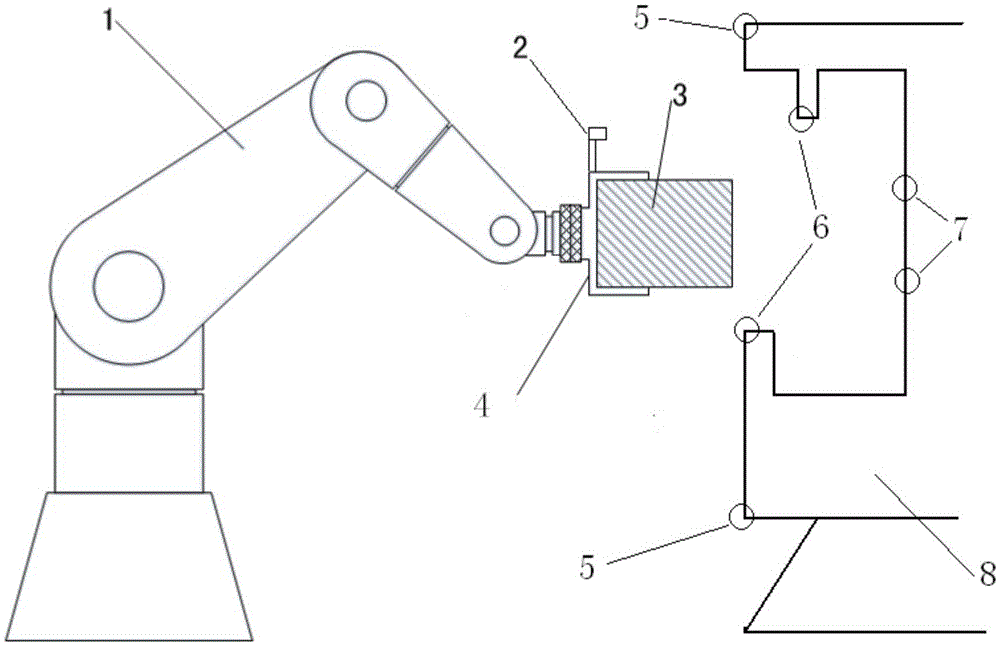

Robot automatic assembling method and system based on vision positioning

InactiveCN107538508AFlexible operationLarge working spaceSpecial data processing applicationsManipulatorGeneral assemblyPersonal computer

The invention discloses a robot automatic assembling system based on vision positioning. The robot automatic assembling system comprises an industrial personal computer, a path planning controller, amoving platform, a robot, a robot controller and the like, and the industrial personal computer is connected with the robot controller, a vision system, the moving platform and the like. The moving platform is controlled to transfer the robot to an assembly site; the collected data of the visual system are received and processed, and thus the conversion relationship between the spacecraft coordinate system and the robot base coordinate system is obtained; and then a tail-end actuator is controlled to grab to-be-assembled parts and sends a motion instruction to the robot controller according tothe assembly path given by the path planning controller to control the robot to drive the tail-end actuator to move, and thus automatic assembly of aerospace products is completed. The advantages that operation of the robot is flexible and the working space is large are utilized, the visual system is carried to identify the geometrical features of the mounting position, the detection range is large, positioning accuracy is high, operation is easy and convenient, the response speed is high, and the robot automatic assembling system can be quickly applied to different general assembly stationsof a spacecraft.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

Method for assembling special-shaped curved radome cover body and connecting ring

ActiveCN108994360ARealize the assemblySolving Assembly ChallengesMaterial gluingMilling equipment detailsAdhesiveEngineering

The invention discloses a method for assembling a special-shaped curved radome cover body and a connecting ring. The method comprises the following steps: 1) matching the connecting ring with a milling: fixing the connecting ring on an assembly fixture and positioning, matching a milling according to the actual size of the inner curved surface of the cover body, and machining the outer curved surface of the connecting ring, in which the cover body and the connecting ring are subjected to trial assembly until the outer curved surface of the connecting ring meets the fit clearance requirements;2) radome assembly: uniformly brushing and applying an adhesive onto the assembly surface of the outer curved surface of the connecting ring and the inner curved surface of the cover body, lifting thecover body with a cover body spreader, aligning an open end of the cover body with the connecting ring, slowly loading the cover body onto the connecting ring, and then fixing the cover body and positioning to fit the cover body in place. By adopting the method, not only is the assembly precision of the cover body and the connecting ring is ensured, but also the difficulty of matching milling andmachining on the assembly surface of the cover body and the connecting ring is reduced.

Owner:湖北三江航天江北机械工程有限公司

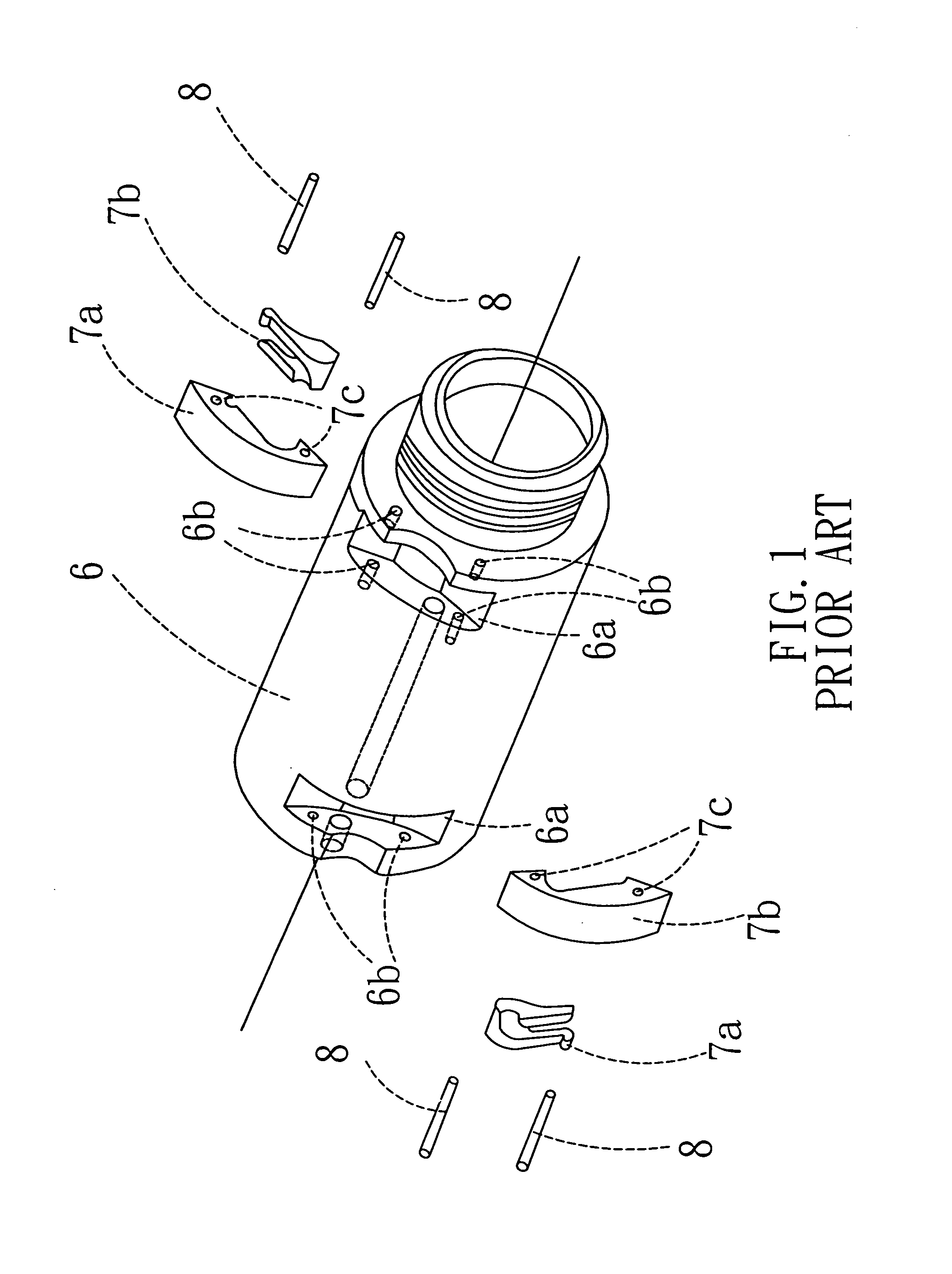

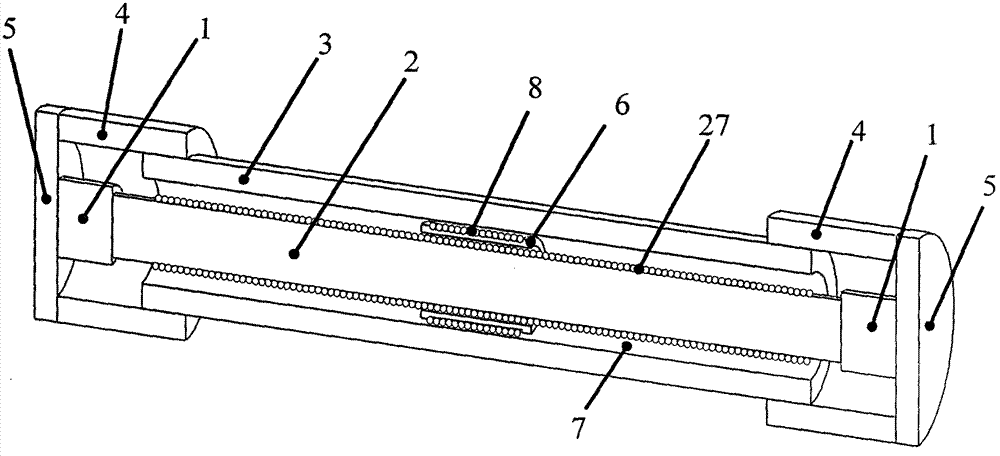

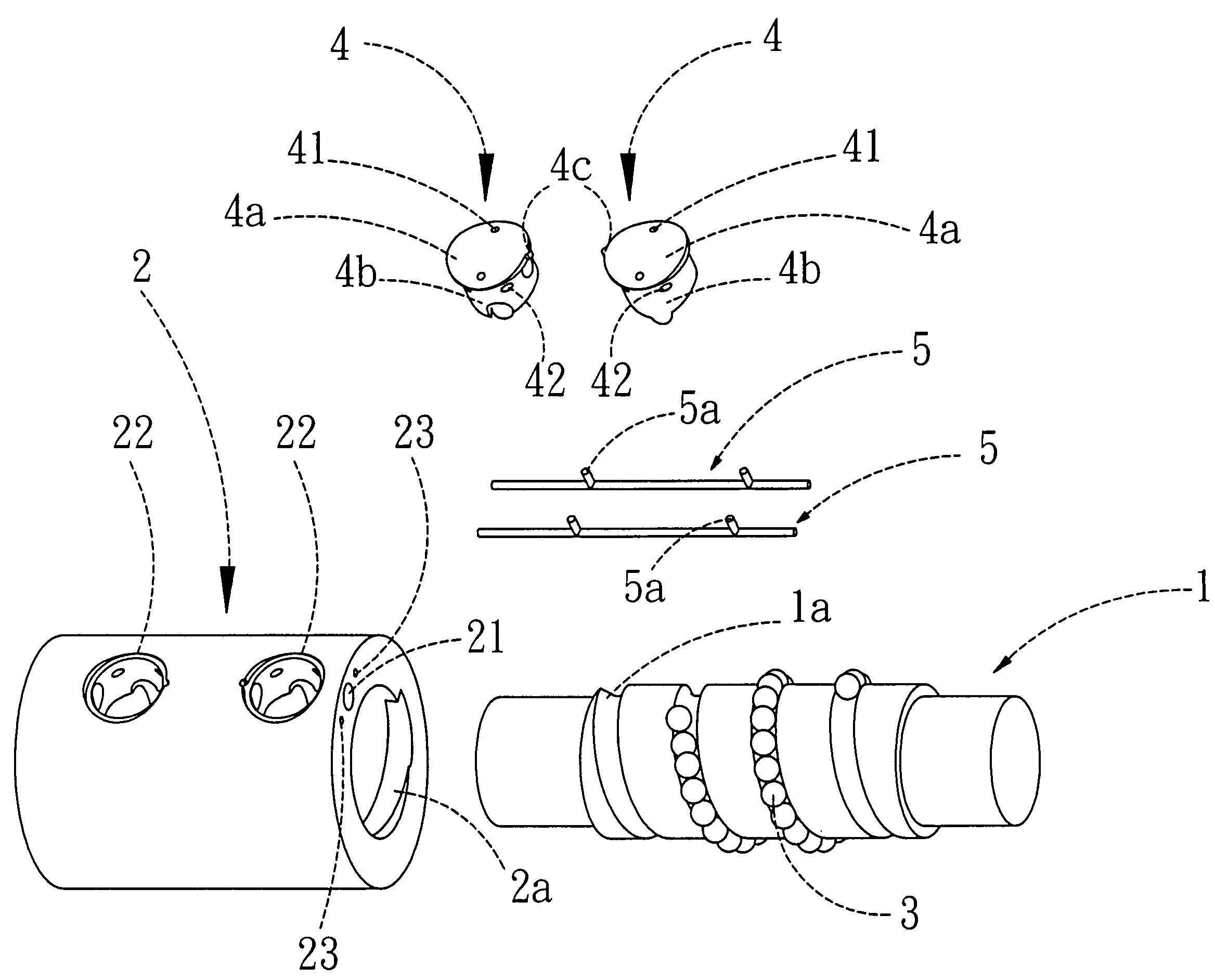

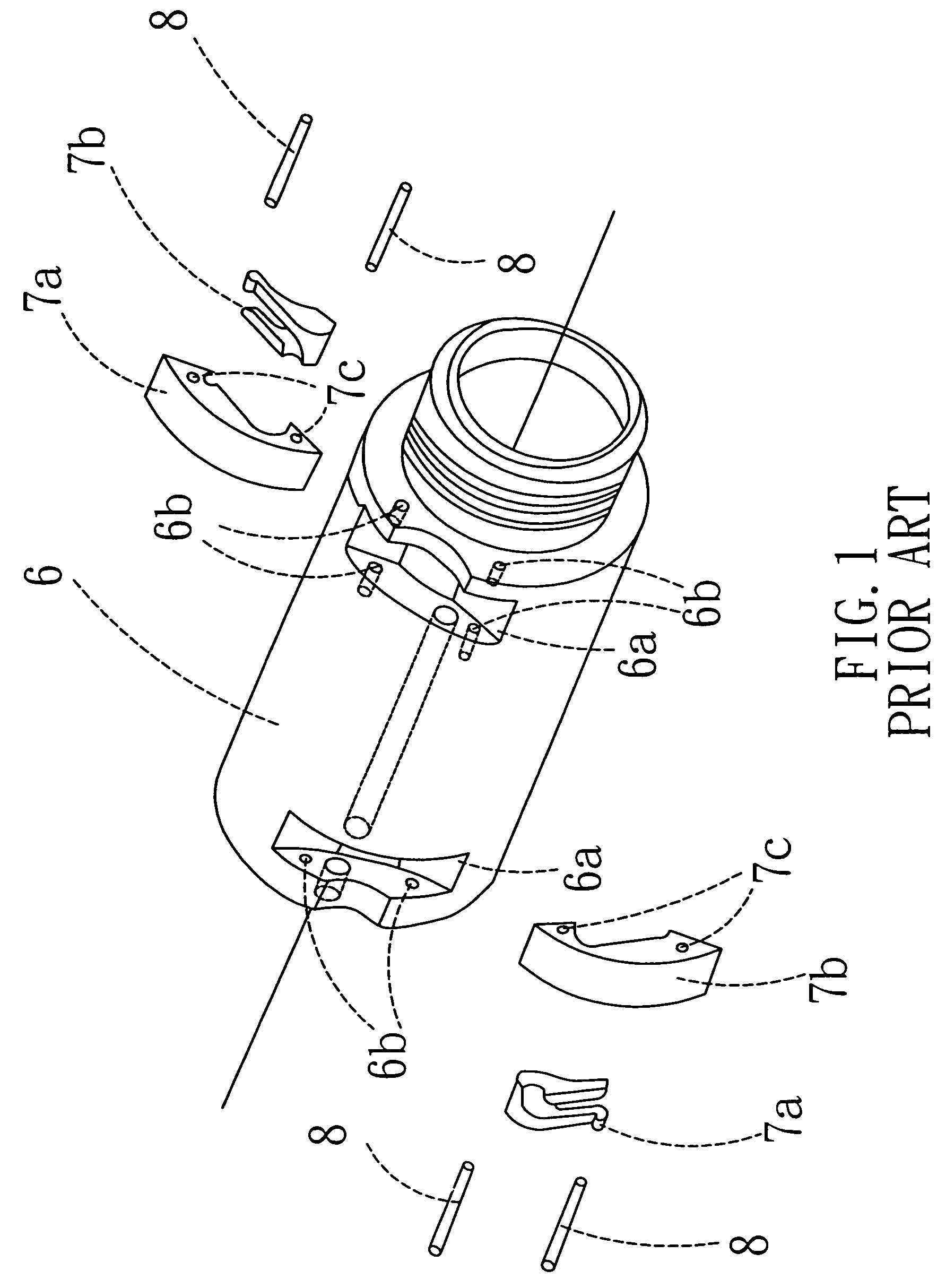

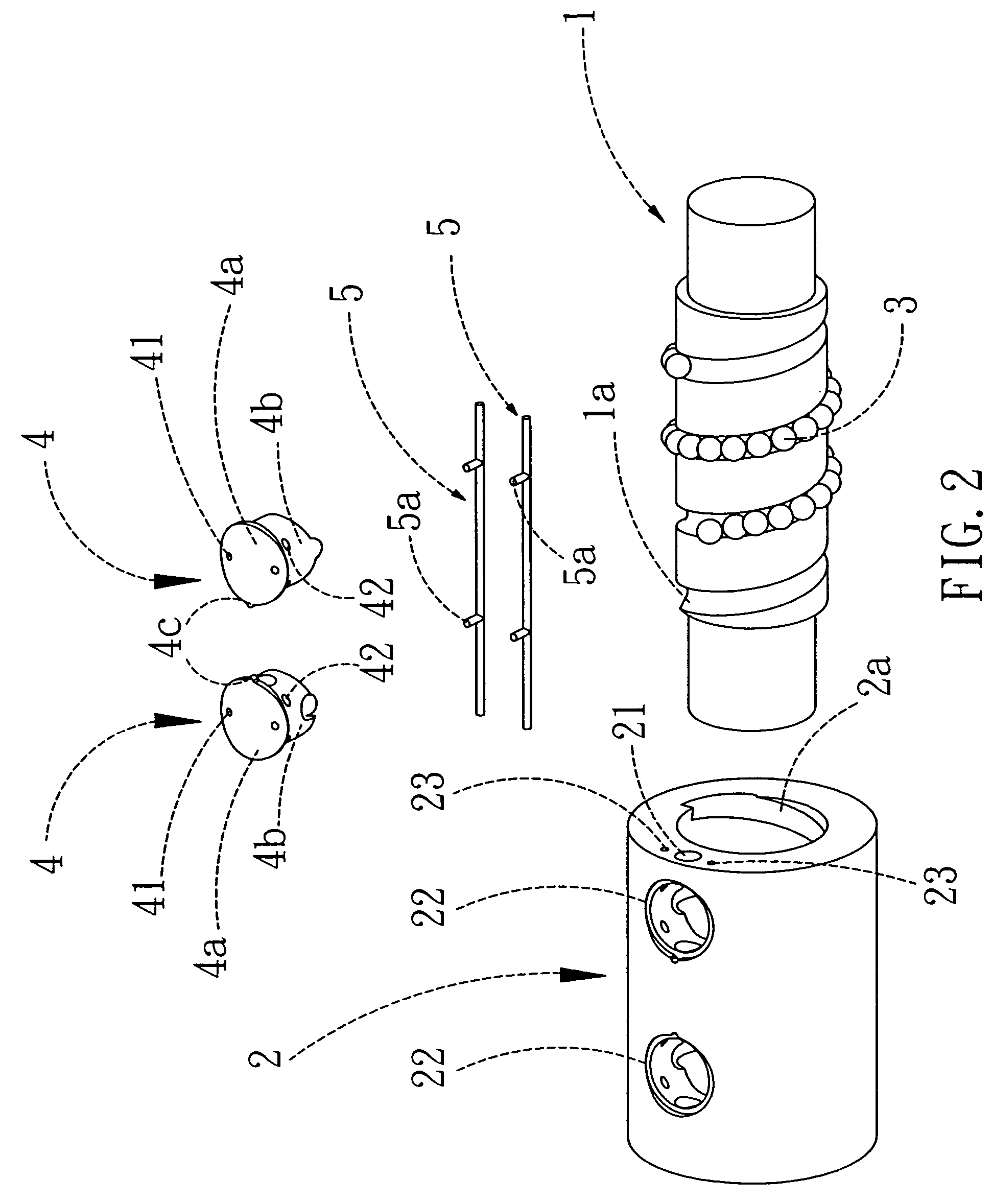

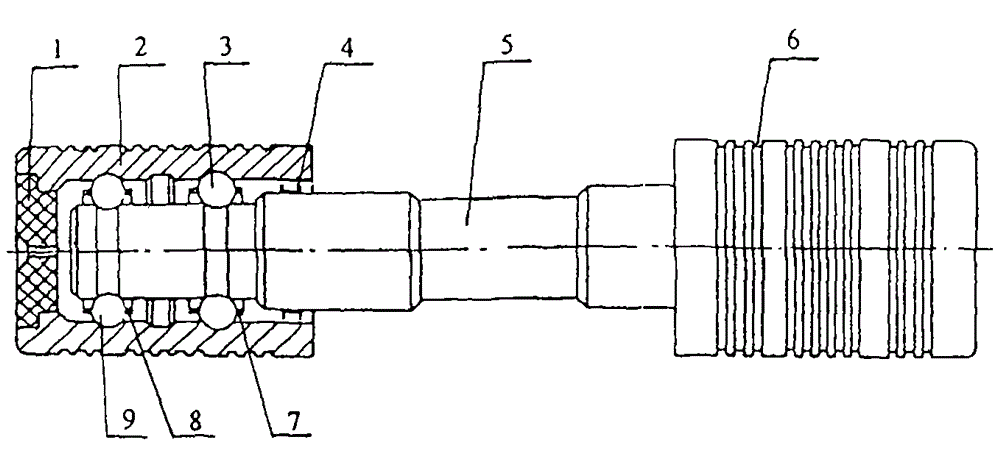

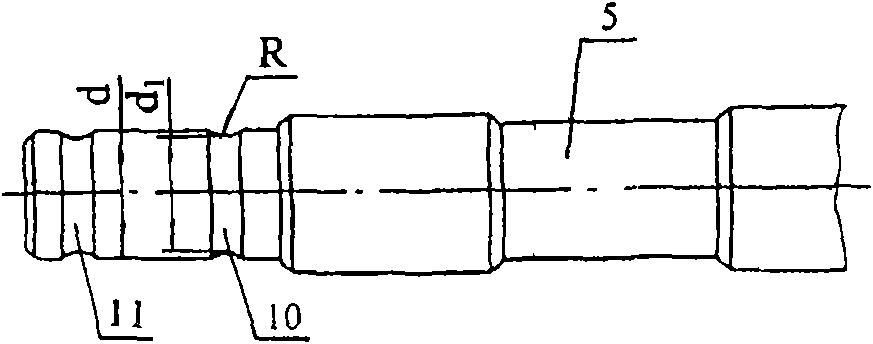

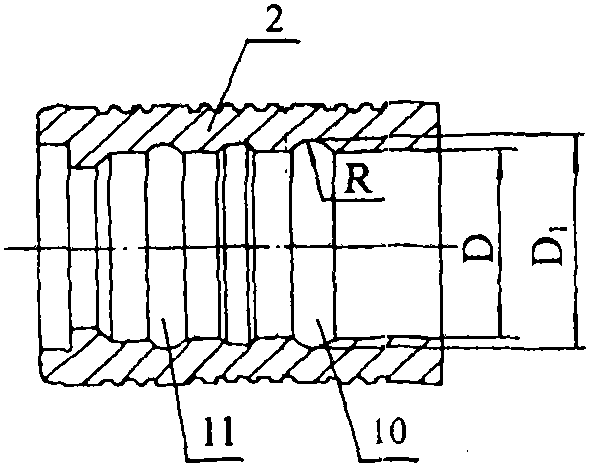

Ball screw assembly

ActiveUS20070204713A1Solving Assembly ChallengesPrecise positioningToothed gearingsPortable liftingBall screwLiquid state

A ball screw assembly, wherein the circulate component is positioned in the nut by inserting a protrusion in a notch, so that the circulate component is positioned easily, and the problem of assembly difficulty is solved. The method of fixing the circulate components in the nut is that: the circulate component is formed with an axial hole and the radial hole that are connected to each other, the axial hole of the circulate component is aligned to the axial locking hole of the nut, and then liquid resin is injected into the axial hole of the circulate components, and the liquid resin will form a locking members after curing, thus fixing the circulate component in the nut. Due to the formation of the locking member is determined by the diameter of the hole to be machined, the configuration of locking member will be varied in response to the diameter of the hole to be machined. Whatever the diameter of the hole to be machined changes or not, it will not affect the interchangeability of the locking member. Therefore, the production cost is saved since it doesn't need to prepare different sized locking members.

