Linear bearing assembly device

A technology for linear bearings and assembly devices, which is applied to bearing components, shafts and bearings, mechanical equipment, etc. It can solve problems such as lowering production efficiency, misplaced steel balls, and dropped steel balls, so as to improve the qualified rate of assembly and improve the quality of bearings , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

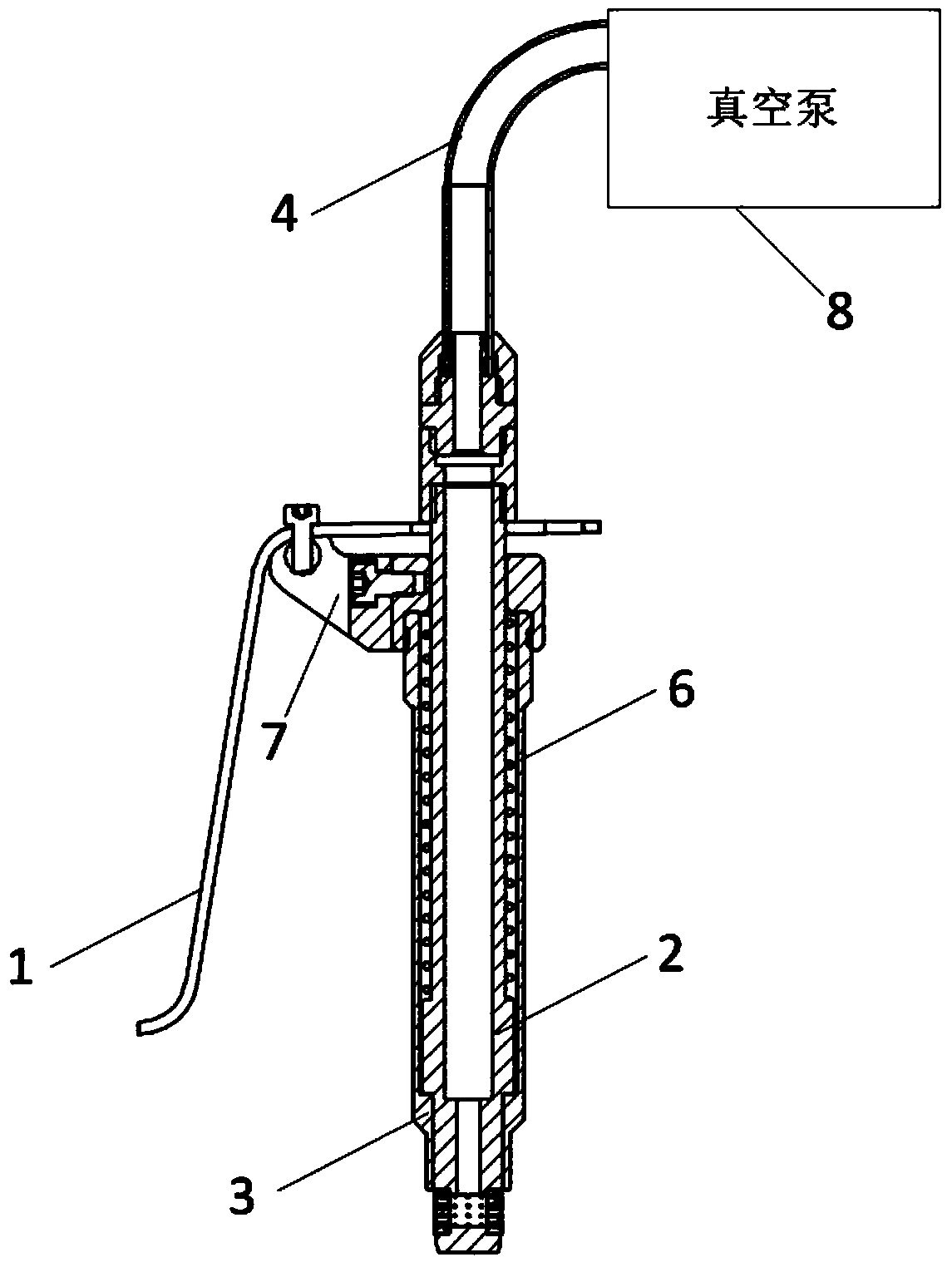

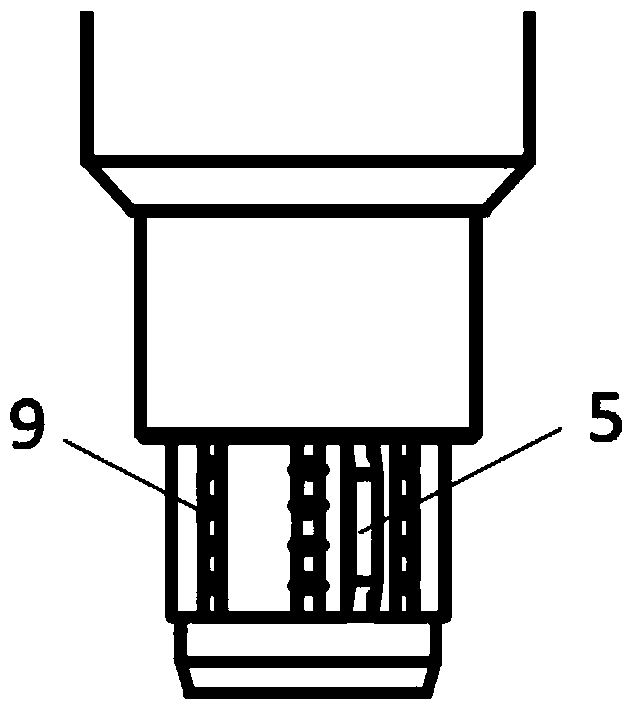

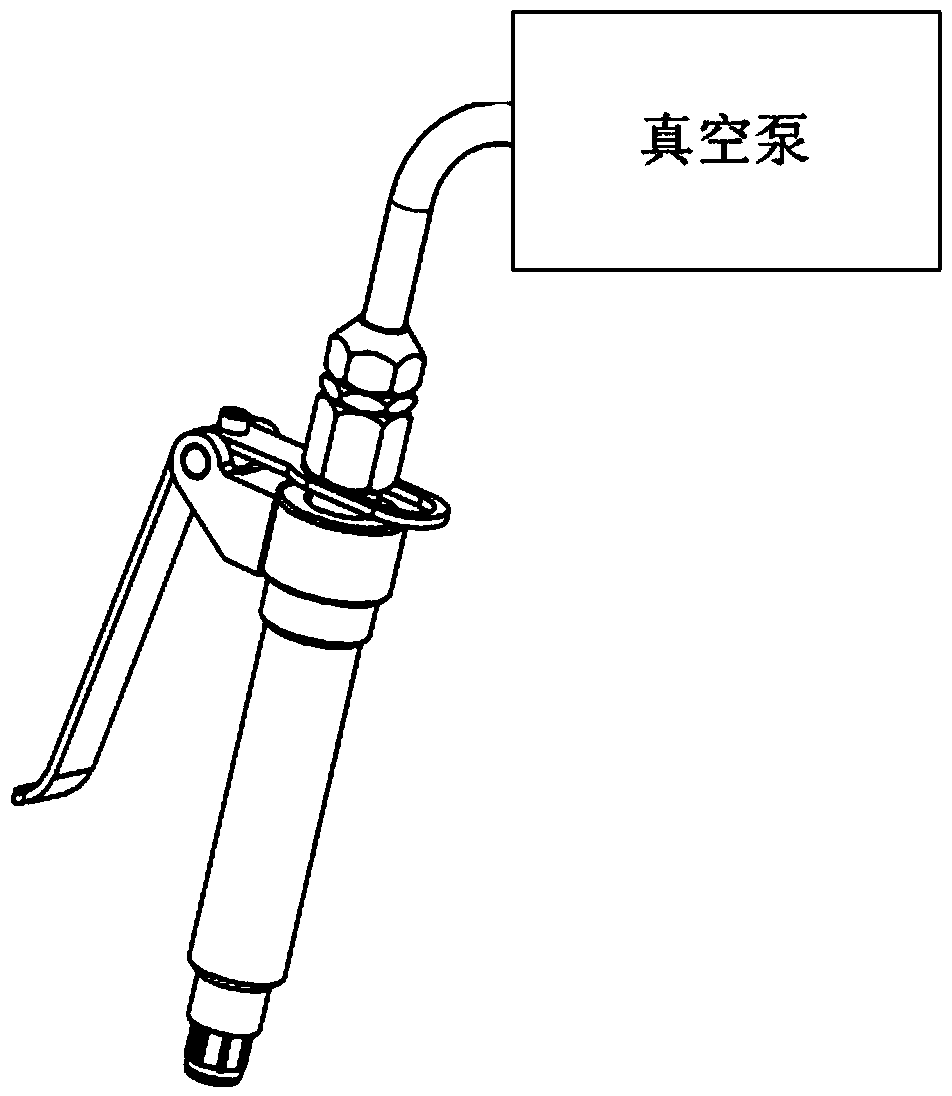

[0029] See Figure 1-Figure 3 , the embodiment of the present invention provides a linear bearing assembly device, including an outer shell 3, an inner shell 2, a handle 1, a vacuum suction tube 4 and a vacuum pump 8, the outer shell 3 is arranged outside the inner shell 2 and can be The surface of the shell 2 moves, the inner shell 2 is a hollow structure, the front end of the inner shell 2 is connected with the vacuum pump 8 through the vacuum suction pipe 4, the end of the inner shell 2 is provided with an elastic head positioning member 5, and the inner shell There are also several through vacuum suction holes 9 distributed on the end side wall of the body 2 , the handle 1 is arranged on the inner shell 2 and is located between the outer shell 3 and the vacuum suction pipe 4 .

[0030] In order to quickly reset the inner casing, the outer wall of the inner casing 2 is provided with a groove, and a spring 6 is arranged in the groove, the upper end of the spring is the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com