Patents

Literature

59results about How to "Achieve radial positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

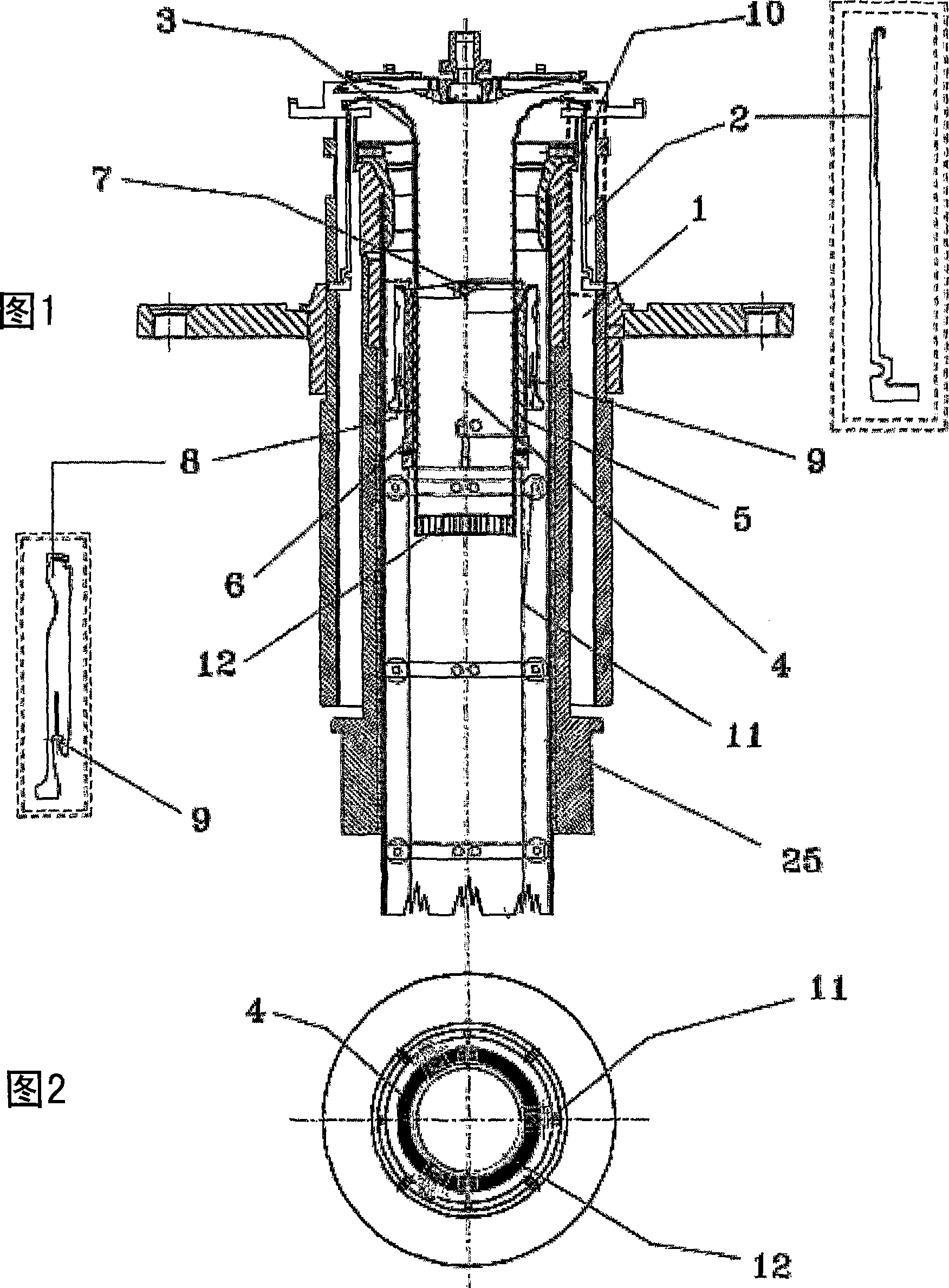

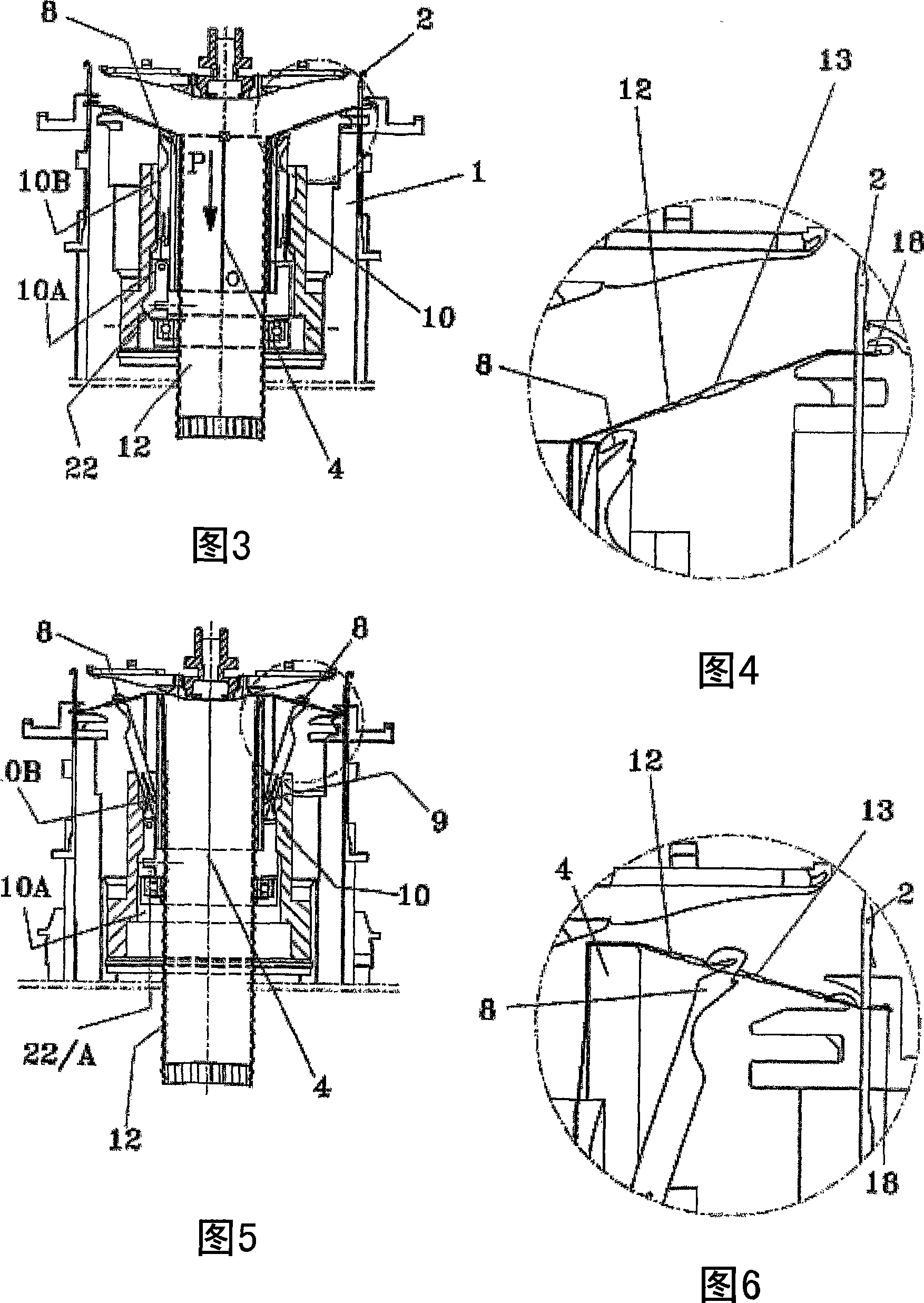

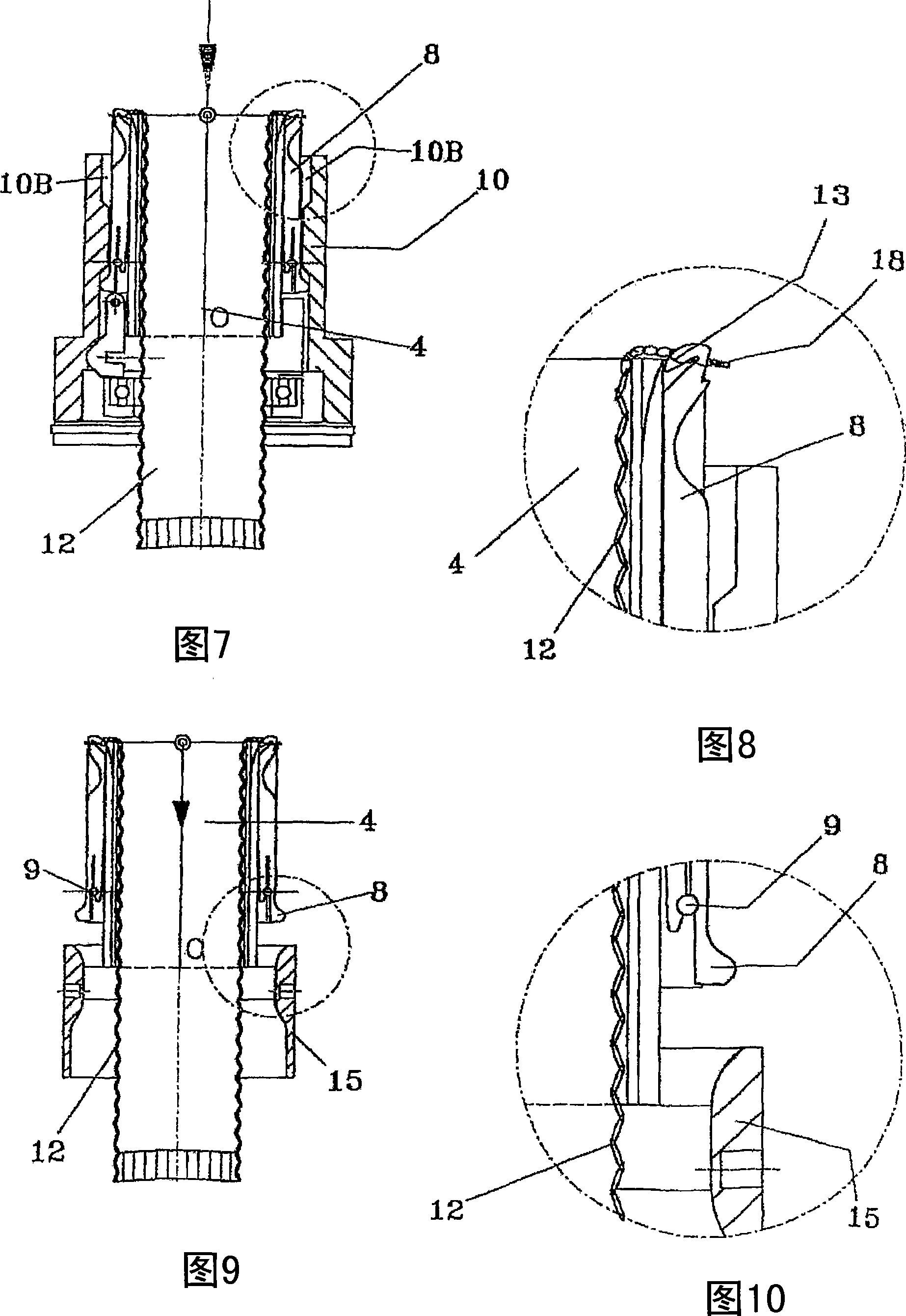

Integrated system for the close-down of the stocking on circular machines for tubular semifinished production in stitch and the device relative to it

InactiveCN101501259AImprove productivityProduction time synchronizationCircular knitting machinesWork in processEngineering

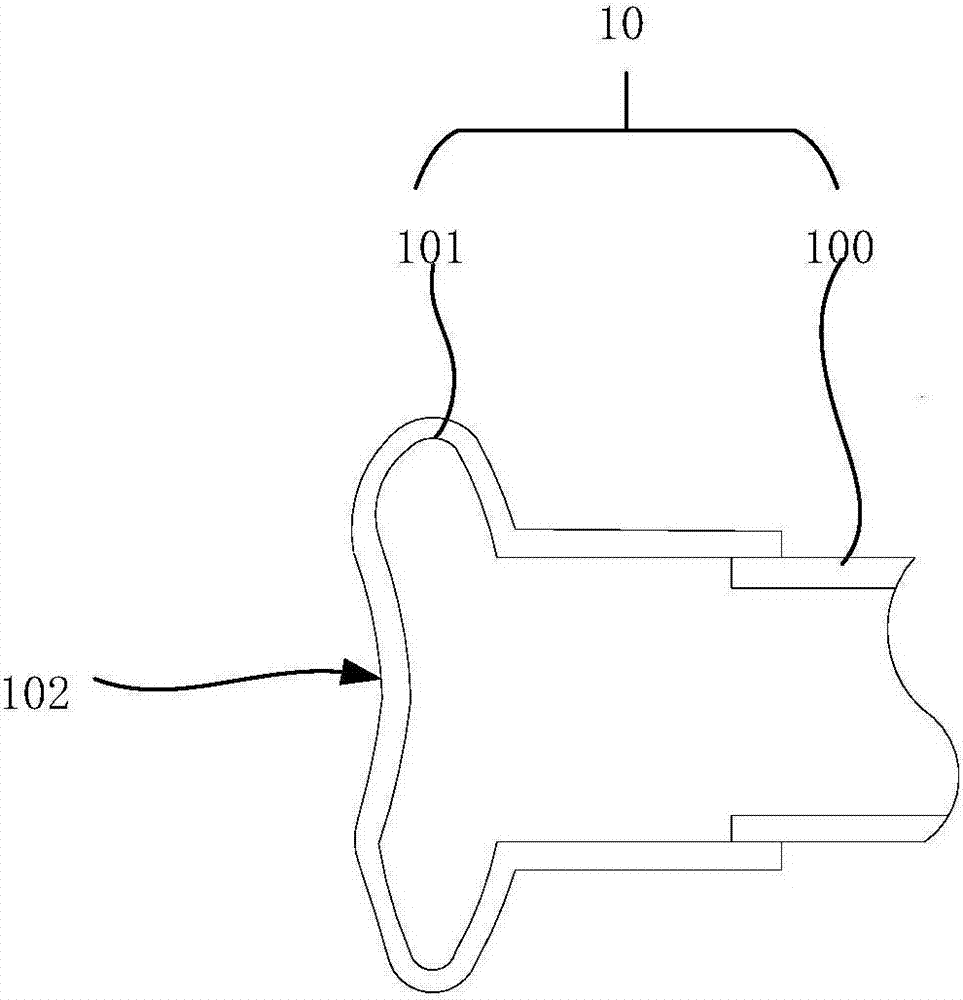

The invention provides a system and a method in the production of stitch tubular products for the closing of the seam of the point of a tubular stitch product. The system consists of a circular knitting machine with a cylinder of needles; a tacking-on device with a rim of holding crooks; and a stapler arranged on the outside of the cylinder of needles and used to carry out the closing of the point. Characteristically according to an aspect of the invention is that the tacking-on device includes a body substantially circulate subdivided in two substantially specular portions, wherein each of them is equipped with a semi-arc of holding crooks. The specular portions are hinged around to the overturn axis which is substantially diametral, so as to obtain the overturning of a portion on the other and therefore to bring a semi-arc of oppositely holding crooks with the semi-arc of opposite holding crooks. In this arrangement the tacking- on device can allow the closing by the stitching or looping of the point, for example placing the stapler below the circular machine, in a position in which the tacking-on device is placed after having taken and extracted the tubular stitch product to sew from the circular machine.

Owner:NTA INC +1

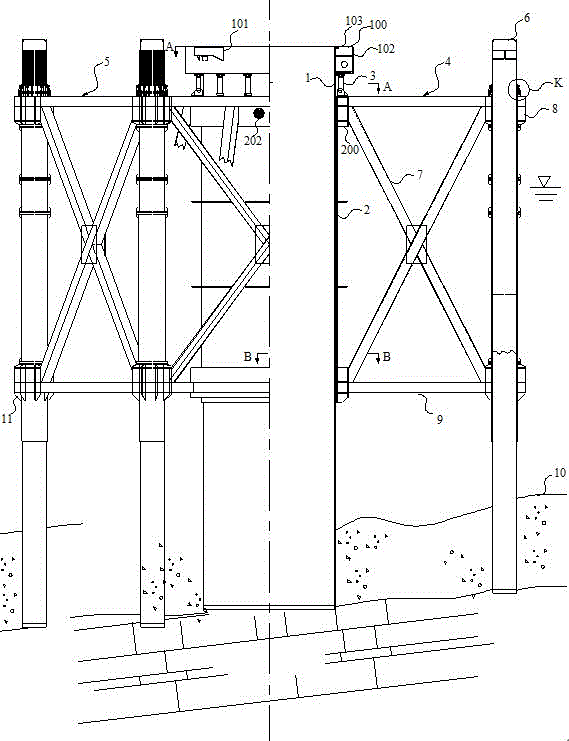

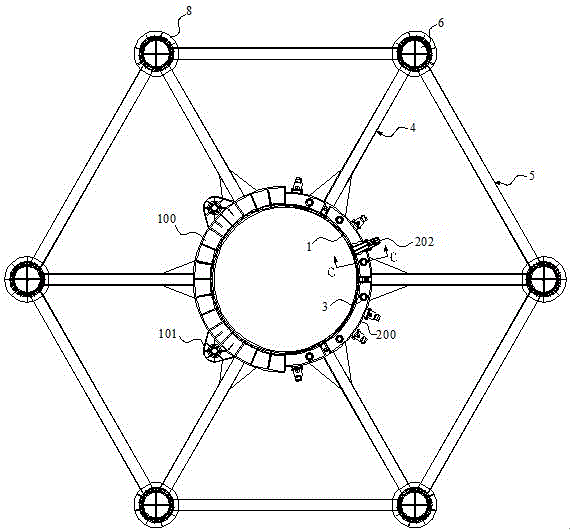

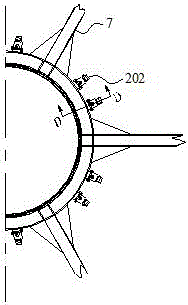

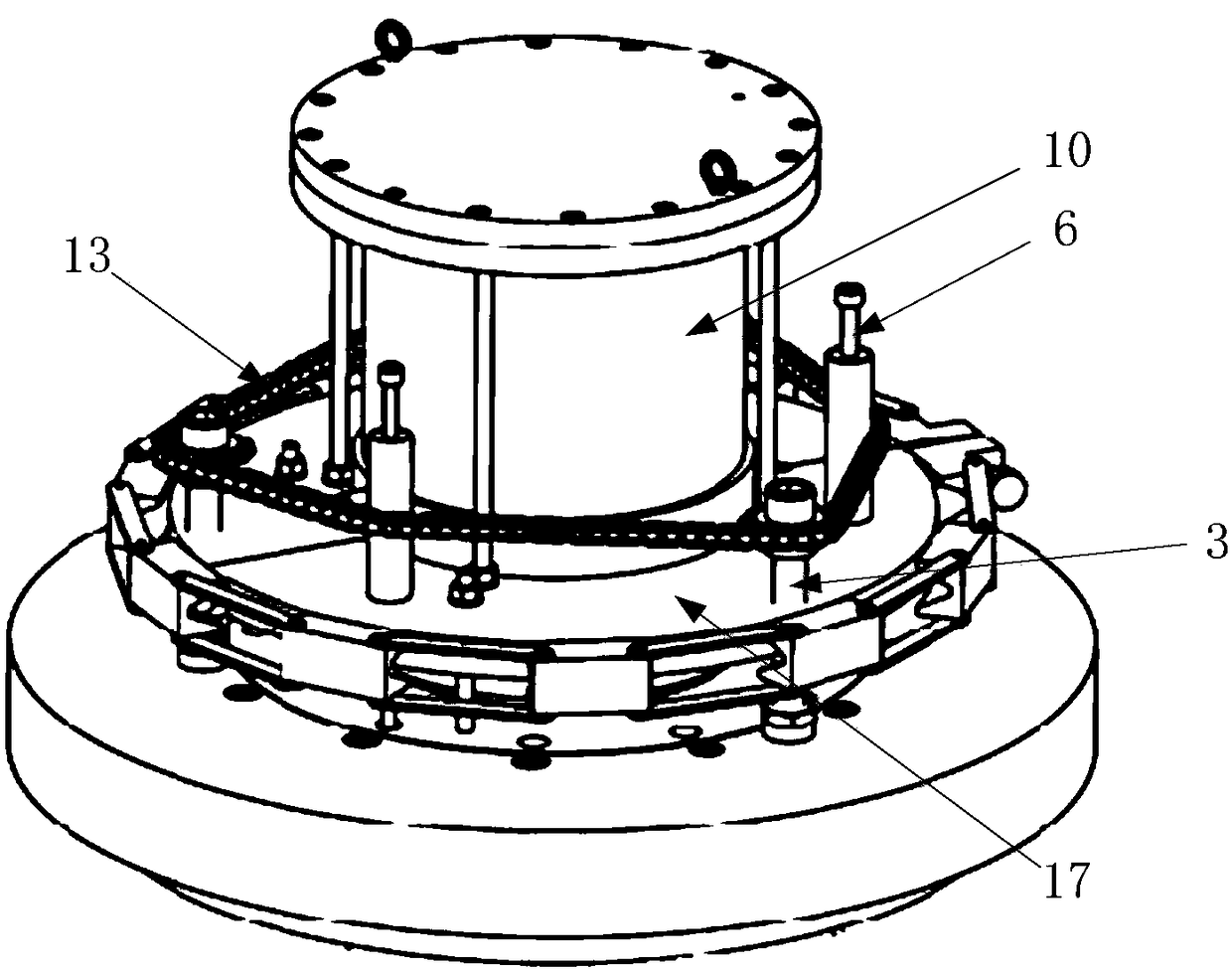

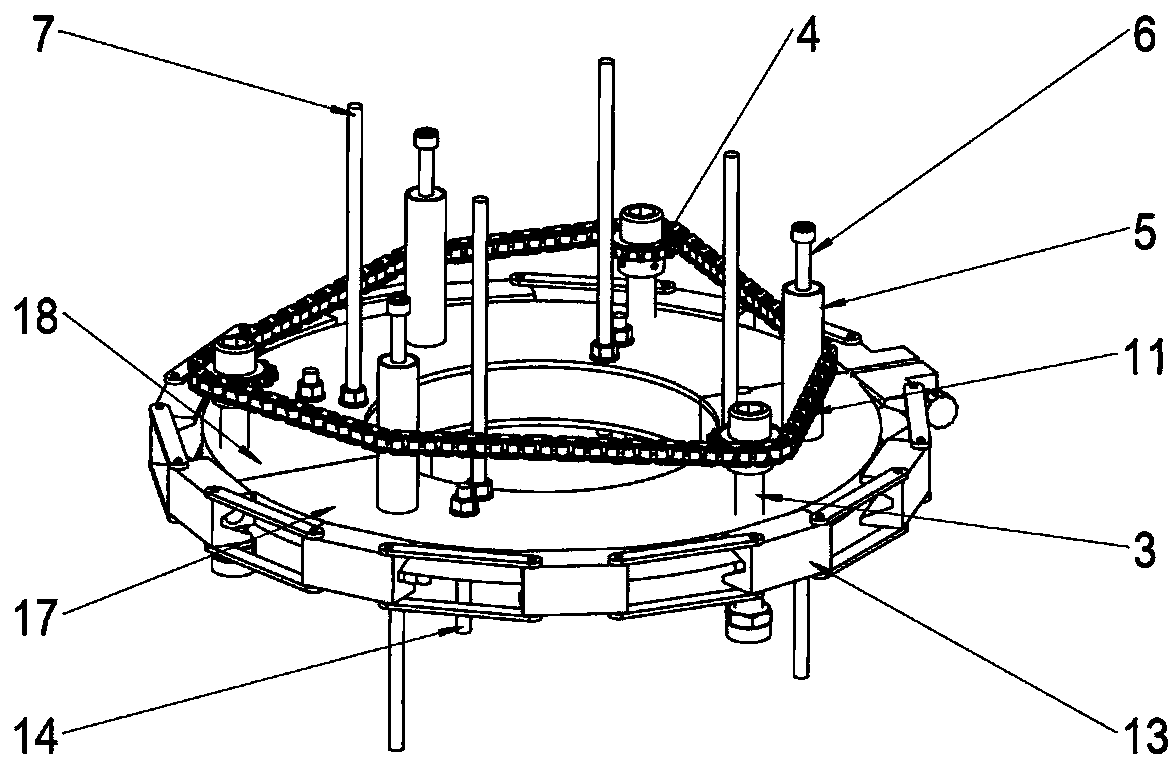

Assembled offshore single-pile foundation construction platform and construction process thereof

ActiveCN106400764AAchieve high strengthRealize high stiffness designArtificial islandsUnderwater structuresWave loadingBuilding construction

The invention provides an assembled offshore single-pile foundation construction platform. The construction platform can serve as a large single-pile foundation drilling platform or a large single-pile driving stable pile platform, and comprises a stable pile frame, a steel protection cylinder and steel pipe piles; a positioning cylinder is arranged in the center position of the stable pile frame; multiple locking oil cylinders are symmetrically embedded in the upper end and / or the lower end of the positioning cylinder in the peripheral direction; the steel protection cylinder is inserted in the positioning cylinder, and is radially positioned by the locking oil cylinders; multiple mounting sleeves are uniformly and annularly arranged at the external of the positioning cylinder; the mounting sleeves and the positioning cylinder are fixedly connected through radial trusses; the adjacent mounting sleeves are fixedly connected through peripheral trusses; and the steel pipe piles are inserted in the mounting sleeves, and are connected with the mounting sleeves through clamping keys. The construction platform is quickly assembled through a detachable mode without needing offshore welding work, and can be recycled; and more importantly, through unique structural design, the construction platform is high in stability of bearing the wave load.