Owner:HIWIN TECH

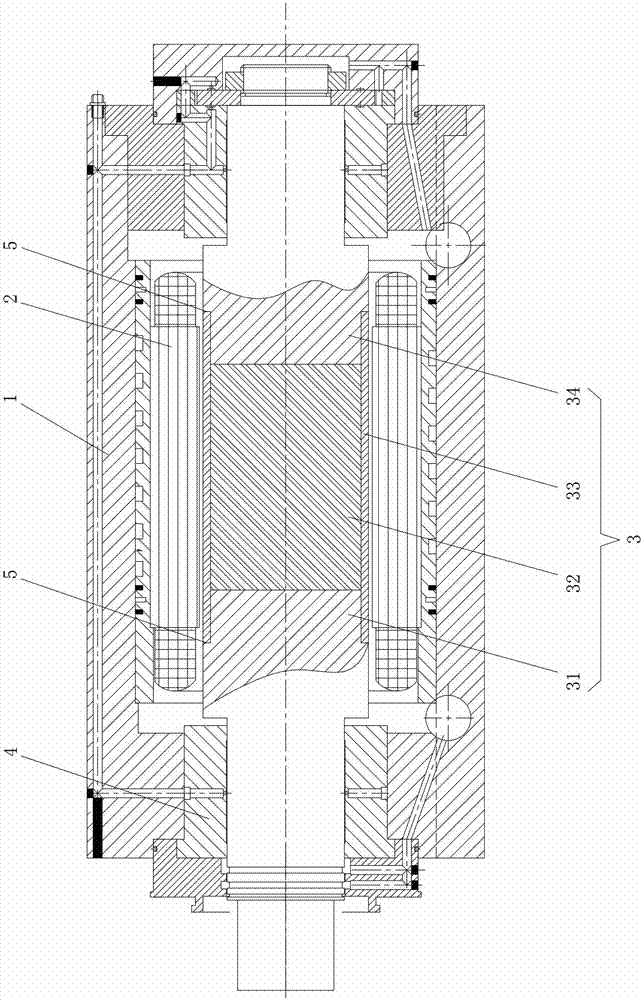

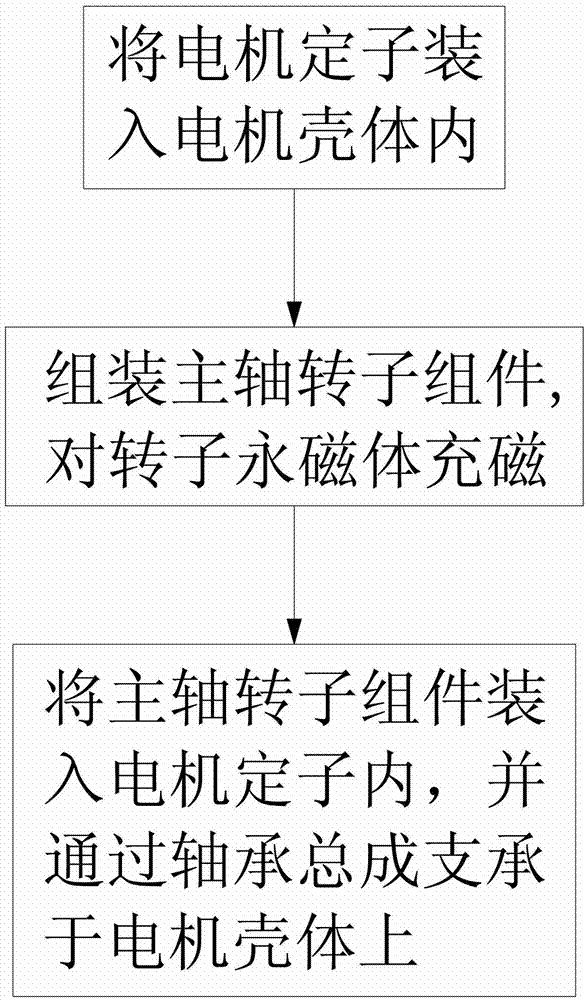

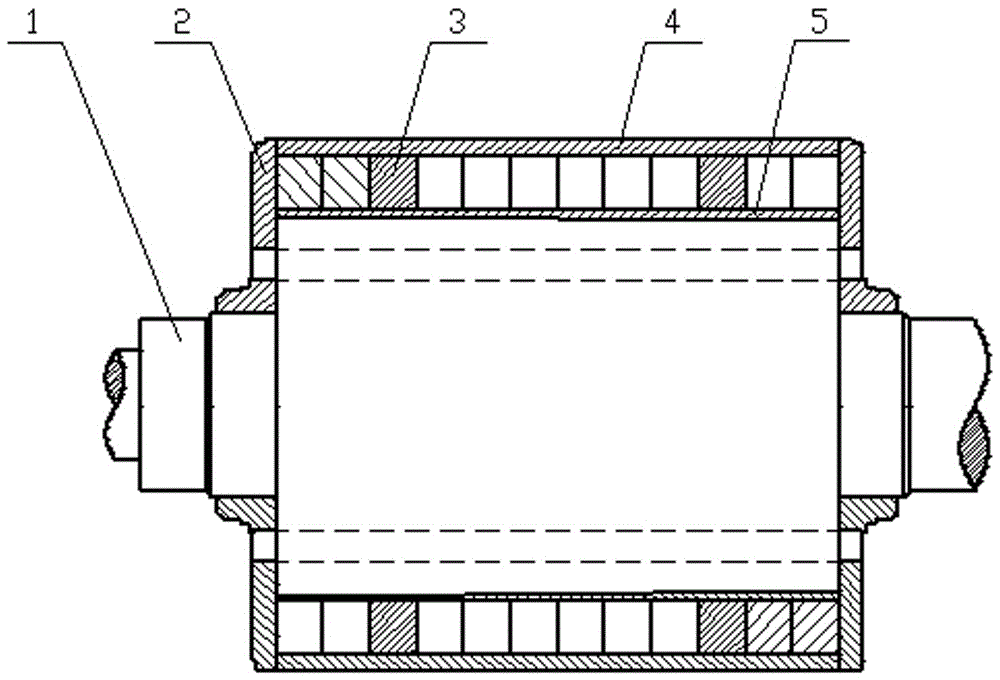

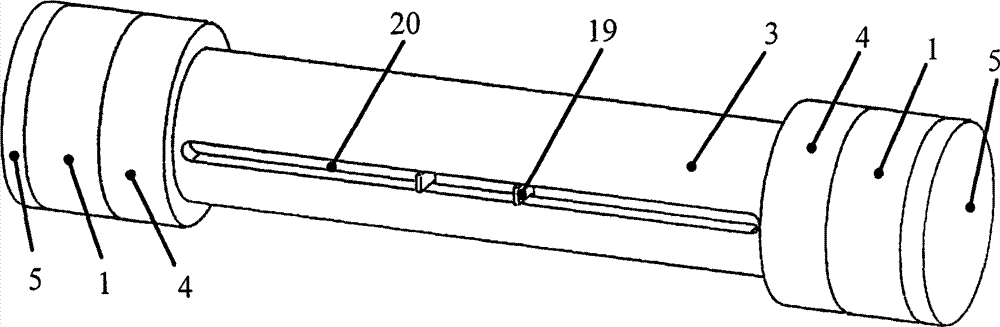

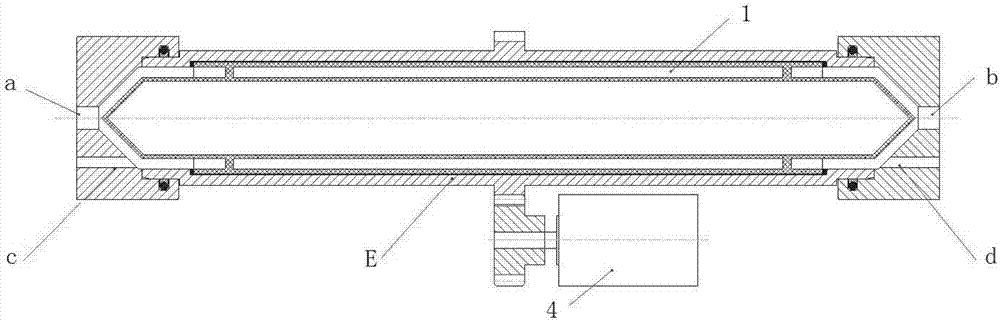

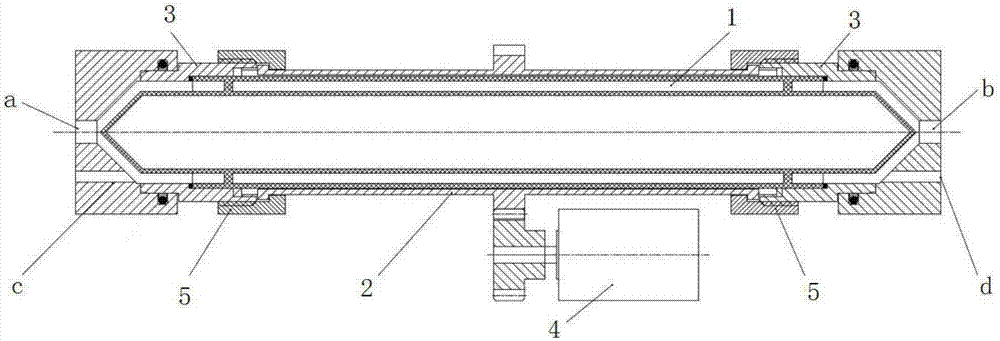

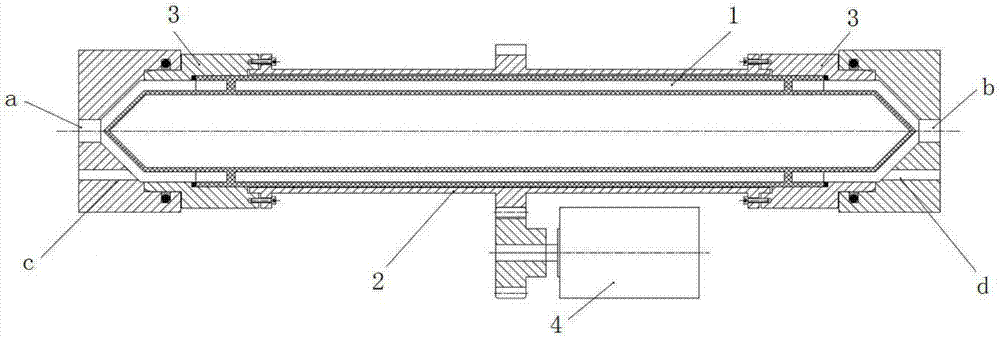

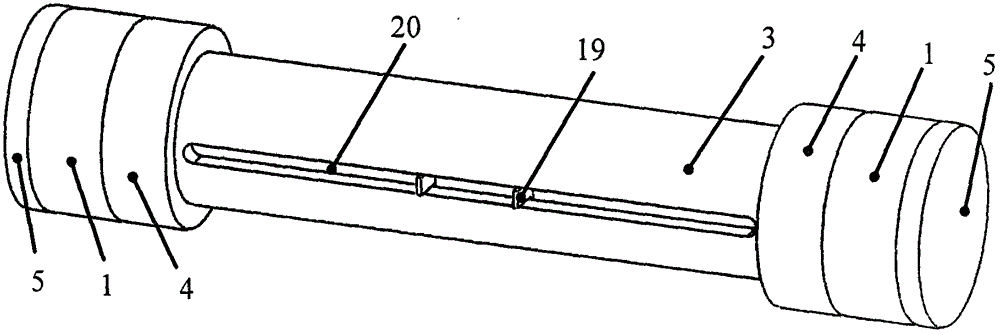

High-speed permanent magnet synchronous motor and assembly method thereof

InactiveCN103117633AIncrease speedImprove efficiencyMagnetic circuit rotating partsManufacturing dynamo-electric machinesPermanent magnet synchronous motorPermanent magnet synchronous generator

Disclosed are a high-speed permanent magnet synchronous motor and an assembly method thereof. The motor comprises a motor shell, a motor stator, a spindle rotor component and a pair of bearing assemblies, the bearing assemblies are separately arranged at the front end and the rear end of the shell, the motor stator is fixed into the motor shell, the spindle rotor component is sleeved in the motor stator, two ends of the spindle rotor component are supported on the motor shell through the bearing assemblies, the spindle rotor component comprises a front rotor half shaft, a rotor permanent magnet, a rotor sleeve and a rear rotor half shaft, the rotor permanent magnet is sleeved in the rotor sleeve, one end of the rotor sleeve is fixedly connected with the front rotor half shaft, and the other end of the rotor sleeve is fixedly connected with the rear rotor half shaft. The high-speed permanent magnet synchronous motor is compact in structure, sufficient in space usage, small in radial dimension and particularly suitable for meeting the requirement on high rotation speed. The assembly method includes the steps: 1) mounting the motor stator into the motor shell; 2) assembling the spindle rotor component and magnetizing the rotor permanent magnet in the spindle rotor component after the spindle rotor component is assembled; and 3) mounting the spindle rotor component into the motor stator, and supporting the spindle rotor component on the motor shell through the bearing assemblies.

Owner:HUNAN UNIV

Surface type permanent magnet rotor assembling tool with inclined wedge expansion structure, and assembling method for surface type permanent magnet rotor

ActiveCN106300832ARealize the assemblySolving Assembly ChallengesManufacturing stator/rotor bodiesAxial displacementPermanent magnet rotor

The invention relates to a surface type permanent magnet rotor assembling tool with an inclined wedge expansion structure. The surface type permanent magnet rotor assembling tool comprises hoops, an axial fixing tool, and a tool iron core, wherein one end of the tool iron core is in contact with the end plane of a deep groove end of a rotor iron core inclined wedge groove; the tool iron core and a rotor iron core are consistent in shapes; the length of the tool iron core is greater than or equal to an axially-pushed process distance of the inclined wedge; the inclined wedge groove of the tool iron core is an extension inclined groove of the rotor iron core inclined wedge groove with consistent inclination; an upper pressing plate, the rotor iron core, the tool iron core and a bottom plate are fixed together through pull rods; each hoop adopts a circular annular structure; and the inclined wedges and the permanent magnets are radially fixed by tightening screws. According to the surface type permanent magnet rotor assembling tool, by adding the tool iron core, the axial displacement of the permanent magnets on the rotor iron core becomes possible; due to the added axial fixing tool, the assembling, axial pressing and assembling, and radial outward expansion of the permanent magnets are realized, and the problem of difficulty existing in assembling the permanent magnet rotor with the inclined wedge structure is solved. The invention also relates to an assembling method for the surface type permanent magnet rotor with the inclined wedge expansion structure.

Owner:XIANGTAN ELECTRIC MFG CORP LTD

Motion Path Compensation Method of Manipulator Based on Vision Measurement

InactiveCN104476549BSolve unfixed application challengesSports are safer and more reliableManipulatorVision basedEngineering

The invention discloses a method for compensating a motion path of a mechanical arm based on vision measurement. Vision guides the mechanical arm to move. According to the method, due to vision measurement, the position of the mechanical arm, the position of a spacecraft and a position to be mounted are different from theoretical positions in a theoretical model, and a path planning deviation of the mechanical arm is compensated, so that a control effect on safe get in and get out of a narrow space is achieved, and a requirement on high-precision and high-reliability assembling of the spacecraft is met. Due to the method, an error between an actual position of the spacecraft and the theoretical position of an ideal model is identified, and the motion path of the mechanical arm is compensated, so that the position and the path can be more precisely controlled, and the control effect on safe get in and get out of the narrow space is achieved. The measurement method disclosed by the invention is wide in application range and can be applied to a spacecraft assembling process for different types under different assembling working conditions.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

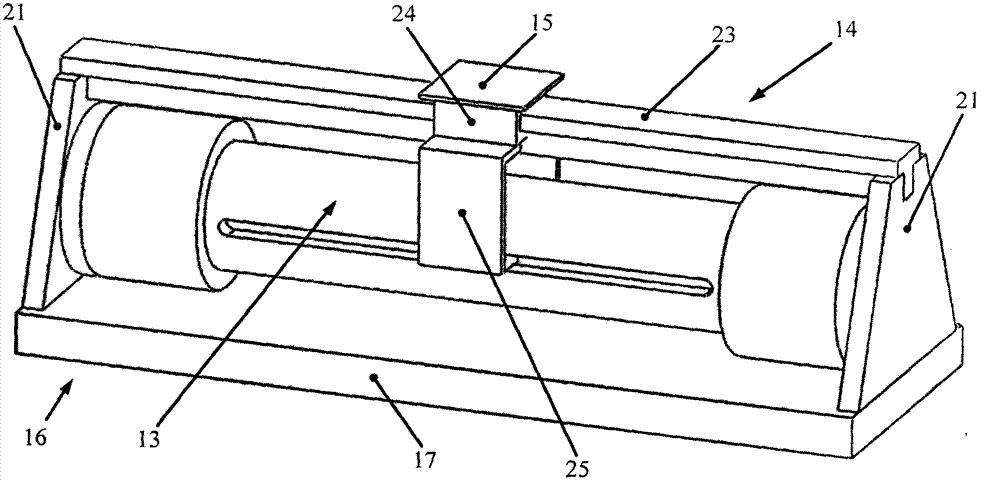

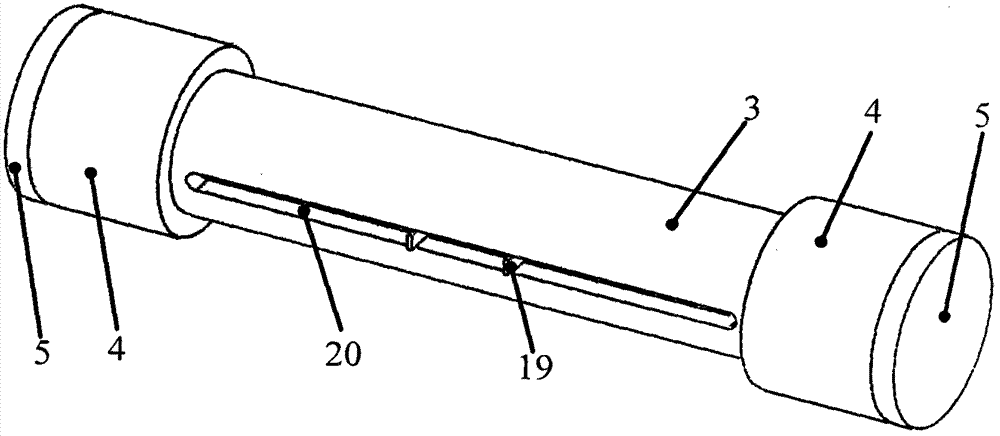

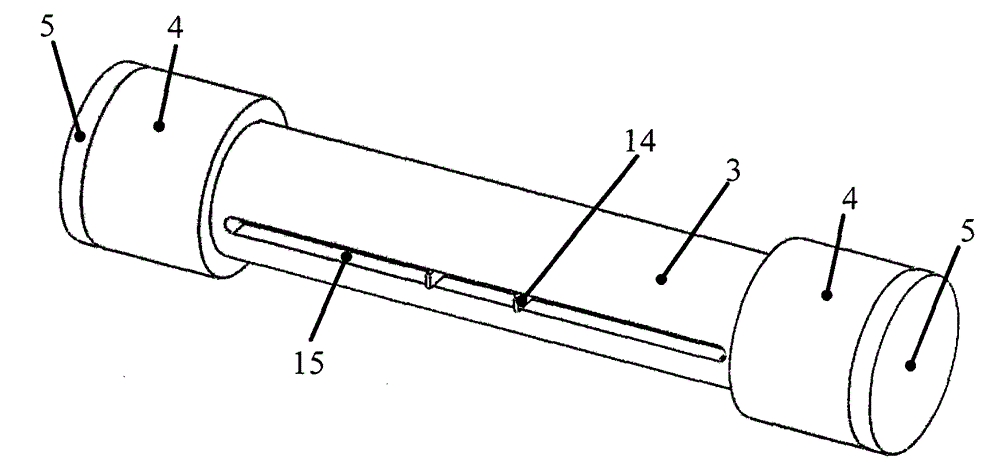

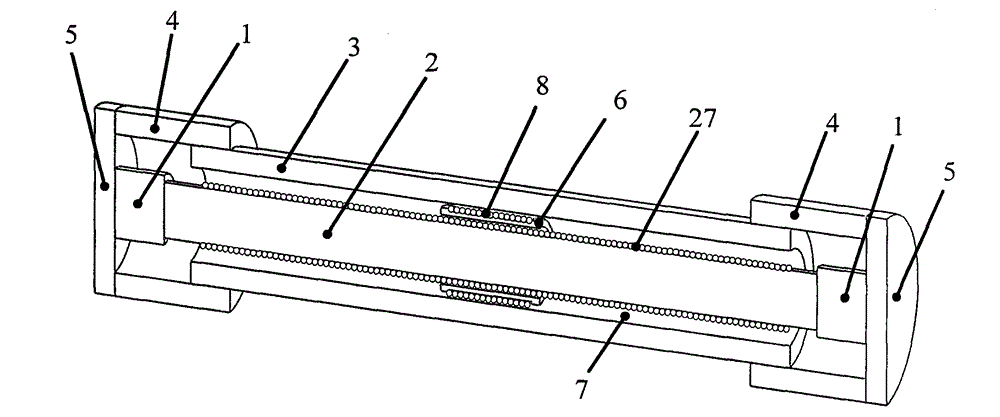

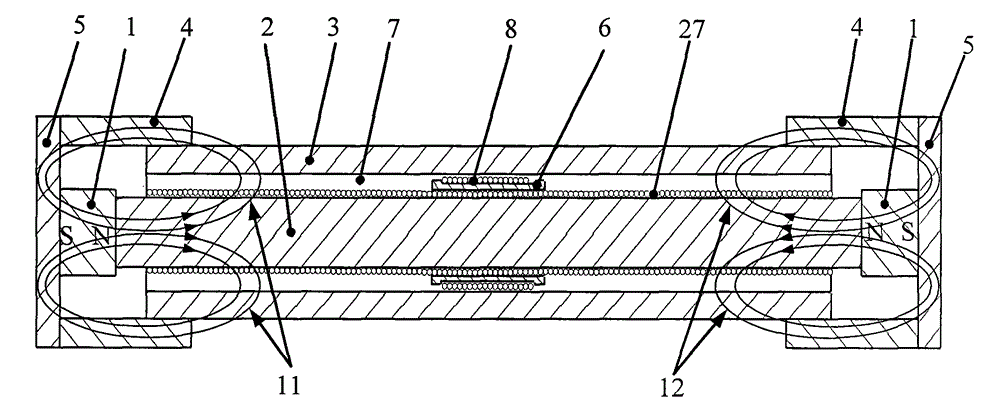

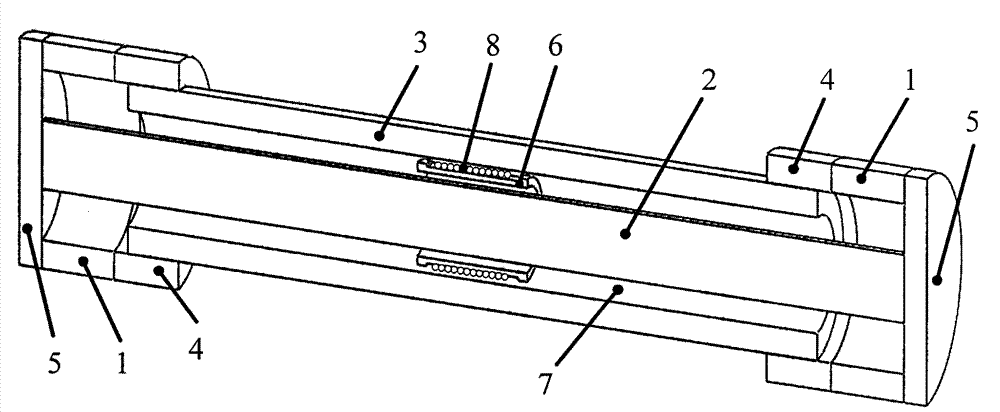

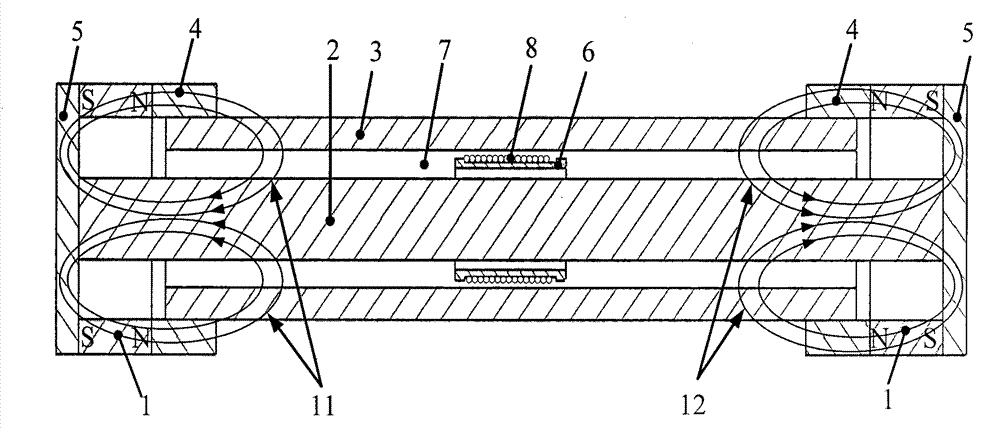

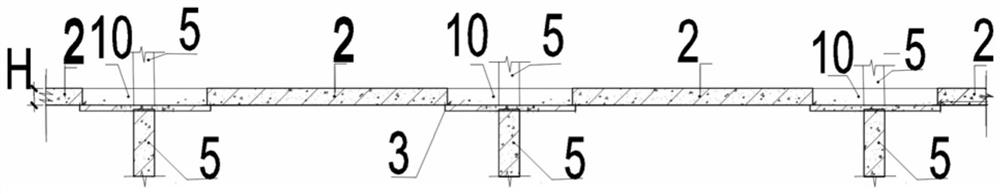

Double-magnetic-circuit two-end symmetric excitation cylindrical low frequency vibration calibration table with magnetic field tracking compensation

ActiveCN104848938ASimple structural designReduce processing difficultySubsonic/sonic/ultrasonic wave measurementMicro structureVibration measurement

The invention provides a double-magnetic-circuit two-end symmetric excitation cylindrical low frequency vibration calibration table with magnetic field tracking compensation, belonging to the field of vibration measurement technology. A cylindrical closed type magnetic field structure design is provided. Two cylindrical permanent magnets are symmetrically installed at two ends of a center magnet yoke and face magnetic poles. Two symmetric closed magnetic circuits are formed by magnet yokes. The magnetic induction intensity distribution with high uniformity is generated in air gaps. The surfaces of the magnet yokes adjacent to the air gaps are provided with an array type micro structure in the form of deep trenches, and the eddy current loss can be effectively inhibited. The center magnet yoke is provided with a compensation coil, and a formed compensation magnetic field carries out synchronous tracking compensation on the influence of an armature reaction. The organic integration design of air lubricated guide technology is employed, and outstanding electromagnetic drive mechanical performance and high movement guide precision are obtained at the same time. According to the double-magnetic-circuit two-end symmetric excitation cylindrical low frequency vibration calibration table, large stroke, high thrust, a linear electromagnetic driving force characteristic and high movement guide precision can be considered, and a high precision and large stroke high performance low frequency vibration calibration table technical scheme is provided for low-frequency / ultra-low frequency vibration calibration.

