Assembly method of flexible nozzle

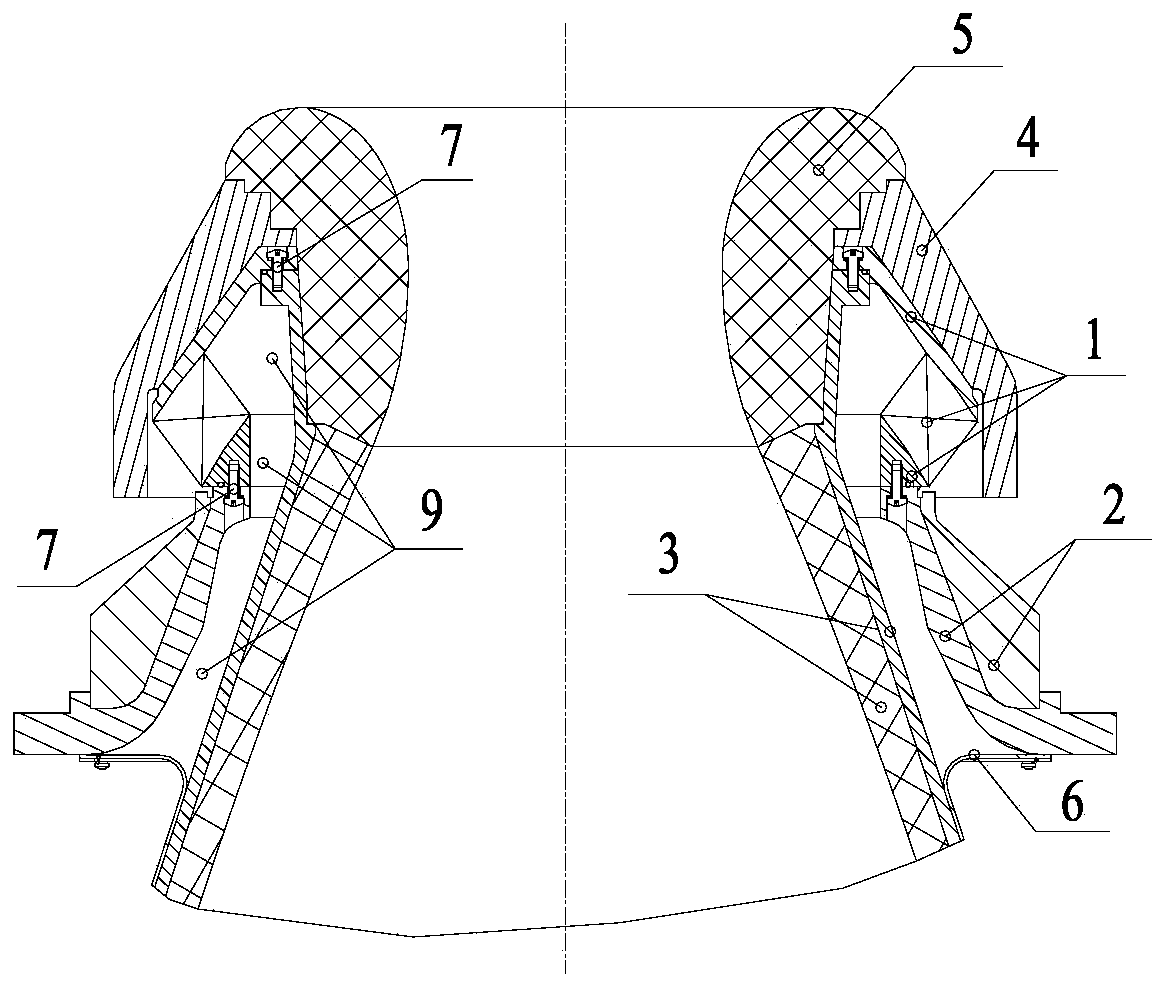

A flexible nozzle and assembly method technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problem of coaxiality and end face verticality difference, no circumferential and radial positioning, flexible nozzle assembly and throat The problem of uneven gap between the linings can ensure the assembly accuracy and quality, improve the coaxiality and verticality, and improve the production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] 1) Processing assembly surface allowance

[0059] A margin of 0.2 mm is reserved for the assembly A side of the movable inverted cone shell 1b of the flexible joint 1 and the throat lining body 5 during the processing; C surface, assembly D surface, assembly E surface, assembly F surface and assembly G surface all reserve 0.2mm allowance, and assembly B surface, assembly D surface and assembly F surface are unilateral bridge clearances;