Owner:PINGMEI JIANGONG GRP SPECIAL DRILLING ENG CO LTD +1

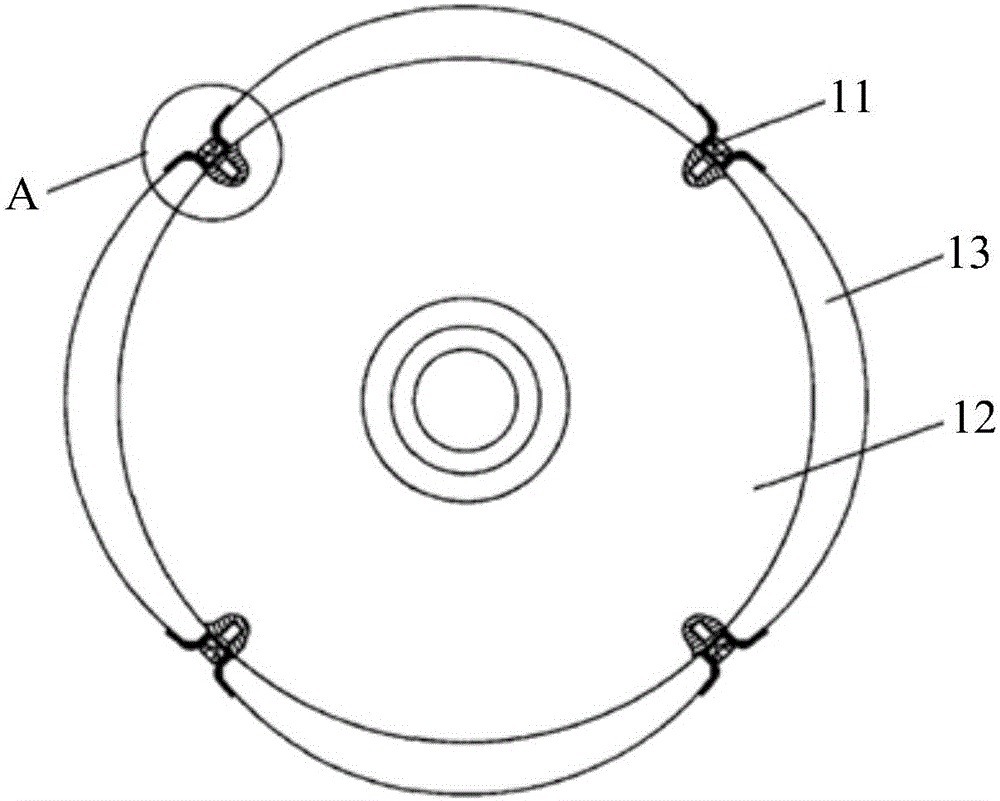

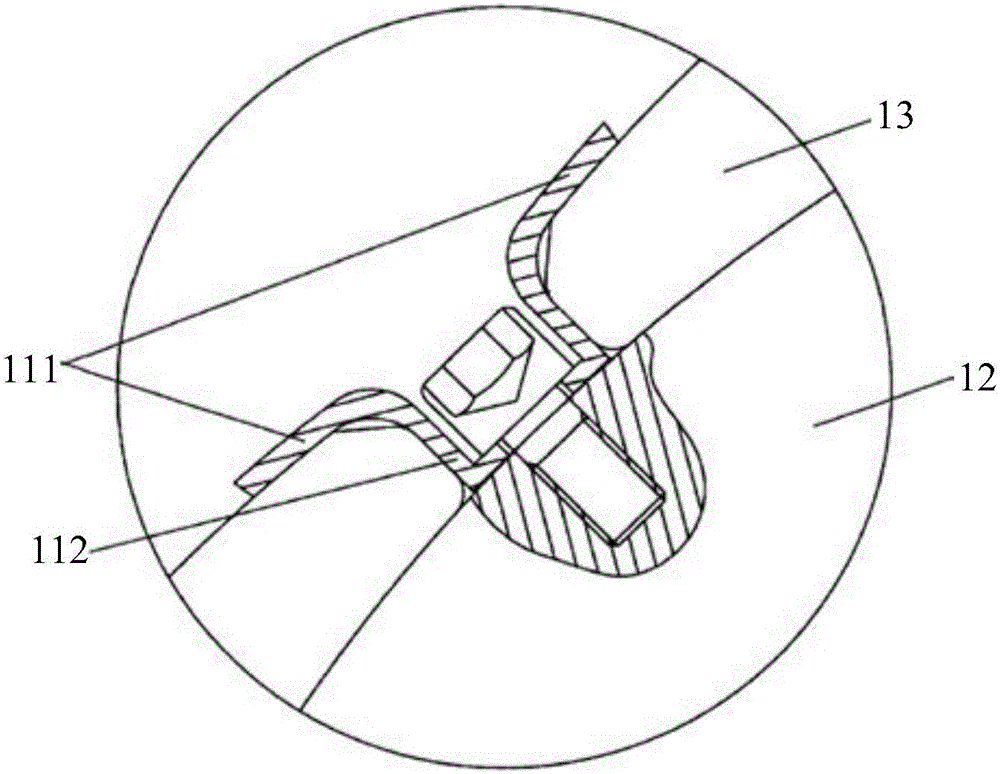

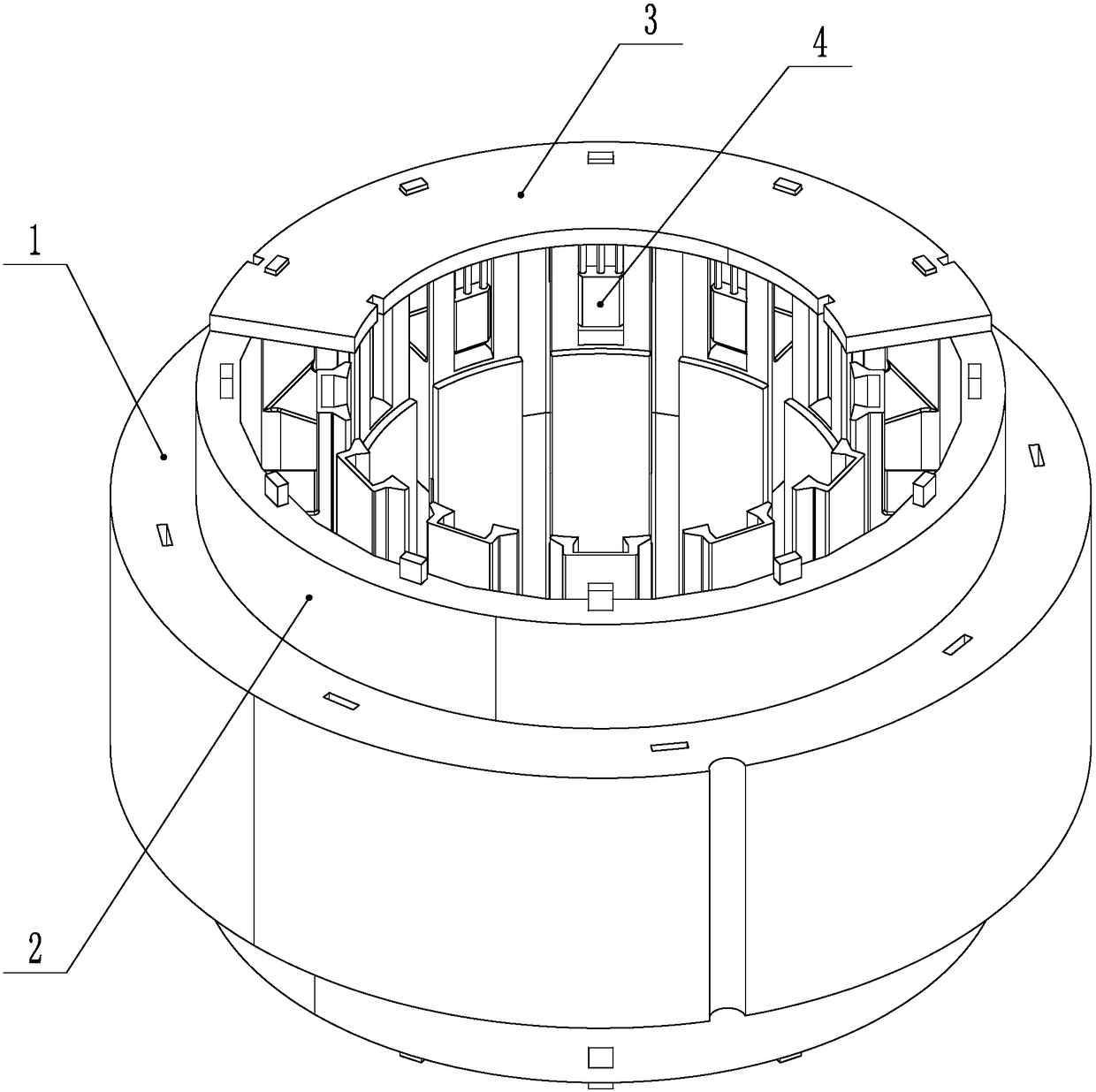

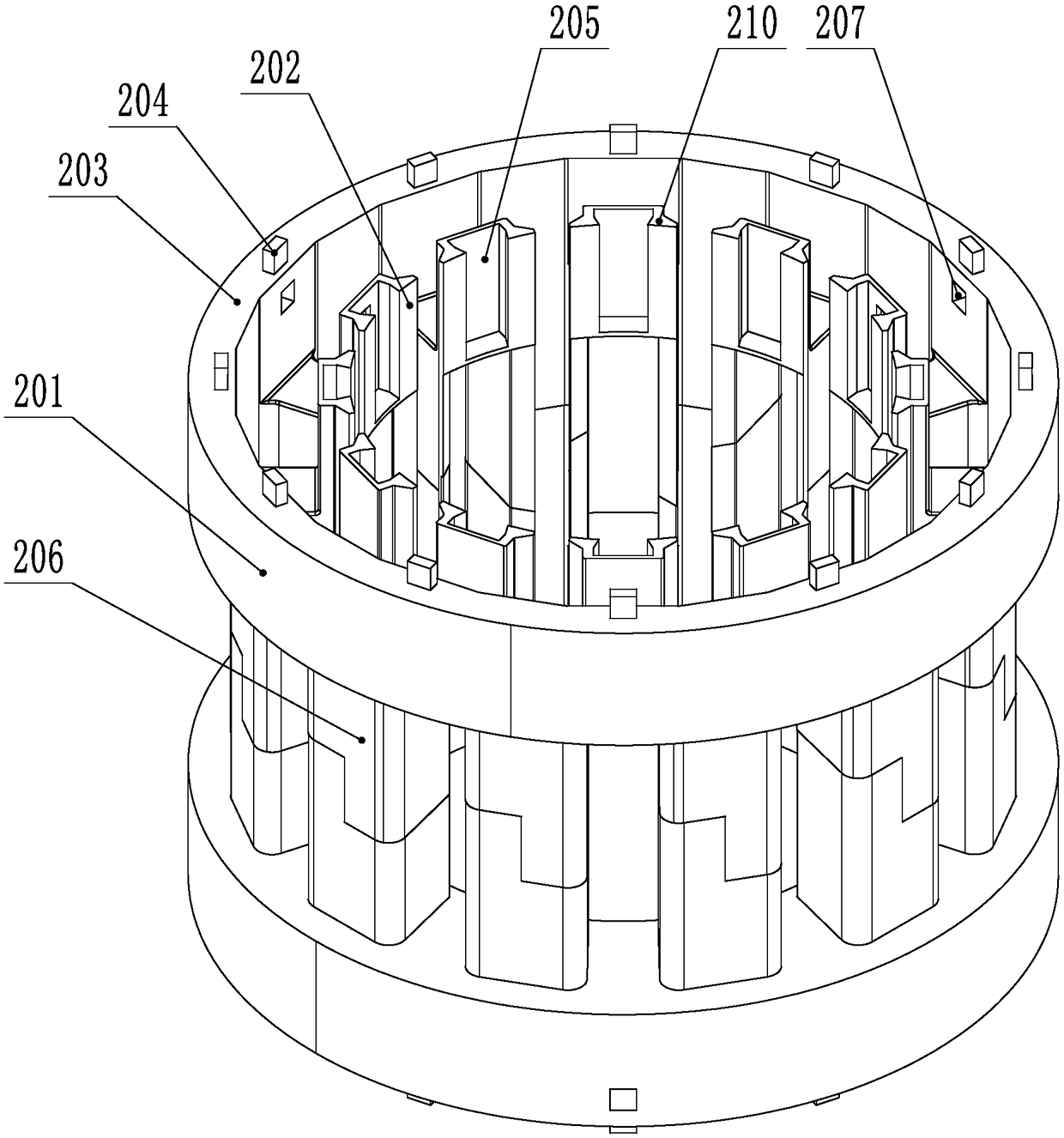

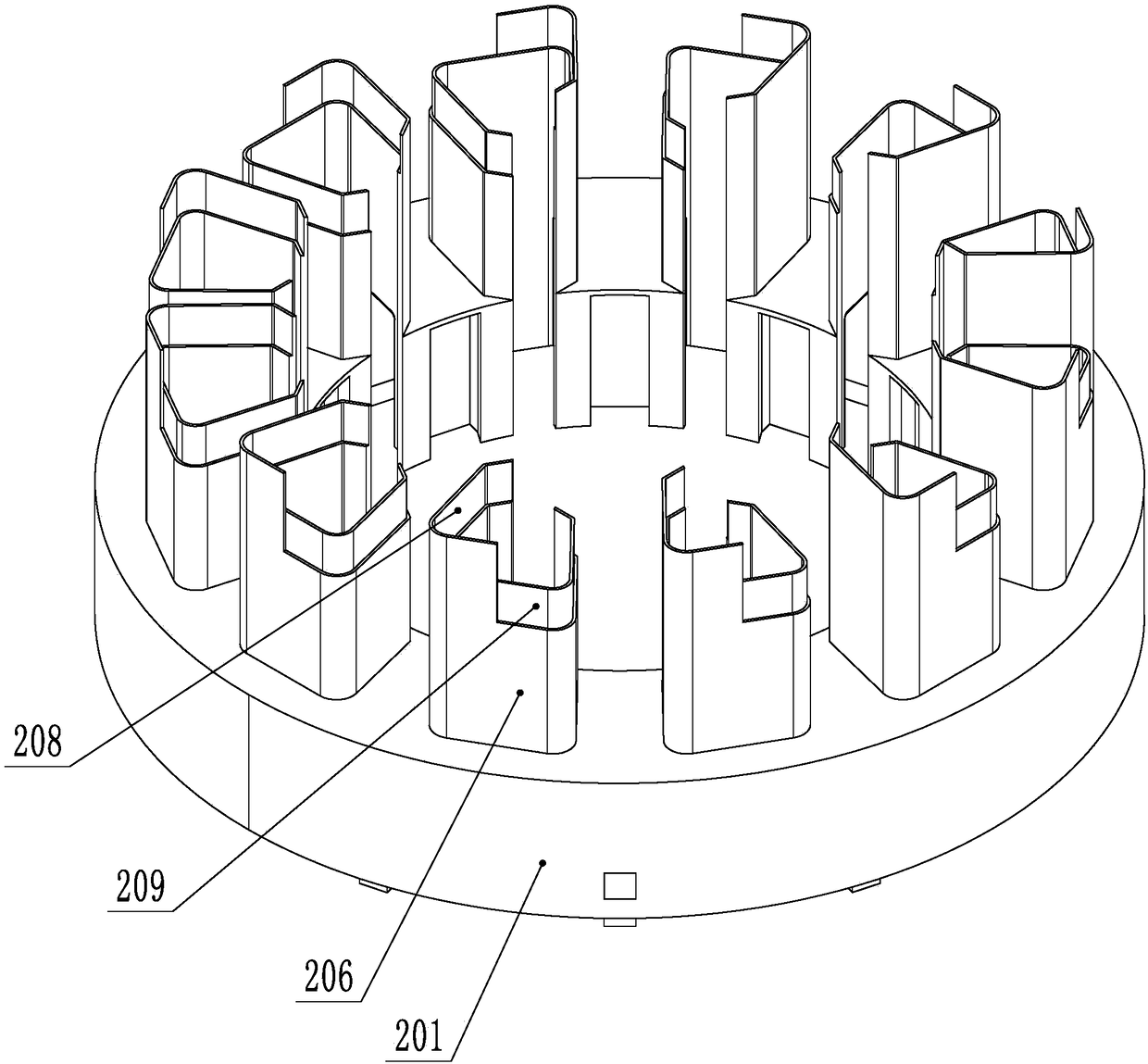

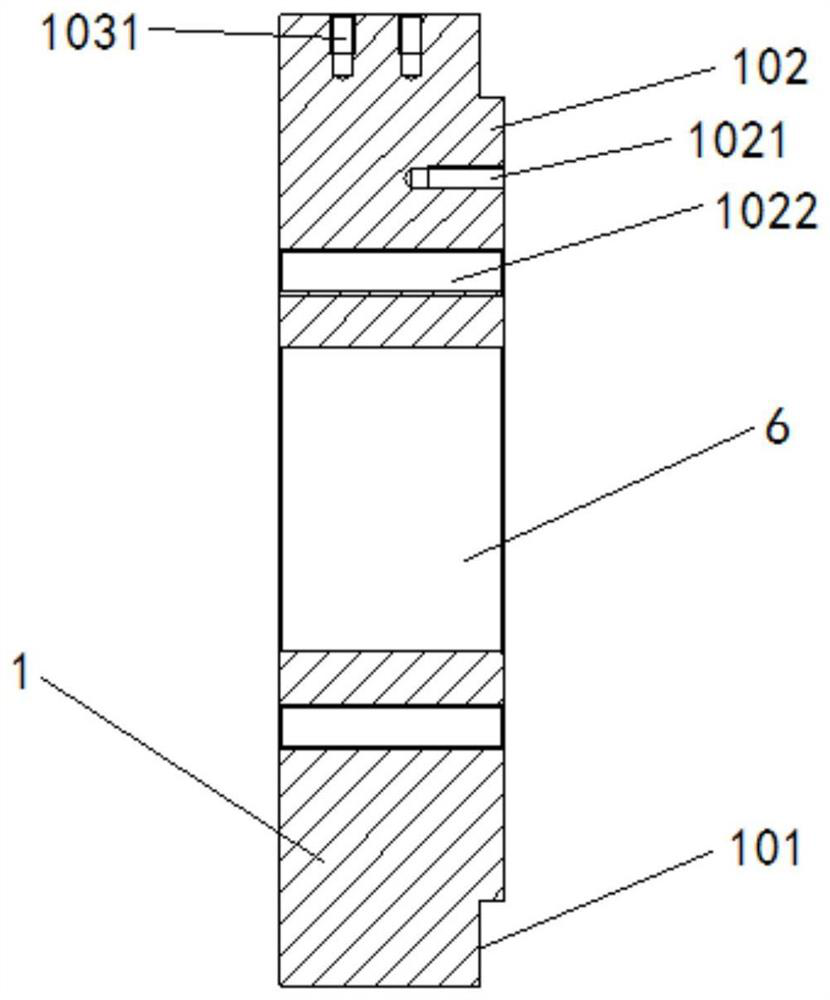

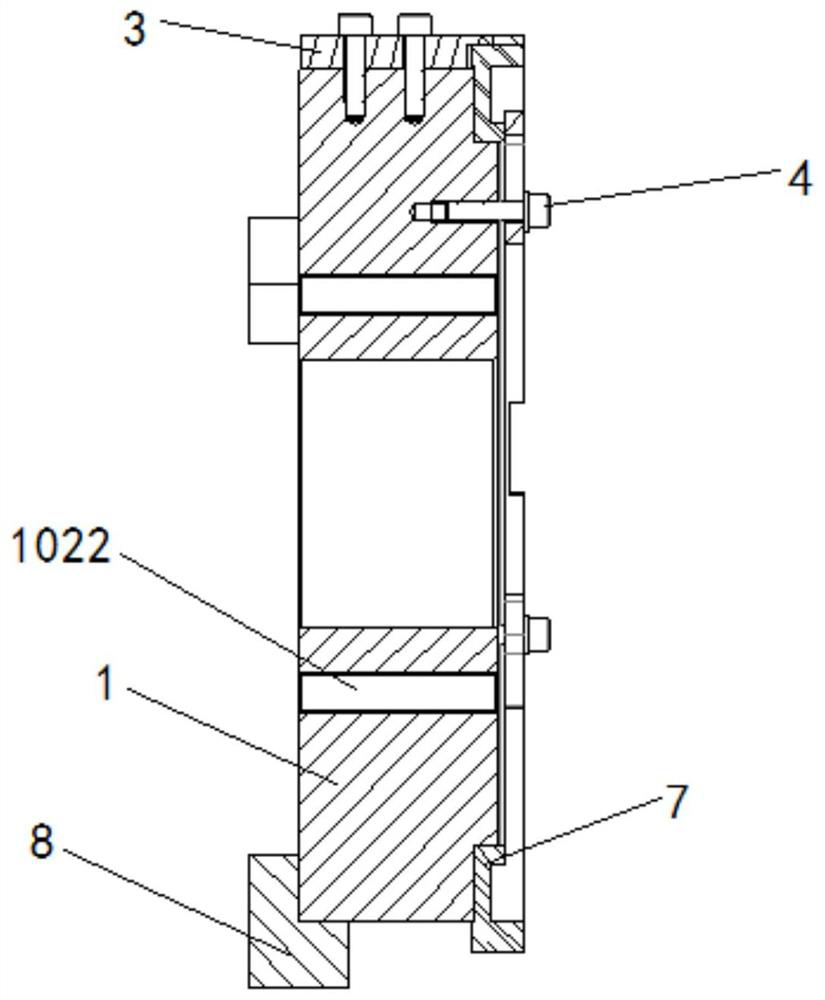

Rotor, magnetic steel fixing structure thereof, and motor

InactiveCN106130225AAchieve radial positioningAchieve circumferential positioningMagnetic circuit rotating partsPunchingMagnet