Owner:HARBIN INST OF TECH

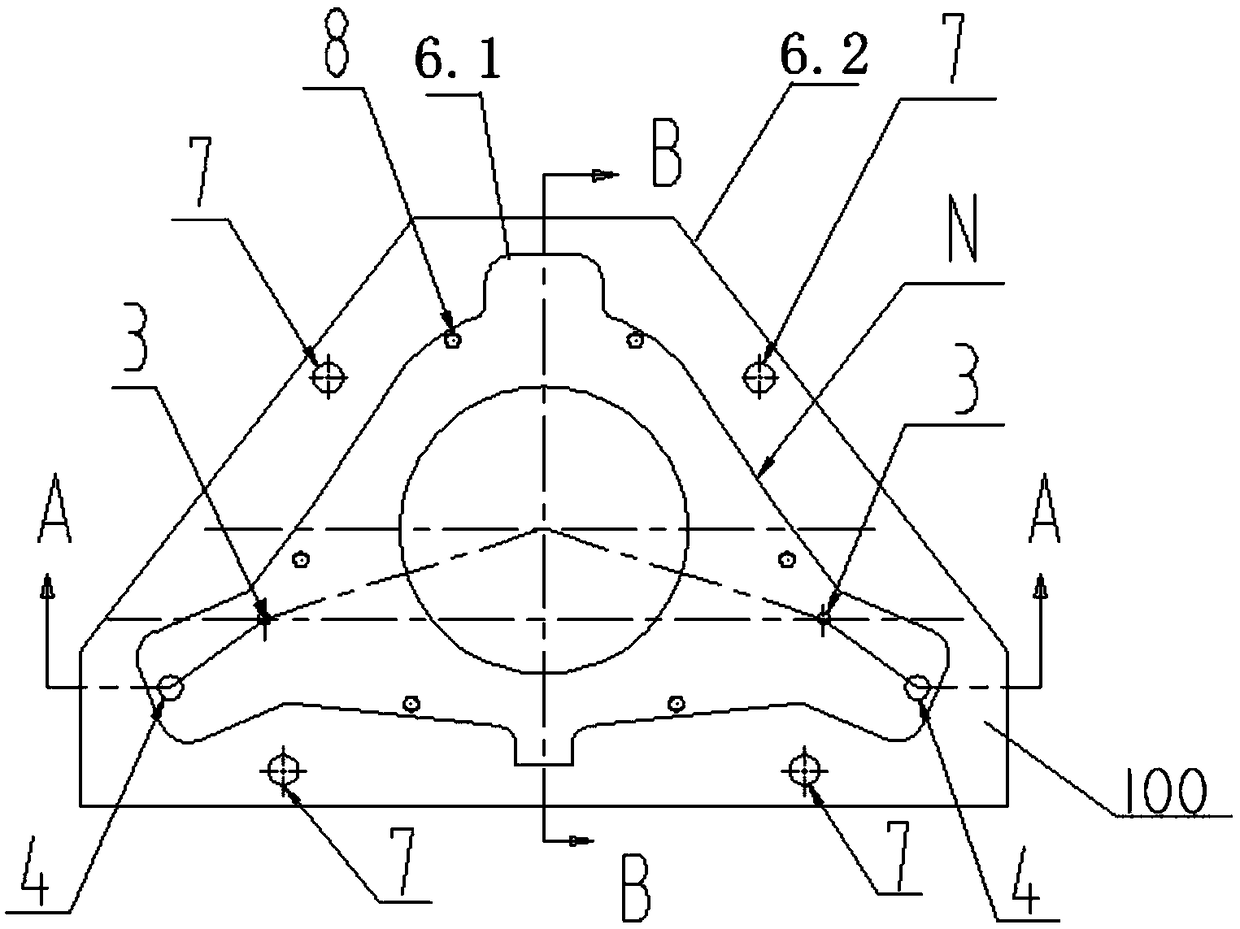

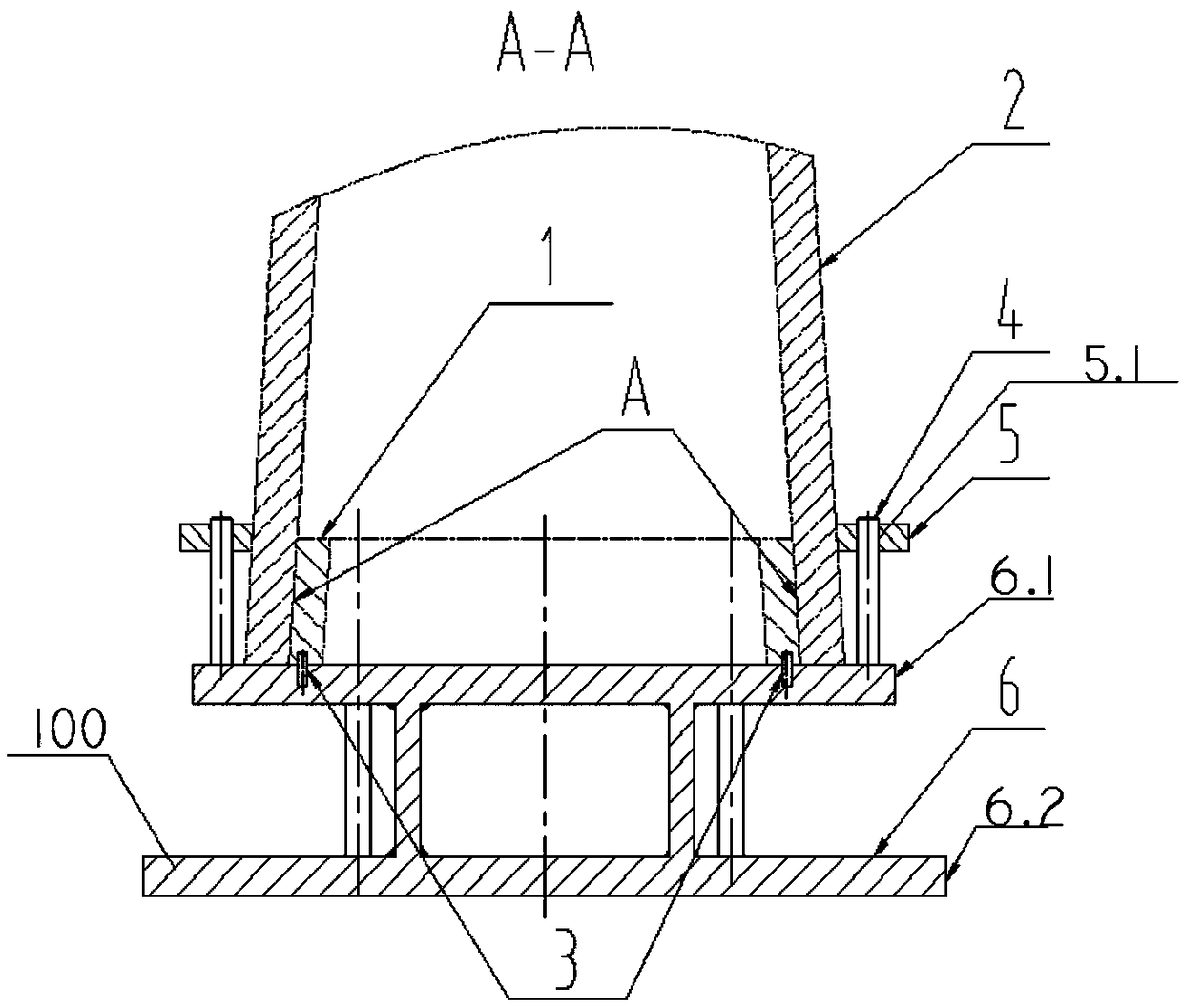

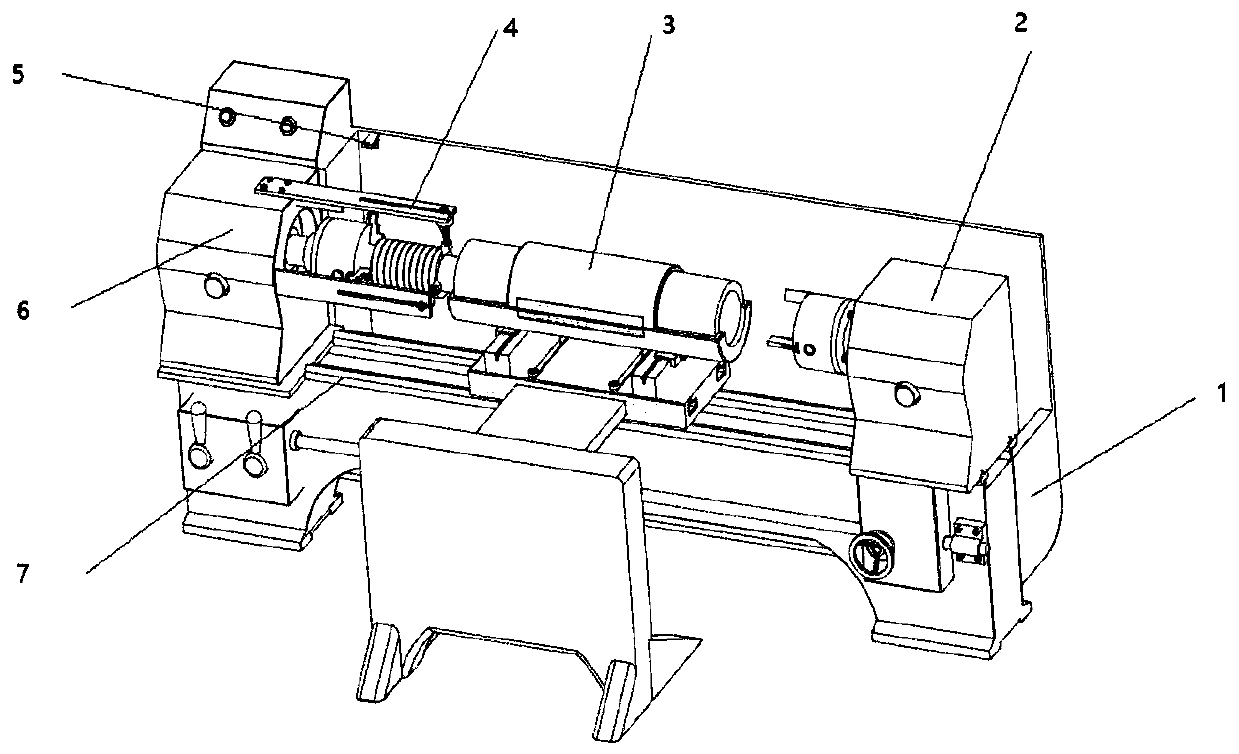

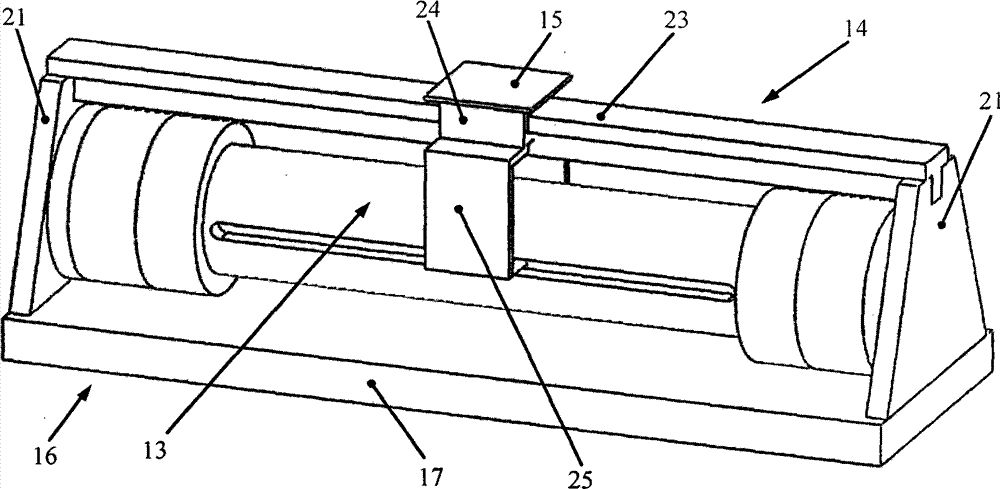

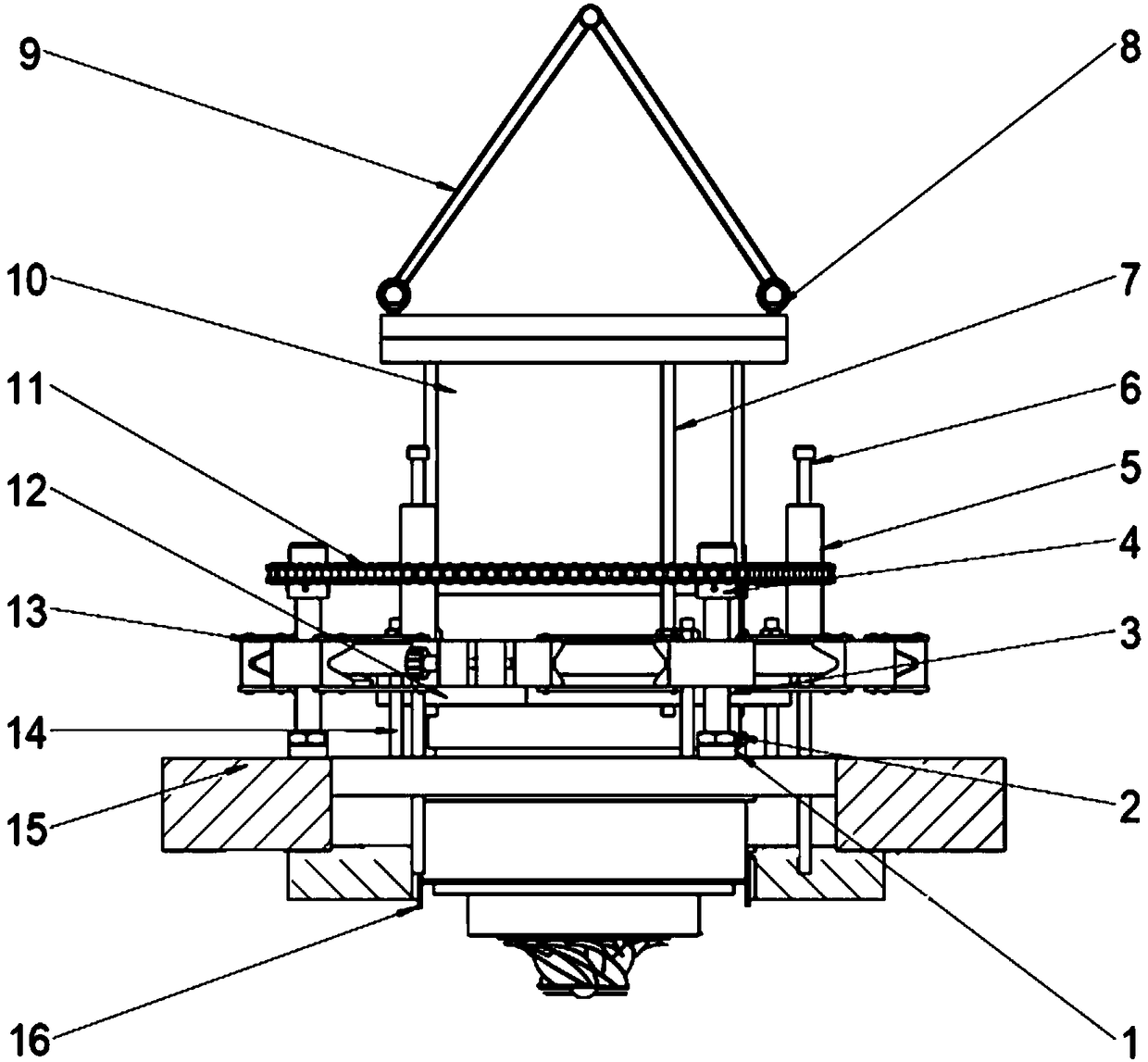

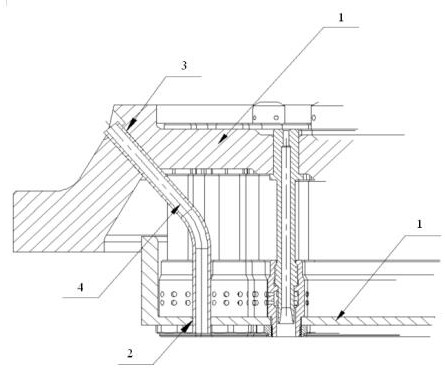

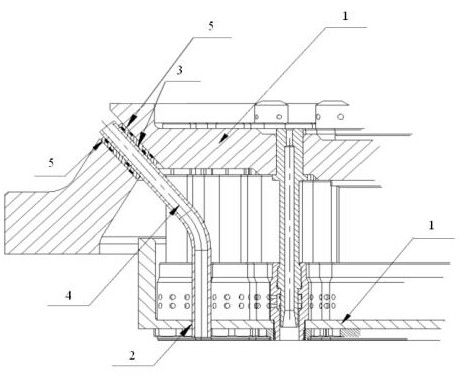

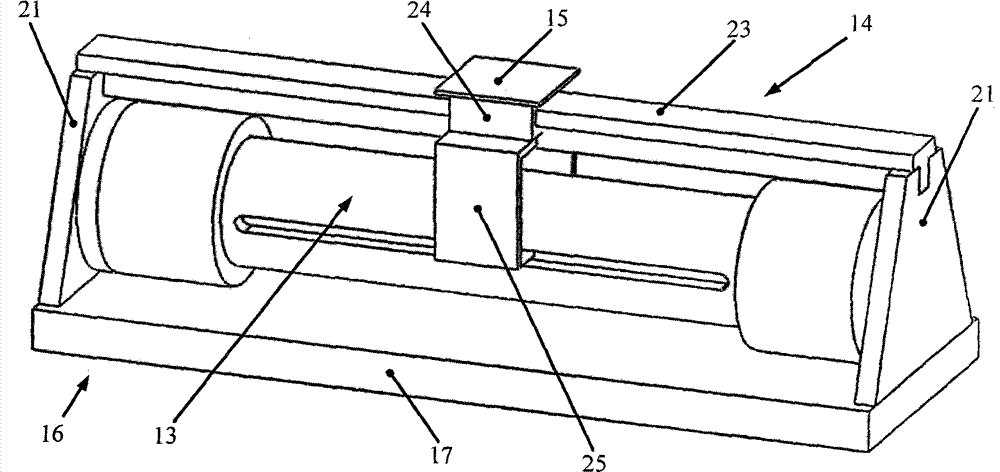

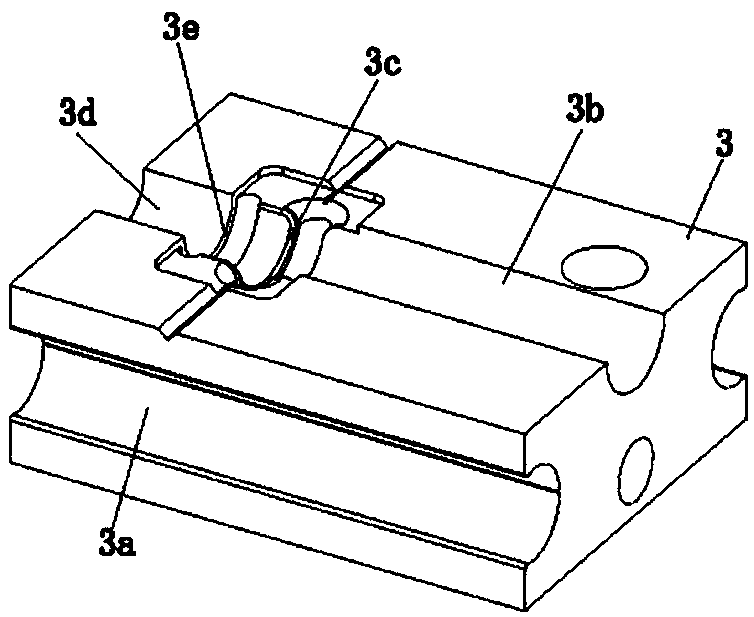

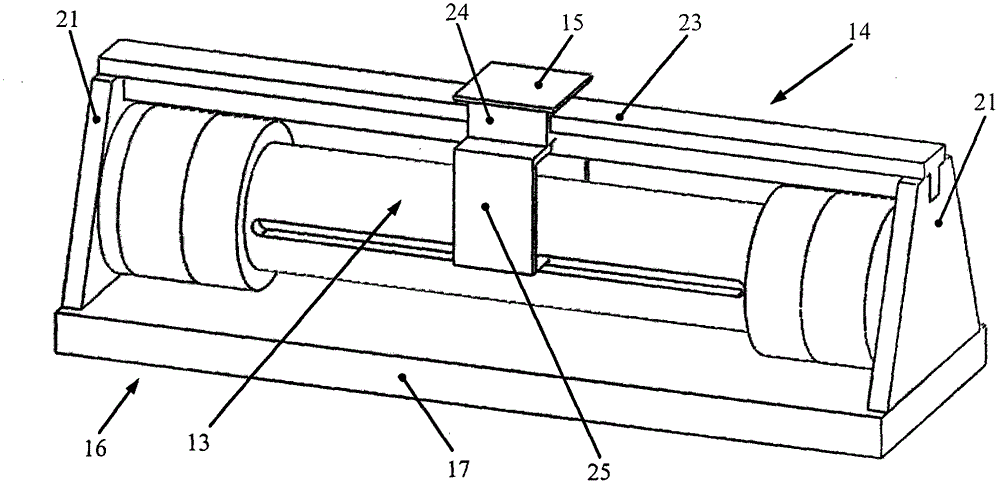

Assembling device for magnetic damping shock absorbers

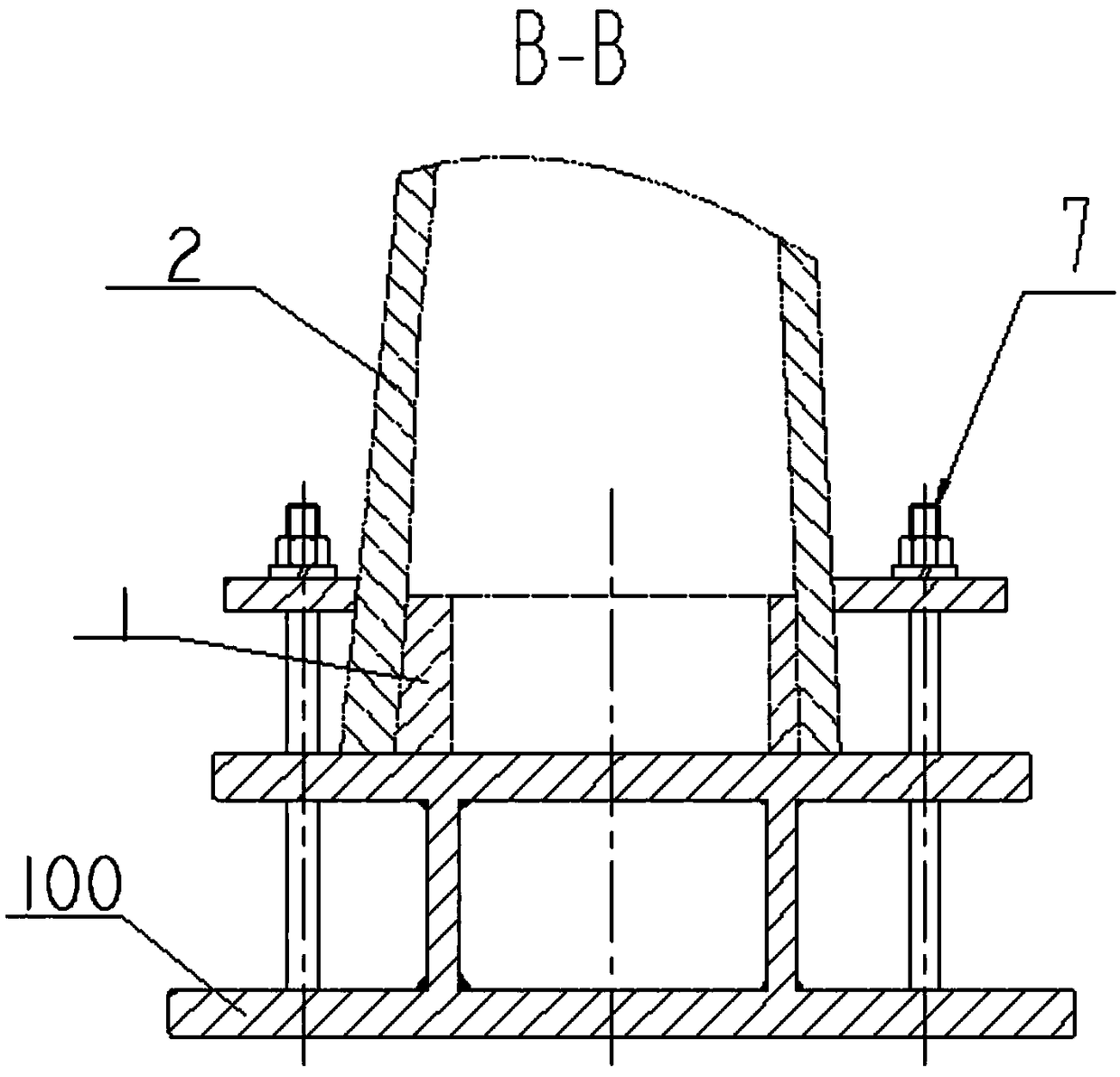

ActiveCN111043208AEfficient and reliable installationSafe and Accurate InstallationMagnetic springsSprings/dampers manufactureMagnetic dampingEngineering

The invention relates to an assembling device for magnetic damping shock absorbers. The assembling device comprises a platform base (1), two guiderails (7), a center rod clamping device (6), a permanent magnetic iron hoop clamping device (2), a metal outer barrel fixing device and two limiting devices, wherein the two guiderails are fixed mounted on the upper surface of the platform base in parallel; the center rod clamping device and the permanent magnetic iron hoop clamping device are respectively connected with two ends of the two guiderails in a sliding manner; nuts are arranged at both the lower end of the center rod clamping device (6) and the lower end of the permanent magnetic iron hoop clamping device; the two nuts are respectively screwed at two ends of a lead screw guiderail; the metal outer barrel fixing device comprises a support (44), a slide (34) and a metal outer barrel; each limiting device comprises a limiting rod, a spring and a limiting pin (22); and the permanent magnetic iron hoop clamping device and the center rod clamping device are the same in the aspect of structure. The assembling device is capable of solving the assembling difficulties of consuming plenty of labor and time and being low in mounting efficiency in the assembling process of the magnetic damping shock absorbers, and then improving the assembling precision.

Owner:ZHONGBEI UNIV

Double-permanent-magnetic-tube two-end symmetric excitation cylindrical low frequency vibration calibration table with magnetic field tracking compensation

ActiveCN104848937AGood effectSimple structural designSubsonic/sonic/ultrasonic wave measurementMicro structureVibration measurement

The invention provides a double-permanent-magnetic-tube two-end symmetric excitation cylindrical low frequency vibration calibration table with magnetic field tracking compensation, belonging to the field of vibration measurement technology. A cylindrical closed type magnetic field structure design is provided. Two cylindrical permanent magnetic tubes are symmetrically installed at two ends of an electromagnetic drive structure and face magnetic poles. Two symmetric closed magnetic circuits are formed by magnet yokes. The magnetic induction intensity distribution with high uniformity is generated in air gaps. The surfaces of the magnet yokes adjacent to the air gaps are provided with an array type micro structure in the form of deep trenches, and the eddy current loss can be effectively inhibited. A center magnet yoke is provided with a compensation coil, and a formed compensation magnetic field carries out synchronous tracking compensation on the influence of an armature reaction. The organic integration design of air lubricated guide technology is employed, and outstanding electromagnetic drive mechanical performance and high movement guide precision are obtained at the same time. According to the double-permanent-magnetic-tube two-end symmetric excitation cylindrical low frequency vibration calibration table, large stroke, high thrust, a linear electromagnetic driving force characteristic and high movement guide precision can be considered, and a high precision and large stroke high performance low frequency vibration calibration table technical scheme is provided for low-frequency / ultra-low frequency vibration calibration.

