Cabin loading method of large overall equipment cabinet of space station working cabin

A work cabin and space station technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of complex movements, large investment, low equipment utilization, etc., and achieves strong operability, good economy, and structure. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

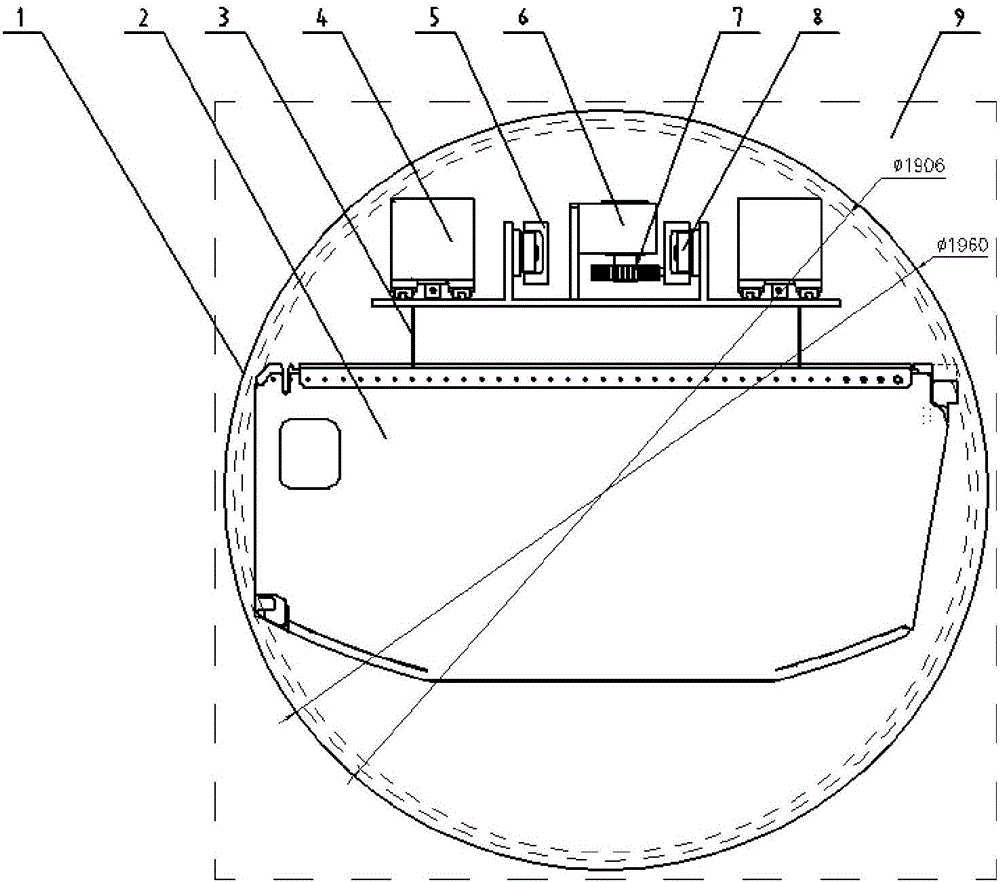

[0022] figure 1 It is a structural diagram of the relative positions of the working cabin door and the cabinet in the embodiment of the present invention. In the figure, 1 is the boundary of the cabin door, 5 is the guide rail, and 9 is the activity space in the cabin; a method for loading a large overall cabinet of a space station working cabin, including the following steps

[0023] Step 1, radial delivery process outside the cabinet

[0024] The cabinet 2 controls four groups of hoisting devices 4 through synchronous driving, so that the hoisting lengths of the four steel wire ropes 3 are equal to ensure that the radial delivery of the cabinet 2 is stable, and the radial vertical height of the cabinet is controlled so that the center of the cabinet is close to the axis of the cabin.

[0025] Step 2, Axial advancement process outside the cabinet cabin

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com