The present invention relates to a rotor, a magnet steel fixing structure thereof, and a motor. The motor magnet steel fixing structure includes a rotor core, magnet steels sequentially distributed in the circumferential direction of the rotor core, and stoppers located between two adjacent magnet steels, wherein each stopper includes a connecting portion and two pressing plates both fixedly connected with the connecting portion, the two pressing plates are respectively pressed on two adjacent magnet steels, and the connecting portion is in positioning connection with the rotor core in a radial direction through a concave-convex cooperative structure. In the magnet steel fixing structure, the connecting portion is in positioning connection with the rotor core in a radial direction through a concave-convex cooperative structure, and the structure required by the concave-convex cooperative structure can be formed in a rotor core punching process, so that compared with the prior art, a processing flow is reduced, the rotor core production process is simplified, thereby the production of a whole rotor is simplified, and rotor production efficiency is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

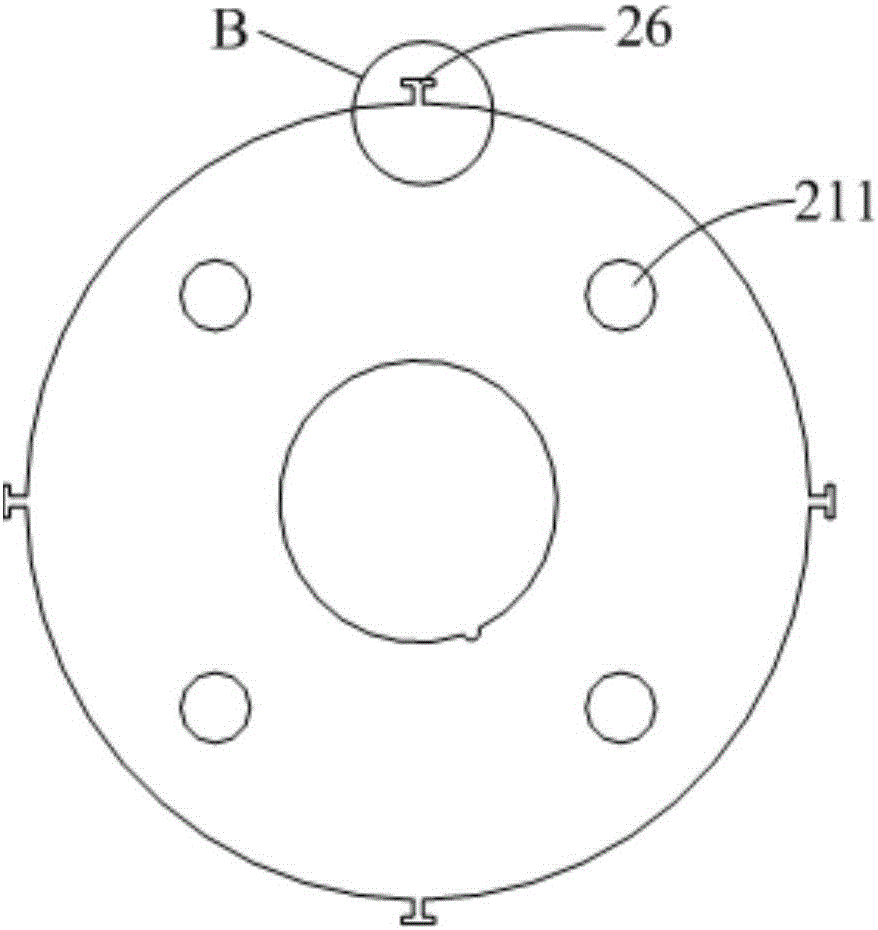

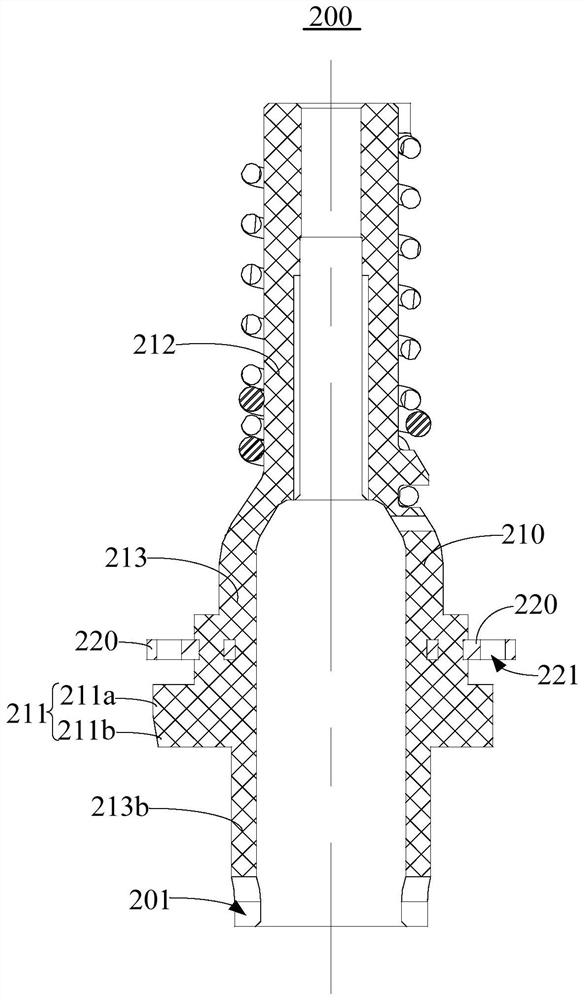

Grouting sleeve assembly

PendingCN108316565APrecise Axial ControlGuaranteed positioning accuracyBuilding reinforcementsArchitectural engineeringSlurry

The invention belongs to the technical field of construction of building structures, and in particular relates to a grouting sleeve assembly. The grouting sleeve assembly comprises a sleeve body, an exhaust pipe and a grouting pipe, wherein the sleeve body is provided with an exhaust hole and a grouting hole; the exhaust pipe and the grouting pipe are respectively connected with the exhaust hole and the grouting hole; an air permeable plugging device used for preventing a grouting material from overflowing is arranged at the exhaust outlet of the exhaust pipe; a non-return device used for preventing backflow of the grouting material is arranged at a grouting mouth of the grouting pipe. In the grouting process, the air in the sleeve body can be smoothly discharged outside through the air permeable plugging device, and the air permeable plugging device provides pre-resistance so as to enable the interior of the grouting sleeve to be densely grouted; the air permeable plugging device canprevent the grouting material from overflowing when the sleeve is grouted or after the sleeve is fully grouted; after the sleeve is fully grouted, if the slurry in the sleeve body has a tendency to backflow, the non-return device can effectively block a grouting channel so as to prevent the slurry from backflowing; the grouting sleeve assembly guarantees dense grouting while achieving the aim of reducing waste, and also guarantees the connection performance.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

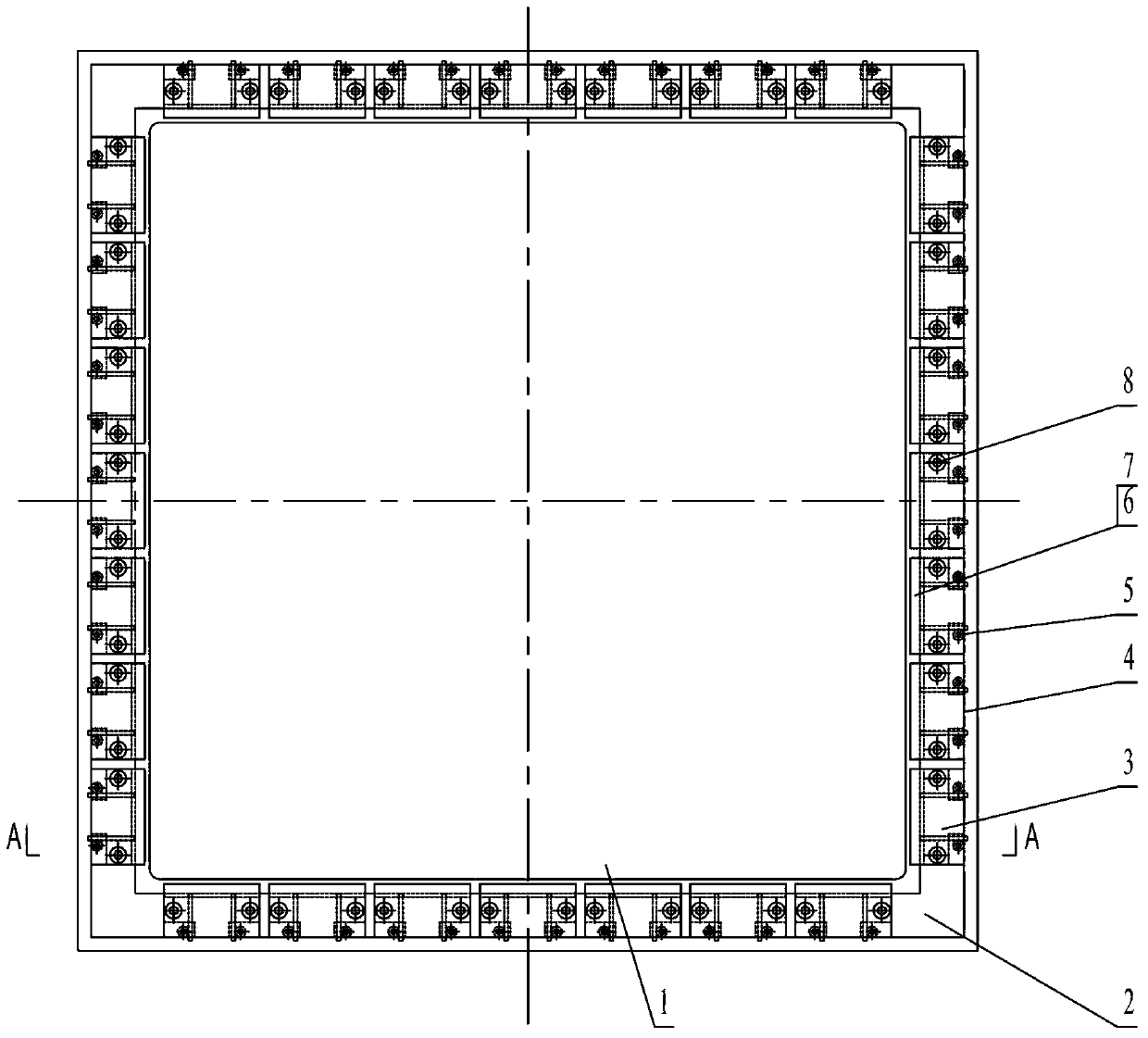

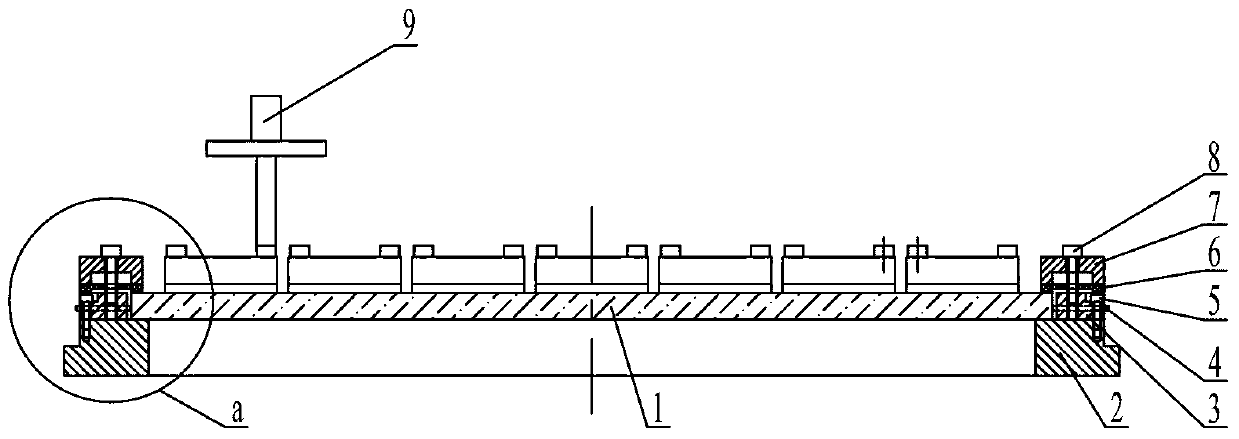

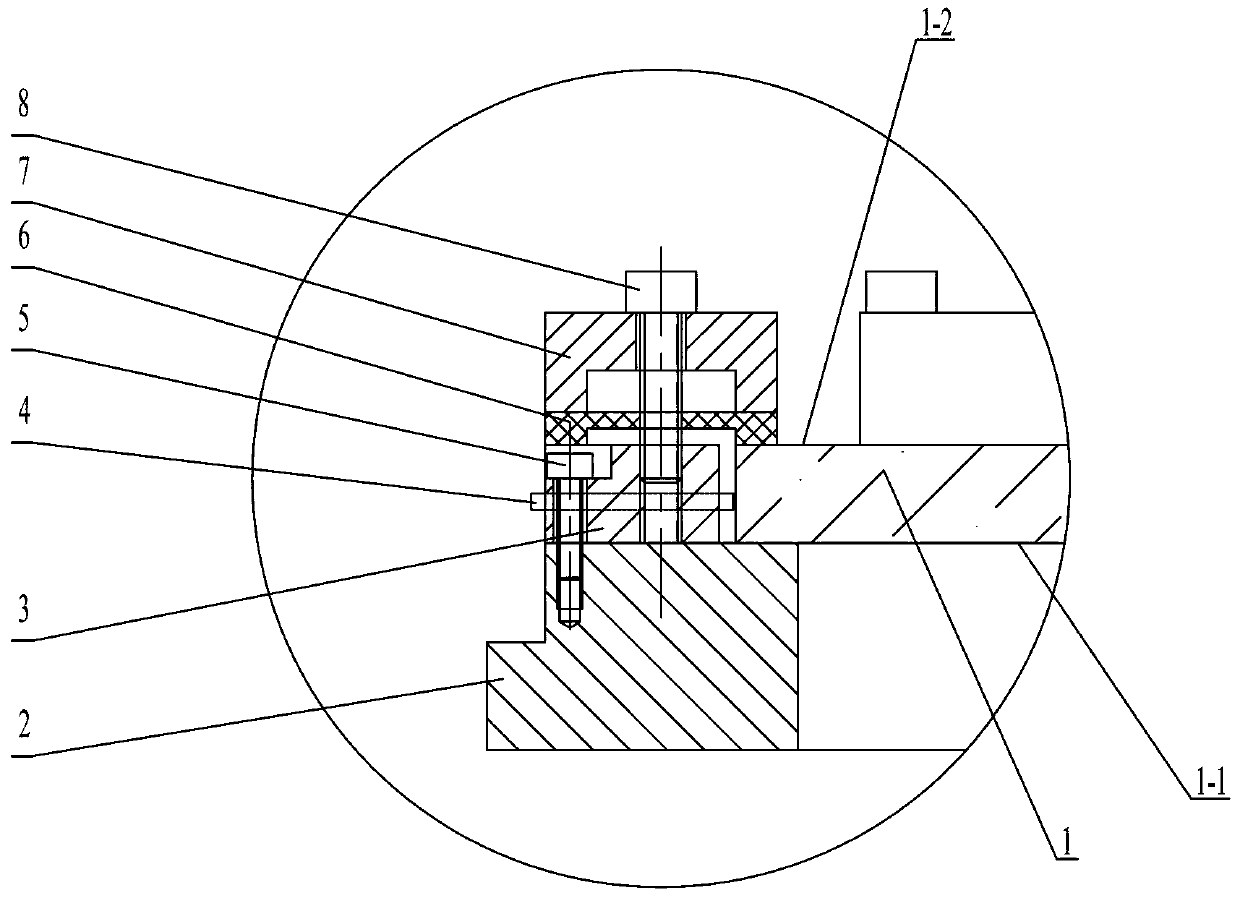

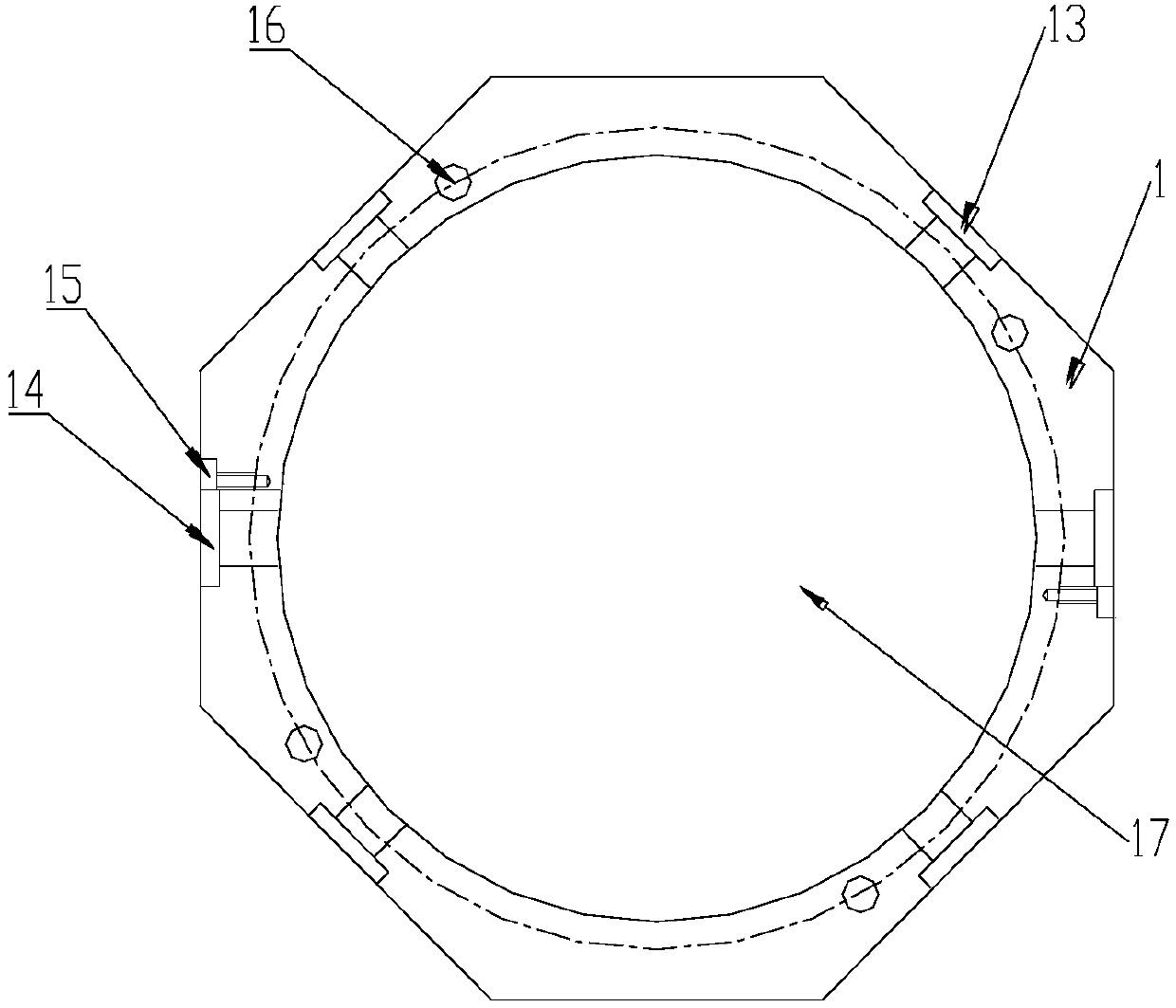

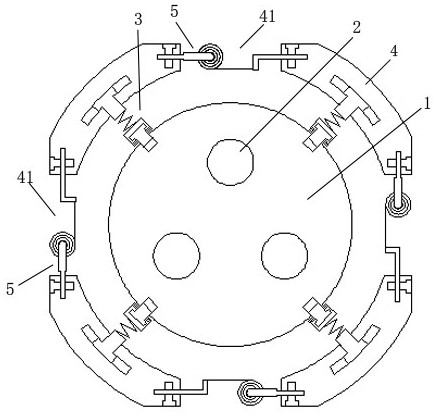

Nonlinear large-aperture optical element clamping device capable of achieving definite value axial load application

ActiveCN103273439AReduce distortionImprove harmonic conversion efficiencyWork holdersMountingsLarge apertureElectrical and Electronics engineering

The invention relates to a nonlinear large-aperture optical element clamping device, in particular to a nonlinear large-aperture optical element clamping device capable of achieving definite value axial load application. The nonlinear large-aperture optical element clamping device capable of achieving definite value axial load application solves the problem that harmonic conversion efficiency of a nonlinear large-aperture optical element is reduced because the nonlinear large-aperture optical element deforms easily under the action of gravity and clamping force. The nonlinear large-aperture optical element is placed on a supporting frame; locating edge blocks are arranged on the periphery of the supporting frame in a distributed mode and are fixedly connected with the supporting frame, plastic staple horizontal installation holes are formed in the locating edge blocks, and plastic staples penetrate through the plastic staple horizontal installation holes and make contact with the nonlinear large-aperture optical element; elastic pressing sheets are arranged on the periphery of a light-facing face of the nonlinear large-aperture optical element in a distributed mode, a rigid pressing sheet is arranged on each elastic pressing sheet, and the elastic pressing sheets and the rigid pressing sheets are connected with the locating edge blocks through load applying screws; a torque wrench acts on the load applying screws. The nonlinear large-aperture optical element clamping device capable of achieving definite value axial load application is applied to experimental schemes for full-circumferential clamping and definite value axial load application of the nonlinear large-aperture optical element.