Owner:HARBIN INST OF TECH

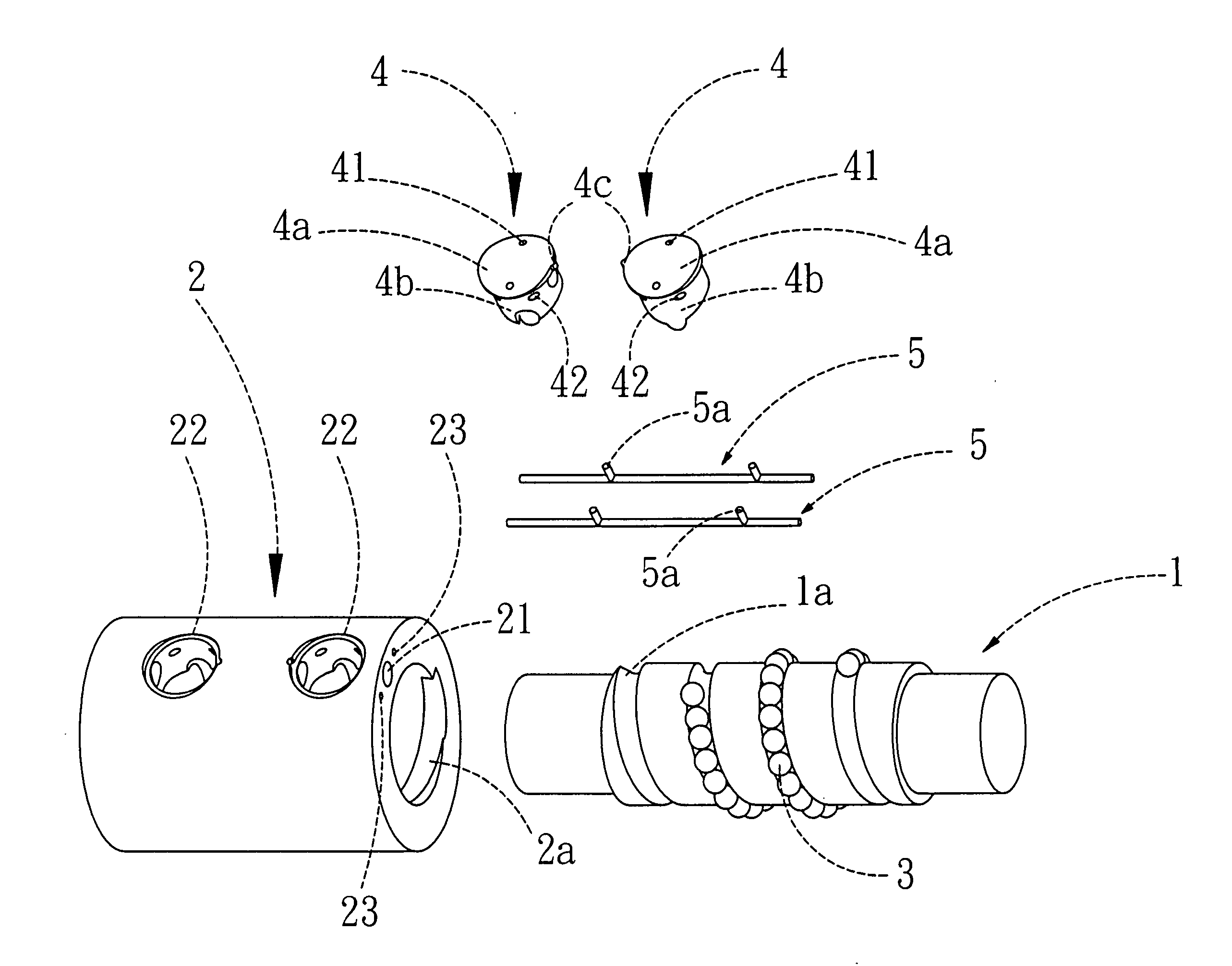

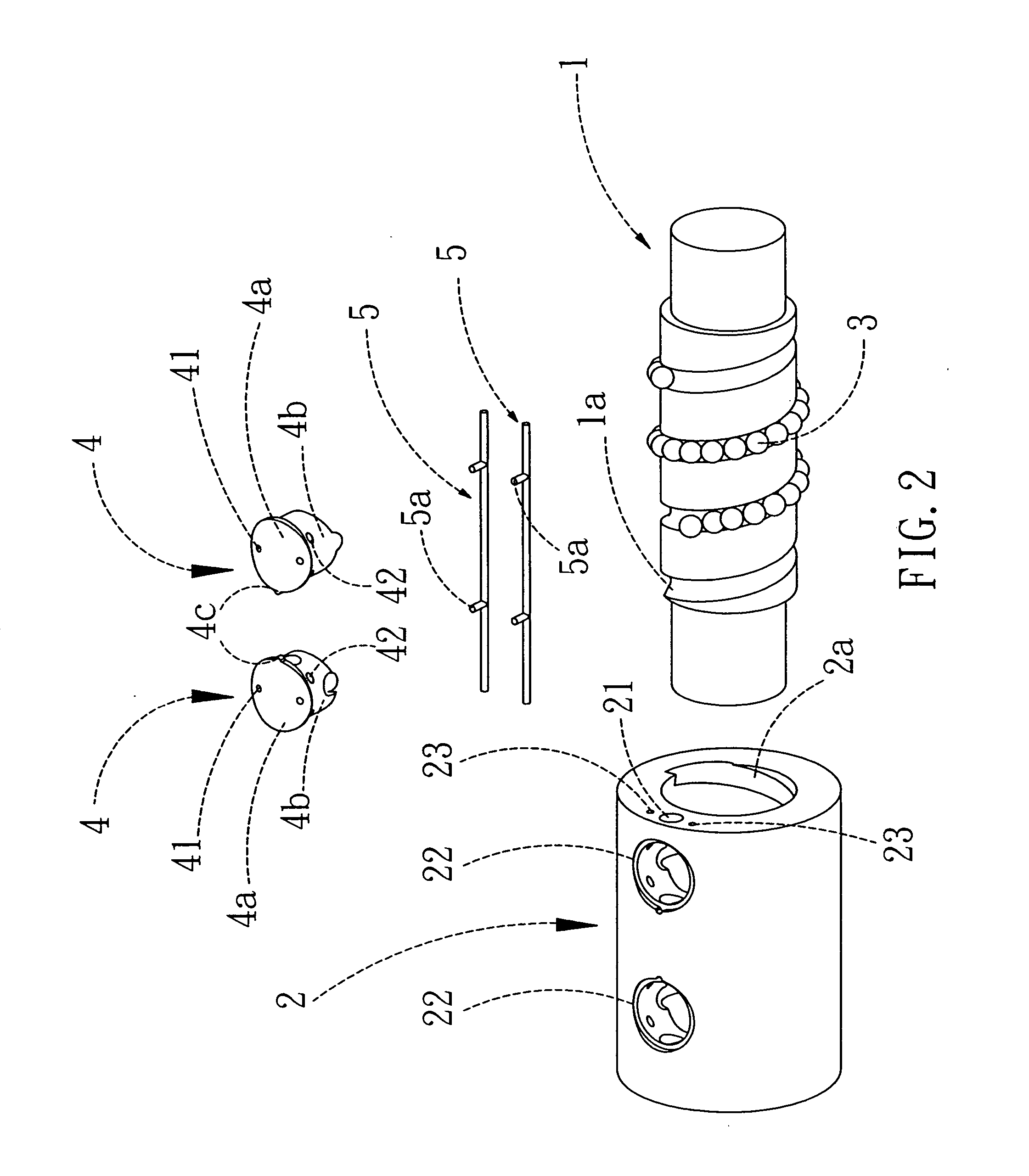

Ball screw assembly

ActiveUS7520193B2Solving Assembly ChallengesPrecise positioningPortable liftingToothed gearingsBall screwLiquid state

A ball screw assembly, wherein the circulate component is positioned in the nut by inserting a protrusion in a notch, so that the circulate component is positioned easily, and the problem of assembly difficulty is solved. The method of fixing the circulate components in the nut is that: the circulate component is formed with an axial hole and the radial hole that are connected to each other, the axial hole of the circulate component is aligned to the axial locking hole of the nut, and then liquid resin is injected into the axial hole of the circulate components, and the liquid resin will form a locking members after curing, thus fixing the circulate component in the nut. Due to the formation of the locking member is determined by the diameter of the hole to be machined, the configuration of locking member will be varied in response to the diameter of the hole to be machined. Whatever the diameter of the hole to be machined changes or not, it will not affect the interchangeability of the locking member. Therefore, the production cost is saved since it doesn't need to prepare different sized locking members.

Owner:HIWIN TECH

Equipment loading and unloading tool, equipment assembling method and equipment disassembling method

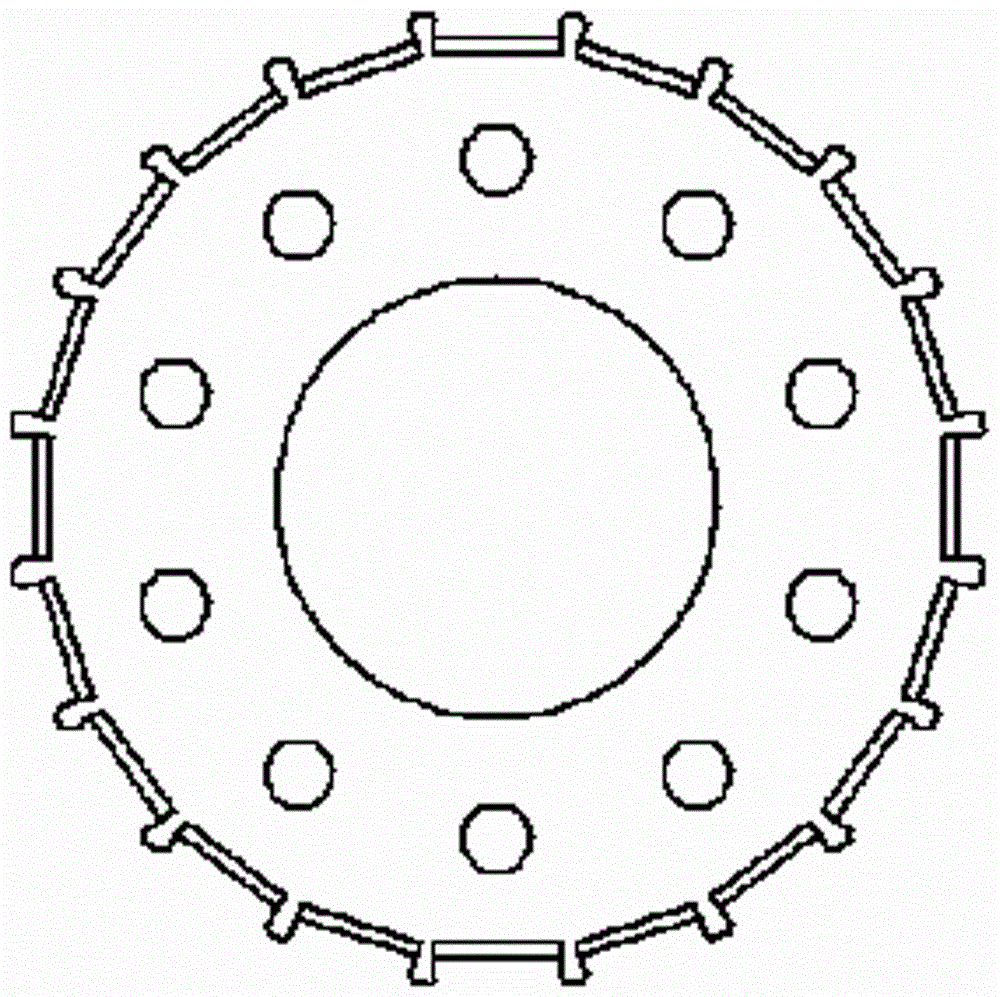

ActiveCN109015484AAchieve radial positioningImprove coaxialityNuclear energy generationWork holdersAxial displacementEngineering

The invention provides an equipment loading and unloading tool. The equipment loading and unloading tool comprises a clamping and fastening structure, an axial adjusting structure and a radial alignment structure; the clamping and fastening structure comprises an annular chuck and a fastener, the annular chuck comprises at least two arc-shaped tooling support blocks, the tool supporting blocks arespliced end to end to form an annular chuck, and the fastener is used for tightly fixing the annular chuck; the axial adjusting structure comprises supporting legs, the supporting legs penetrate through the annular chuck, and the supporting legs are in threaded connection with the annular chuck; and positioning rods penetrates through the annular chuck. According to the loading and unloading tool, to-be-installed low-temperature machinery is clamped by adopting the clamping and fastening structure. By rotating the supporting legs, the tool supporting blocks drive the to-be-installed equipmentto generate axial displacement, so that the installing and dismounting are realized. In the installation process of the equipment, the positioning rods are screwed into positioning holes of a flangeat the lower end, so that the radial positioning of the tool and the mechanical assembly can be realized, the coaxiality is improved, and the assembly error is reduced. In addition, the invention further provides an equipment assembling method and an equipment disassembling method adopting the equipment loading and unloading tool.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

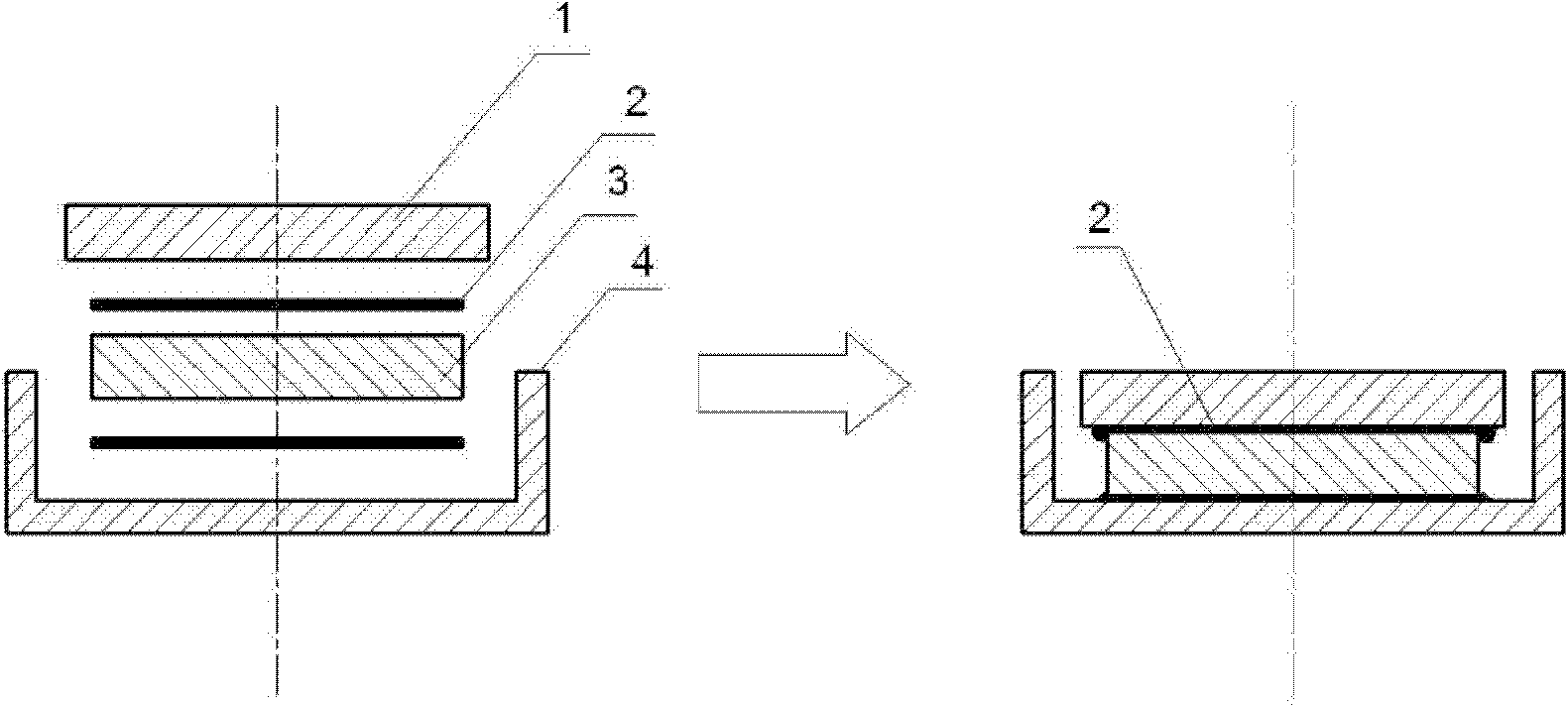

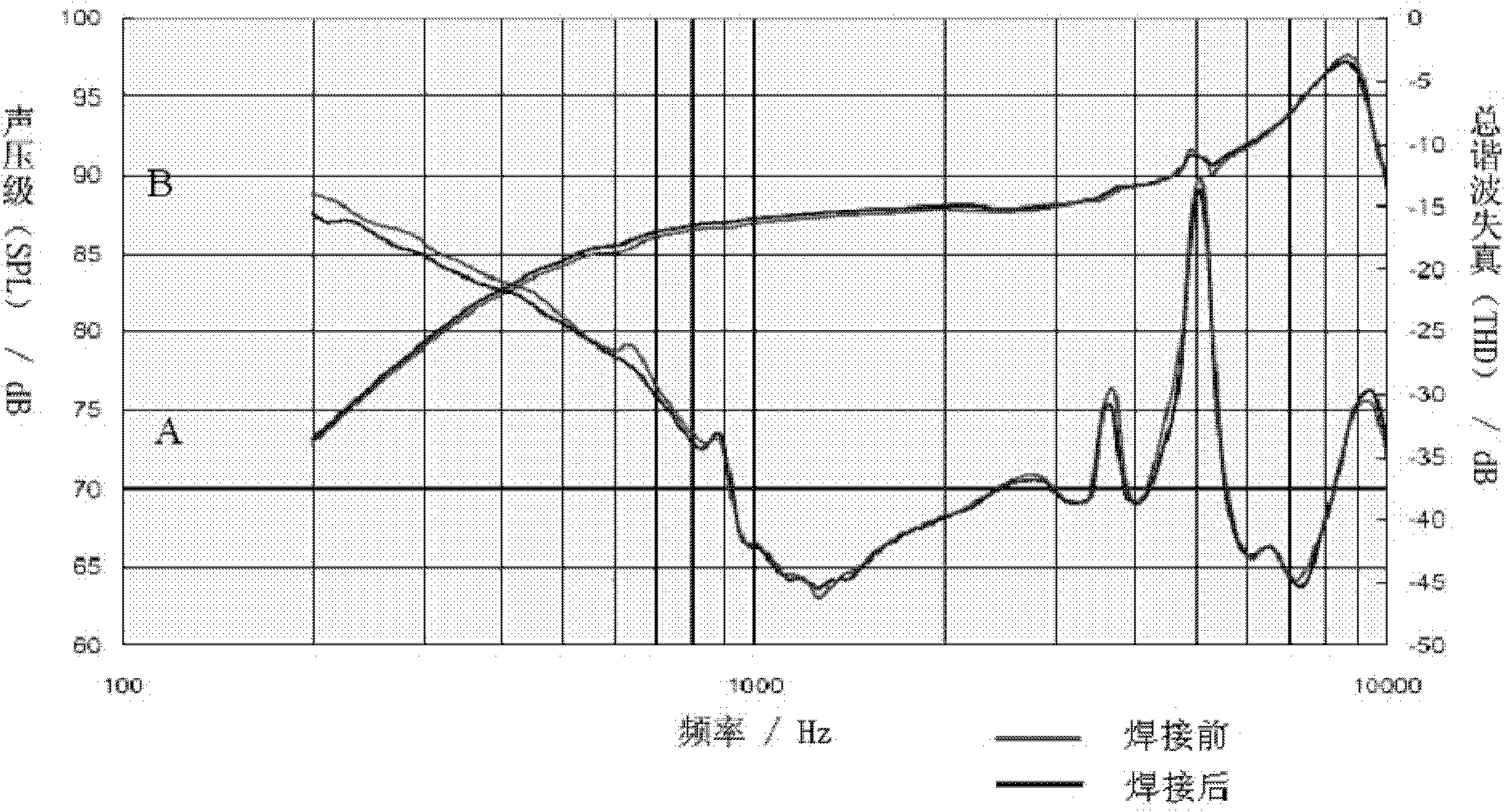

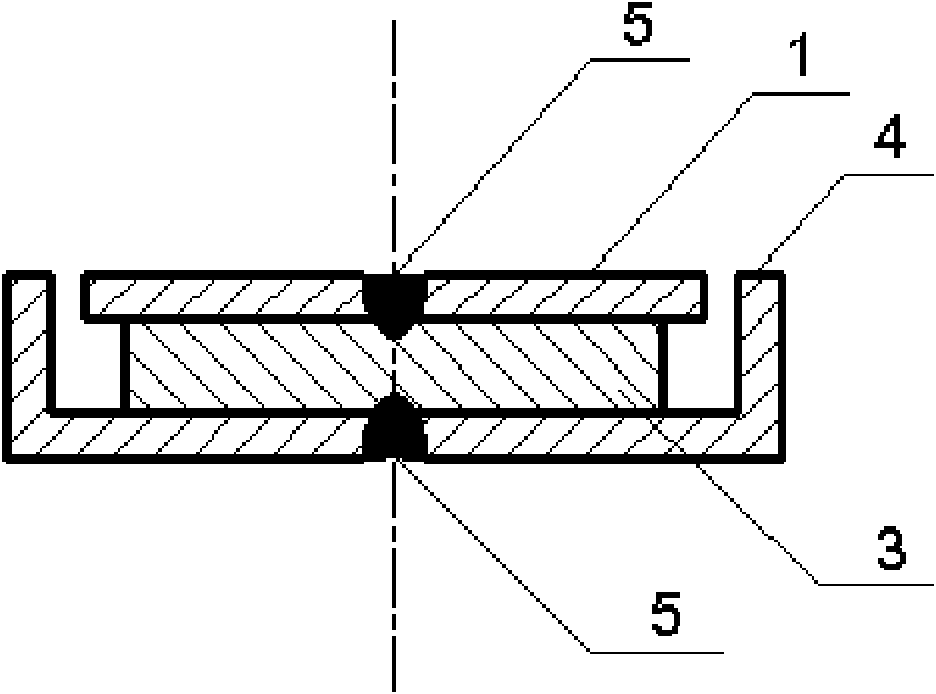

Laser spot welding assembly method of magnetic circuit system of miniature loudspeaker

InactiveCN102151994AReduce volumeMiniaturizationLaser beam welding apparatusManufacturing technologyWorking environment

The invention relates to a laser spot welding assembly method of a magnetic circuit system of a miniature loudspeaker and belongs to the manufacturing technology field of miniature loudspeakers. Welding spots are reasonably arranged by the adoption of the laser spot welding method according to the dimension and the shape of the magnetic circuit system to realize the one-step forming of the laser spot welding of the magnetic circuit system of the miniature loudspeaker; and a joint is stable and has high efficiency and low cost. After the welding, a top plate, a magnet yoke and a permanent magnet are tightly fitted; and the assembled magnetic circuit system has small volume, and the acoustical property of the magnetic circuit system is basically unchanged. Any substances capable of polluting the environment are not used or discharged during the welding process, so that the working environment is clean. Therefore, the laser spot welding assembly method not only can overcome the defects in the prior art, but also can provides a shortcut for solving the assembly problem of the magnetic circuit system of the miniature loudspeaker.

Owner:TSINGHUA UNIV

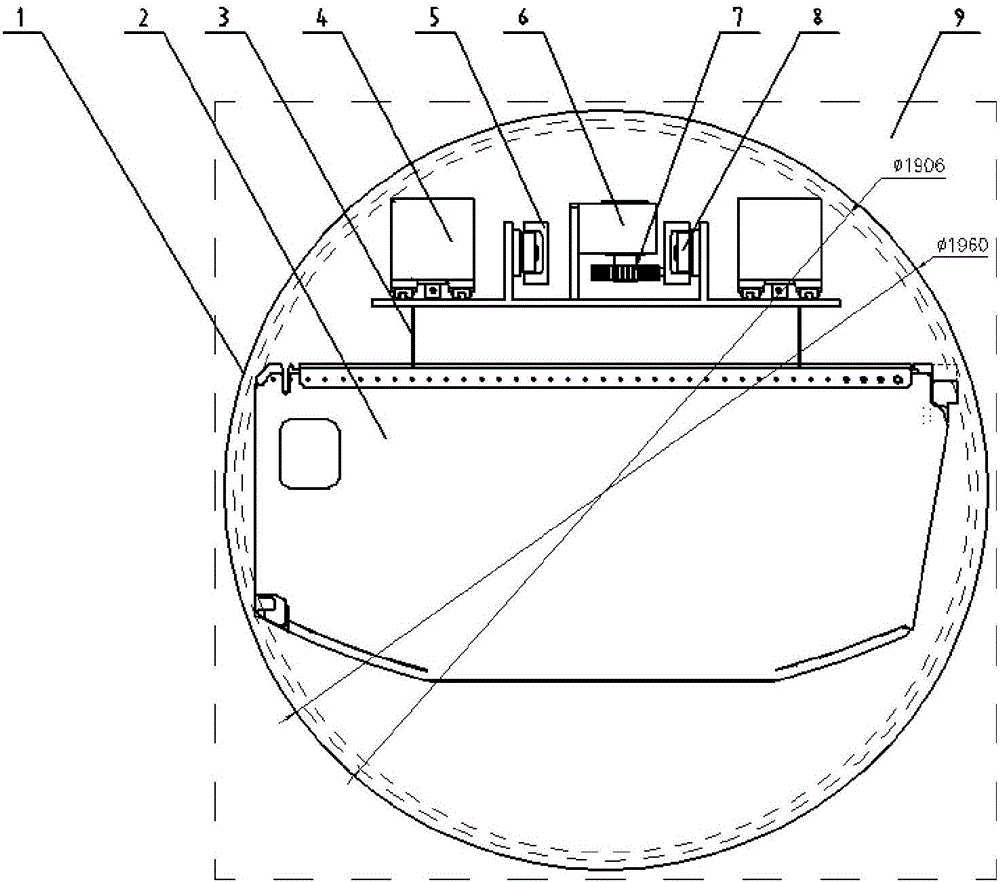

Cabin loading method of large overall equipment cabinet of space station working cabin

InactiveCN106392536ASolving Assembly ChallengesQuick assemblyMetal working apparatusPetroleum engineeringAutonomation

The invention discloses a cabin loading method of a large overall equipment cabinet of a space station working cabin. The cabin loading method includes the following steps that (1) the equipment cabinet is conveyed; (2) radial posture alignment of the equipment cabinet is carried out; (3) axial conveying of the equipment cabinet is carried out; (4) axial and radial posture alignment of the equipment cabinet is carried out; and (5) assembling of the equipment cabinet is completed. By means of the cabin loading method of the large overall equipment cabinet of the space station working cabin, the problems in intra-cabin conveying and intra-cabin installation of the large overall equipment cabinet of the certain-type space station working cabin can be effectively solved, and the functions of automatic detection, posture alignment, positioning and the like are achieved; and meanwhile, the installation reliability and safety of the equipment cabinet are guaranteed, and rapid and accurate intra-cabin assembling of the overall equipment cabinet is achieved.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Double-magnetic-circuit symmetrically-excited cylindrical enclosed magnetic-field-type electromagnetic shake table magnetic circuit structure capable of realizing magnetic field tracking compensation

ActiveCN104865030AGood effectSimple structureMechanical vibrations separationVibration testingVibration measurementMagnetic poles

A double-magnetic-circuit symmetrically-excited cylindrical enclosed magnetic-field-type electromagnetic shake table magnetic circuit structure capable of realizing magnetic field tracking compensation belongs to the technical field of vibration measurement. A cylindrical enclosed magnetic field structure is provided, two cylindrical permanent magnets are symmetrically installed on two ends of a central magnet yoke, and same magnetic poles are arranged in an opposite manner; two symmetrical enclosed magnetic circuits are formed through magnet yokes, the magnetic induction intensity high in uniformity is generated in an air gap; the surface, adjacent to the air gap, of the magnet yoke is provided with an array-type microstructure arranged in a deep channel mode, and the eddy current loss can be effectively inhibited; and a central magnet yoke is provided with a compensation coil, a provided current is opposite to the current in a working coil in direction and is proportional to the current in the working coil in phase synchronous tracking and amplitude, and a formed compensation magnetic field is capable of carrying out synchronous tracking compensation on the influences of an armature reaction. According to the invention, a large stroke, high magnetic field uniformity, a large thrust and linear electromagnetic driving force characteristics can be considered at the same time, and a high-precision and large-stoke electromagnetic shake table magnetic circuit structure technical scheme is provided for low-frequency / ultralow-frequency vibration calibration.

