The device for assembling the fluffy hose and the sleeve

A hose and sleeve technology, which is applied in the field of assembly tooling, can solve the problems of high labor intensity, difficult assembly, and inability to connect metal braided tubes to sleeves, etc., and achieve the effect of solving assembly problems and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

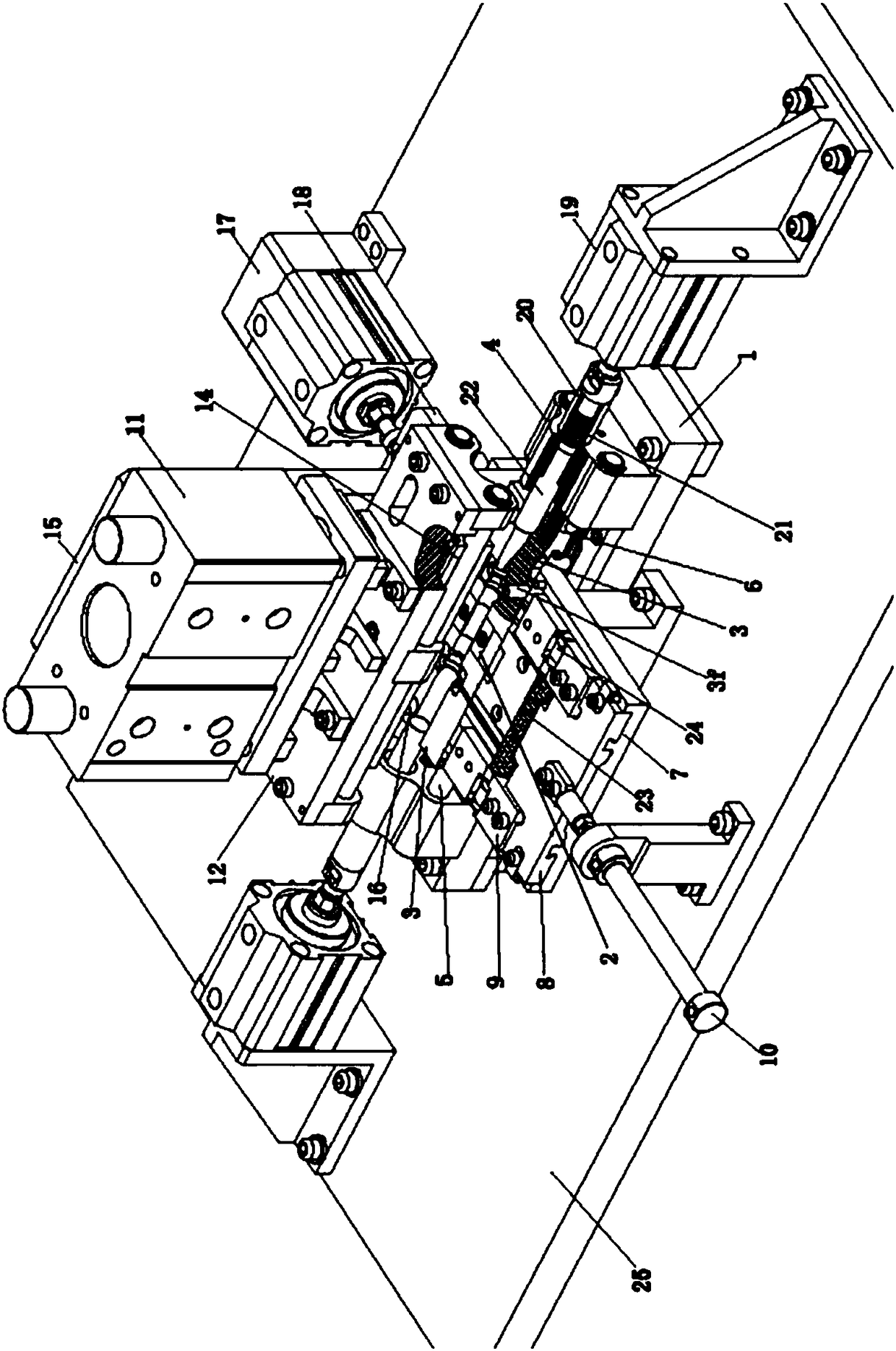

[0033] Such as figure 1 As shown, the device for assembling the fluffy hose and the sleeve of the present invention includes: a bottom plate, a lower die, a feeding mechanism positioned on one side of the lower die, an upper die positioned above the lower die, a linkage rod, a second drive mechanism, a push The following is a detailed description of each part and the relationship between them:

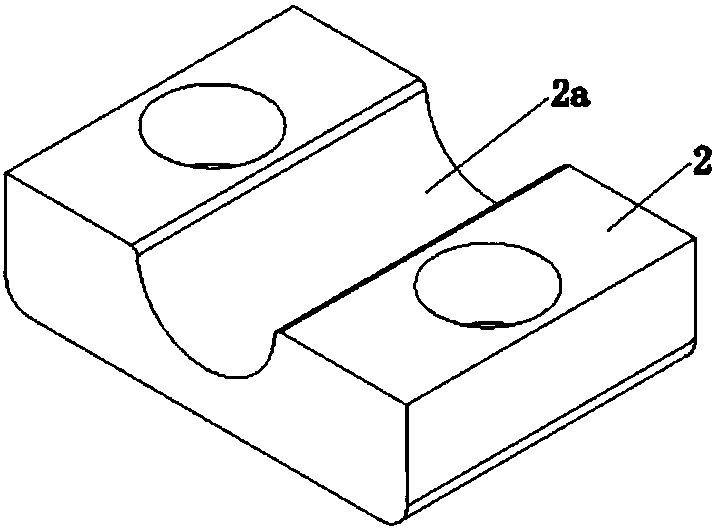

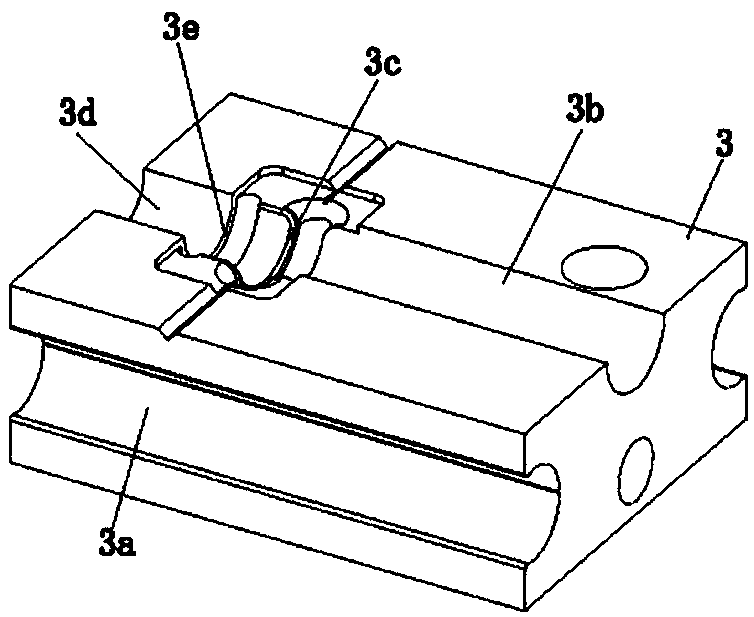

[0034] Such as Figure 1 to Figure 3 As shown, the lower mold is arranged on the bottom plate 25, and the lower mold includes a carrier plate 1, a lower clamping mold 2, a first slider 3 symmetrically arranged on both sides of the lower clamping mold, a first bracket 4, a first guide rod 5, a first One end of the lower clamping mold 2 is fixed on the carrier plate 1, and the other end of the lower clamping mold 2 is provided with a first groove 2a for accommodating a part of the hose. The first slider 3 is movably arranged on the carrier board 1, the first bracket 4 is fixed on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com