Owner:HARBIN INST OF TECH

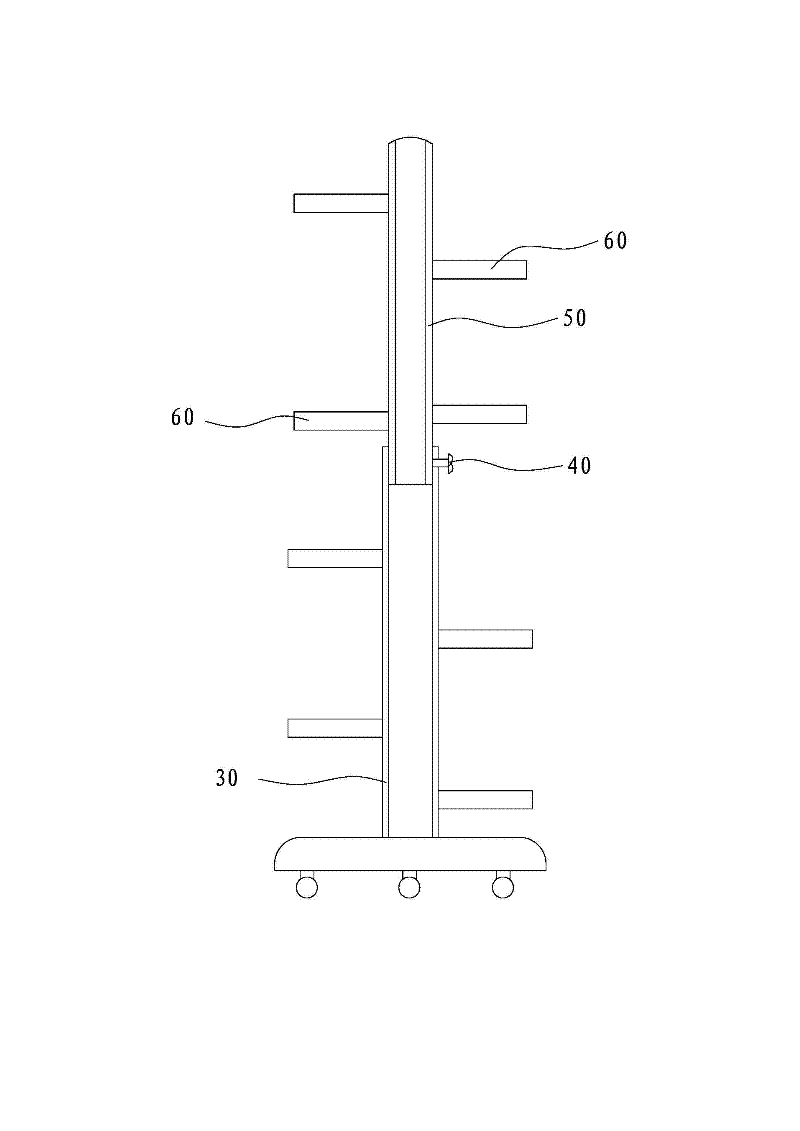

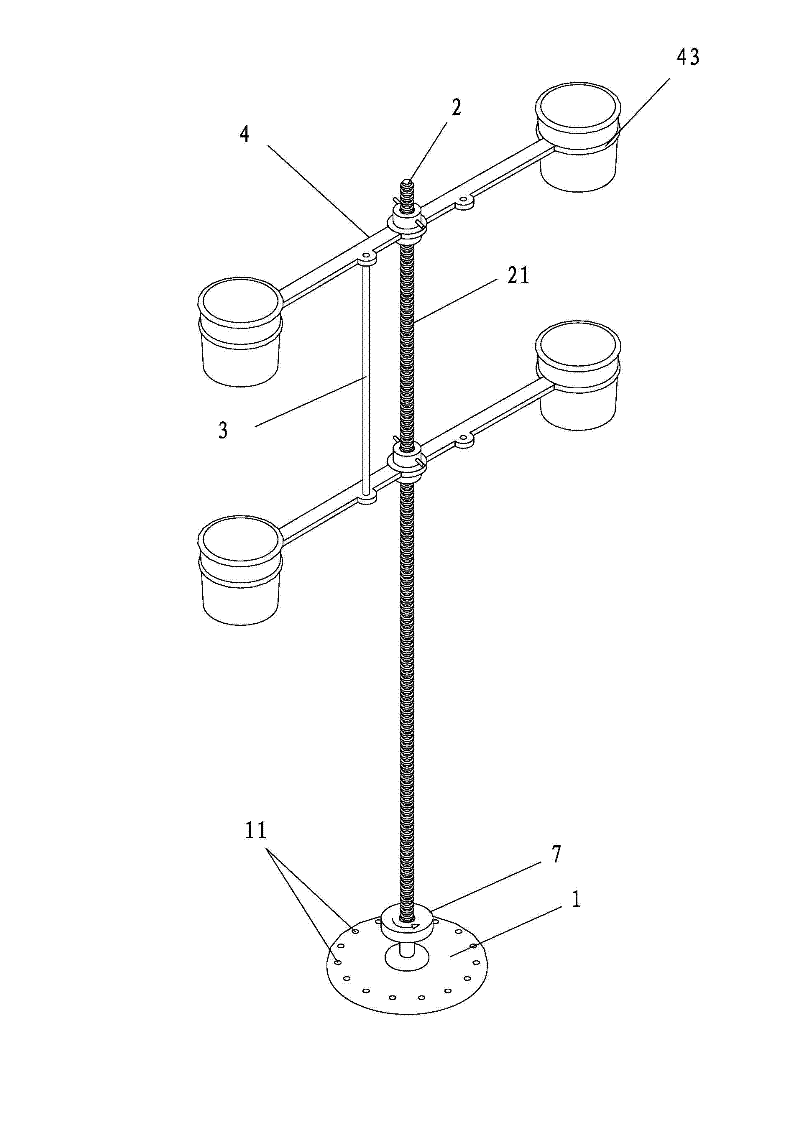

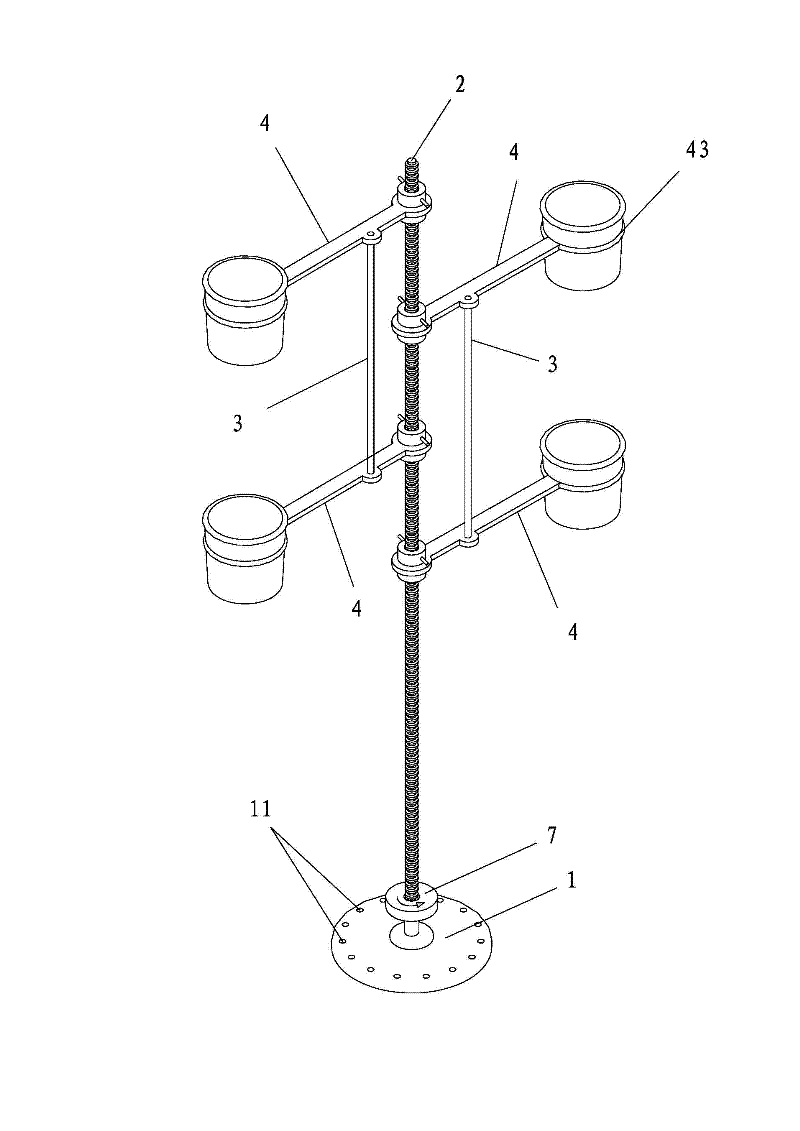

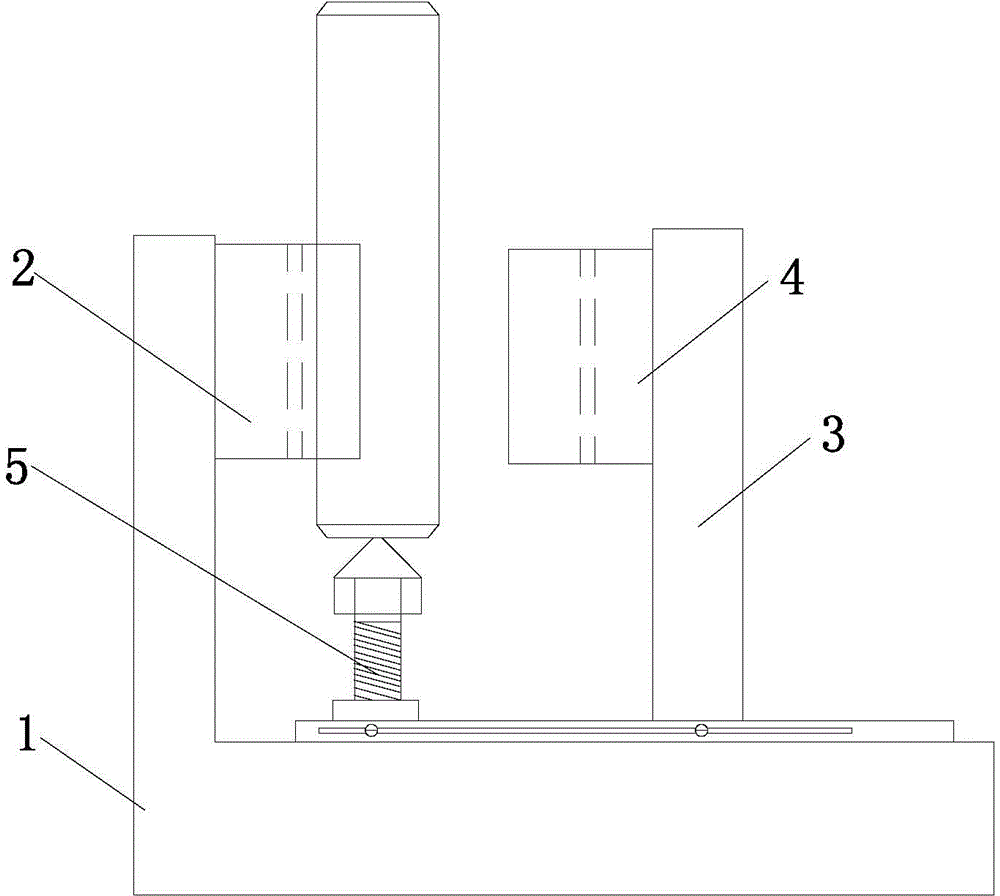

A planting rack with height regulation by thread

InactiveCN102283531ARealize regulationFlexible adjustmentFlower holdersEngineeringStructural engineering

The invention discloses a planting frame for height regulation by using threads, which comprises a base, a screw rod and a flowerpot bracket. The screw rod with external thread is screwed on the base, and the screw rod is provided with a dial for turning the screw rod on the base. The invention realizes the axial and radial adjustment of the flower pot bracket on the whole planting frame, meanwhile, the structure of the planting frame is stable and reliable, and the use is flexible and diverse.

Owner:王毅

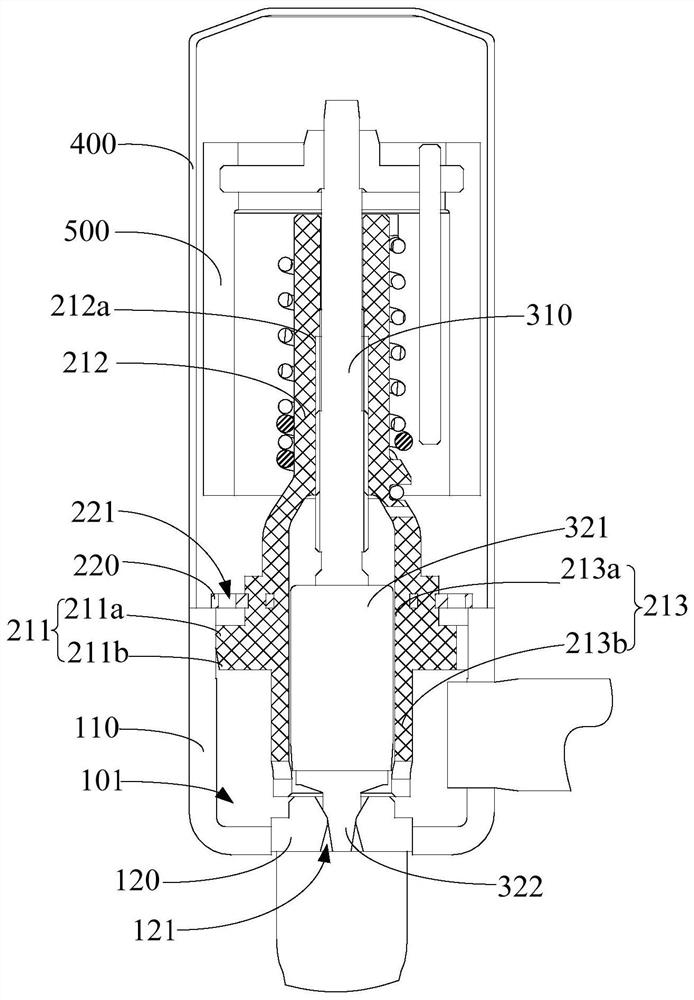

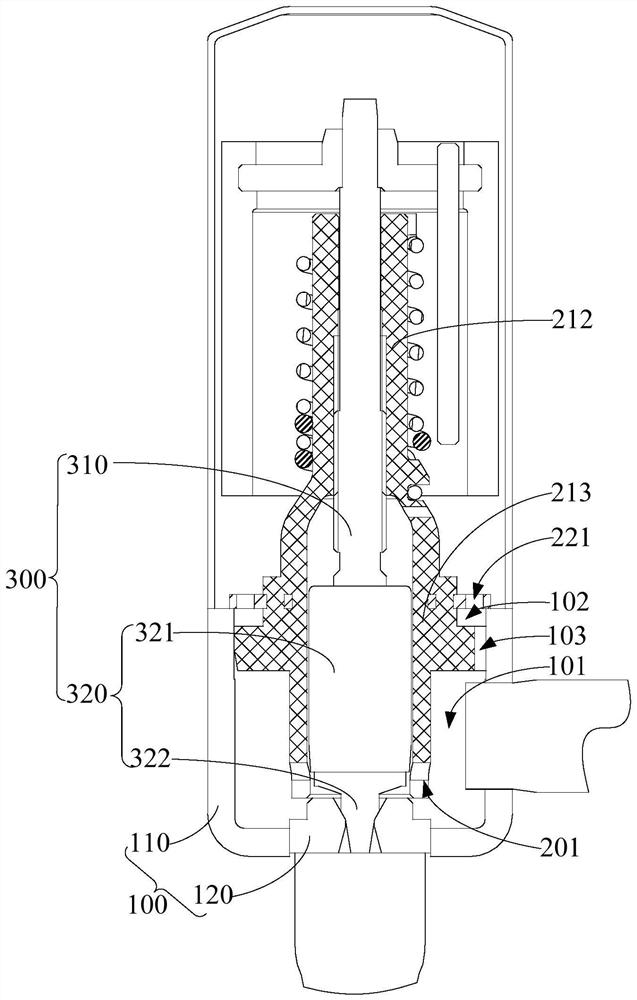

Electronic expansion valve and refrigeration equipment

PendingCN112524261APrevent stuck phenomenonImprove work performanceOperating means/releasing devices for valvesEfficient regulation technologiesEngineeringElectronic expansion valve

The invention discloses an electronic expansion valve and refrigeration equipment. The electronic expansion valve comprises a valve seat, a nut and a connecting piece. The valve seat is provided witha valve cavity, one end of the nut is installed in the valve cavity, an annular positioning part is arranged on the outer wall of the nut in a protruding manner, and the positioning part is connectedwith the cavity wall of the valve seat in an abutting manner to achieve positioning. One end of the connecting piece is fixedly connected with the nut, and the other end of the connecting piece extends away from the nut and is fixedly connected with the axial end face of the valve seat. According to the technical scheme, the electronic expansion valve achieves the function of positioning the nut and the valve seat in the axial and radial directions, the coaxiality of the nut and the valve seat is guaranteed, then the coaxiality of the nut and the valve element seat is guaranteed, the phenomenon that the electronic expansion valve gets stuck is avoided, and the working performance of the electronic expansion valve is improved.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

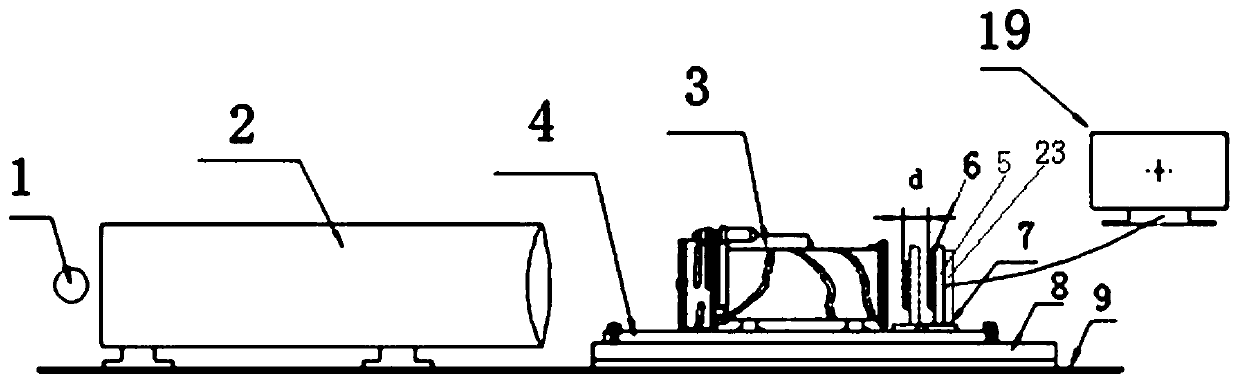

Full-wave-band high-precision zoom optical system image surface butt joint and coaxial adjustment device and method

ActiveCN111458896AConsistent clarityImprove trimming accuracyNuclear energy generationOptical elementsGratingDisplay device

The invention provides a full-wave-band high-precision zoom optical system image surface butt joint and coaxial adjustment device and method, and solves the problems that an existing zoom optical lensimage surface adjustment method is low in efficiency, an imaging assembly is easy to damage, and the image surface adjustment precision is relatively low. The device comprises an optical platform, agrating ruler, a display, a light source, a full-waveband collimator, a zoom lens fixing mechanism and an image plane adjusting assembly, the full-waveband collimator is arranged on the optical platform; the zoom lens fixing mechanism is arranged on the optical platform through the four-dimensional adjusting platform, and the four-dimensional adjusting platform adjusts the position of a zoom optical lens on the zoom lens fixing mechanism; the image plane adjusting assembly comprises a CCD mounting frame, a four-dimensional adjustable base, a sliding block and a guide rail control assembly fordriving the sliding block to move; the CCD mounting frame is arranged on the four-dimensional adjustable base; the four-dimensional adjustable base is arranged on the sliding block; the grating ruleris used for recording the position of the CCD imaging assembly; and the display is connected with the CCD imaging assembly.