Owner:HARBIN INST OF TECH

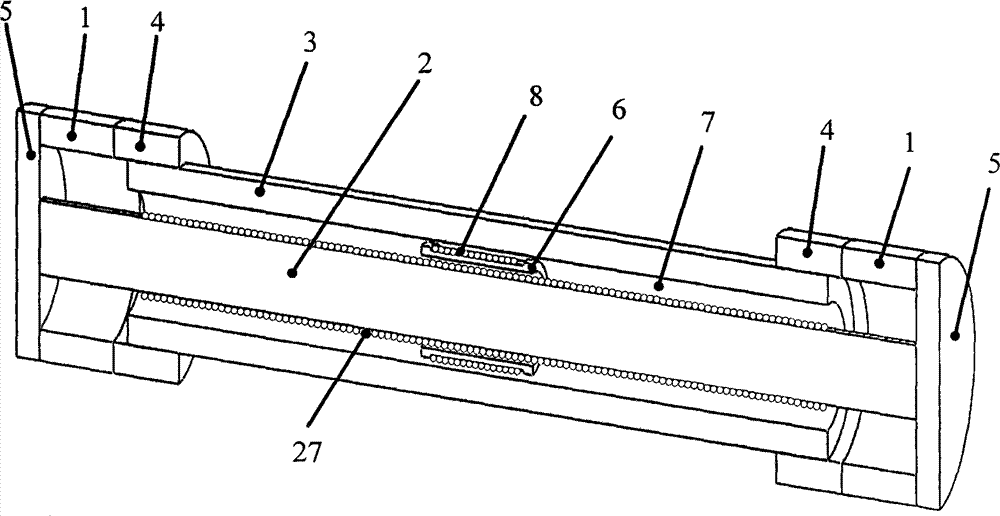

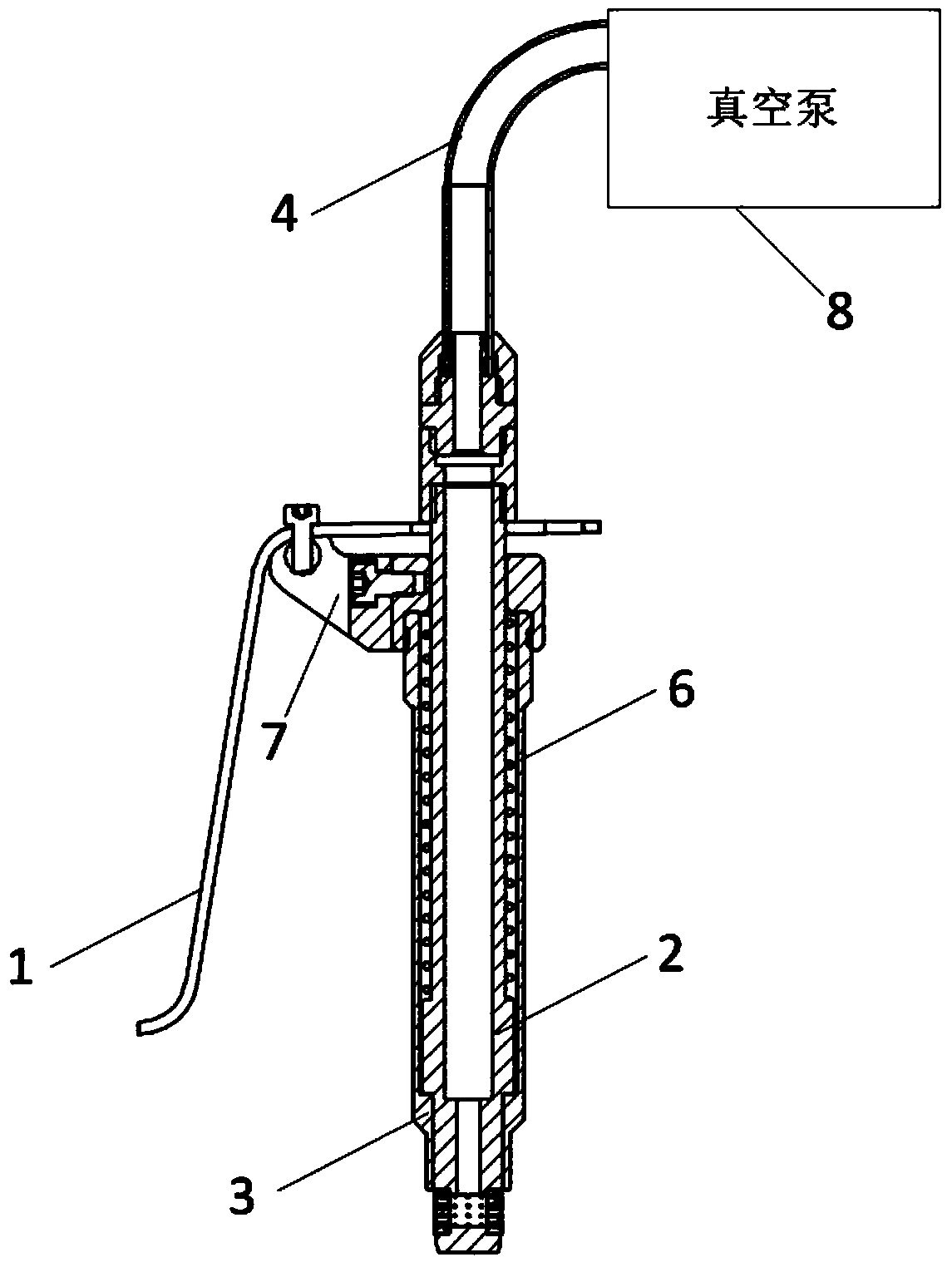

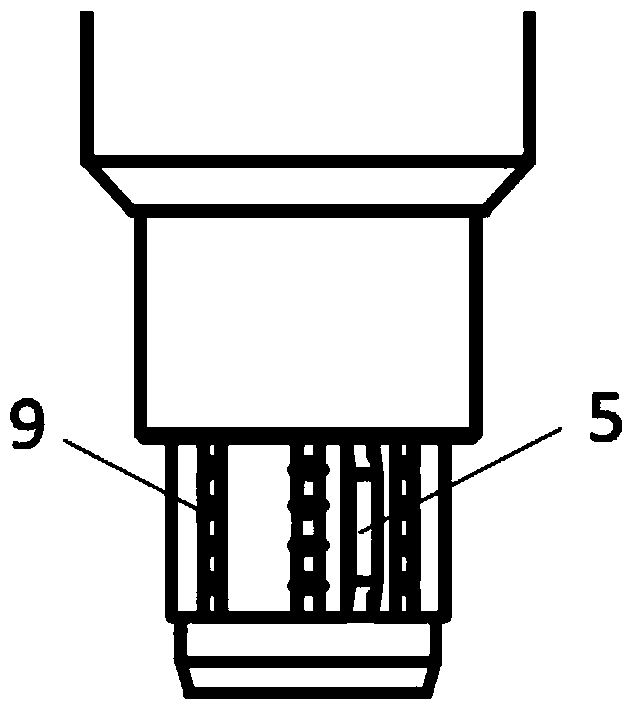

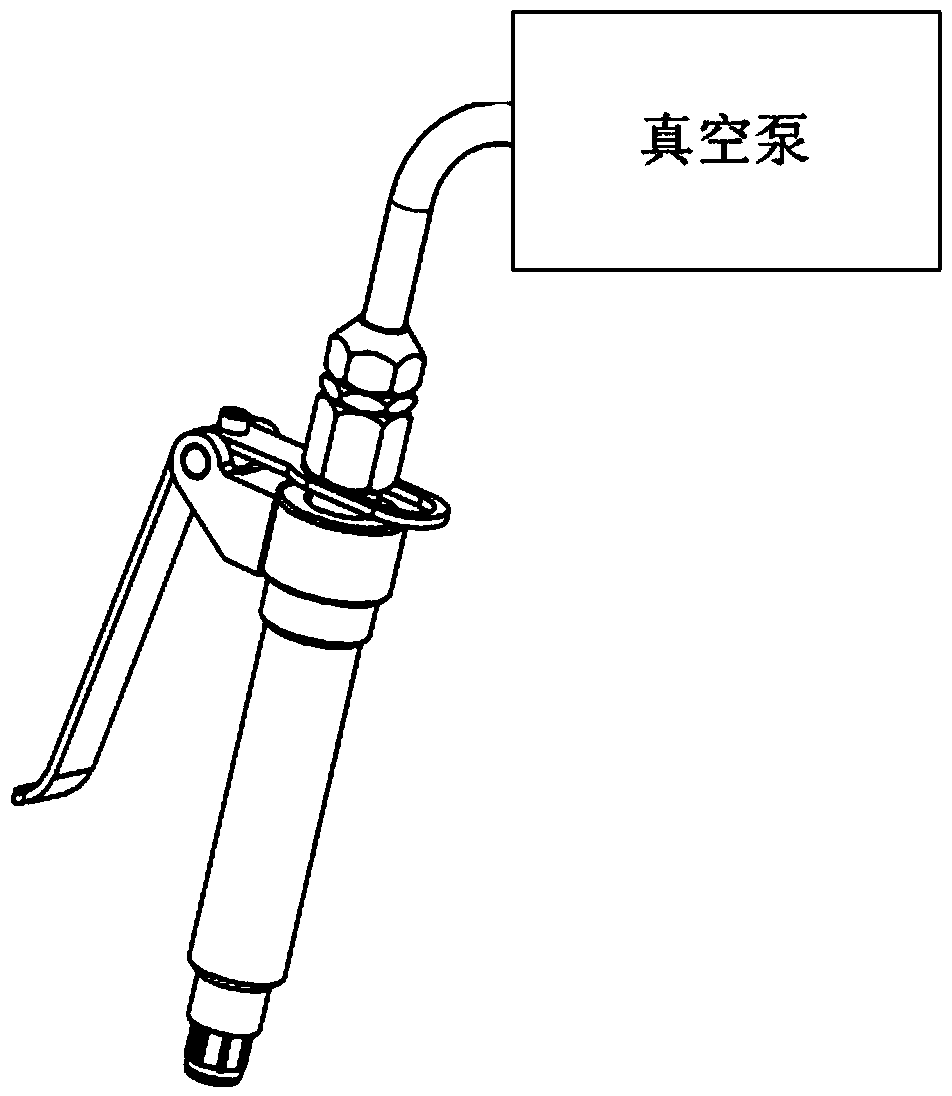

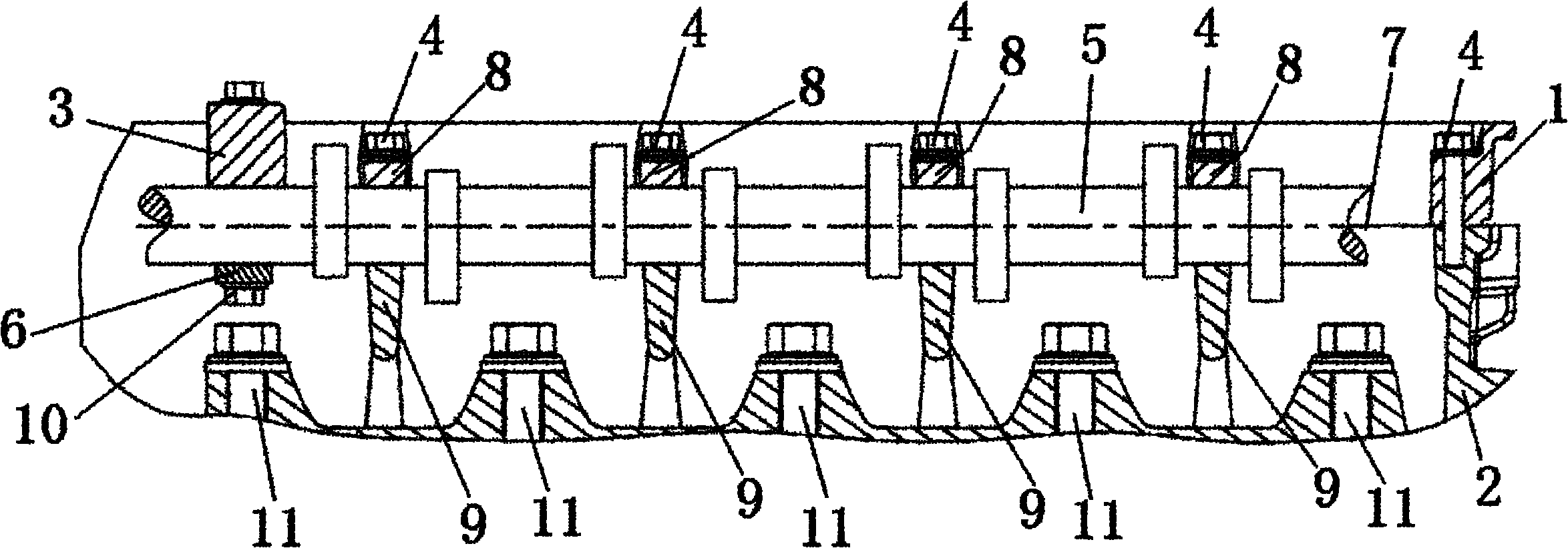

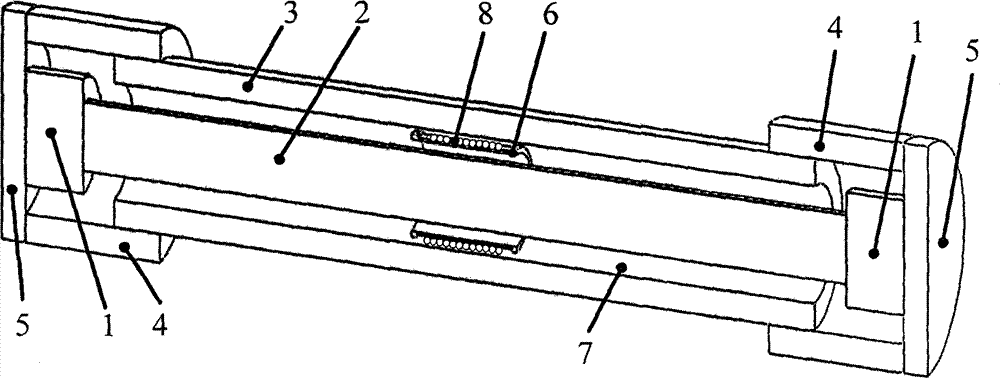

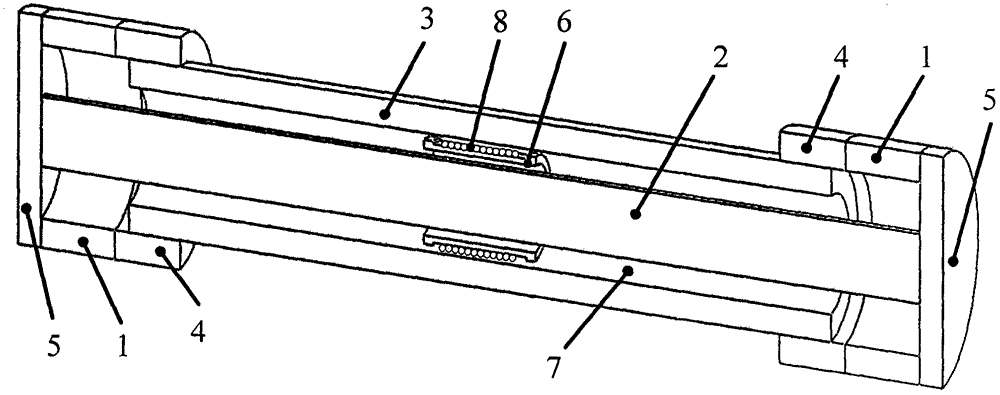

Linear bearing assembly device

ActiveCN104373468ASolving Assembly ChallengesQuality improvementBearing componentsSteel ballEngineering

The invention provides a linear bearing assembly device which comprises an outer shell, an inner shell, a handle, a vacuum sucker and a vacuum pump, wherein the outer shell is arranged outside the inner shell and can move along the surface of the inner shell; the inner shell is of a hollow structure; the front end of the inner shell is connected with the vacuum pump through the vacuum sucker; an elastic head positioning piece is arranged at the tail end of the inner shell; a plurality of through vacuum suction holes are distributed in the side wall of the tail end of the inner shell; the handle is arranged on the inner shell and is positioned between the outer shell and the vacuum sucker. According to the linear bearing assembly device, the difficulty in assembly of balls and a retainer of a linear bearing is smartly solved, when the linear bearing is assembled, only the retainer needs to be sleeved, the handle is pressed to suck the balls, then the balls are sleeved by the outer ring, and the whole assembly process of the linear bearing can be finished, so that the production efficiency is improved, the problems that the steel balls are missed, the positions of the steel balls are mistaken and the like are solved, and the quality of the bearing is improved.

Owner:SUZHOU XINHAO BEARING

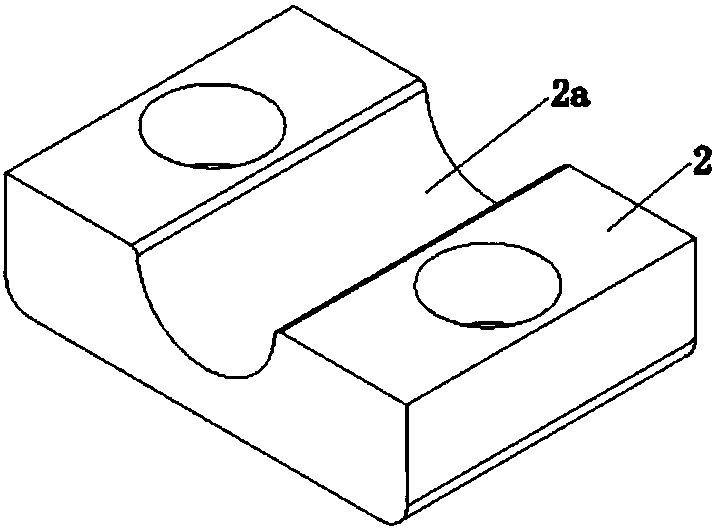

Novel camshaft bearing seat

InactiveCN101984223ALimit lengthShorten the lengthValve arrangementsLubrication of auxillariesCylinder headAgricultural engineering

The invention discloses a novel camshaft bearing seat which comprises an upper bearing seat framework (1), an upper bearing seat (8) arranged on the upper bearing seat framework (1), a cylinder cover (2), a lower bearing seat (9) arranged on the cylinder cover (2), bearing seat tightening bolts (4) for fixing the upper bearing seat (8) and the lower bearing seat (9), a first bearing upper bearing seat (3), a first bearing lower bearing seat (6) and a first bearing seat tightening bolt (10), wherein the first bearing upper bearing seat (3) is arranged on the upper bearing seat framework (1), and the first bearing lower bearing seat (6) is fixed on the first bearing upper bearing seat (3) through the first bearing seat tightening bolt (10). The novel camshaft bearing seat can abandon the structural design of arranging the bearing seats and the cylinder cover into a whole through the way of arranging the camshaft lower bearing seat alone, thereby effectively limiting the length of the cylinder cover, reducing the weight of the cylinder cover and being conductive to reducing the weight of an engine.

Owner:CHERY AUTOMOBILE CO LTD

Top roller bearing assembling process for loom double rolling way and its special correcting tool

InactiveCN1587465AOvercoming the long-standing problem of short lifespanExtend your lifeDrafting machinesBearing componentsEngineeringSteel ball

The present invention discloses double rolling way roller bearing assembling process and special correcting tool for loom. The assembling process includes matching steel balls, spindle and bearing casing with double rolling way. The tools including back row tool, front row tool, shifting pin, radial interval correcting pin and U-shaped spring clamp are used in the assembling of spindle, bearing casing, back holder, back row of balls, front row of balls, front holder, etc. Using double rolling way bearing to replace single rolling way bearing has the effects of prolonged service life, homogeneous pressure, smooth rotation and raised yarn quality.

Owner:陈兆南

Positioning assembly machining method of bent pipe

InactiveCN112247303ASolving Assembly ChallengesGuaranteed integritySoldering apparatusVacuum furnaceStructural engineering

The invention discloses a positioning assembly machining method of a bent pipe. The method comprises the following steps of, on a workpiece provided with a through hole and an inclined hole which arecommunicated with each other, reaming the inclined hole from the tail end of the inclined hole, and enabling the aperture of the reamed inclined hole to be matched with the outer diameter of a bent pipe sleeve; enabling the bent pipe to extend into the inclined hole from the through hole of the workpiece, and enabling a straight section of the bent pipe to be located in the through hole of the workpiece and a bent section of the bent pipe to be located in the reamed inclined hole of the workpiece; previously placing pasty brazing filler metal in brazing filler metal grooves reserved in the outer wall and the inner wall of the bent pipe sleeve, wherein the inner diameter of the bent pipe sleeve is matched with the outer diameter of the bent section of the bent pipe, and the outer diameter of the bent pipe sleeve is matched with the inner diameter of the reamed inclined hole; sleeving the bent pipe sleeve on the bent section of the bent pipe from the tail end of the inclined hole, and guaranteeing that the bent pipe sleeve blocks a circular seam between the bent section of the bent pipe and the reamed inclined hole; and putting the workpiece into a vacuum furnace, performing vacuum brazing, cooling, and then taking out from the furnace. By using the method, the technical problem of the positioning assembly of the bent pipe is solved; and meanwhile, the integrity of the workpieceis ensured.