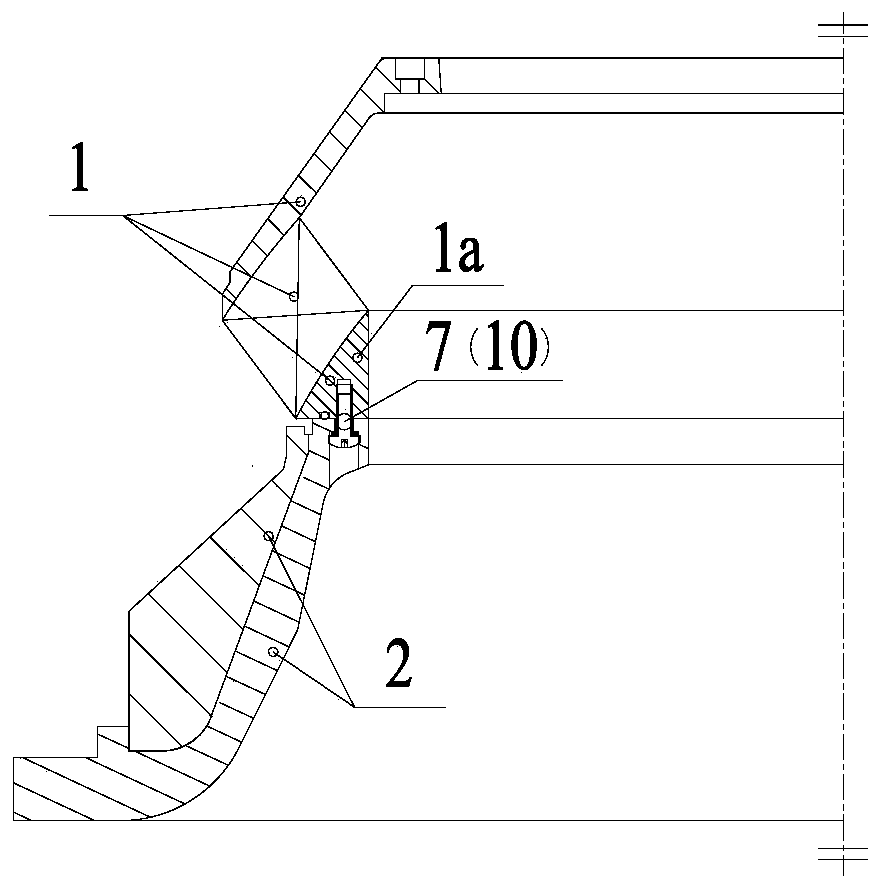

[0060] 2) The flexible joint 1 is assembled with the fixed inverted cone assembly 2

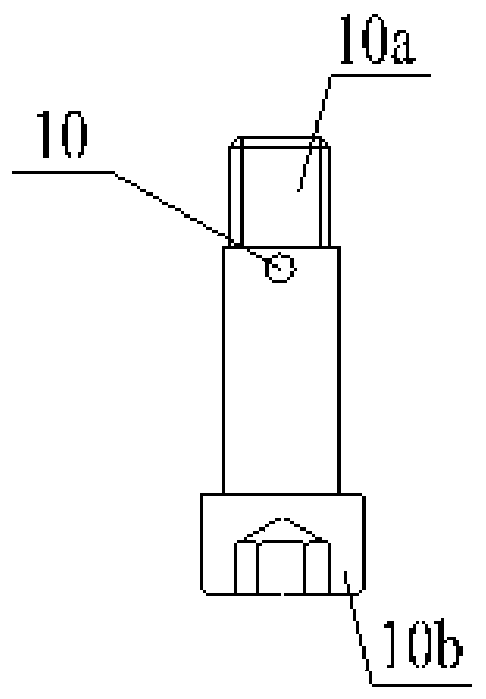

[0061] During the assembly process of the fixed rear joint 1a of the flexible joint 1 and the fixed inverted cone assembly 2, two first positioning screws 10 are firstly installed to carry out circumferential and radial alignment of the fixed rear joint 1a of the flexible joint 1 and the fixed inverted cone assembly 2. The two first positioning screws 10 are symmetrically distributed along the central axis of the flexible joint 1; after the two first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com