Owner:西安中科西光光电科技有限公司

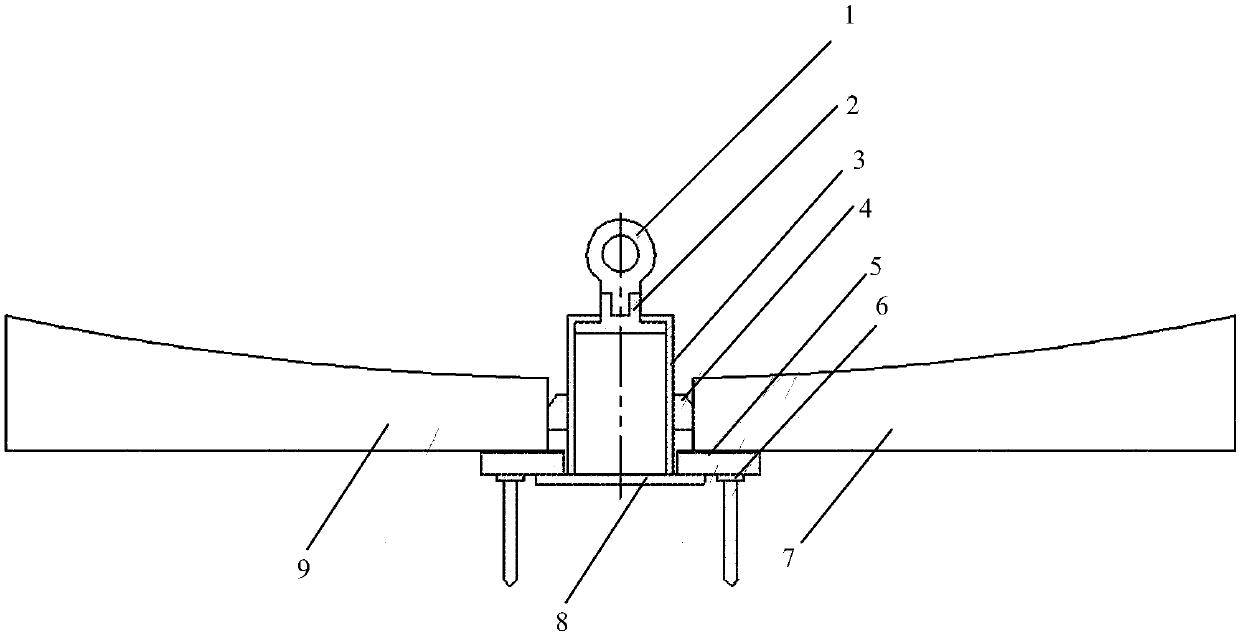

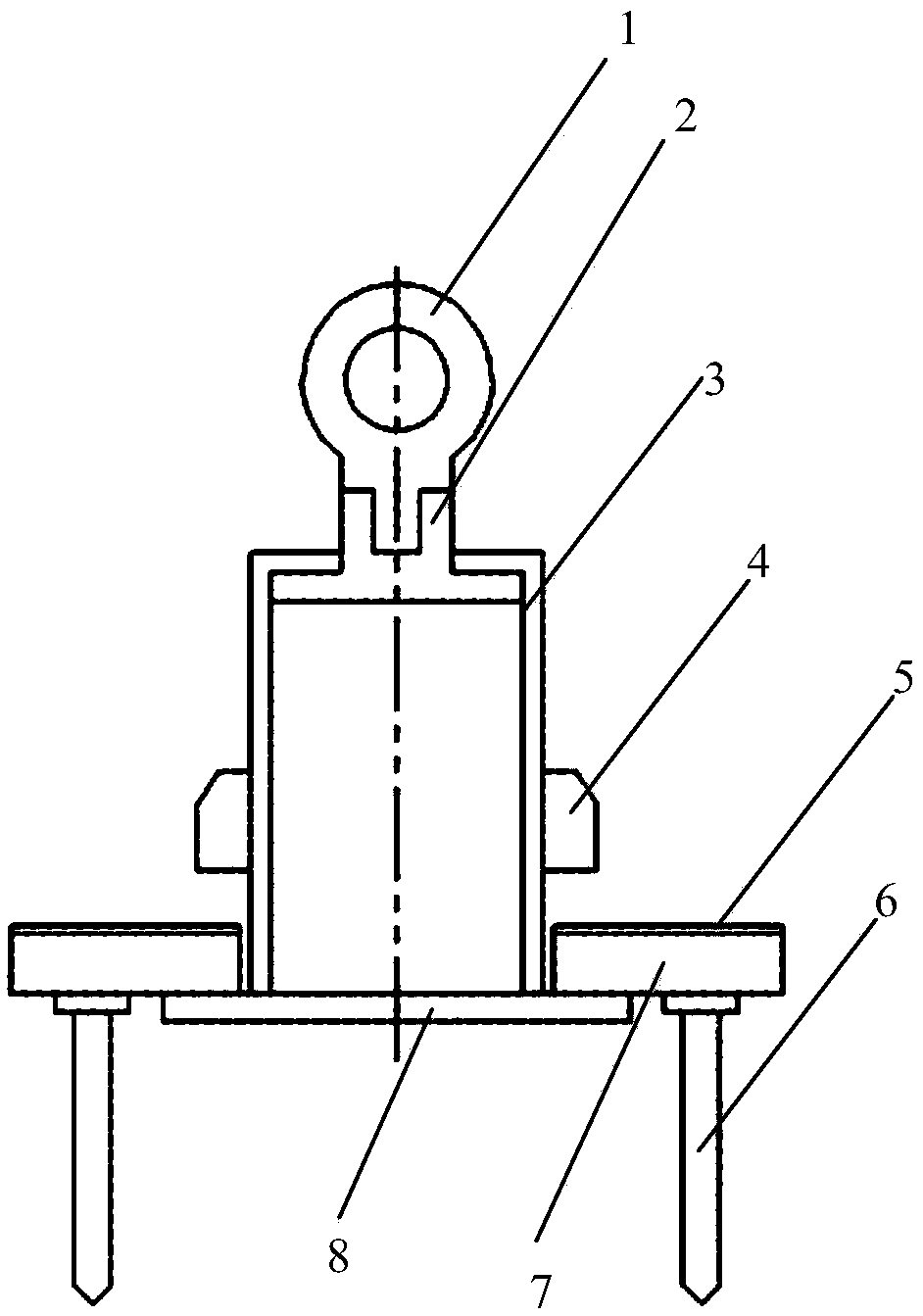

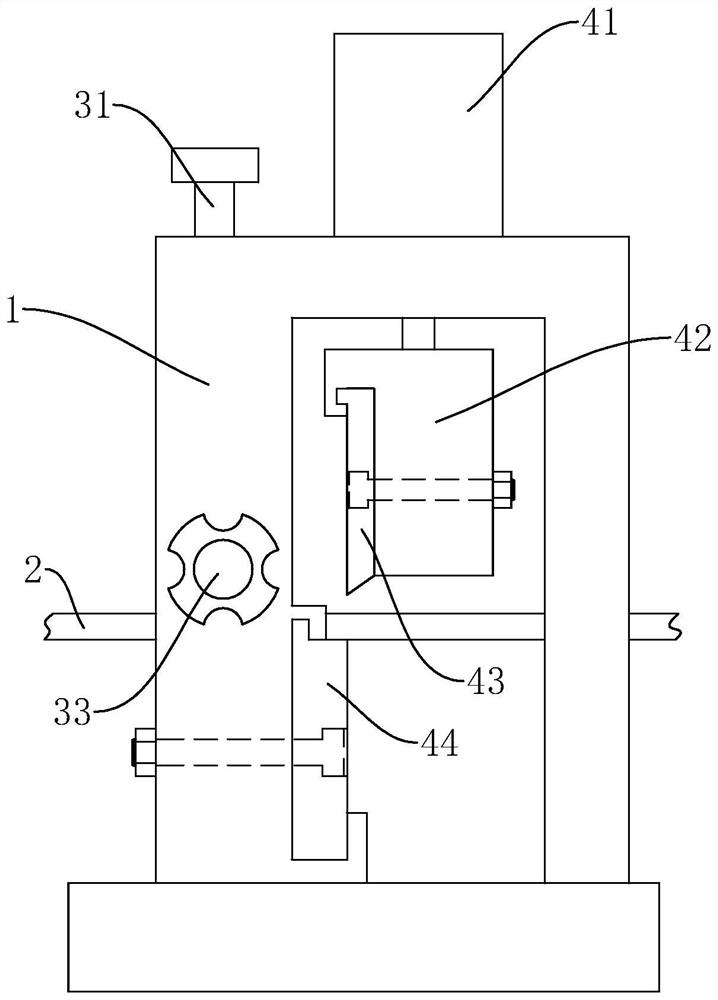

Equipment loading and unloading tool, equipment assembling method and equipment disassembling method

ActiveCN109015484AAchieve radial positioningImprove coaxialityNuclear energy generationWork holdersAxial displacementEngineering

The invention provides an equipment loading and unloading tool. The equipment loading and unloading tool comprises a clamping and fastening structure, an axial adjusting structure and a radial alignment structure; the clamping and fastening structure comprises an annular chuck and a fastener, the annular chuck comprises at least two arc-shaped tooling support blocks, the tool supporting blocks arespliced end to end to form an annular chuck, and the fastener is used for tightly fixing the annular chuck; the axial adjusting structure comprises supporting legs, the supporting legs penetrate through the annular chuck, and the supporting legs are in threaded connection with the annular chuck; and positioning rods penetrates through the annular chuck. According to the loading and unloading tool, to-be-installed low-temperature machinery is clamped by adopting the clamping and fastening structure. By rotating the supporting legs, the tool supporting blocks drive the to-be-installed equipmentto generate axial displacement, so that the installing and dismounting are realized. In the installation process of the equipment, the positioning rods are screwed into positioning holes of a flangeat the lower end, so that the radial positioning of the tool and the mechanical assembly can be realized, the coaxiality is improved, and the assembly error is reduced. In addition, the invention further provides an equipment assembling method and an equipment disassembling method adopting the equipment loading and unloading tool.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

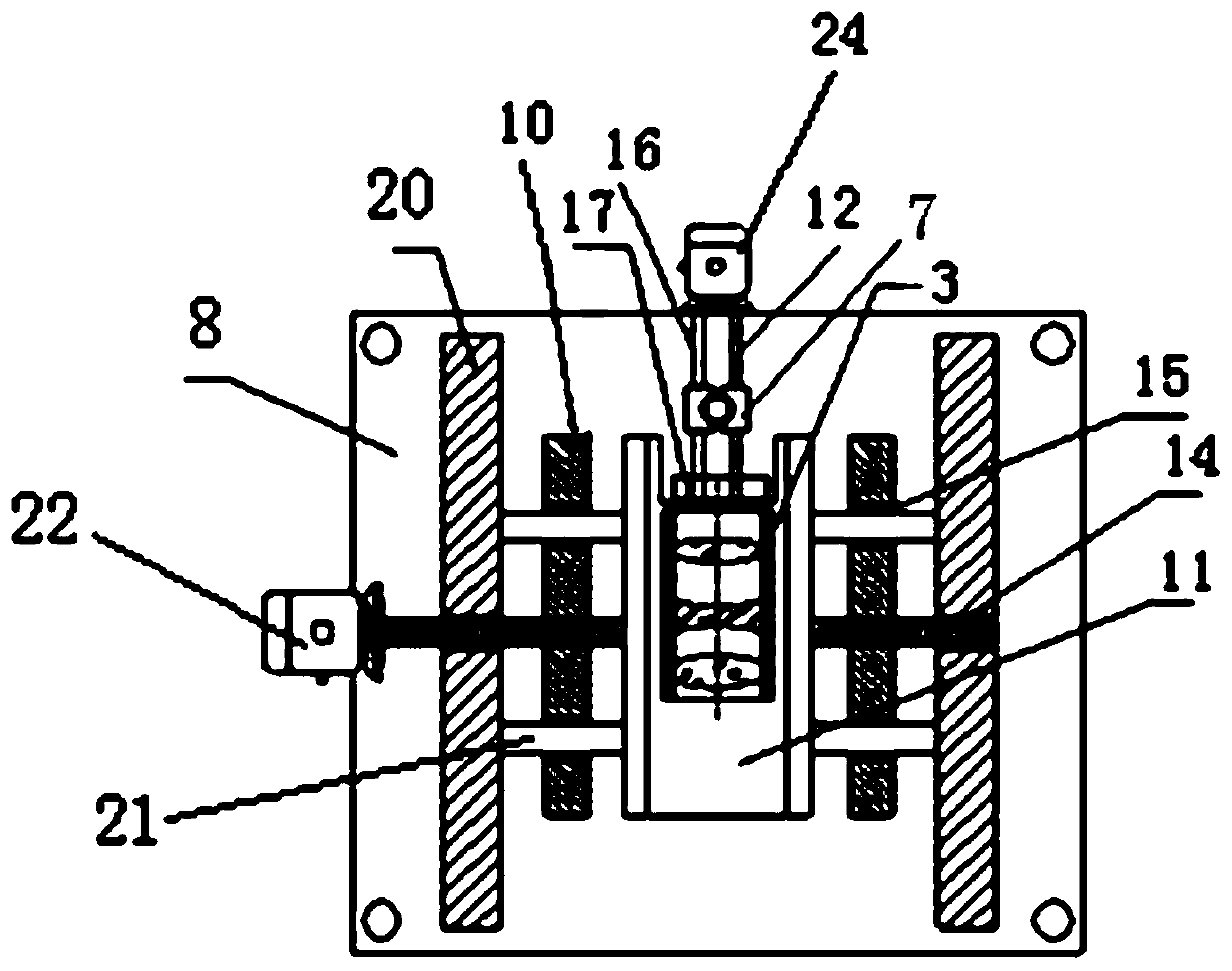

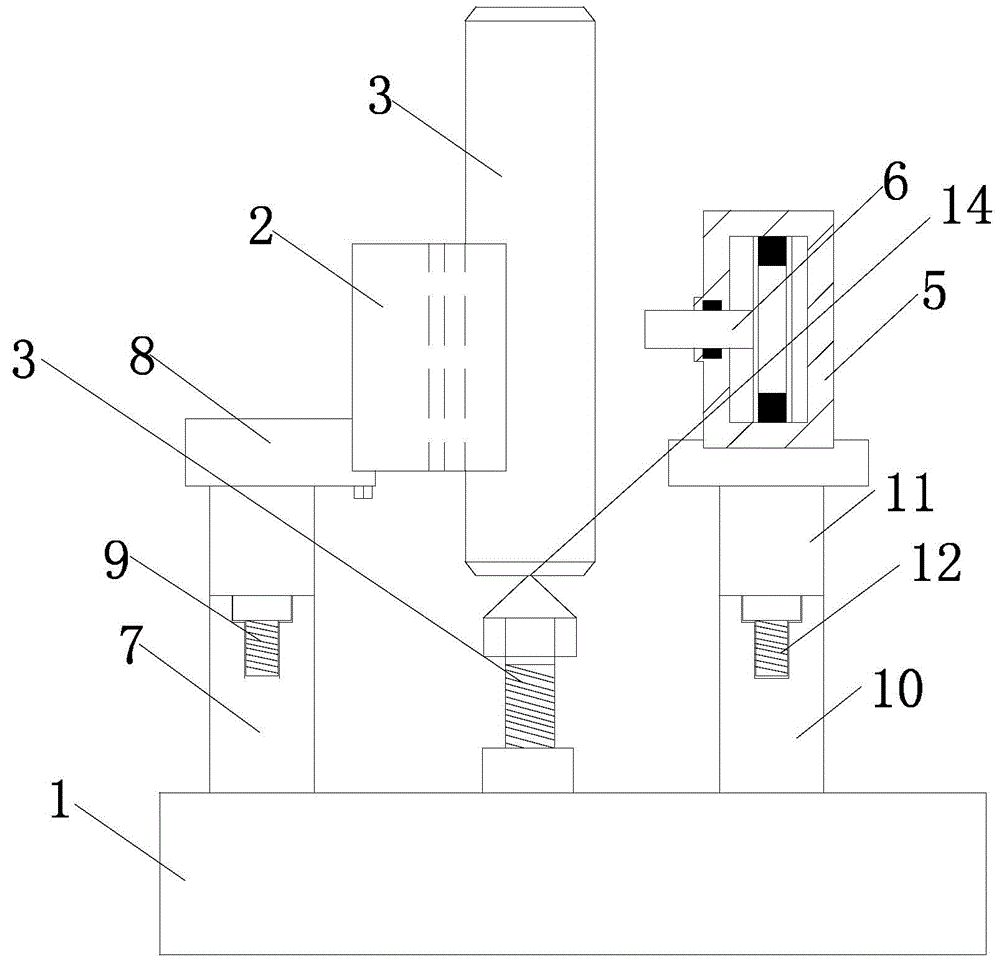

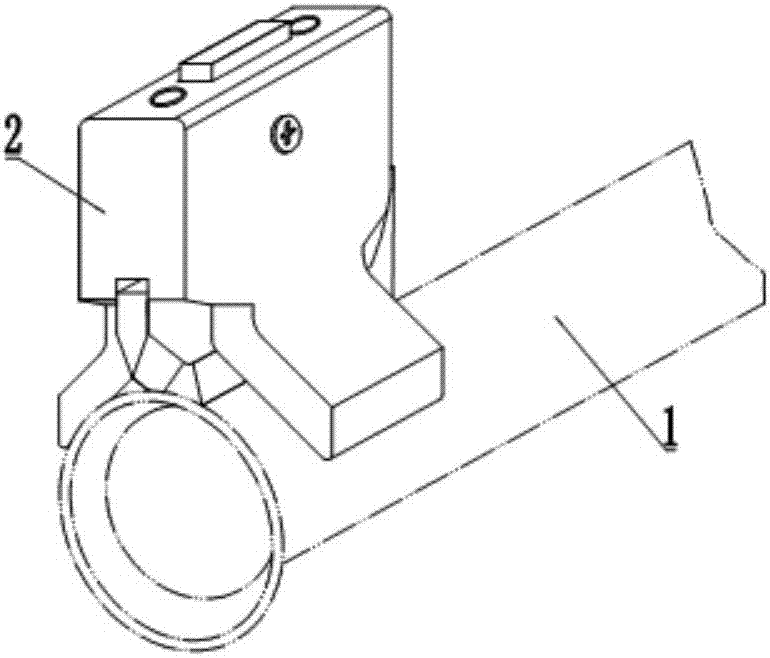

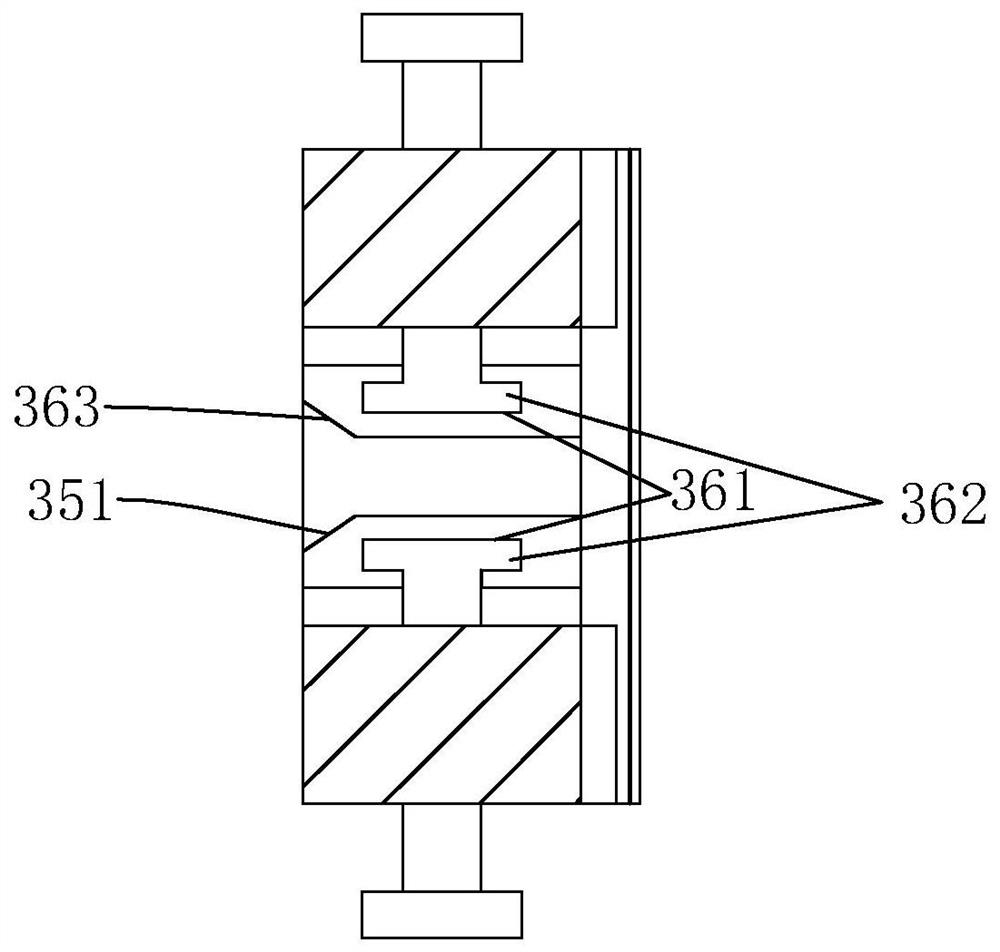

Liftable fixture for groove milling of end faces of hinge pins

InactiveCN104551786AAvoid rotation and downward movementStable clampingWork clamping meansPositioning apparatusHinge angleEngineering

The invention relates to the technical field of mechanical clamping, in particular to a liftable fixture for groove milling of end faces of hinge pins. A first limiting device, a second limiting device and a third limiting device are disposed on a base; the first limiting device comprises a 'T'-shaped first lifting device and a 'V'-shaped limiting block which is inwardly arranged at the top end of the first lifting device; a second limiting device comprises a 'T'-shaped second lifting device and a clamping device arranged at the top end of the second lifting device; the third limiting device comprises a supporting nail with the sharp end up, and the supporting nail is arranged on a transverse portion of the base. The liftable fixture for groove milling of the end faces of the hinge pins has the advantages of convenience in clamping and avoidance of influences on surface smoothness and machining.

Owner:TERRENCE ENERGY

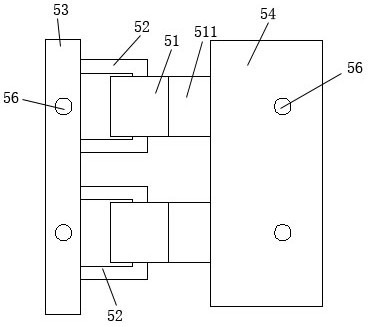

Hall circuit board fixing structure

PendingCN108462327AAchieve positioningAchieve fixationWindings insulation shape/form/constructionStructural associationFixed frameEngineering

The invention relates to a Hall circuit board fixing structure, and relates to the field of motors. Currently, a fixing mode of a brushless DC motor Hall circuit board is troublesome in installation.A Hall circuit board is disposed on a stator core, wherein the stator core is provided with a yoke, teeth and a slot hole, and an inner side between the teeth is a slot opening. The stator core is provided with a fixed frame. The Hall circuit board is fixed on the fixed frame, and the fixed frame is provided with a positioning and mounting structure of the Hall circuit board, a mounting frame forpositioning and mounting a Hall, and an insulating slot hole sleeve for isolating the stator core and a winding coil. The insulating slot hole sleeve covers the inner side surface of the yoke and theside surface and upper and lower end surfaces of the teeth, so that the slot hole is separated from the yoke and the teeth, and is opened at the slot opening. The structure improves the insulating property between a winding stator iron core coil and the stator core, is convenient to install, is firm in structure, and is good in stability.