Owner:XIAN YUANHANG VACUUM BRAZING TECH

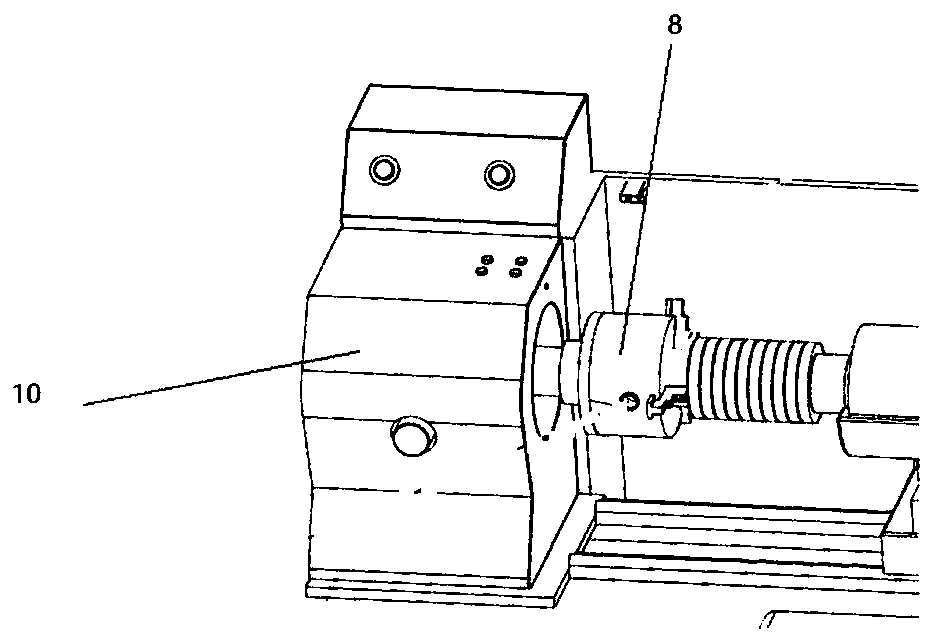

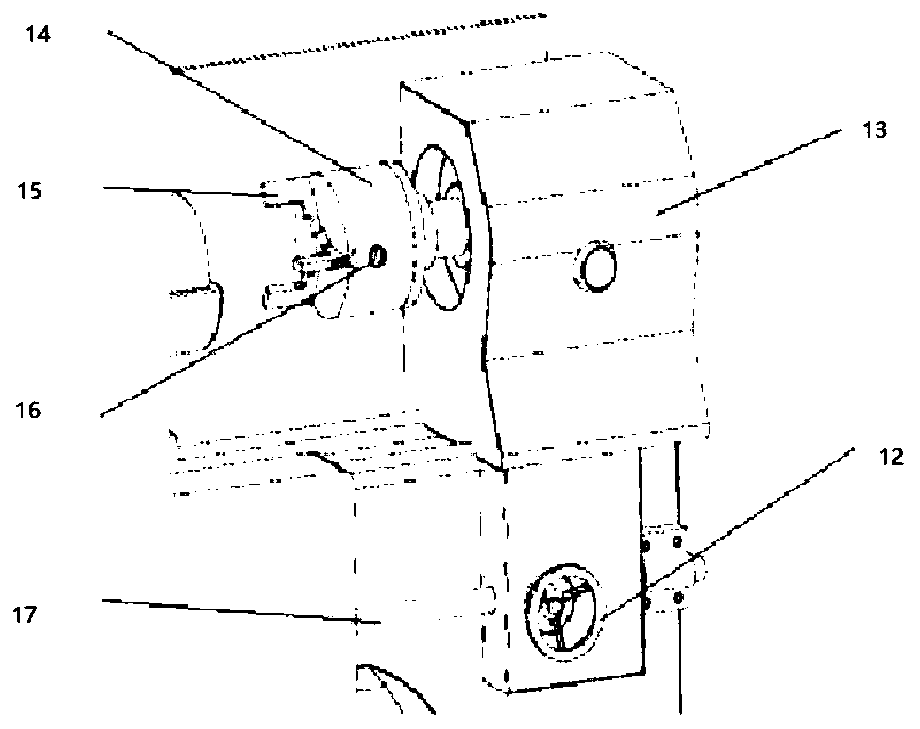

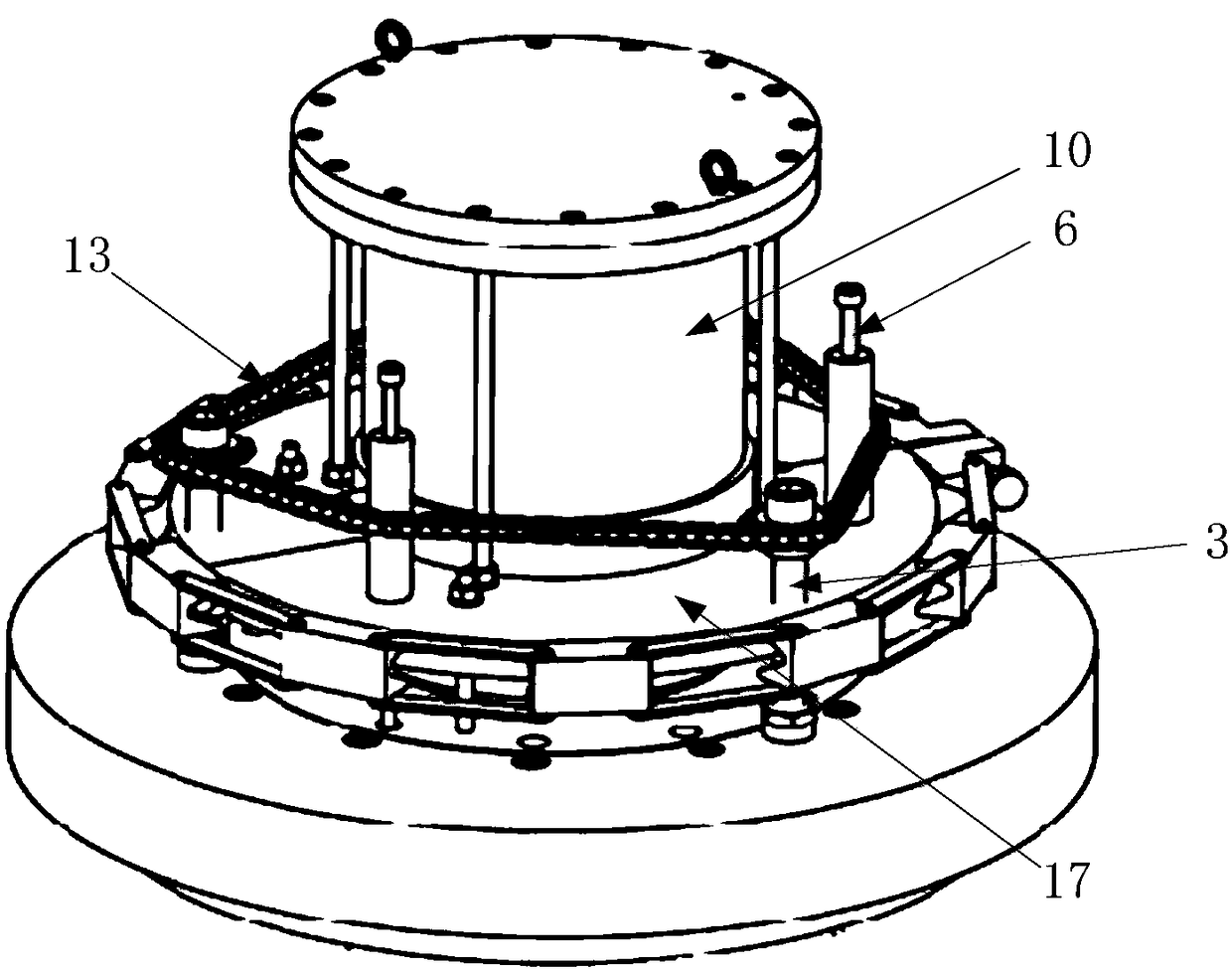

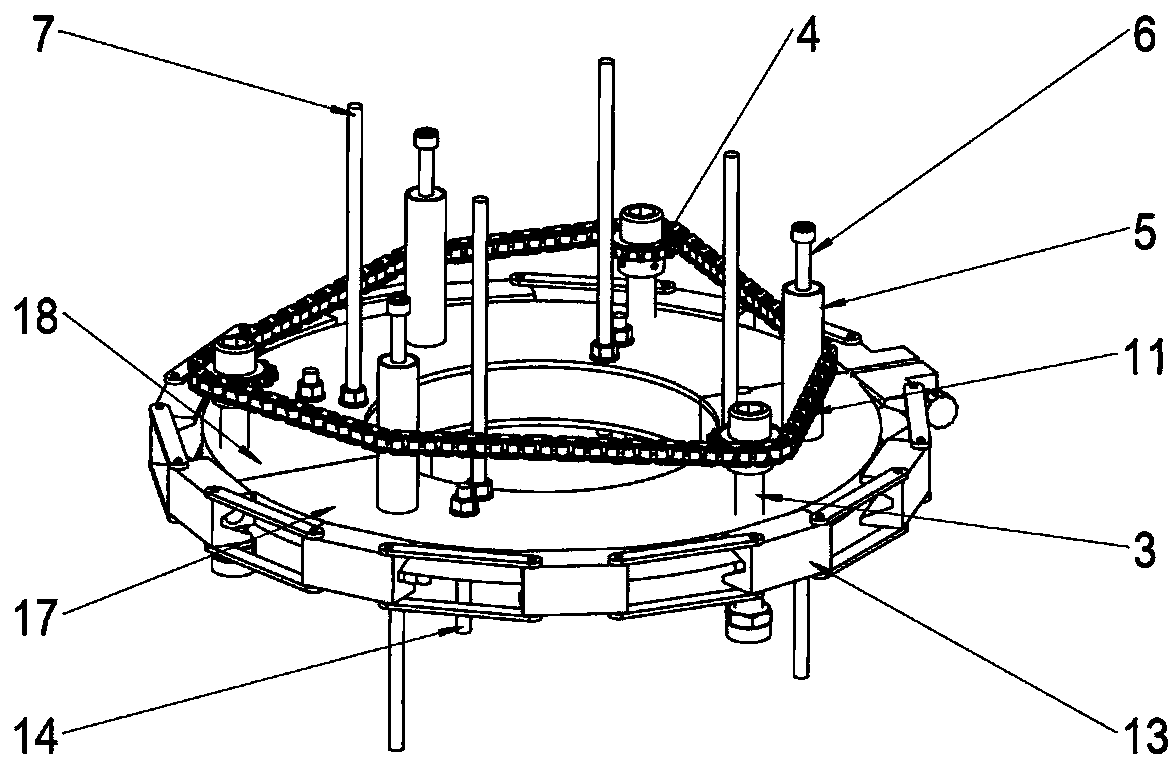

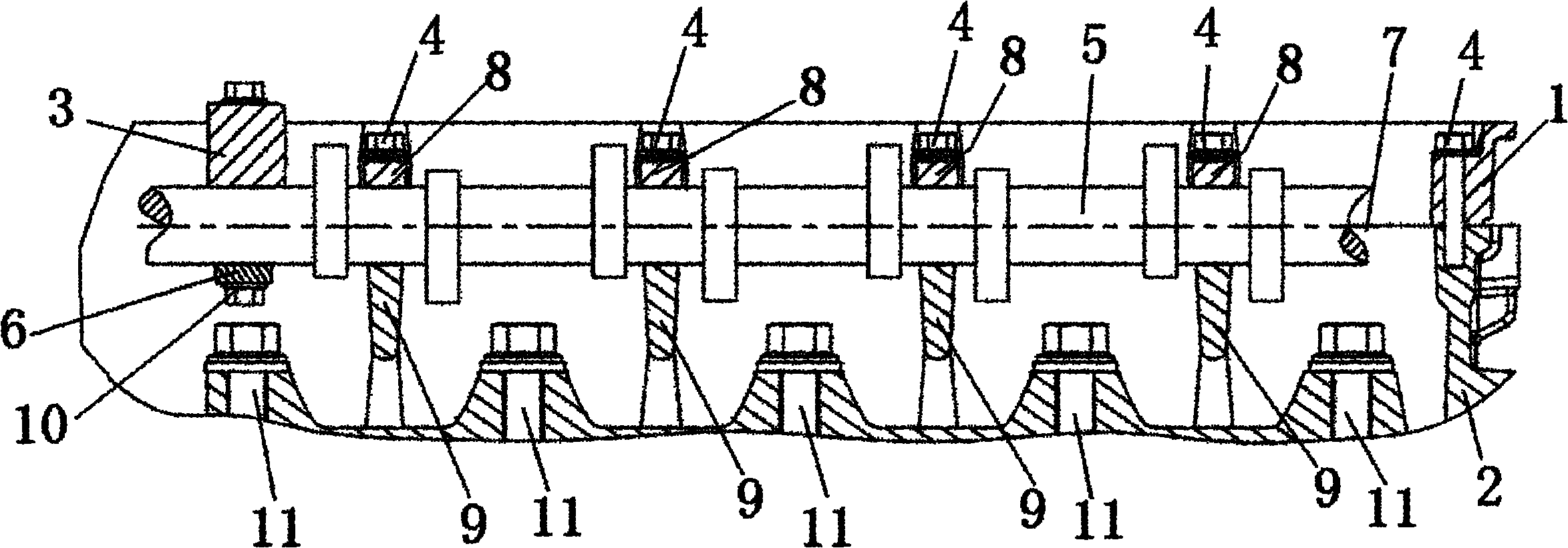

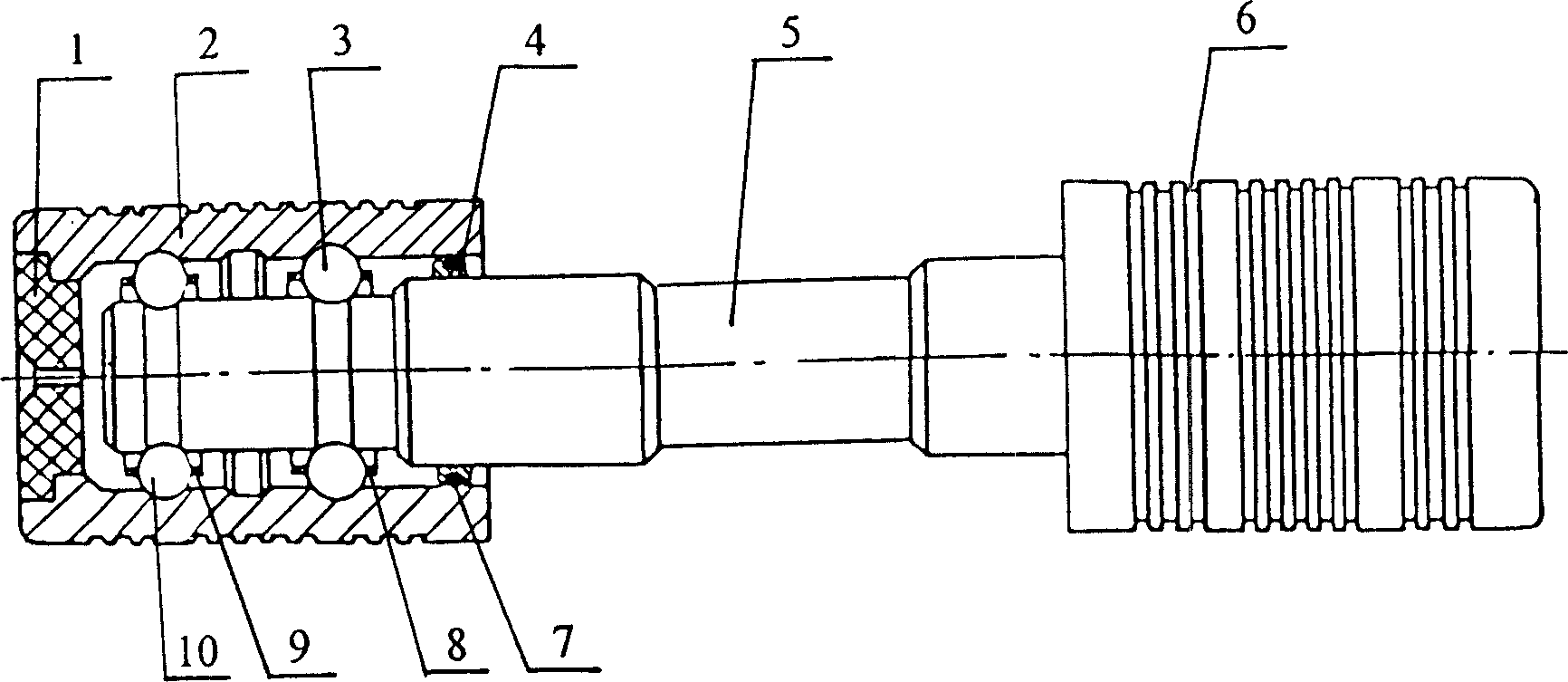

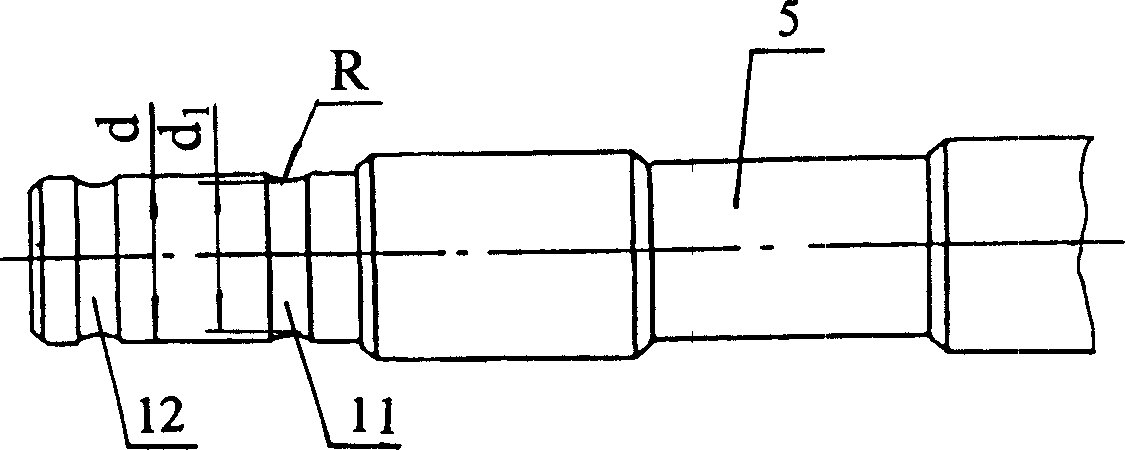

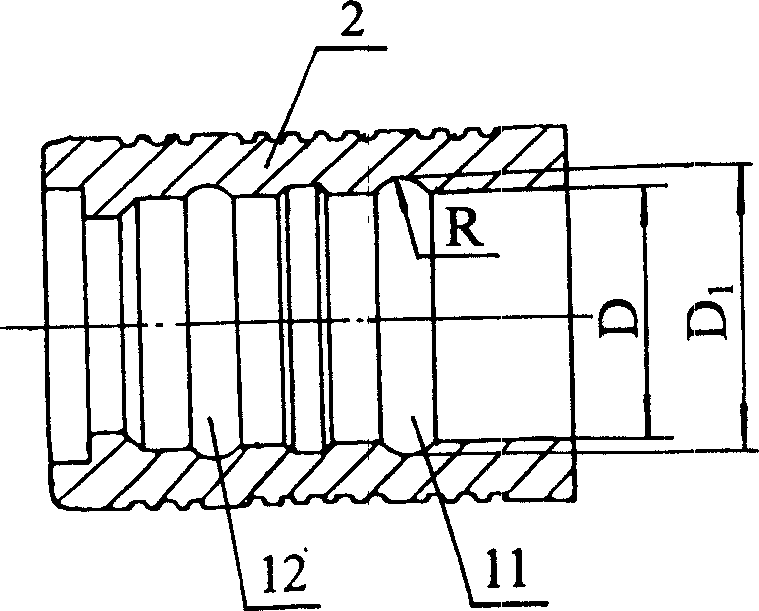

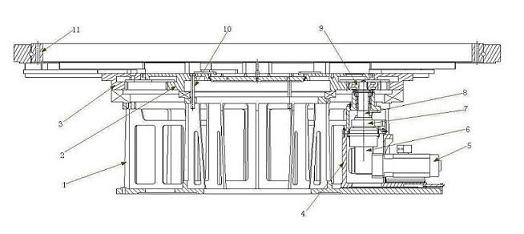

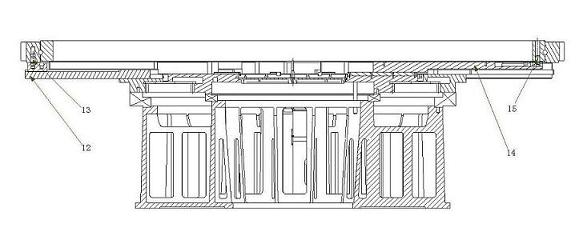

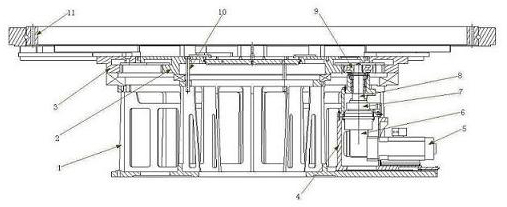

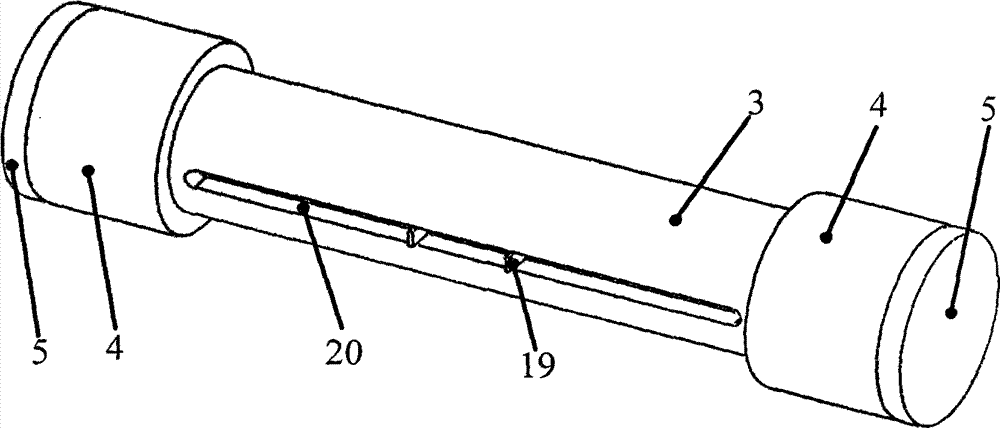

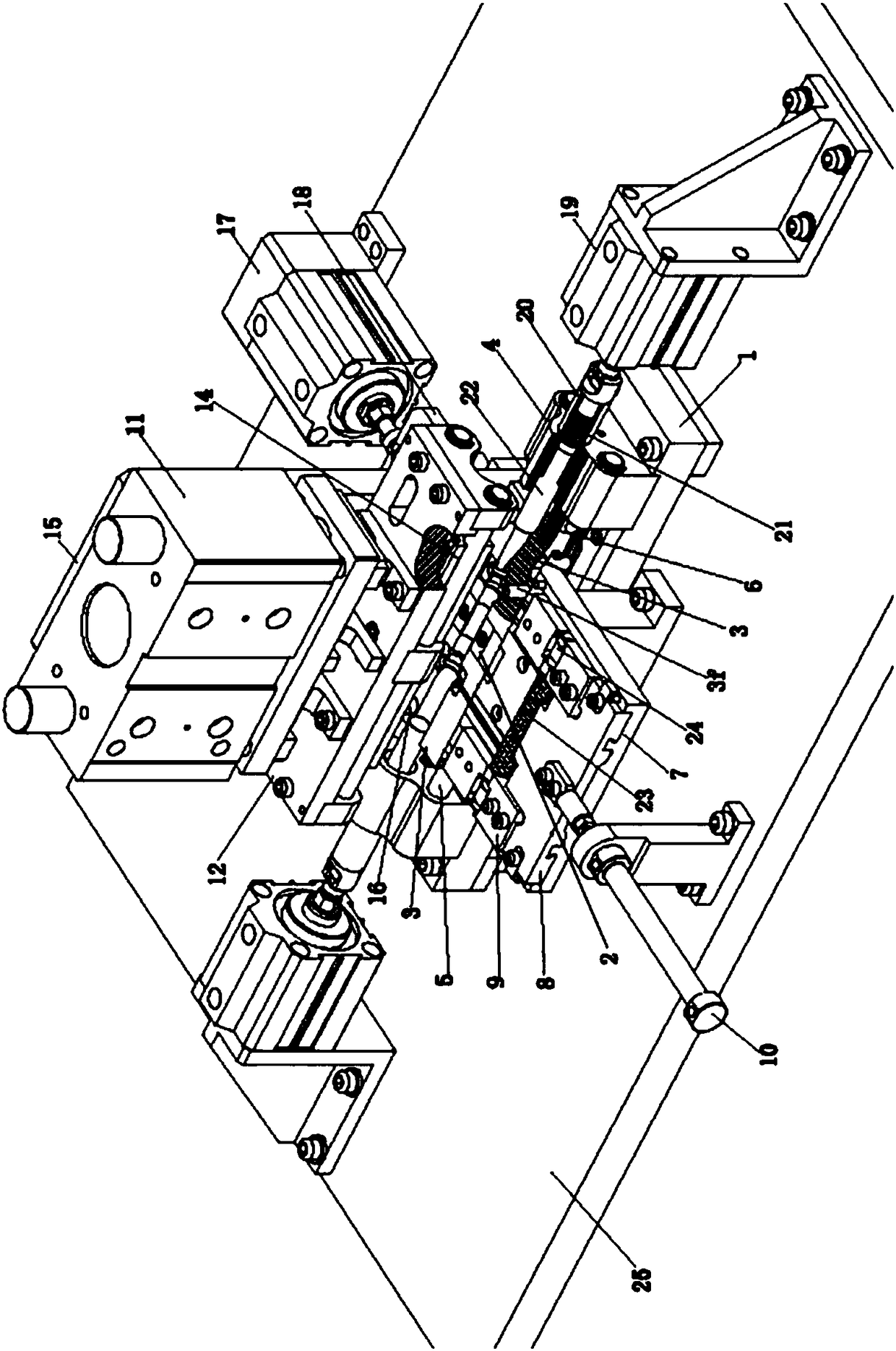

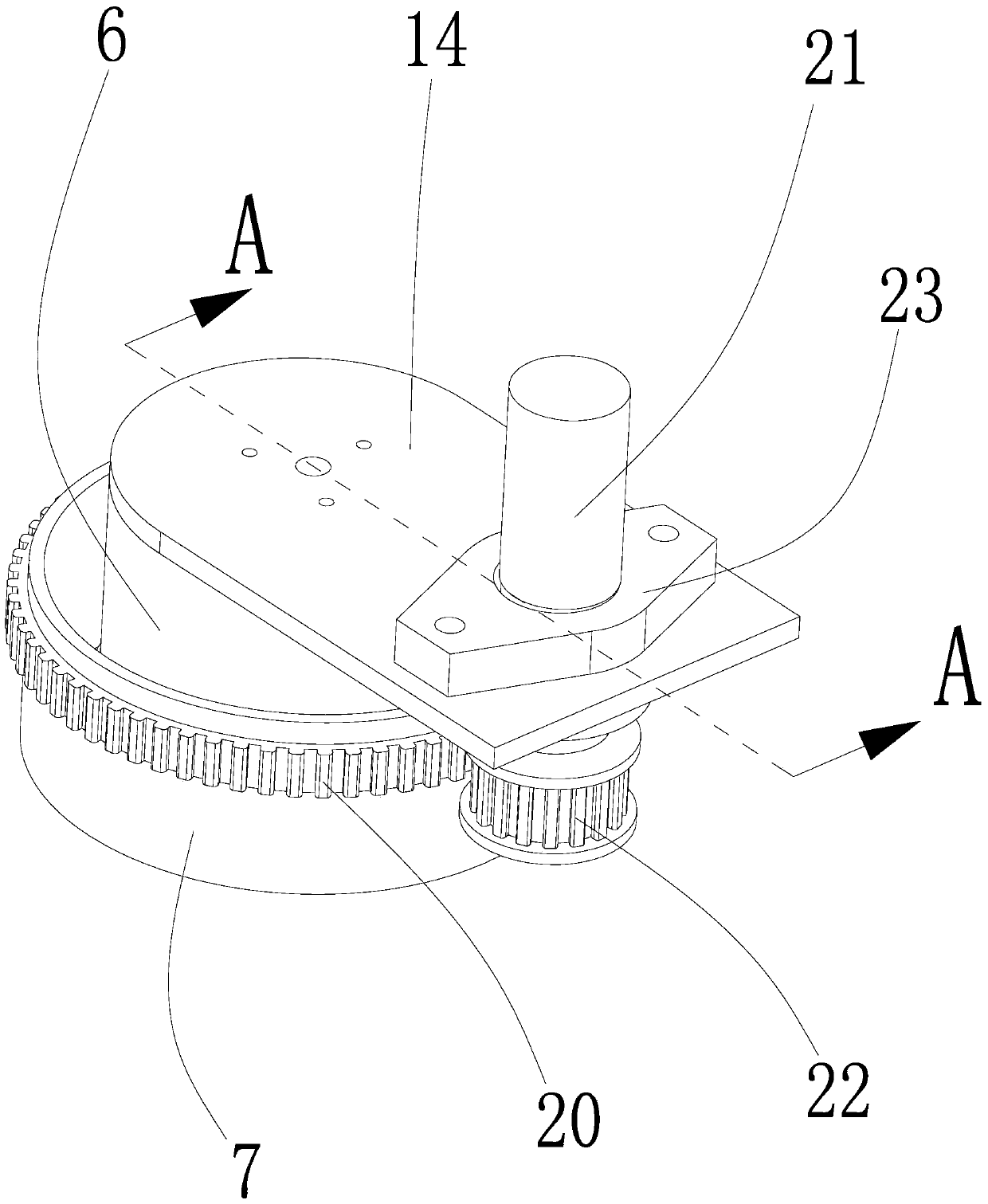

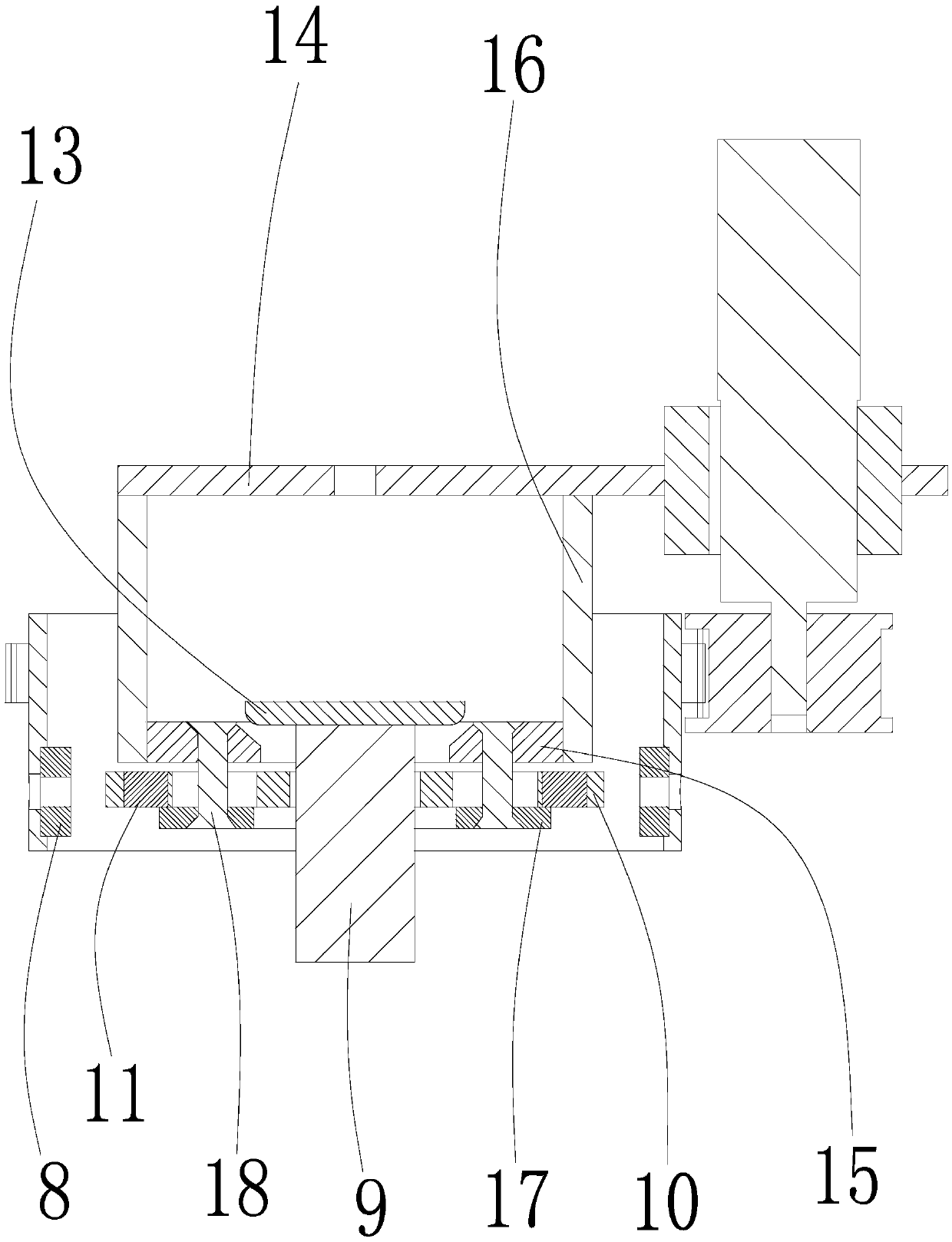

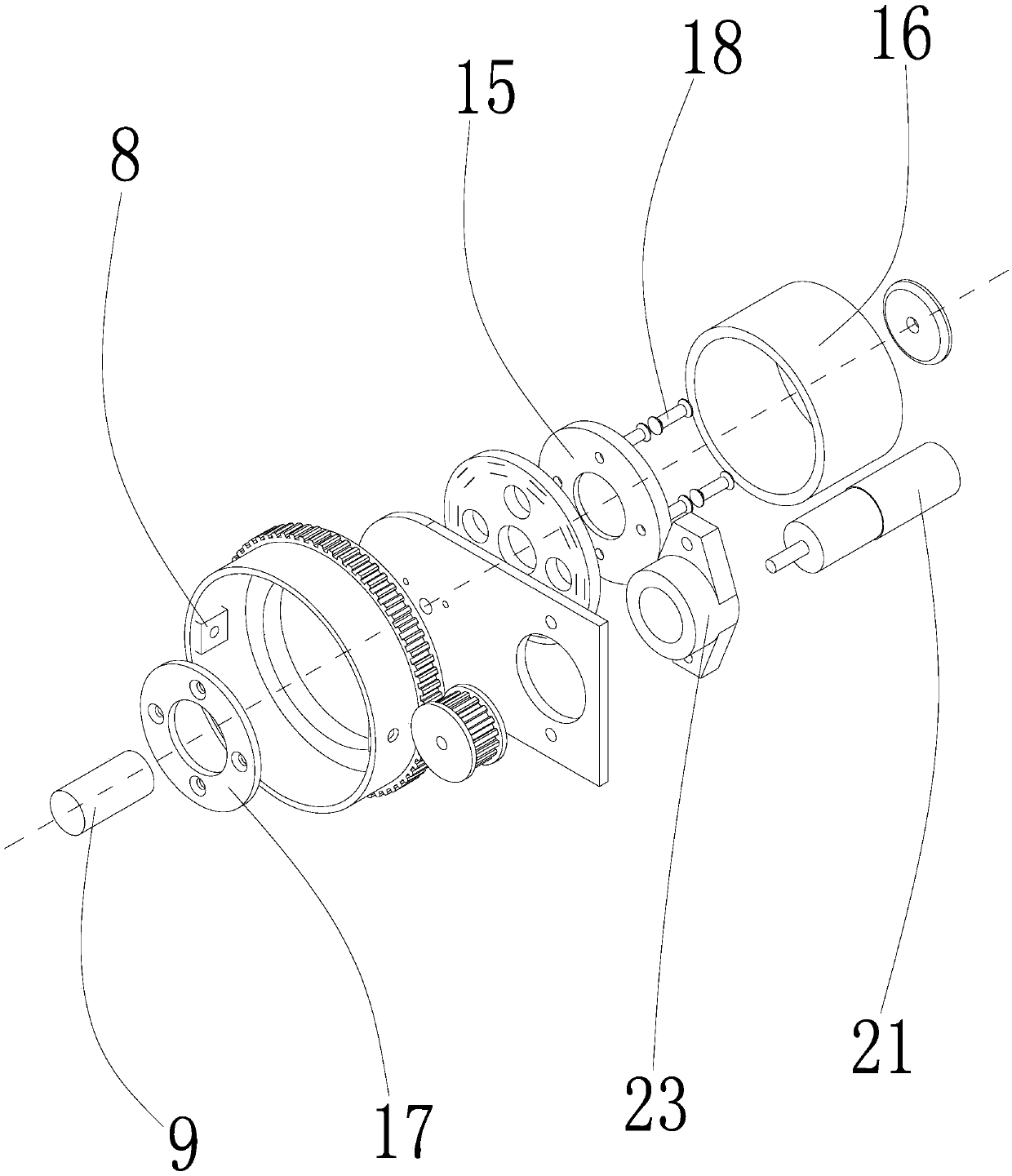

Internal and external dual-drive rotary table bearing assembly machine

ActiveCN102102711ACompact structureSmall footprintBearing componentsReducerUltimate tensile strength

The invention discloses an internal and external dual-drive rotary table bearing assembly machine. The machine mainly comprises a frame (1), an outer gear rotary table (2), an inner gear rotary table (3), a movable seat (4), a variable frequency motor (5), a precise planetary reducer (6), a torque sensor (7), a transmission shaft (8), a driving gear (9), a fixed pin (10), an outer telescopic arm (12), an outer drive pin (13), an inner telescopic arm (14) and an inner drive pin (15), wherein the outer gear rotary table (2) and the inner gear rotary table (3) are arranged on the frame (1); and the variable frequency motor (5), the precise planetary reducer (6), the torque sensor (7), the transmission shaft (8) and the driving gear (9) are arranged on the movable seat (4). The internal and external dual-drive rotary table bearing assembly machine has a compact structure, a small floor space and a wide application range and is convenient for internal and external transmission and switchover; and by the machine, the problem of the assembly of a rotary table bearing with the diameter of more than 4 meters is solved, the labor intensity of assembly workers is reduced and working efficiency is improved.

Owner:WAFANGDIAN BEARING GRP CO LTD +1

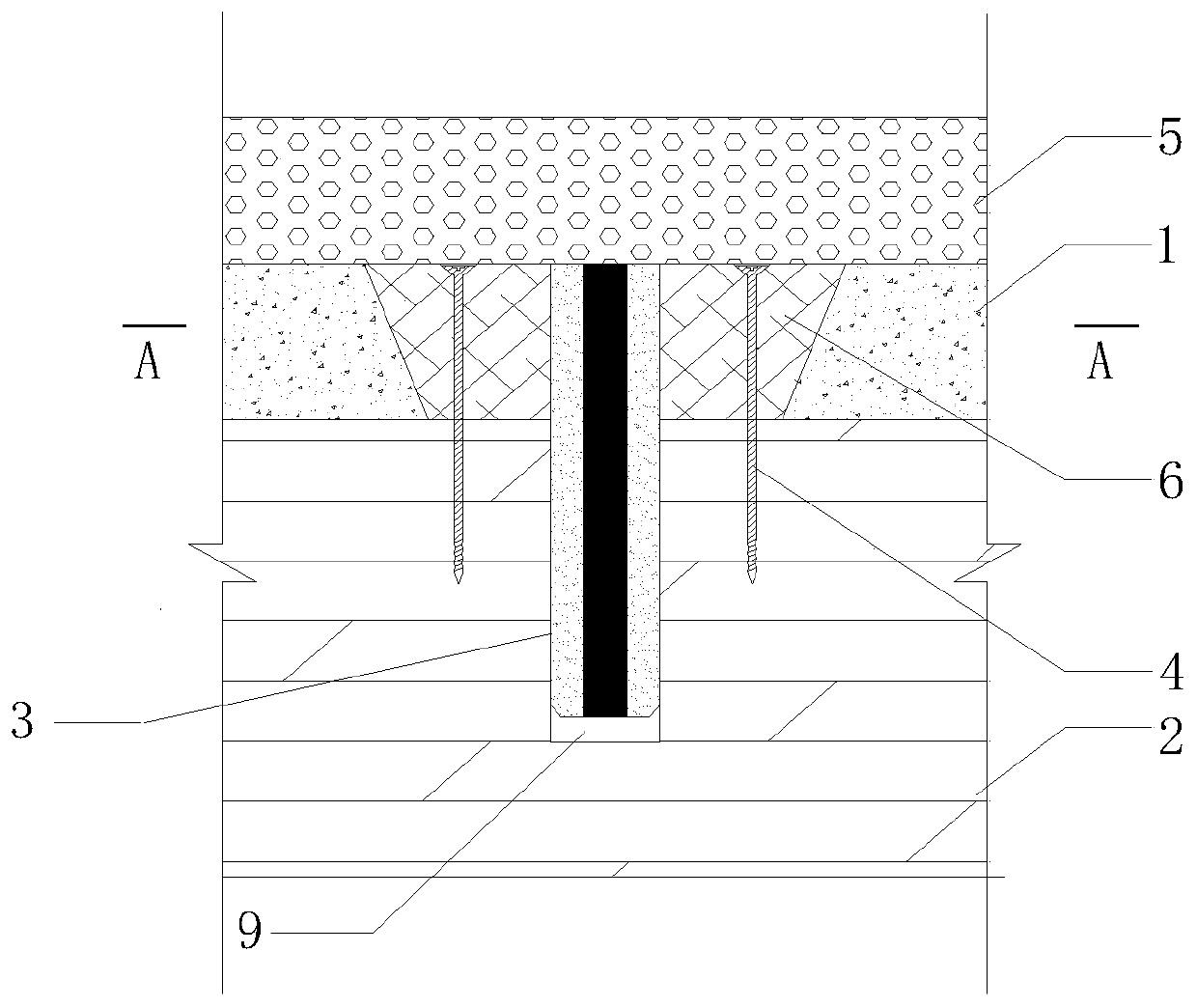

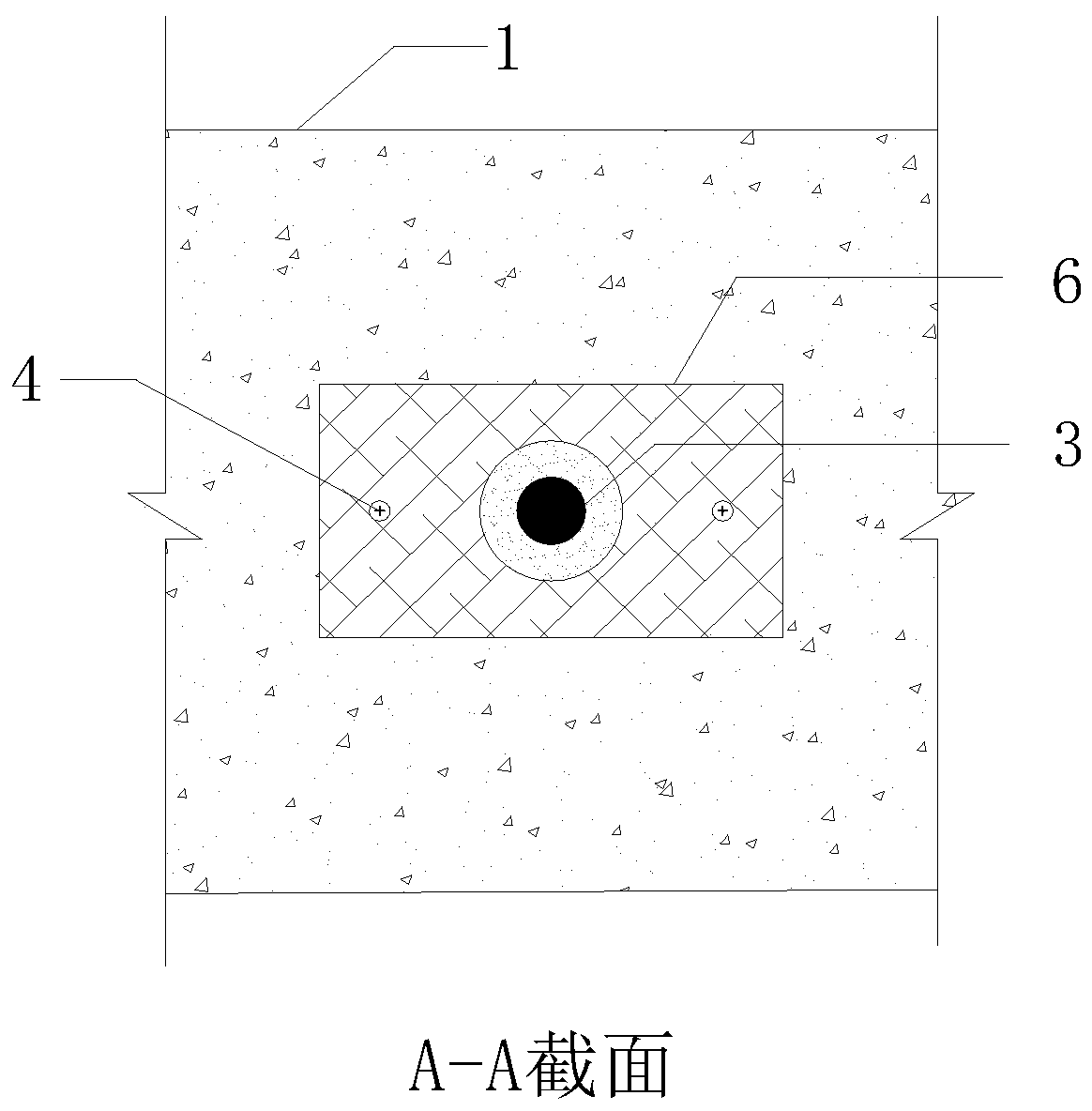

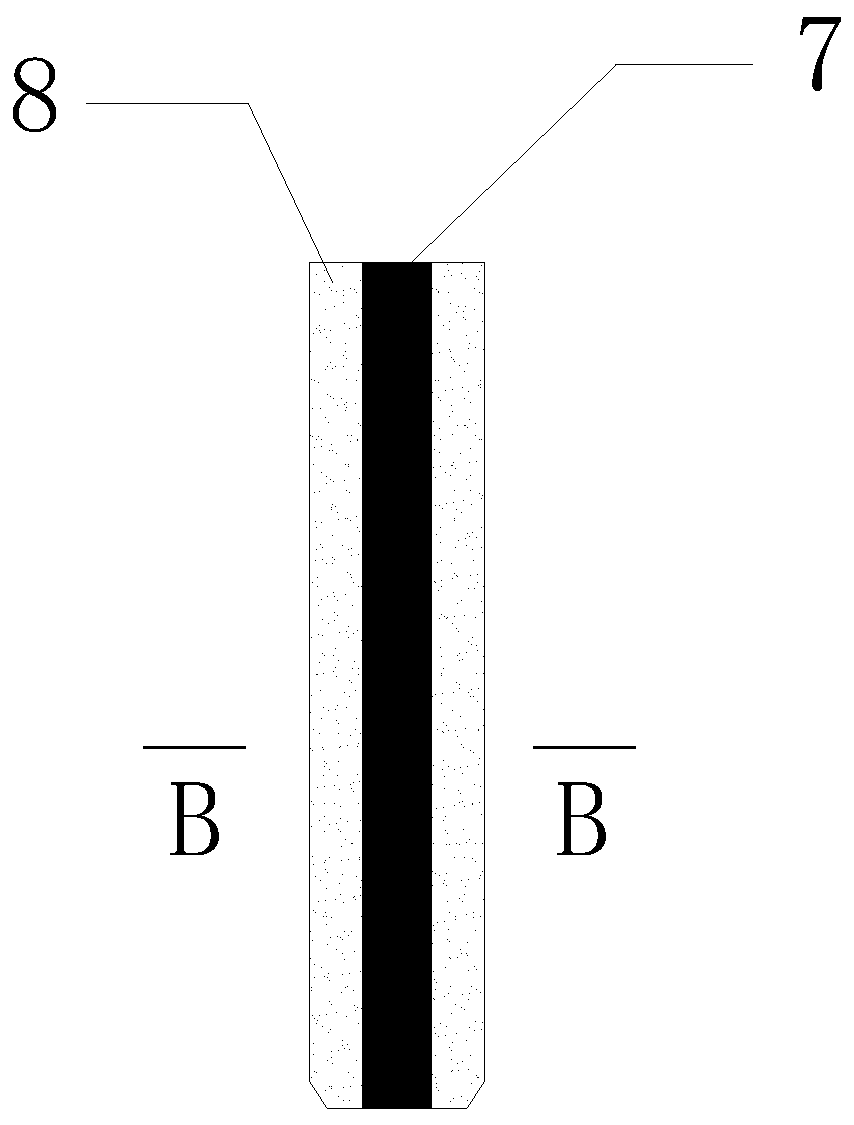

Light weight assembly type bamboo-concrete built-up beam

The invention discloses a light weight assembly type bamboo-concrete built-up beam. The light weight assembly type bamboo-concrete built-up beam is characterized in that a precast concrete plank (1) is combined with a bamboo beam (2) through a composite shear force connector (3), and a light concrete composite layer (5) is poured on the upper part; pre-embedded bamboo blocks (6) are arranged on the precast concrete plank (1), and bolts (4) penetrate through the pre-embedded bamboo blocks (6) from the top and are fixed in the bamboo beam (2); and the composite shear force connector (3) is composed of a steel core bar (7) and outer wrapped ultra-high performance concrete (8). The light weight assembly type bamboo-concrete built-up beam has the advantages that the self-weight is small, the integrality is good, producing technology is simple, the assembling efficiency is high, and the flexural rigidity is high.

Owner:HUNAN UNIV

Double-magnetic-circuit two-end symmetric excitation cylindrical closed magnetic field type low frequency vibration calibration table with eddy current compensation

ActiveCN104848935ASimple structural designReduce processing difficultySubsonic/sonic/ultrasonic wave measurementMicro structureVibration measurement

The invention provides a double-magnetic-circuit two-end symmetric excitation cylindrical closed magnetic field type low frequency vibration calibration table with eddy current compensation, belonging to the field of vibration measurement technology. A cylindrical closed type magnetic field structure design is provided. Two cylindrical permanent magnets are symmetrically installed at two ends of a center magnet yoke and face magnetic poles. Two symmetric closed magnetic circuits are formed by magnet yokes. The magnetic induction intensity distribution with high uniformity is generated in air gaps. After a working coil is energized, the working coil is affected by Lorentz force in a magnetic field, and precisely controllable electromagnetic drive force is generated. The surfaces of the magnet yokes adjacent to the air gaps are provided with an array type micro structure in the form of deep trenches, and the eddy current loss can be effectively inhibited. The organic integration design of air lubricated guide technology is employed, and outstanding electromagnetic drive mechanical performance and high movement guide precision are obtained at the same time. According to the double-magnetic-circuit two-end symmetric excitation cylindrical closed magnetic field type low frequency vibration calibration table, large stroke, high thrust, a linear electromagnetic driving force characteristic and high movement guide precision can be considered, and a high precision and large stroke high performance low frequency vibration calibration table technical scheme is provided for low-frequency / ultra-low frequency vibration calibration.

Owner:HARBIN INST OF TECH

Double-permanent-magnetic-tube two-end symmetric excitation cylindrical closed magnetic field type electromagnetic vibration table magnetic circuit structure with eddy current compensation

ActiveCN104849006AGood effectSimple structureMechanical vibrations separationVibration testingMicro structureMagnetic poles

The invention provides a double-permanent-magnetic-tube two-end symmetric excitation cylindrical closed magnetic field type electromagnetic vibration table magnetic circuit structure with eddy current compensation, belonging to the field of vibration measurement technology. A cylindrical closed type magnetic field structure design is provided. Two cylindrical permanent magnetic tubes are symmetrically installed at two ends of a magnetic circuit structure and face magnetic poles. Two symmetric closed magnetic circuits are formed by magnet yokes. The magnetic induction intensity distribution with high uniformity is generated in air gaps. After a working coil is energized, the working coil is affected by Lorentz force in a magnetic field, and precisely controllable electromagnetic drive force is generated. The surfaces of the magnet yokes adjacent to the air gaps are provided with an array type micro structure in the form of deep trenches, and the eddy current loss can be effectively inhibited. According to the double-permanent-magnetic-tube two-end symmetric excitation cylindrical closed magnetic field type electromagnetic vibration table magnetic circuit structure, large stroke, high magnetic field uniformity, high thrust and a linear electromagnetic driving force characteristic can be considered, and a high precision and large stroke electromagnetic vibration table magnetic circuit structure technical scheme is provided for low-frequency / ultra-low frequency vibration calibration.

Owner:HARBIN INST OF TECH

Assembly Technology of Double-groove Top Roller Bearings in the Outer Ring of Textile Machinery

The invention discloses an assembly process of an upper roller bearing with outer ring double grooves of a spinning machine, which comprises the selection of the dimensions of steel balls, a spindle and outer ring double R circular grooves of a bearing, realizes the assembly working procedures of the spindle, the outer ring of the bearing, a rear retainer, the rear row of the steel balls, a front retainer, the front row of the steel balls and the like by utilizing special tools and dialing needles in a rear row and solves the assembly problems of the steel balls in the double grooves of the bearing, thus the popularization and application of the double-groove bearing, in particular a double-groove bearing with 6 balls in a textile industry are realized, thereby solving the big problem of short service life of a single-groove bearing. The enhancement of the service life of the bearing reduces the consumption of materials for the textile industry and saves a large quantity of steel for a country; and simultaneously, because the double-groove bearing with the 6 balls has the advantage of uniform compression and stable rotation, the quality of yarns can be continuously stabilized.