Owner:WOLONG ELECTRIC GRP CO LTD +1

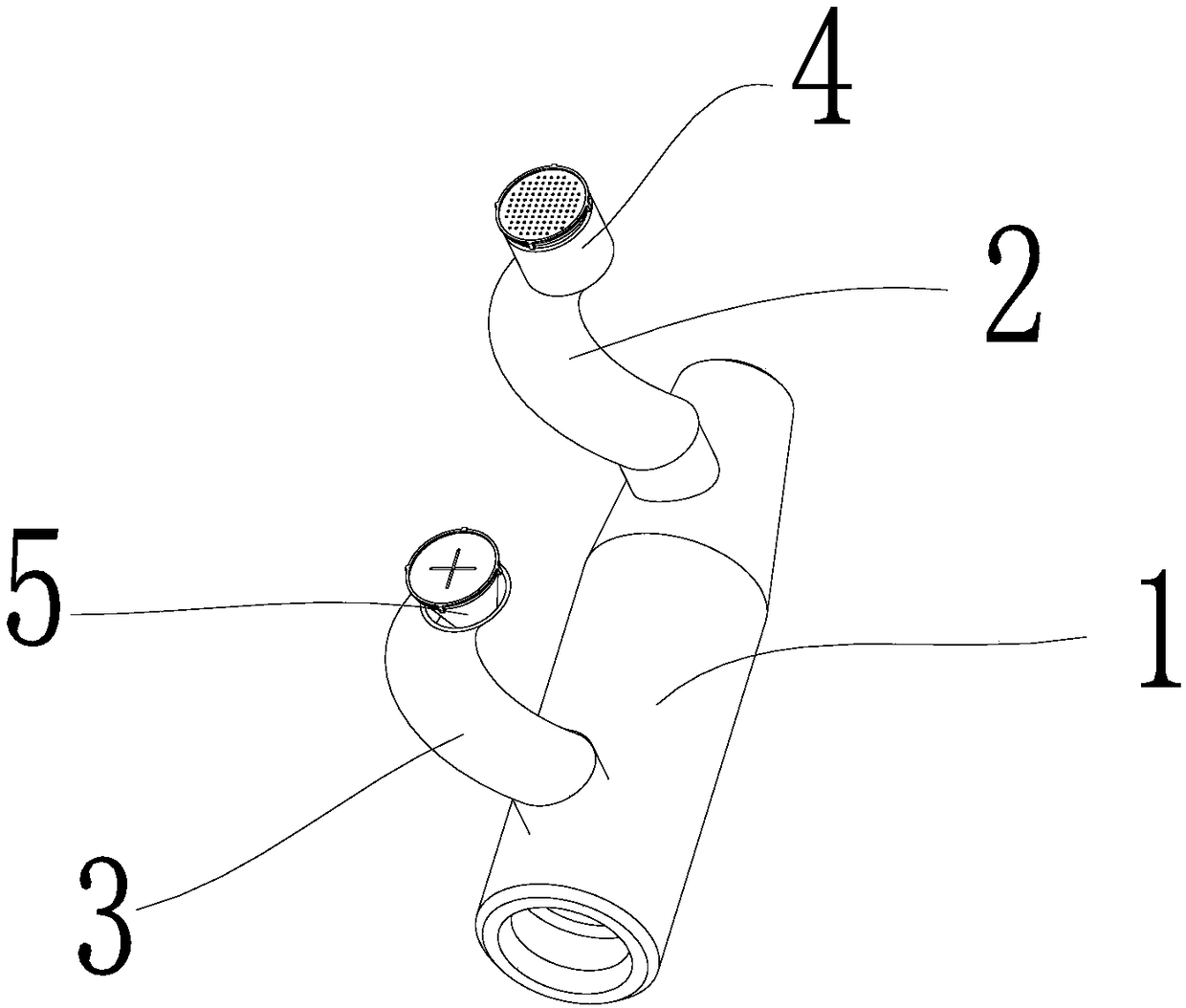

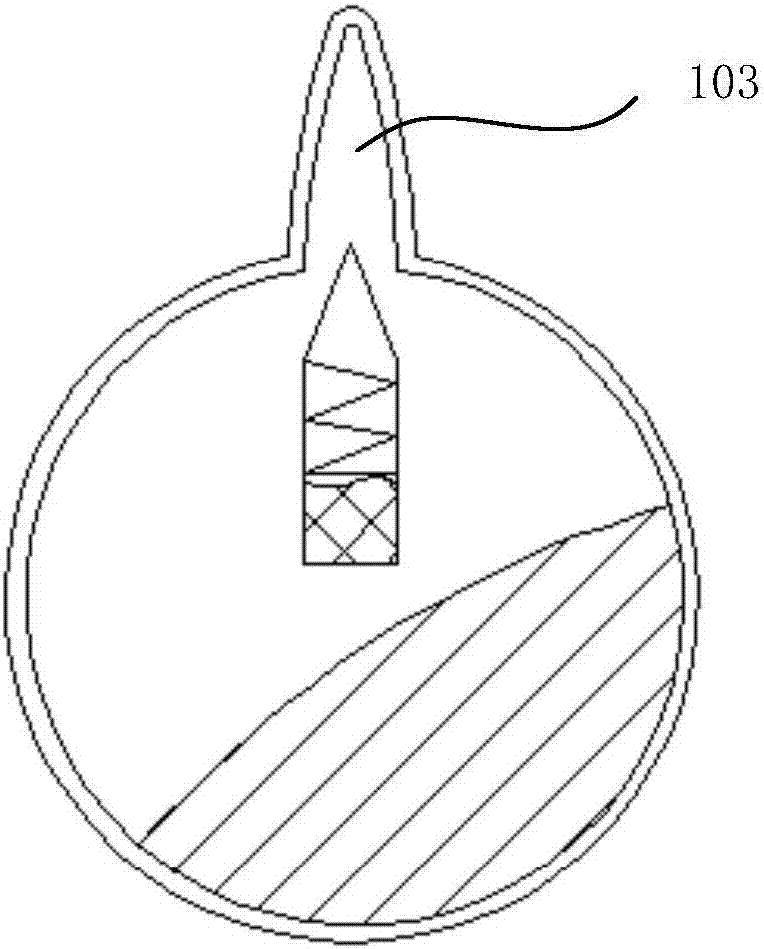

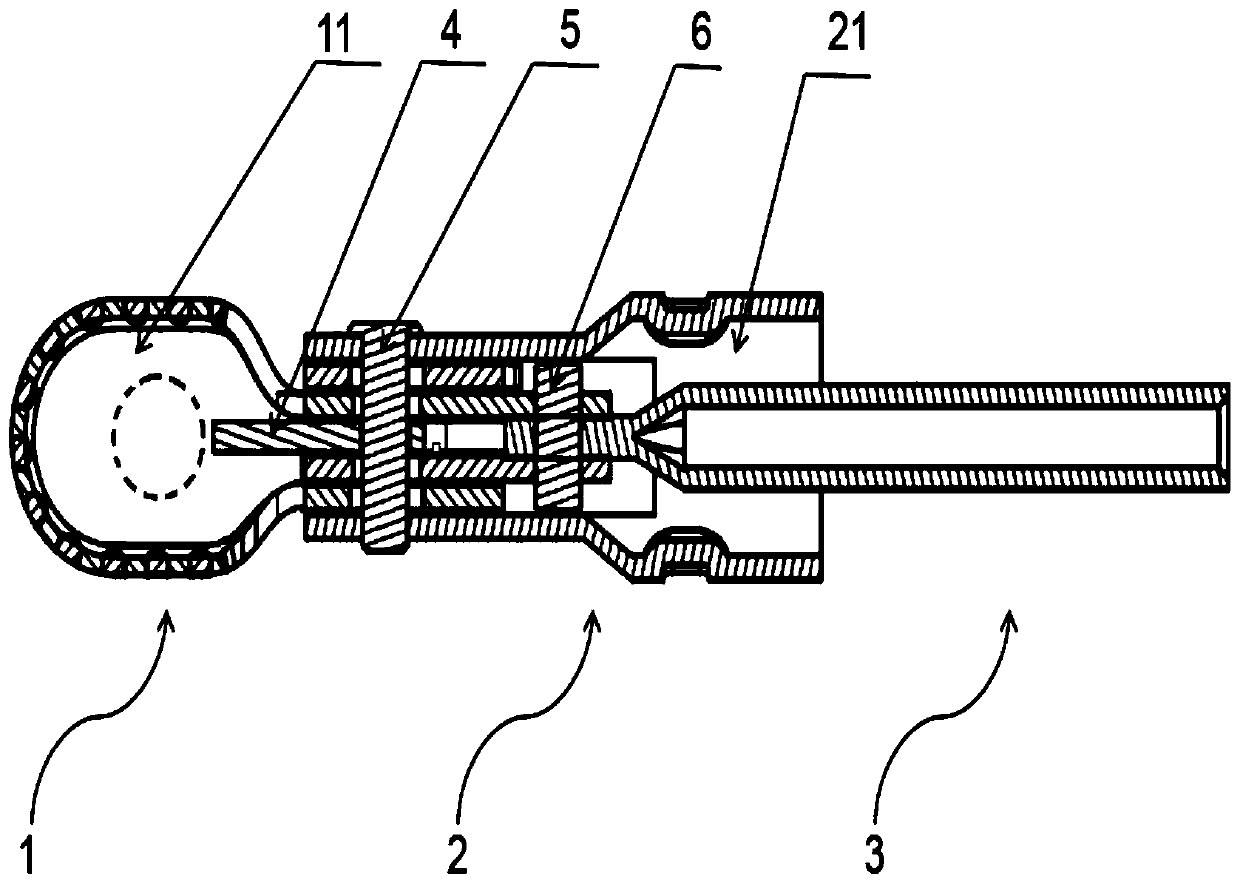

Guide tube for punching of intramedullary nail and punching device

The invention provides a guide tube for punching of an intramedullary nail and a punching device. The guide tube comprises a guide tube main body and a flexible bulge structure located at the far end. The punching device comprises the guide tube and a flexible drill. The flexible drill is located in the guide tube and used for penetrating through a nail hole in the intramedullary nail and then punching on a skeleton. According to the guide tube for punching of the intramedullary nail and the punching device, the nail hole can be found rapidly through the flexible bulge structure, meanwhile radial positioning is achieved, and thus the problems that an existing guide tube is only axially positioned, consequently, in the drilling process, the guide tube is deflected circumferentially and cannot keep consistent with the nail hole of the intramedullary nail, and thus the far end cannot be accurately locked are solved.

Owner:SHANGHAI MICROPORT MEDICAL (GROUP) CO LTD

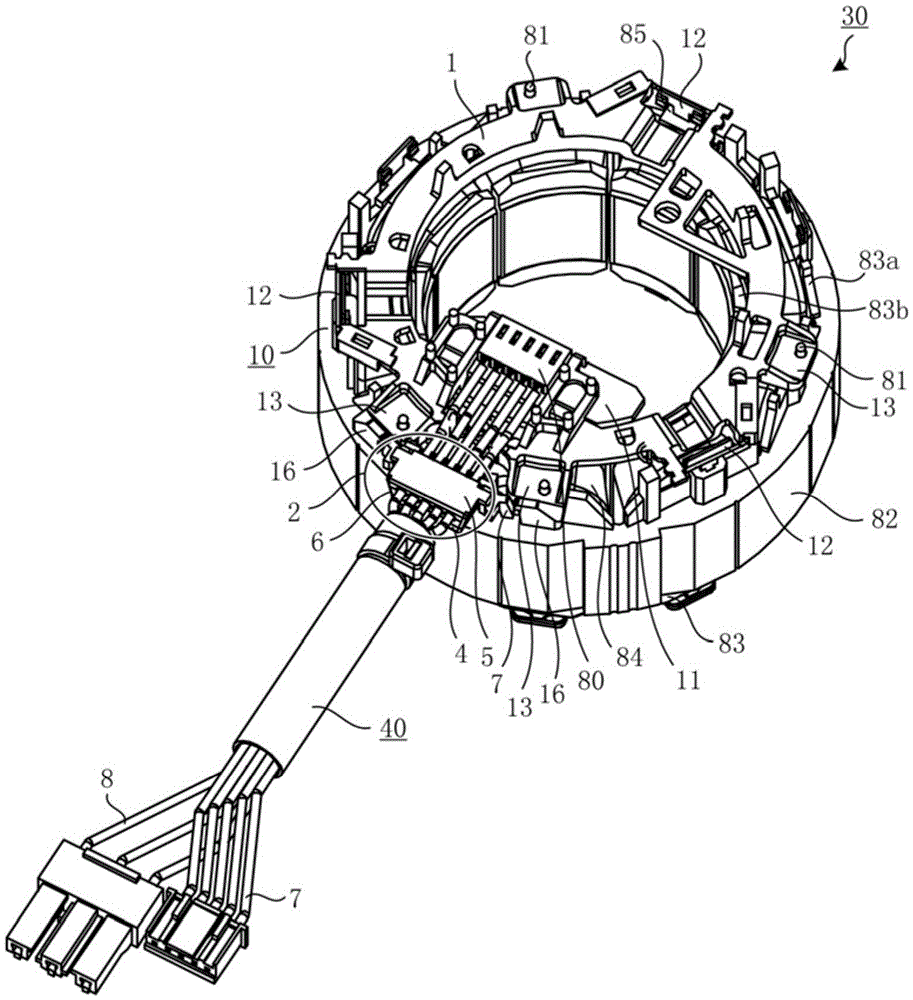

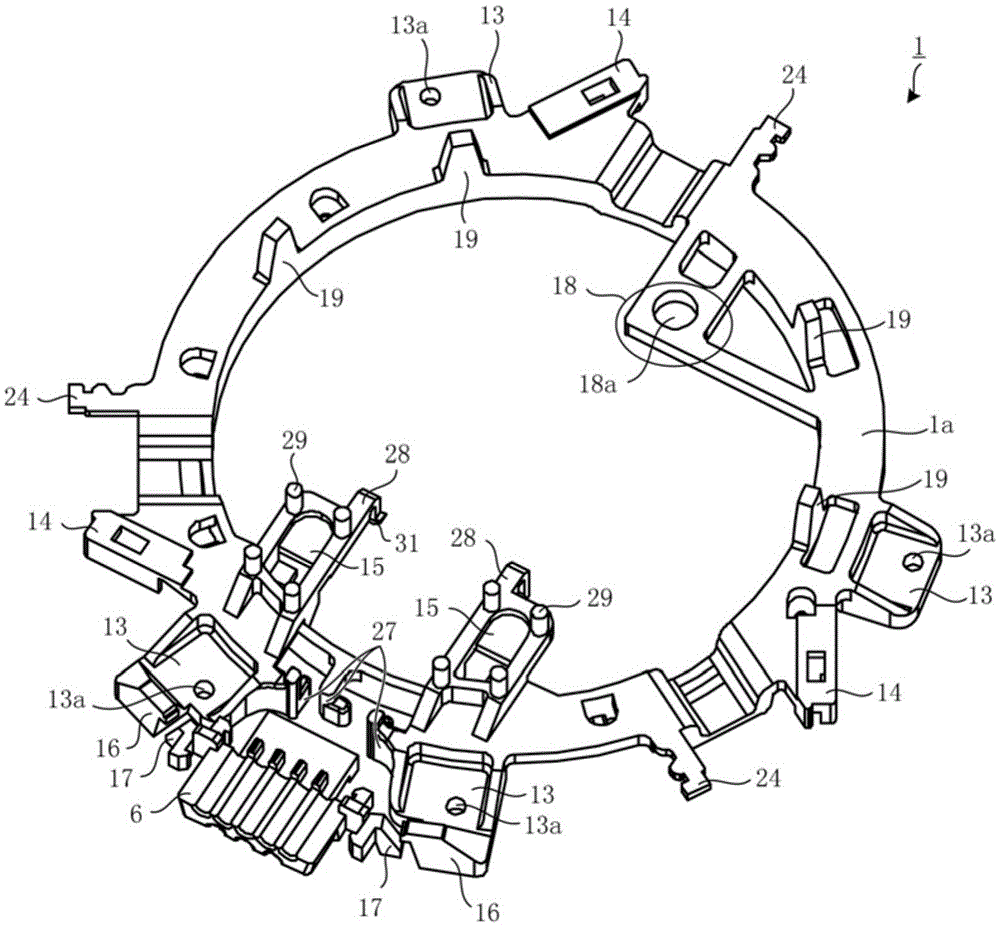

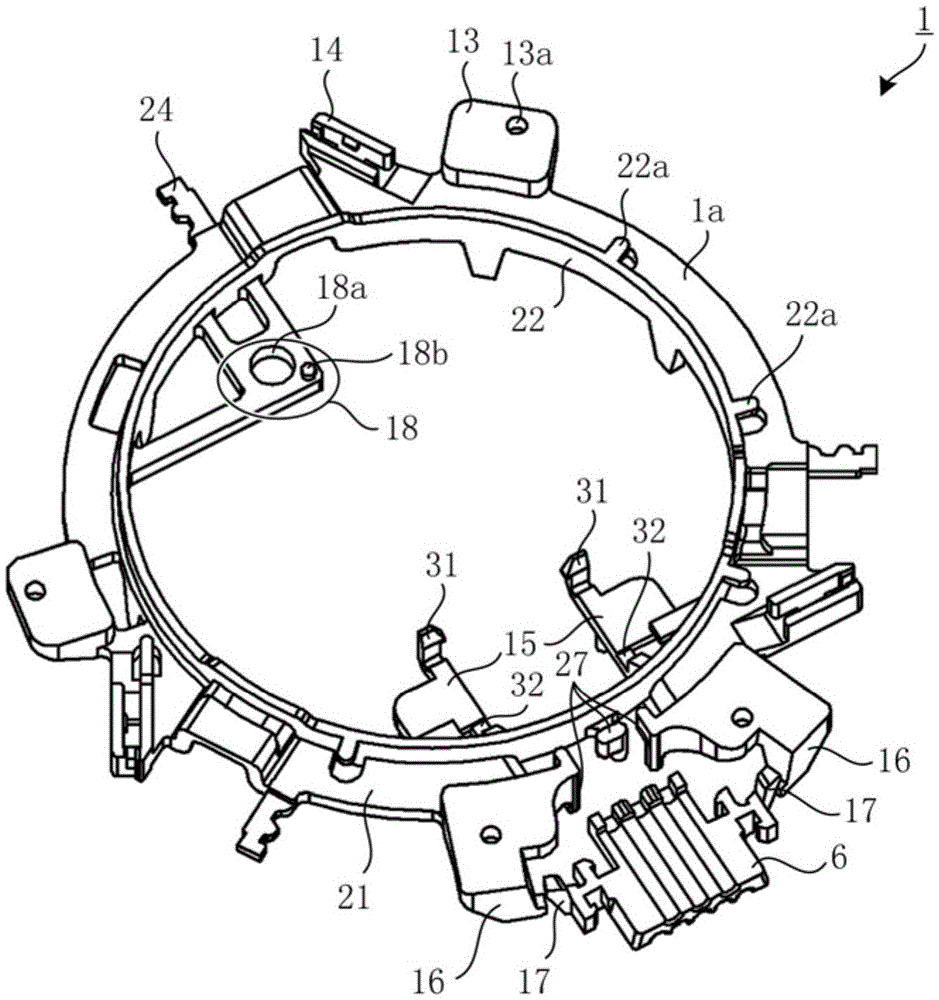

Molded stator, molded electric motor, and air conditioner

InactiveCN105637746AAchieve radial positioningWindingsLighting and heating apparatusLocation detectionEngineering

Owner:MITSUBISHI ELECTRIC CORP

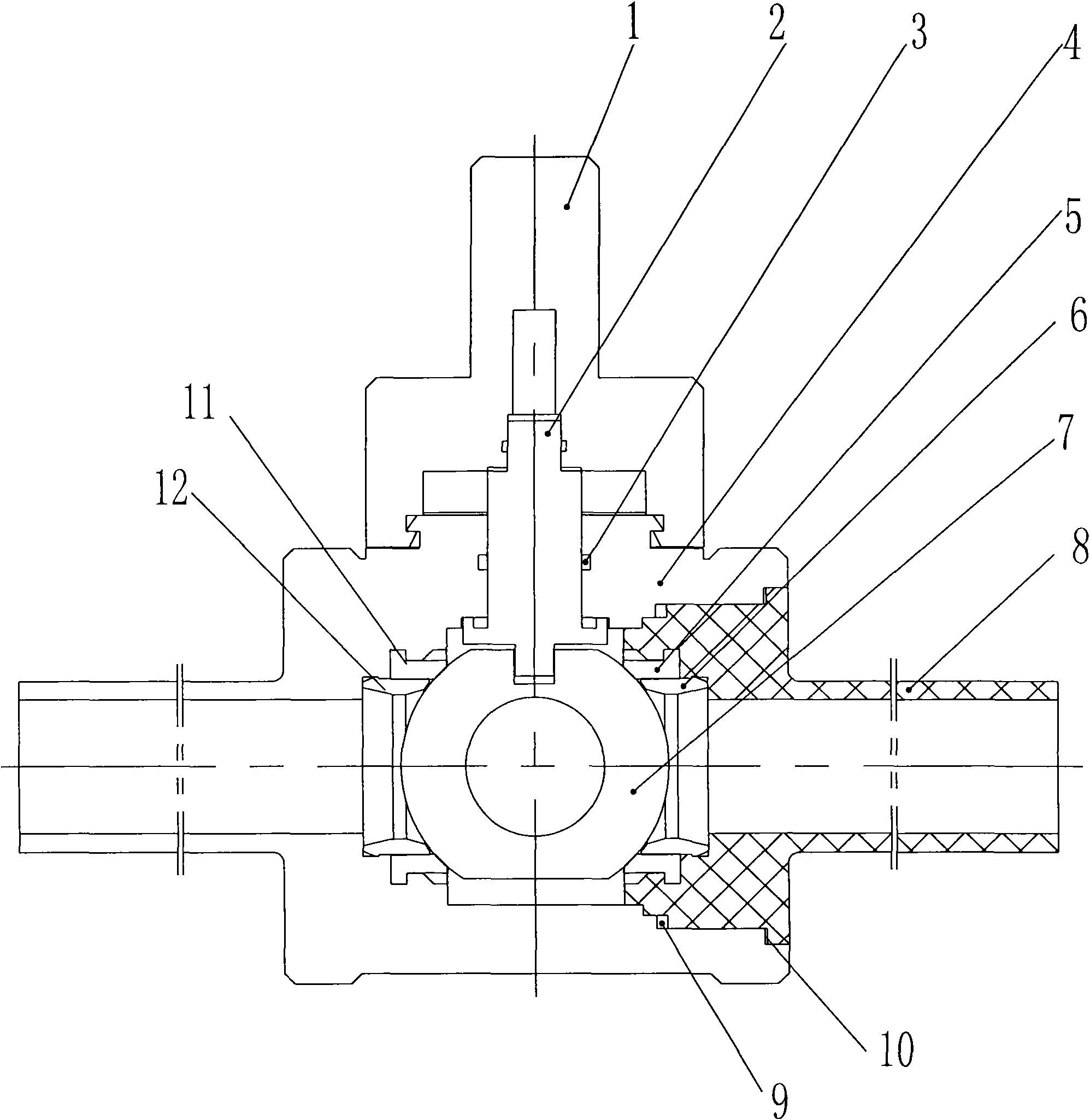

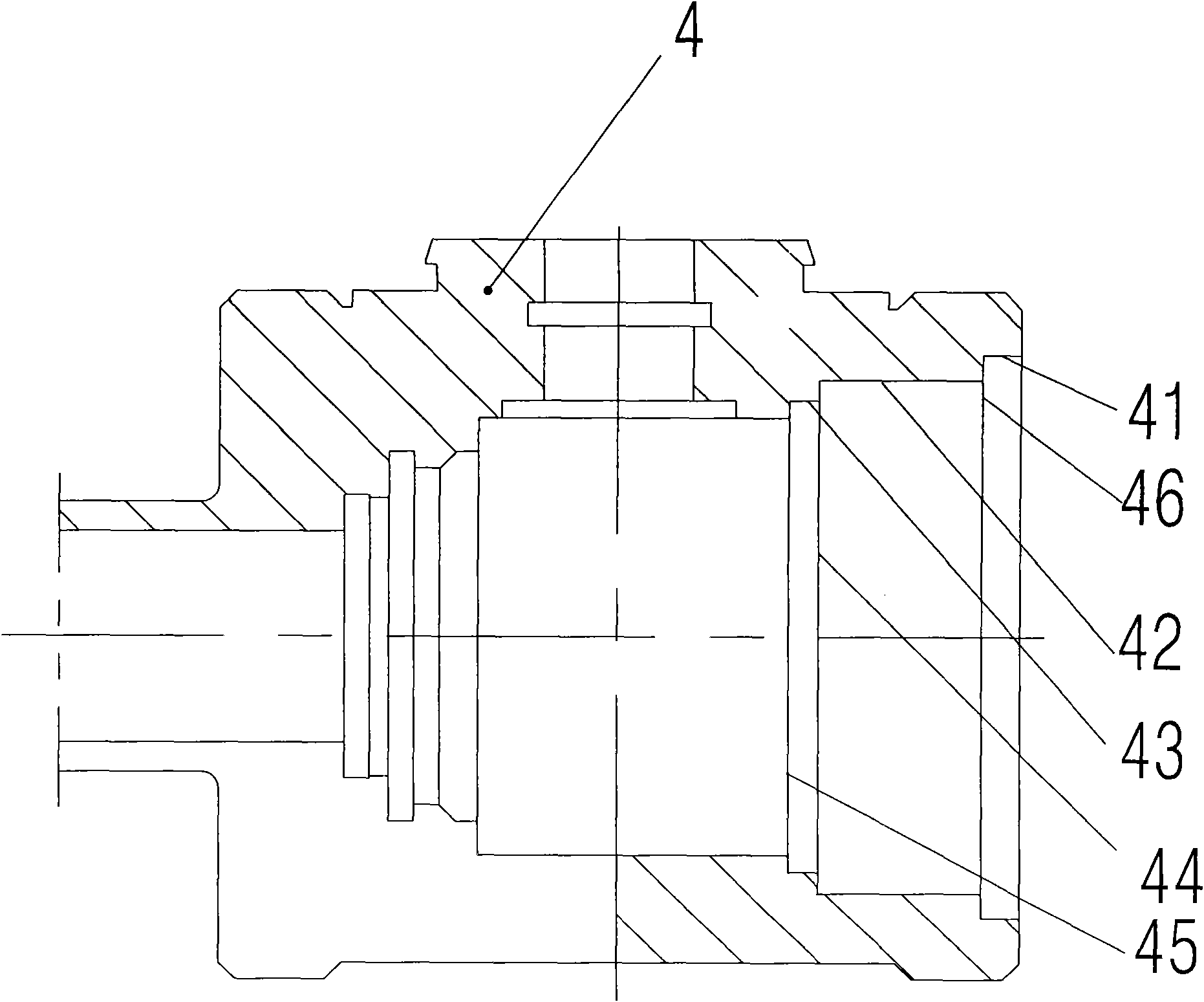

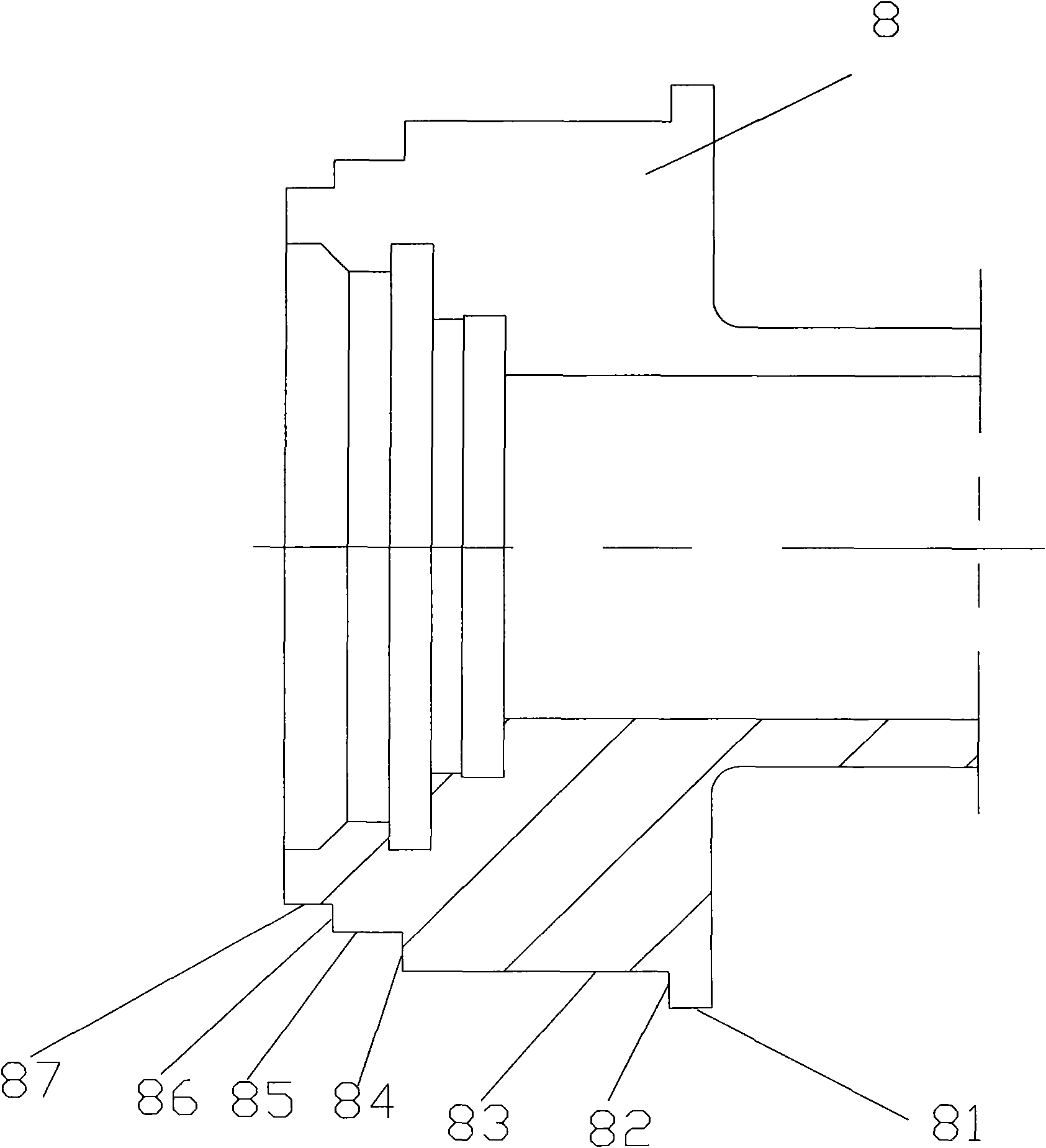

Polyethylene all-plastic ball valve formed by hot melt socket welding

ActiveCN101581376AConsistent preloadAchieve radial positioningSpindle sealingsPlug valvesBall valvePolyethylene

The invention relates to a pipeline cut-off valve, in particular to a polyethylene all-plastic ball valve formed by hot melt socket welding. The ball valve comprises a valve rod, a valve body, a valveball, a stub tube, a first valve ball sealing ring and a second valve ball sealing ring, wherein, the valve ball is arranged in the valve body, and the valve rod which rotates the valve ball is arranged thereon; the first valve ball sealing ring is fixed between the valve body and the valve ball, and the second valve ball sealing ring is fixed between the stub tube and the valve ball; the stub tube and the valve body are in hot melt socket-type connection, the inner surface of the insertion chamber of the valve body is provided with a melt glue surface of the valve body, and the outer surfaceof the stub tube is provided with a melt glue surface of the stub tube; and the valve body is matched with the stub tube and is provided with an axial positioning structure used for positioning the axial depth of the stub tube inserted into the valve body. The axial positioning structure of the invention guarantees the axial depth of the stub tube inserted into the valve body, thereby guaranteeing the axial spacing of sealing faces formed by the two valve ball sealing rings, and enabling the pretightening force of each sealing face to be consistent with the designed pretightening force.