Owner:陈忠和

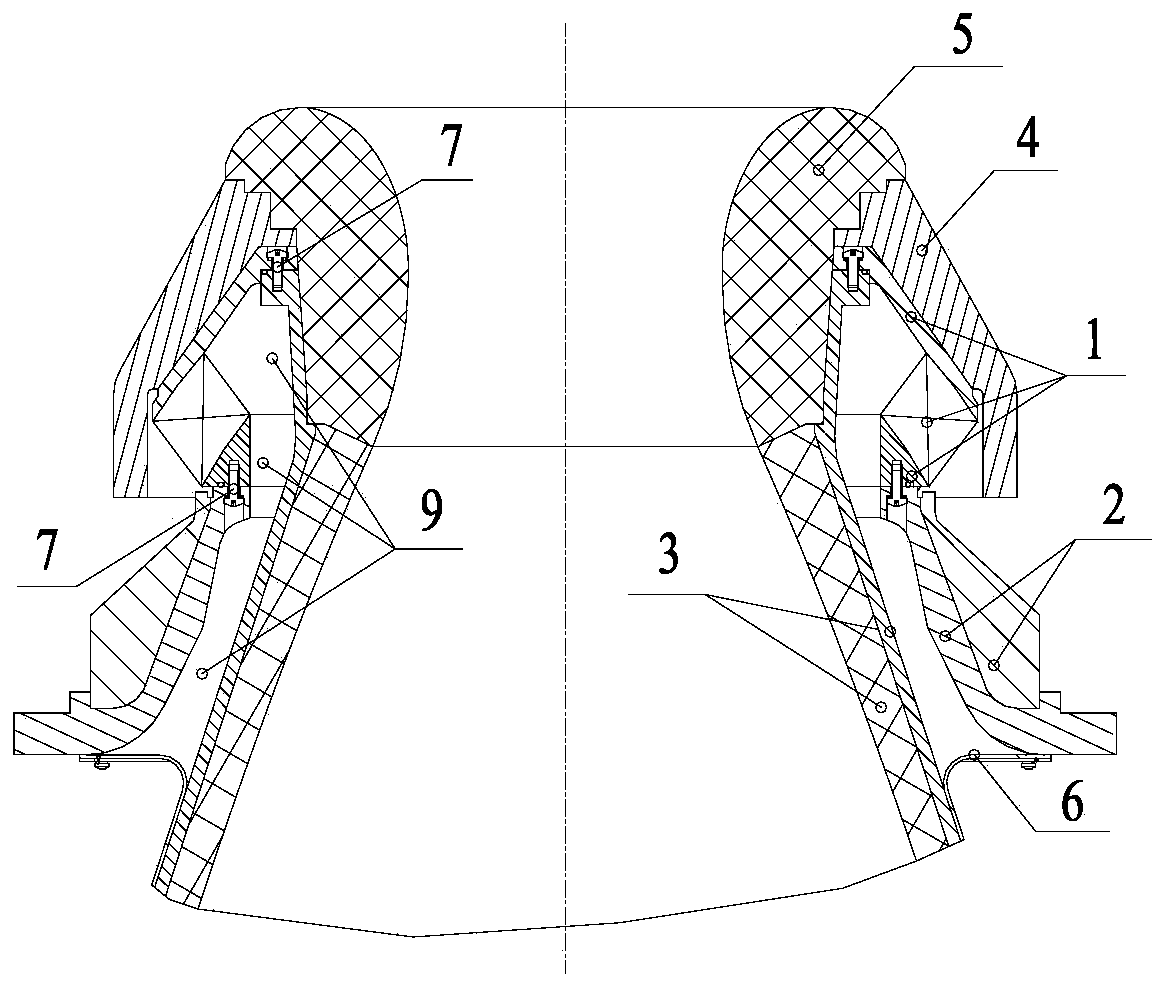

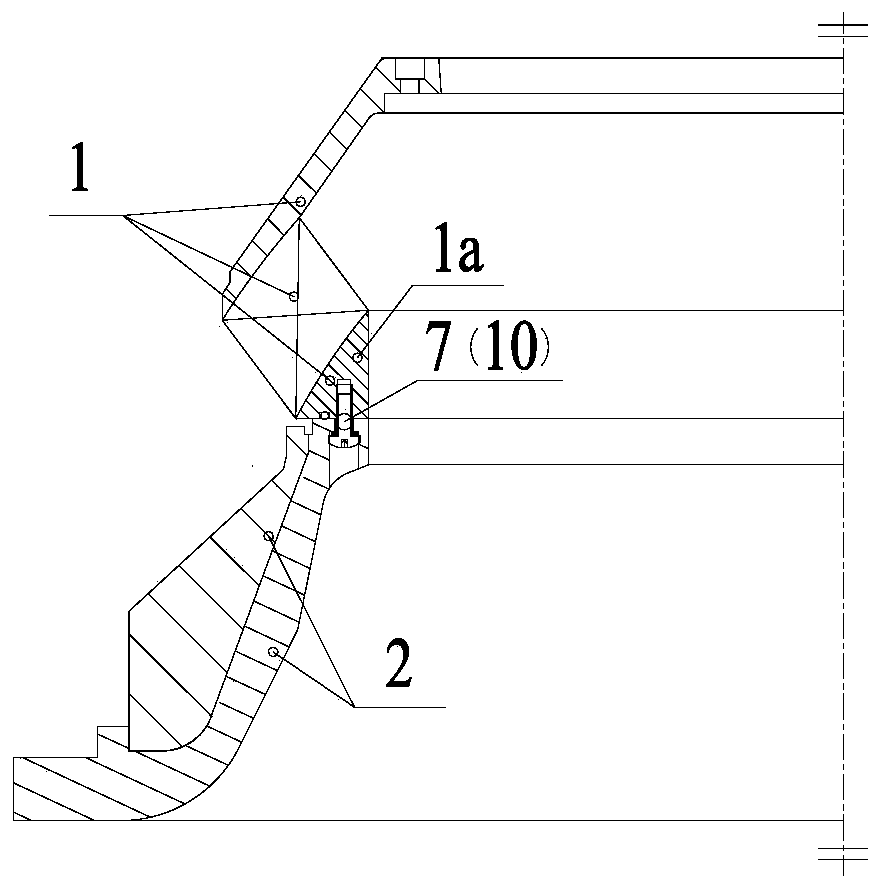

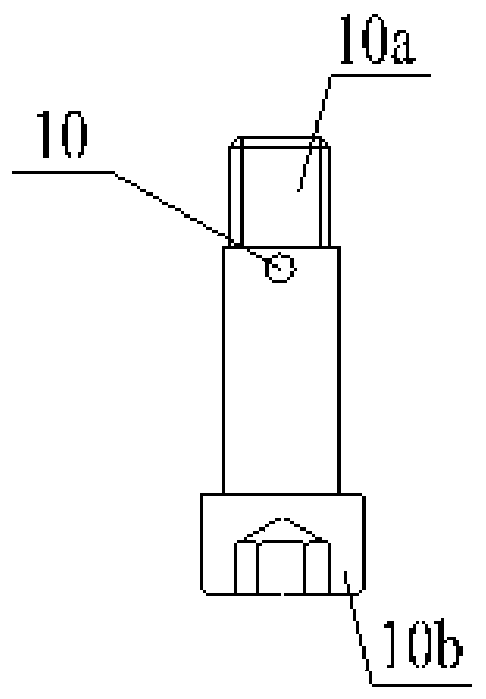

Assembly method of flexible nozzle

ActiveCN109014900BSolving Assembly ChallengesGuaranteed assembly accuracyAssembly machinesAdhesive cementFlight test

The invention discloses an assembly method of a flexible nozzle. The flexible nozzle comprises a flexible joint, a fixed inverted cone component, a diffusion section component, a movable inverted coneheat insulating layer, a throat insert body and a covering shelter. According to the assembly method disclosed by the invention, positional accuracy of all parts of the flexible nozzle is controlledby utilizing positioning screws, coaxiality and perpendicularity of an assembly surface are improved by reserving a machining allowance in advance, the throat insert body is sealed and fixed by utilizing a sealant and adhesives, a swing inner cavity of the flexible nozzle is inspected by utilizing an endoscope before the covering shelter is assembled, and an independent assembly region is arrangedto control the swing inner cavity of the flexible nozzle not to have unnecessary substances, so that the assembly problem of the flexible nozzle is solved, and production efficiency is increased, thereby guaranteeing assembly accuracy and quality of the flexible nozzle; and moreover, checked by a ground test and a flight test for multiple times, the flexible nozzle assembled by the assembly method disclosed by the invention completely meets the design requirement in product quality.

Owner:湖北三江航天江北机械工程有限公司

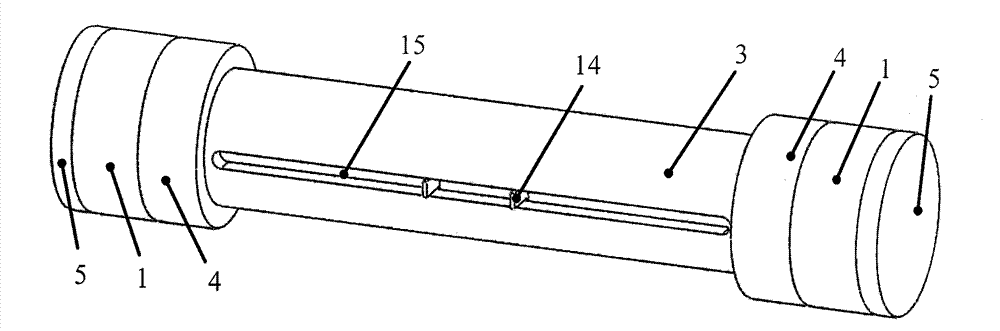

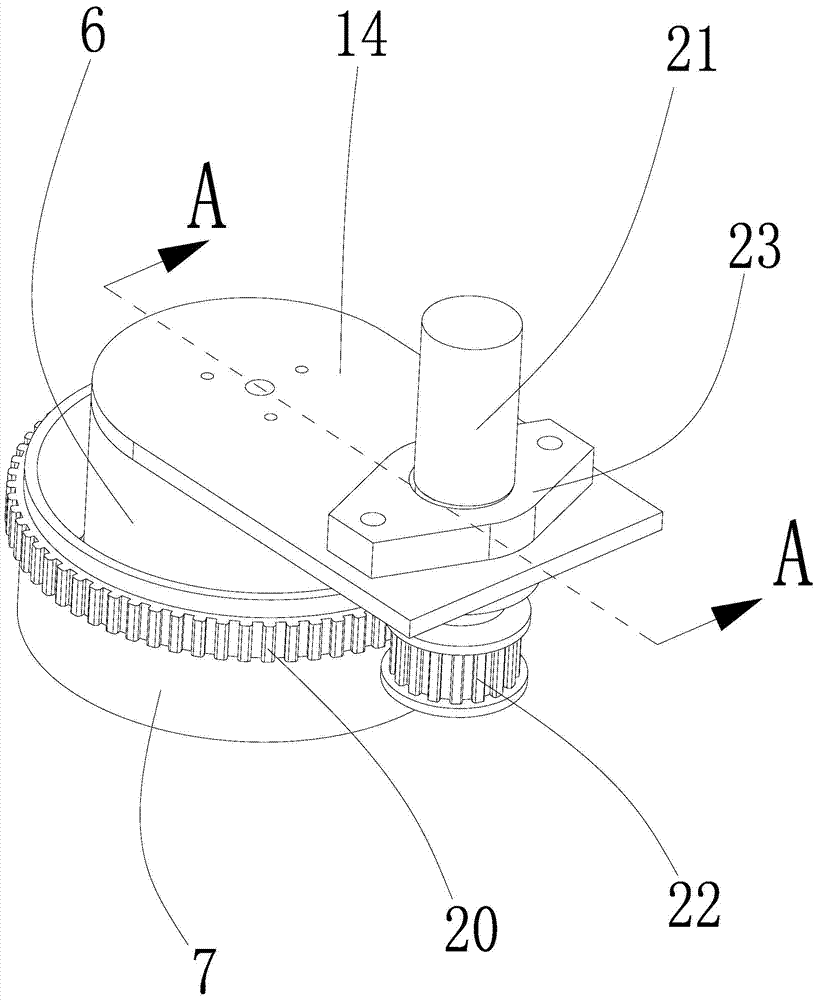

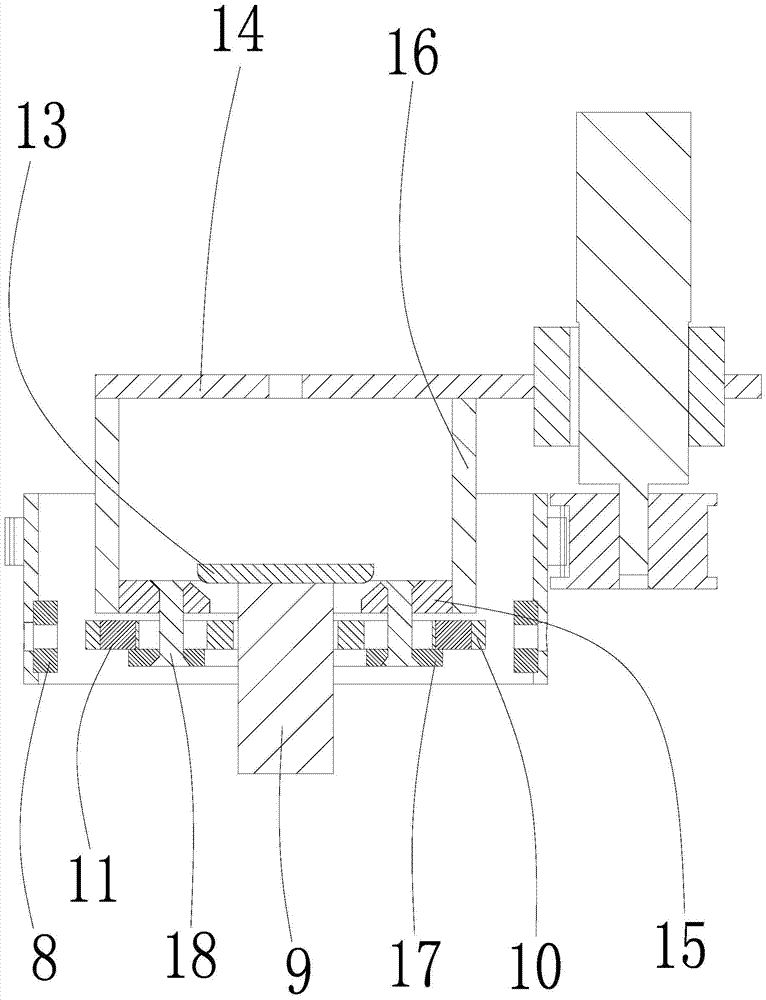

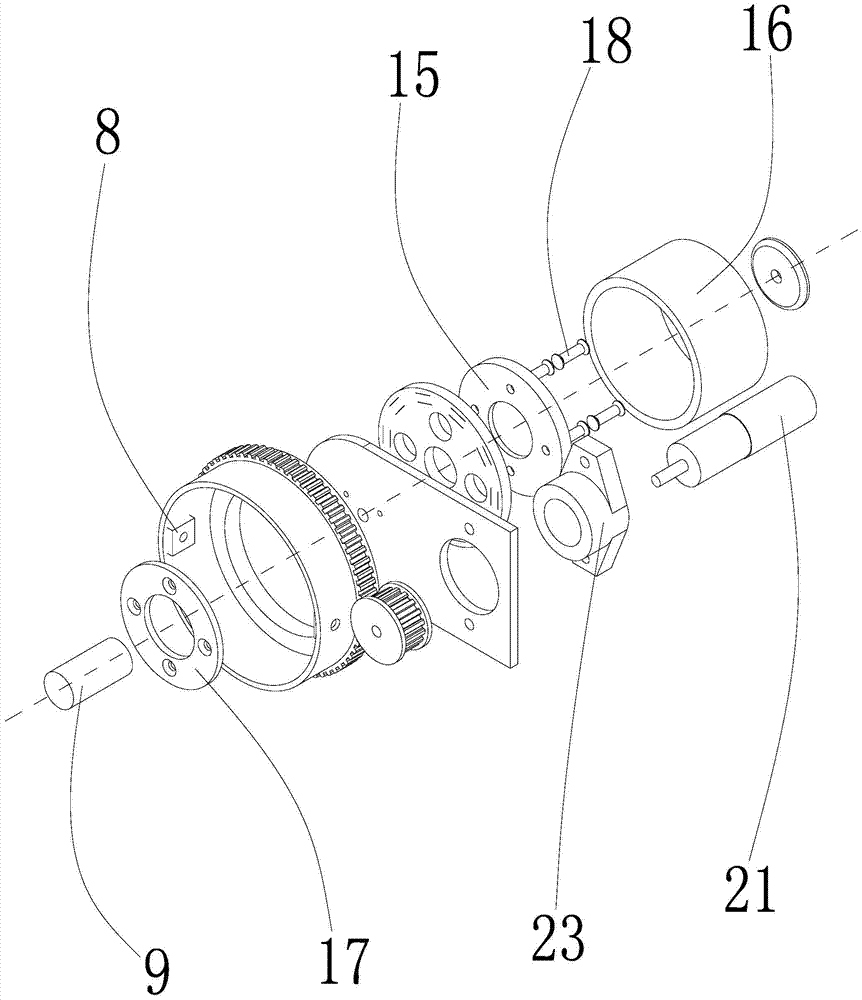

A device and method for shaft hole assembly based on magnetic field force

InactiveCN105522364BAvoid damageSolving Assembly ChallengesMetal working apparatusEngineeringContact force

The embodiment of the invention provides a device and a method based on magnetic field force for realizing peg-in-hole assembly. The device comprises a shell and a rotary sleeve arranged outside the shell in a sleeving mode. When jamming occurs between an assembly shaft and an assembly hole, the driving effect of the magnetic field force to the assembly shaft can be used for realizing peg-in-hole assembly, the problems that the assembly work fails because of low position control precision and uncontrollable contact force in the position control mode and assembled work-pieces are even damaged can be avoided, the assembly problem of the work-pieces with rough assembly hole walls or with high assembly precision requirements is solved, the magnetic field force is adopted in the assembly work, the shortcomings of traditional position control in high-quality and high-accuracy assembly work are overcome, and the assembly quality and the work efficiency are greatly improved.

Owner:中山市工业技术研究中心 +1

The device for assembling the fluffy hose and the sleeve

ActiveCN107175481BImplement automatic assemblyReduce labor intensityVehicle componentsMetal working apparatusEngineeringMechanical engineering

Owner:常州市盛士达汽车空调有限公司

Rotary gas absorption device

ActiveCN107478470ASolving Assembly ChallengesAvoid chippingWithdrawing sample devicesDiffusionCrazing

The invention discloses a rotary gas absorption device. The rotary gas absorption device comprises a protecting transmission part, wherein the protecting transmission part is arranged outside a gas diffusion part (1) to package the gas diffusion part (1), is fixedly connected with the gas diffusion part (1) and is driven to rotate by a driving part (4). According to the rotary gas absorption device, the protecting transmission part is arranged to package the gas diffusion part and is fixedly connected with two ends of the gas diffusion part; the flatness of the end surface of a glass component can be controlled in a machining process, so that the assembling problem caused due to an outer diameter error of the gas diffusion part can be solved; meanwhile, the protecting transmission part packages the gas diffusion part, and the gas diffusion part is not influenced by a radial force and a torque, so that the crazing of glass is prevented, and the stability and reliability of a whole structure are greatly improved.

Owner:LIHE TECH (HUNAN) CO LTD

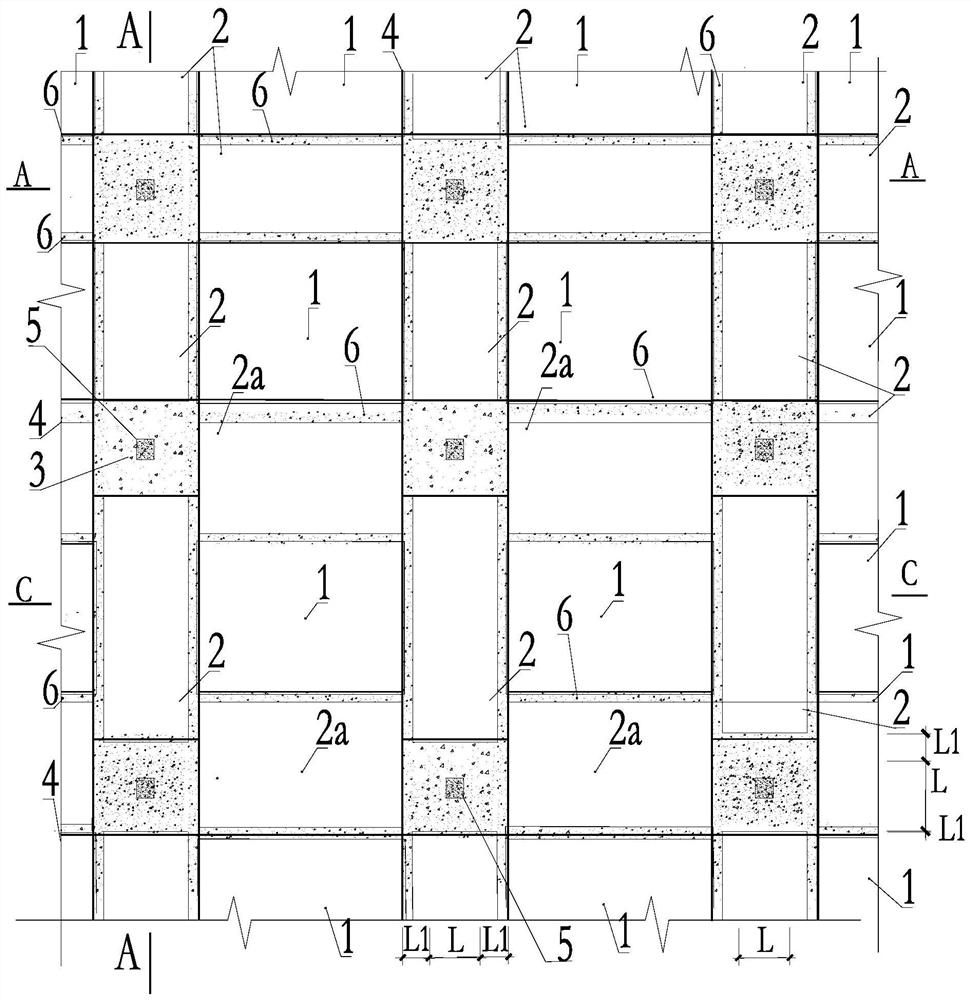

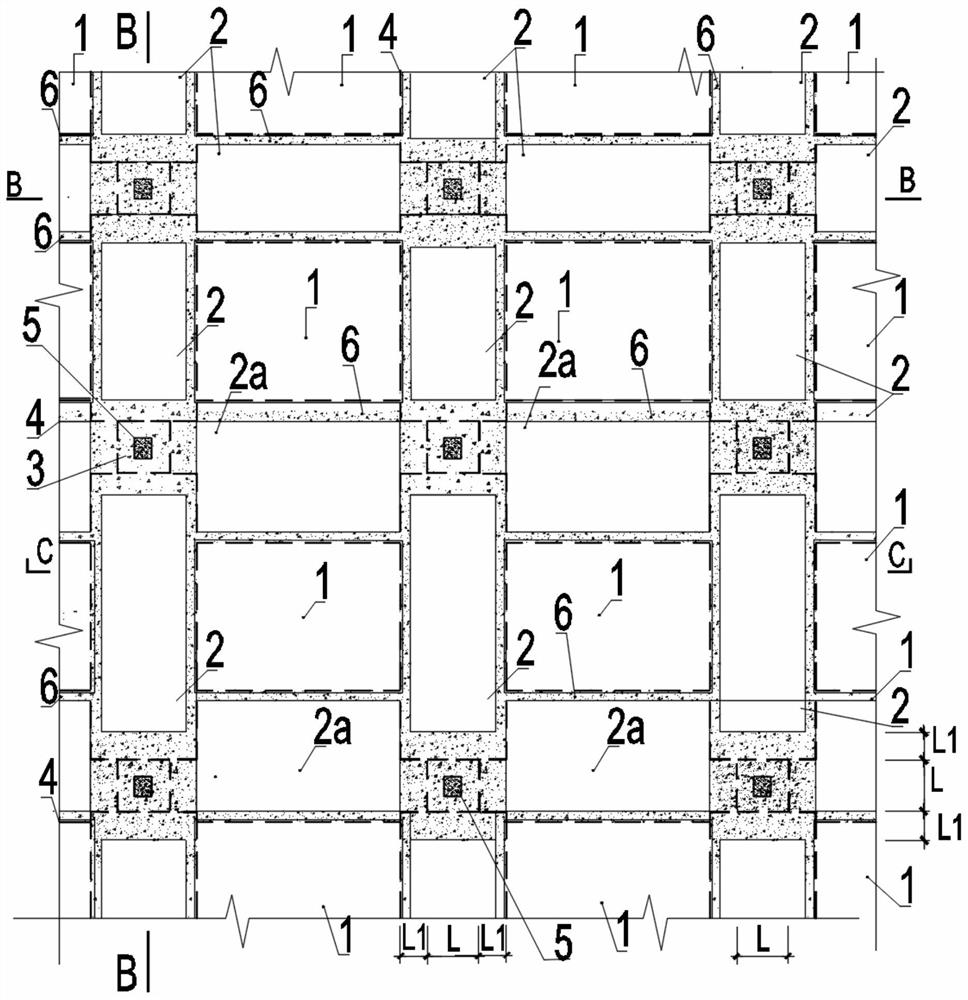

A slab-column structure assembly system, floor prefabricated components and construction method

ActiveCN107724524BSafe Structural Assembly TechnologyFast and convenient structural assembly technologyBuilding material handlingFloor slabClassical mechanics

The invention discloses a plate-column structure assembly system, including column cap connecting plates with floor prefabricated components, no column cap connecting plates with floor prefabricated components, prefabricated column caps or pallets, columns, and connection nodes. The prefabricated column caps or pallets are inserted into the top of the columns. The end of length direction of the column cap connecting plates with floor prefabricated components is connected or shelved at the edge of the prefabricated column caps or pallets. The edge of the no column cap connecting plates with floor prefabricated components is directly shelved on the laminated layer which is on the side of the column cap connecting plates with floor prefabricated components. After the column cap connecting plates with floor prefabricated components, the no column cap connecting plates with floor prefabricated components, the prefabricated column caps or pallets and the joint surface of column top are formed, pouring concrete pouring trough and splicing into a whole closed slab bottom plane, an integral floor structure is formed through connection nodes. The plate-column structure assembly system also discloses floor prefabricated components and construction methods. The plate-column structure assembly system and floor prefabricated components and construction methods can reduce the support and template installation.

Owner:刘祥锦

Dual-permanent-magnetism-tube two-end symmetrically-excited cylindrical enclosed magnetic-field-type low-frequency vibration calibration bench capable of realizing eddy current compensation

ActiveCN104865031ASimple structural designReduce processing and assembly difficultyMechanical vibrations separationVibration testingLow frequency vibrationMicrostructure

A dual-permanent-magnetism-tube two-end symmetrically-excited cylindrical enclosed magnetic-field-type low-frequency vibration calibration bench capable of realizing eddy current compensation belongs to the technical field of vibration measurement. A cylindrical enclosed magnetic field structure is provided. Two cylindrical permanent magnetism tubes are symmetrically installed on two ends of an electromagnetic drive structure, and the same magnetic poles are arranged in an opposite manner. Two symmetrical enclosed magnetic circuits are formed through magnet yokes. The magnetic induction strength high in uniformity is generated in an air gap. After a working coil is powered on, the working coil in the magnetic field is affected by a Lorentz force and generates a precise and controllable electromagnetic driving force. The surface, adjacent to the air gap, of a magnet yoke is provided with an array-type microstructure arranged in a deep channel mode, and the eddy current loss can be effectively inhibited. The dual-permanent-magnetism-tube two-end symmetrically-excited cylindrical enclosed magnetic-field-type low-frequency vibration calibration bench is organically integrated with a static pressure air floatation guiding technology, and outstanding electromagnetic drive mechanical characteristics and high motion guiding precision are realized at the same time. According to the invention, a large stroke, a large thrust, linear electromagnetic drive force characteristics and high motion guiding precision can be considered at the same time, and a high-precision large-stoke high-performance low-frequency vibration calibration bench technical scheme is provided for low-frequency / ultralow-frequency vibration calibration.

Owner:HARBIN INST OF TECH

Device and method based on magnetic field force for realizing peg-in-hole assembly

InactiveCN105522364AAvoid damageSolving Assembly ChallengesMetal working apparatusAssembly lineEngineering

The embodiment of the invention provides a device and a method based on magnetic field force for realizing peg-in-hole assembly. The device comprises a shell and a rotary sleeve arranged outside the shell in a sleeving mode. When jamming occurs between an assembly shaft and an assembly hole, the driving effect of the magnetic field force to the assembly shaft can be used for realizing peg-in-hole assembly, the problems that the assembly work fails because of low position control precision and uncontrollable contact force in the position control mode and assembled work-pieces are even damaged can be avoided, the assembly problem of the work-pieces with rough assembly hole walls or with high assembly precision requirements is solved, the magnetic field force is adopted in the assembly work, the shortcomings of traditional position control in high-quality and high-accuracy assembly work are overcome, and the assembly quality and the work efficiency are greatly improved.

Owner:中山市工业技术研究中心 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com