Owner:GUANGDONG LIANSU TECH INDAL

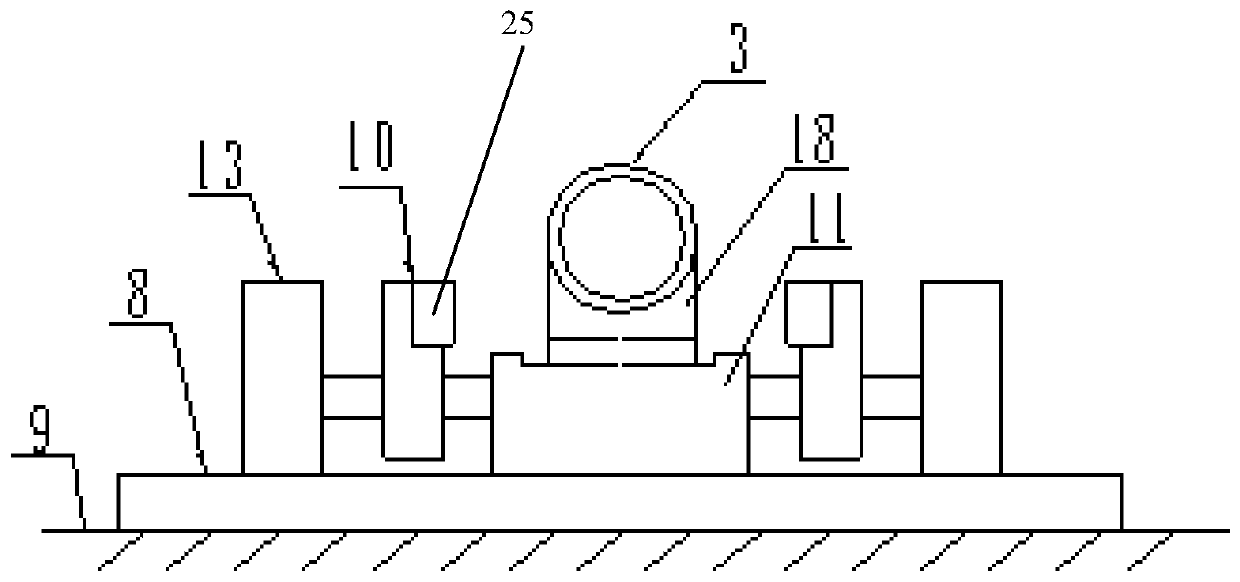

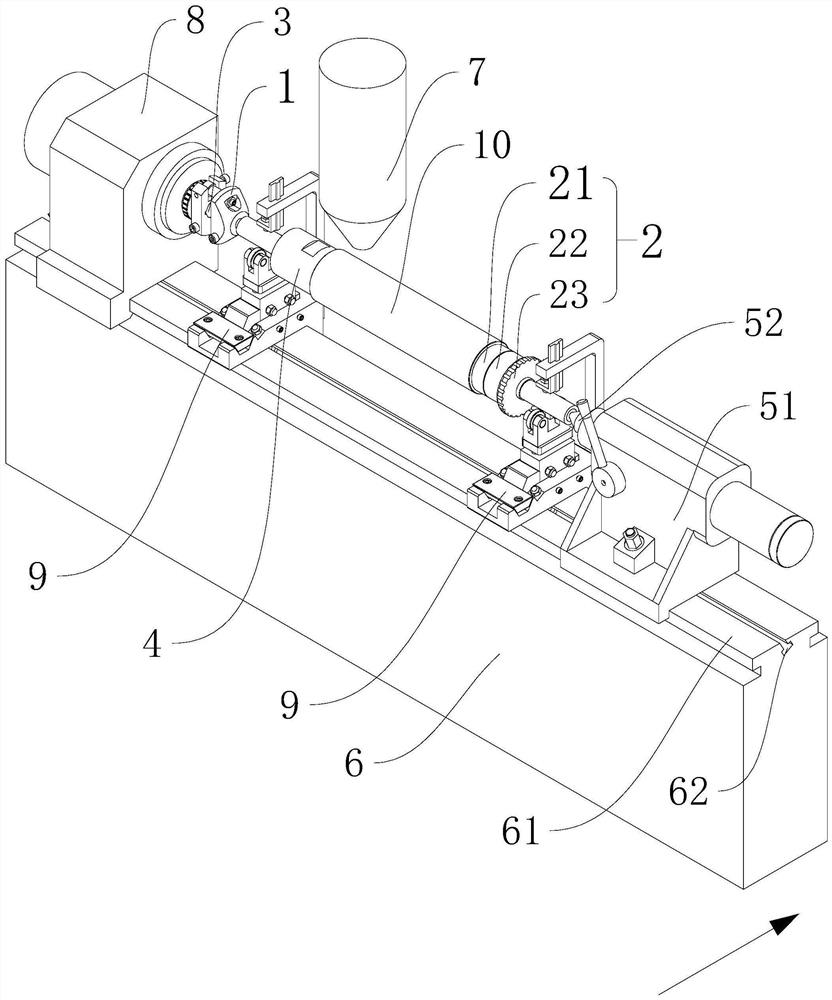

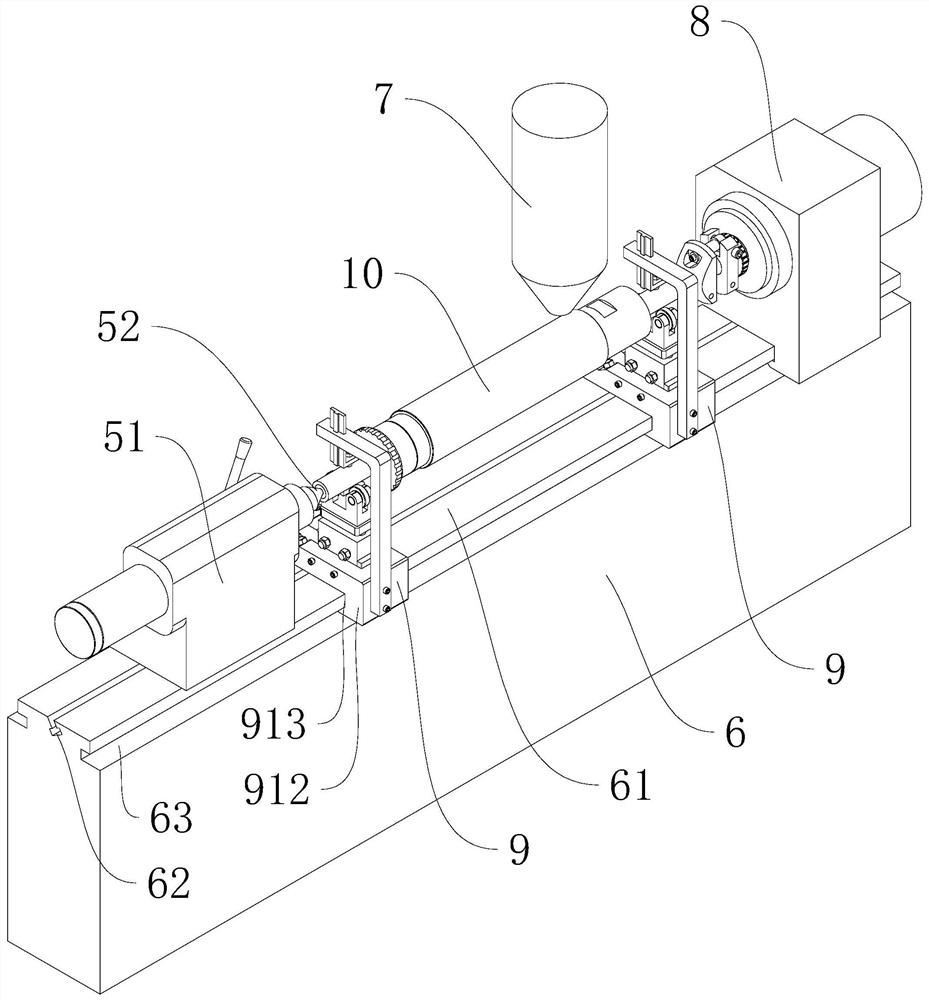

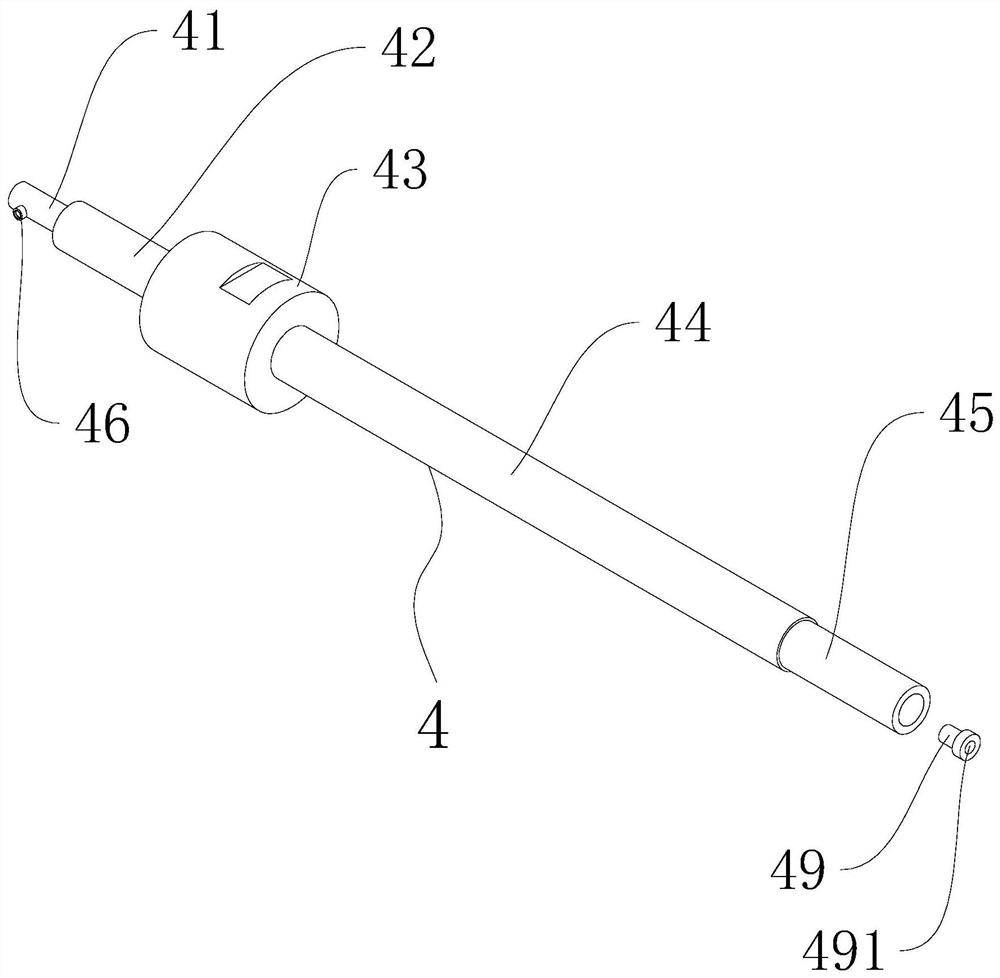

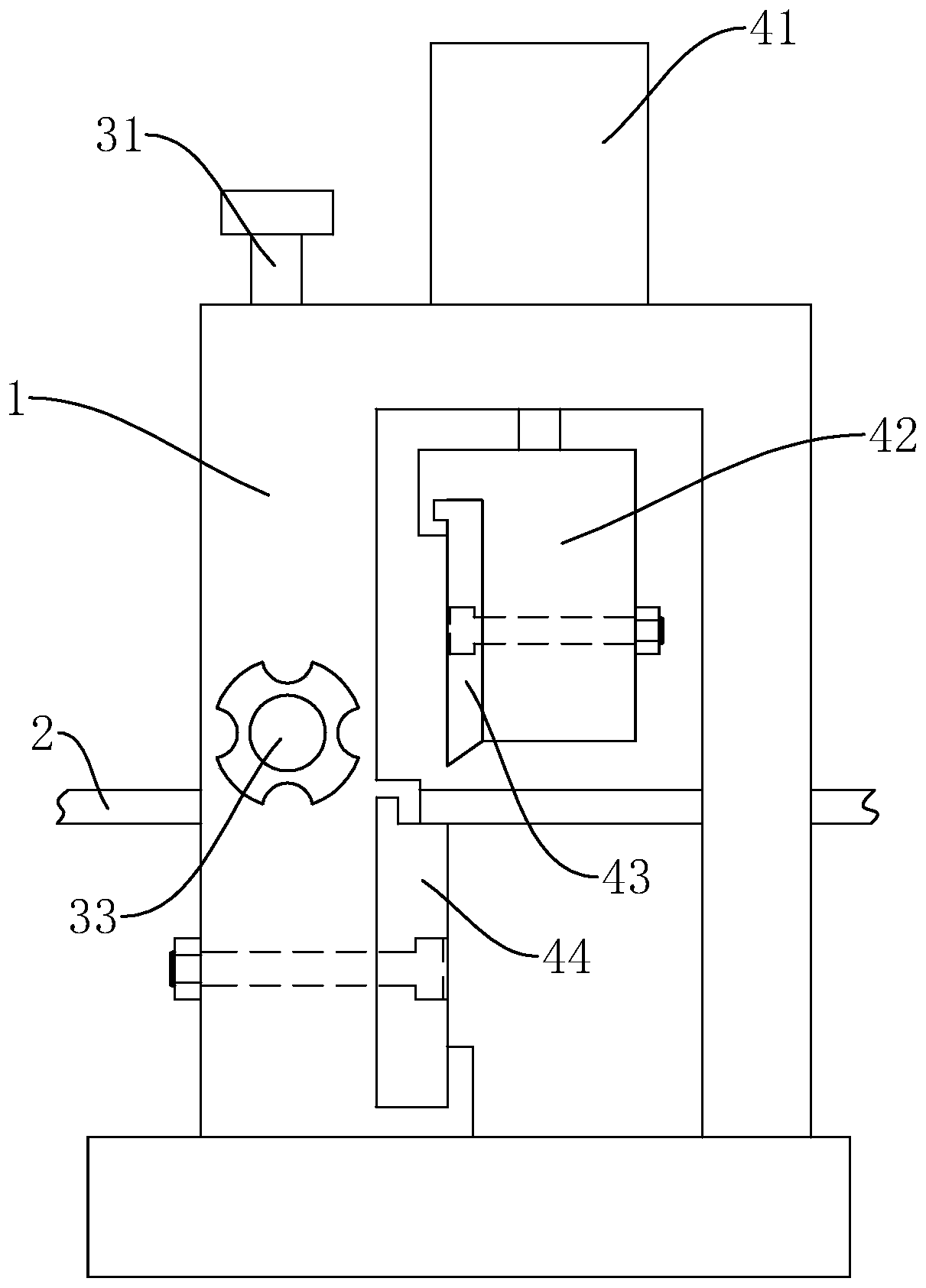

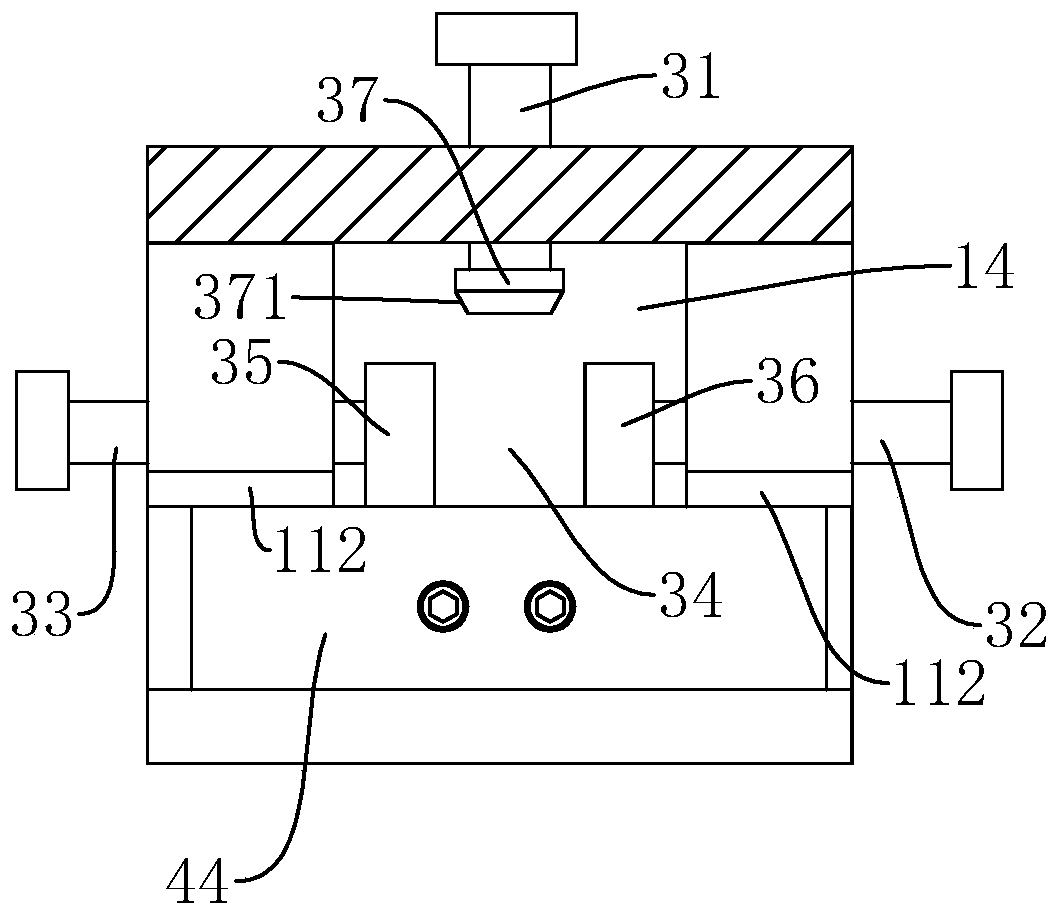

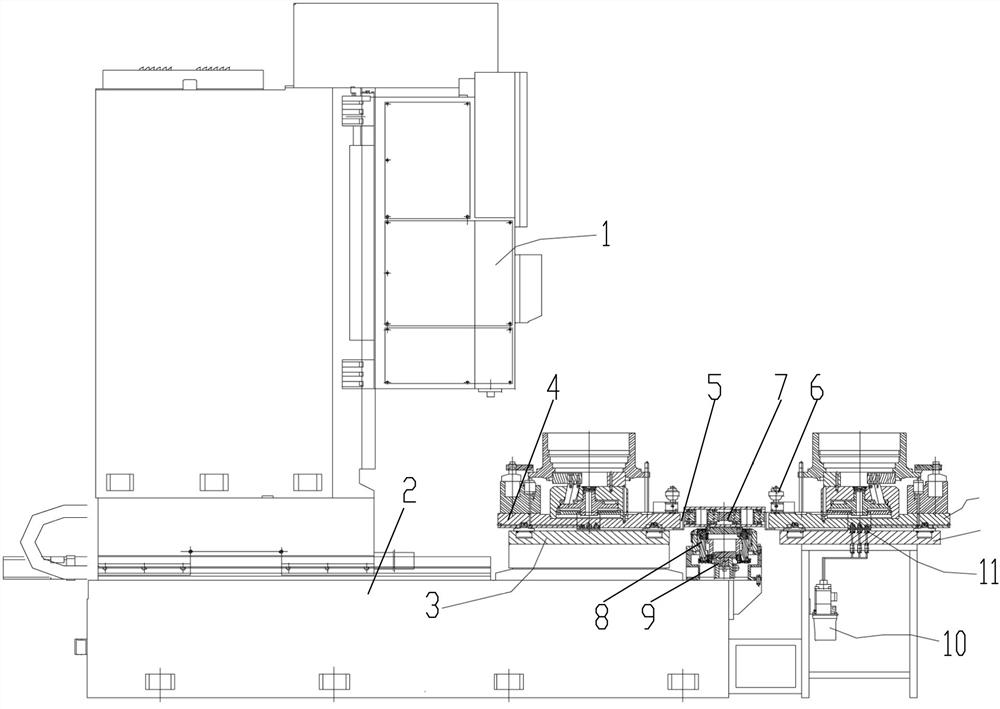

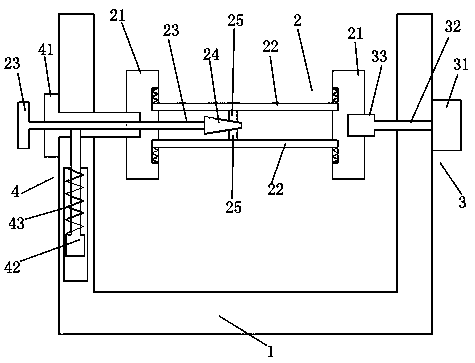

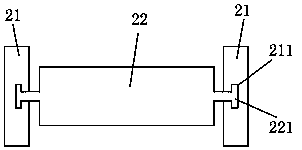

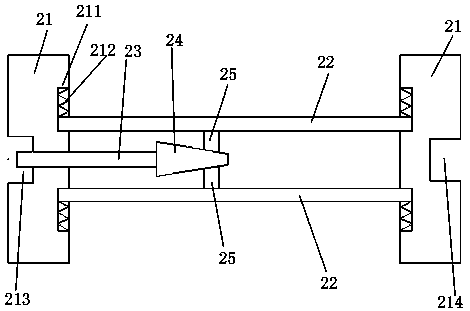

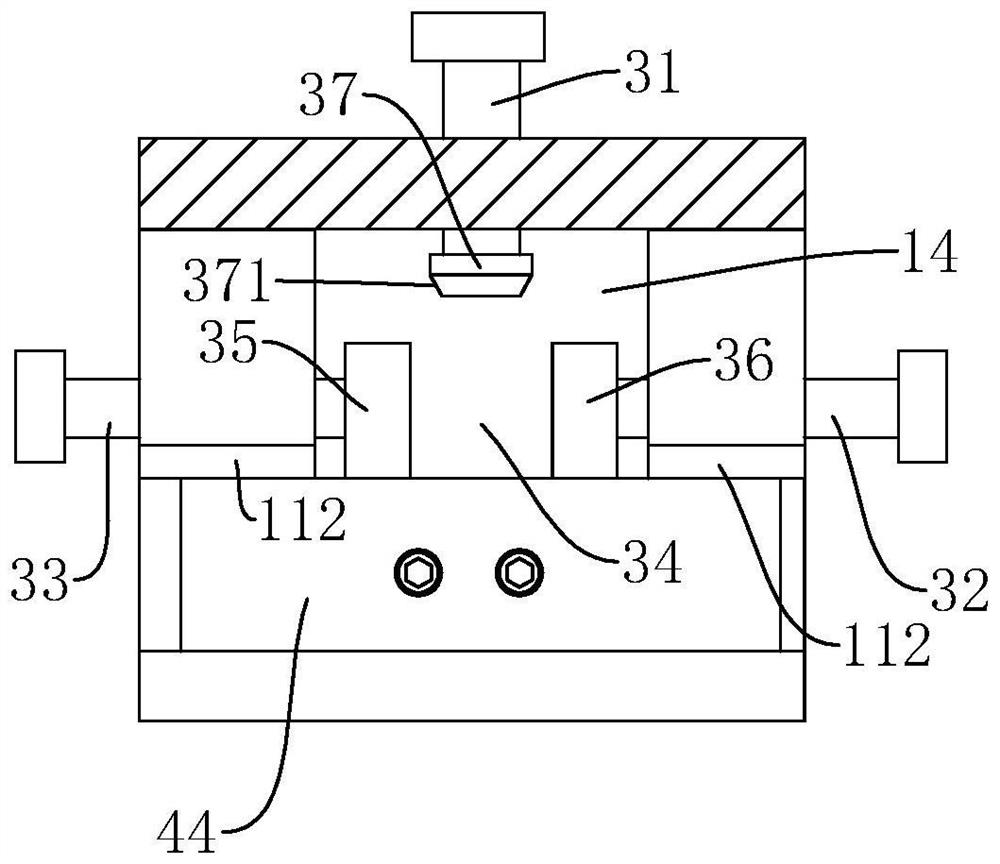

Indexing machining system for long-barrel-shaped workpiece

ActiveCN113385835AEliminates the effects of axial positioningReduce positioning offsetLaser beam welding apparatusEngineeringErbium lasers

The invention discloses an indexing machining system for a long-barrel-shaped workpiece. The indexing machining system comprises a lathe bed, a chuck mechanism, a positioning assembly, a horizontally-arranged indexing center, a mandrel and a tail center; an indexing driving device capable of moving transversely, a tailstock and a supporting device are arranged on the lathe bed, the indexing driving device is in driving connection with the indexing center, the tail center is fixedly arranged on the tailstock, and the indexing center is in transmission connection with the mandrel through the chuck mechanism. According to the indexing machining system for the long-barrel-shaped workpiece, radial positioning of the mandrel is completed through cooperation of the supporting device, the influence of the gravity of the mandrel and the long-barrel-shaped workpiece on indexing positioning is eliminated under the supporting effect of the supporting device, the indexing center and the tail center abut against one end of the mandrel correspondingly under cooperation of the indexing center and the tail center, the positioning deviation of the mandrel is greatly reduced, the mandrel, the indexing center and the tail center are located at the same coaxiality, axial positioning of the mandrel and the workpiece is achieved more accurately, and it is guaranteed that the machining position of a laser is accurate.

Owner:GUANGDONG ORIGINAL POINT INTELLIGENT TECH CO LTD

Fixture and lathe

InactiveCN112517946AAchieve radial positioningAchieve axial positioningChucksStructural engineeringMechanical engineering

The invention provides a fixture and a lathe, relates to the technical field of machining equipment, and aims to optimize the structure of the fixture to a certain extent and improve the machining precision and quality of an inner static ring. The fixture provided by the invention is used for positioning the inner static ring, and comprises a fixture main body, first limiting pieces and a first fastening assembly, wherein a bearing part is formed on one axial side of the fixture body in the circumferential direction of the fixture body; the bearing part enables the fixture main body to form apositioning table; the positioning table is sleeved with the inner static ring; one side of the inner static ring makes contact with the bearing part; a plurality of first positioning holes are formedin the axial direction and the circumferential direction of the positioning table; one end of each first limiting piece makes contact with the inner static ring; the first fastening assembly penetrates through the other end of each first limiting piece and enters the first positioning holes; and the first limiting pieces are pressed on the positioning table, so that the first limiting pieces canpress the inner static ring on the fixture main body.

Owner:南京高精轨道交通设备有限公司

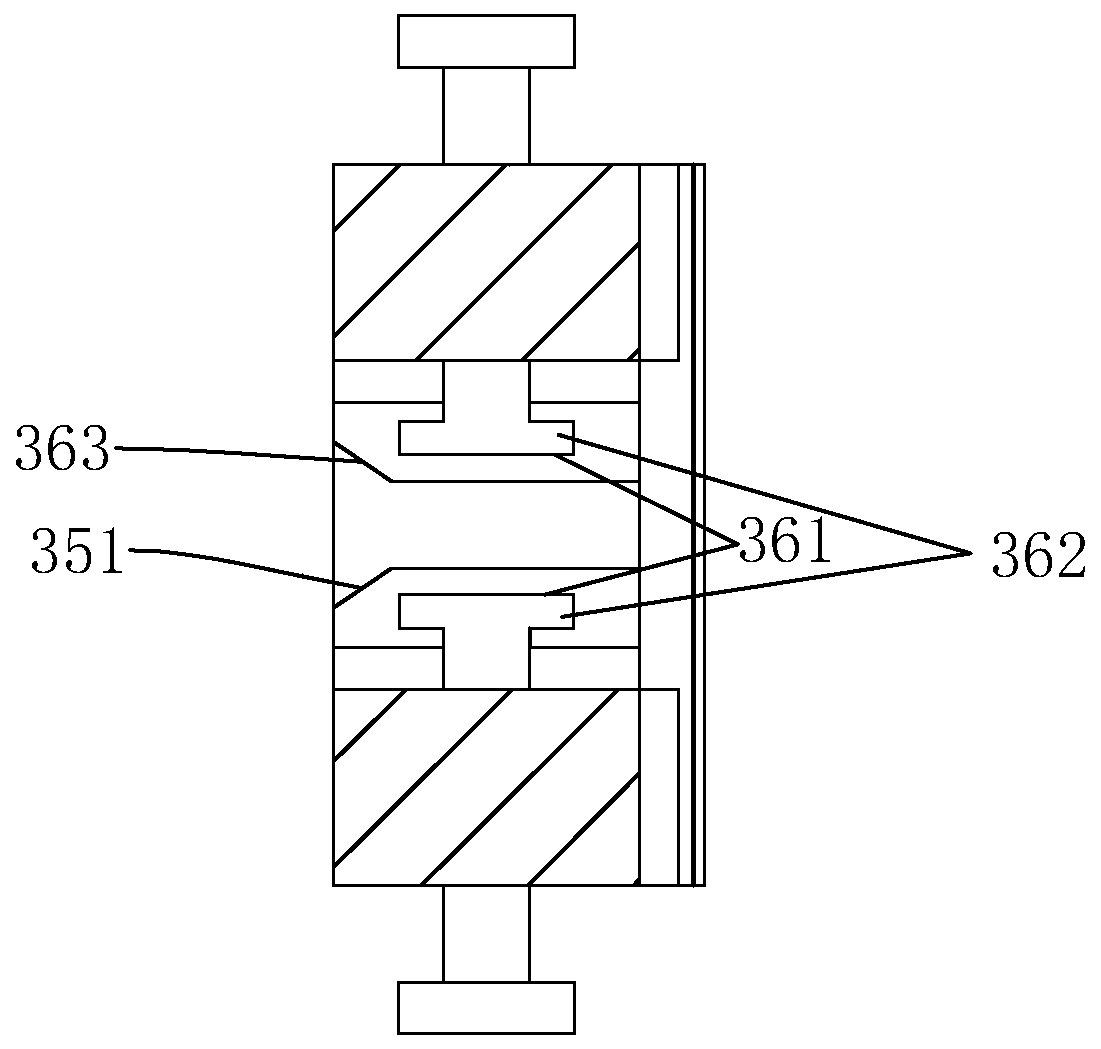

Cutting device of straightening cutting machine

ActiveCN111001731AAchieve radial positioningCrop stabilizationStructural engineeringMechanical engineering

The invention discloses a cutting device of a straightening cutting machine. The cutting device is characterized by comprising a frame body, a workpiece limiting mechanism, a fixed cutter and a movable cutter mechanism, wherein the frame body comprises a vertical plate and a top plate, a workpiece channel is formed on the vertical plate, the workpiece limiting mechanism comprises a left adjustingrod, a right adjusting rod and an upper adjusting rod, the left adjusting rod, the right adjusting rod and the upper adjusting rod are in threaded fit with a left side wall, a right side wall and a top wall of the workpiece channel correspondingly, first ends of the left adjusting rod, the right adjusting rod and the upper adjusting rod are all located in the workpiece channel and form a limitingchannel, the fixed cutter is installed on a back face of the vertical plate, a cutting edge of the fixed cutter and a low point of the limiting channel are located on the same horizontal line, the movable cutter mechanism comprises a movable cutter and an oil cylinder, and the oil cylinder is installed on the top plate and connected with the movable cutter so as to drive the movable cutter to moverelative to the fixed cutter. The cutting device is advantaged in that the cutting quality of a workpiece can be improved, the service life of the cutting knife can be prolonged, and a replacement period of the cutting knife is shortened.

Owner:嘉兴凯鑫五金科技股份有限公司

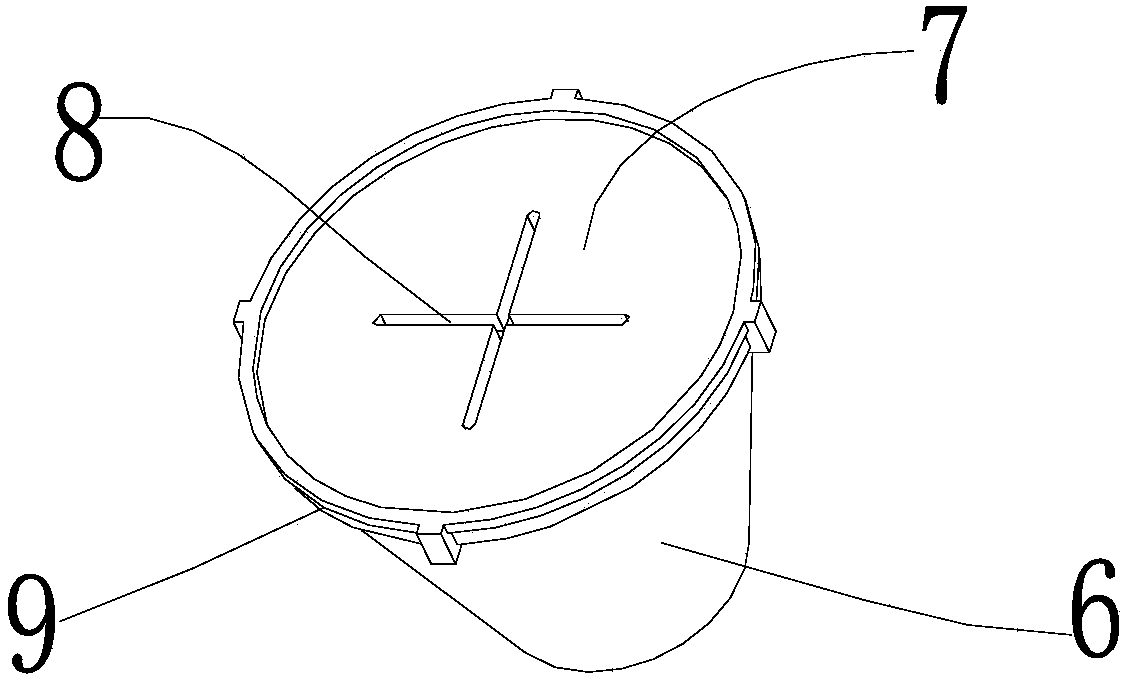

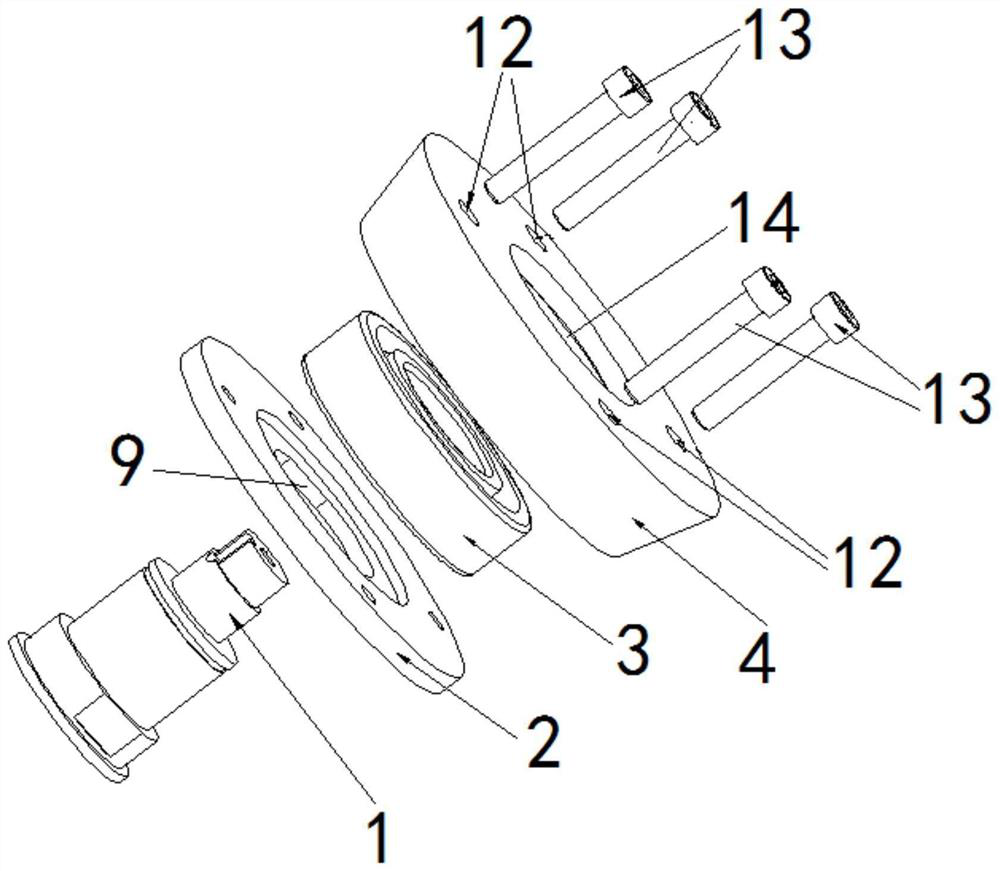

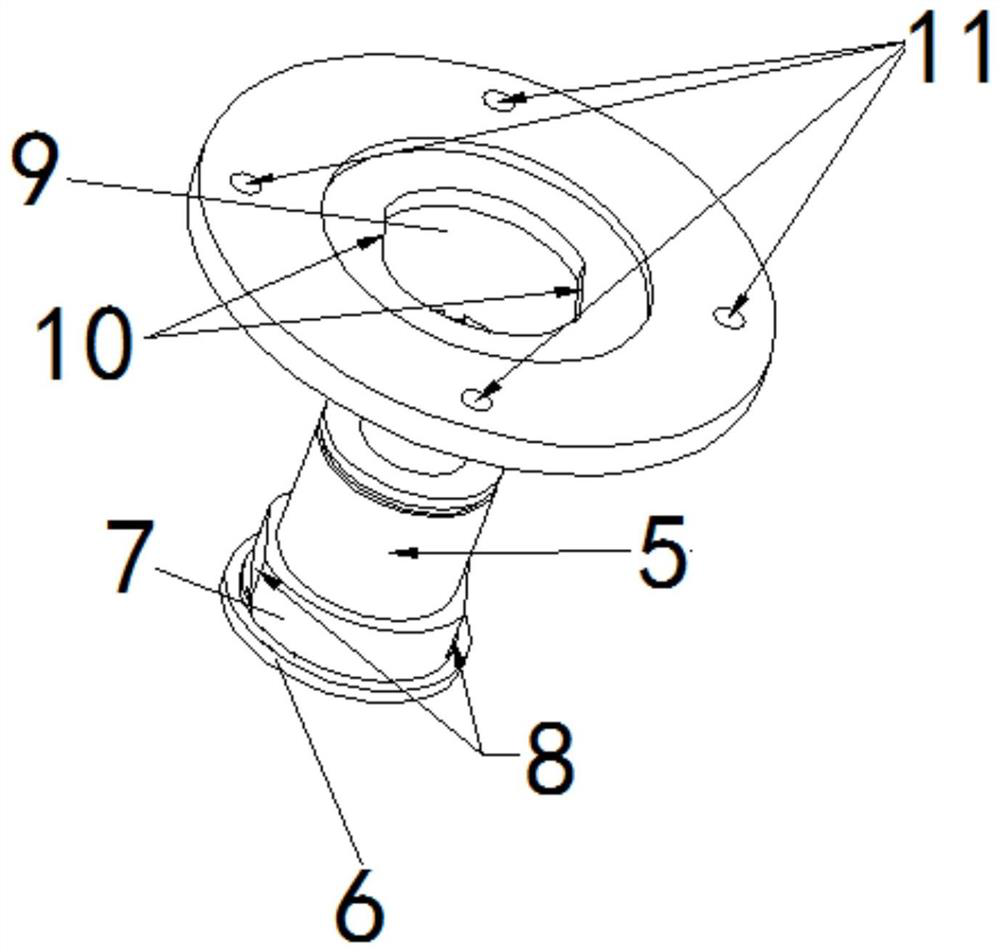

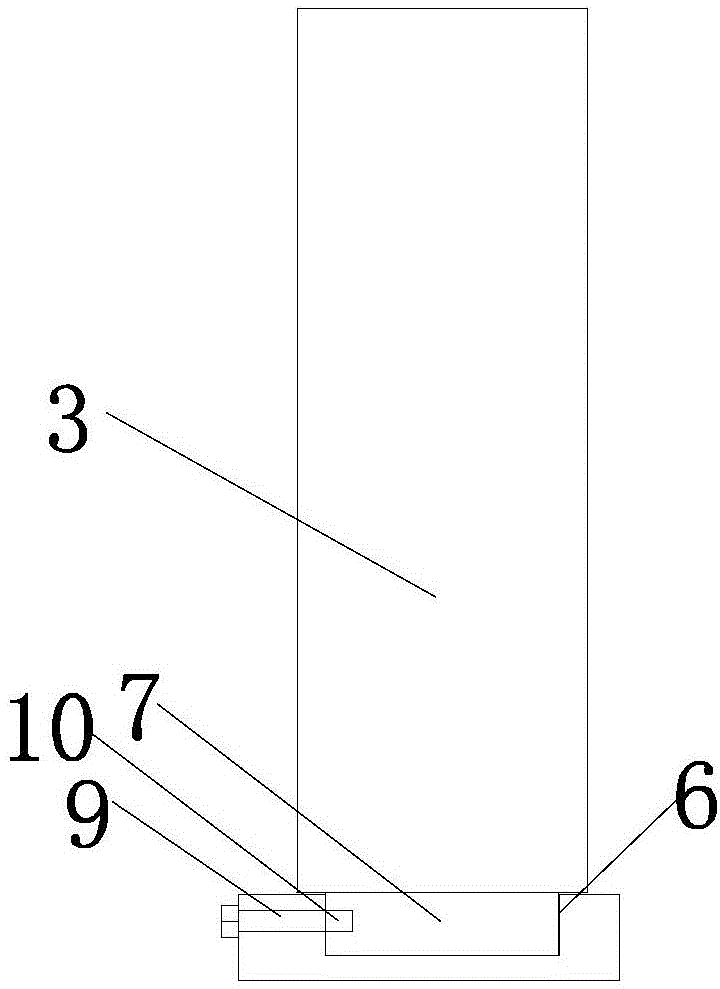

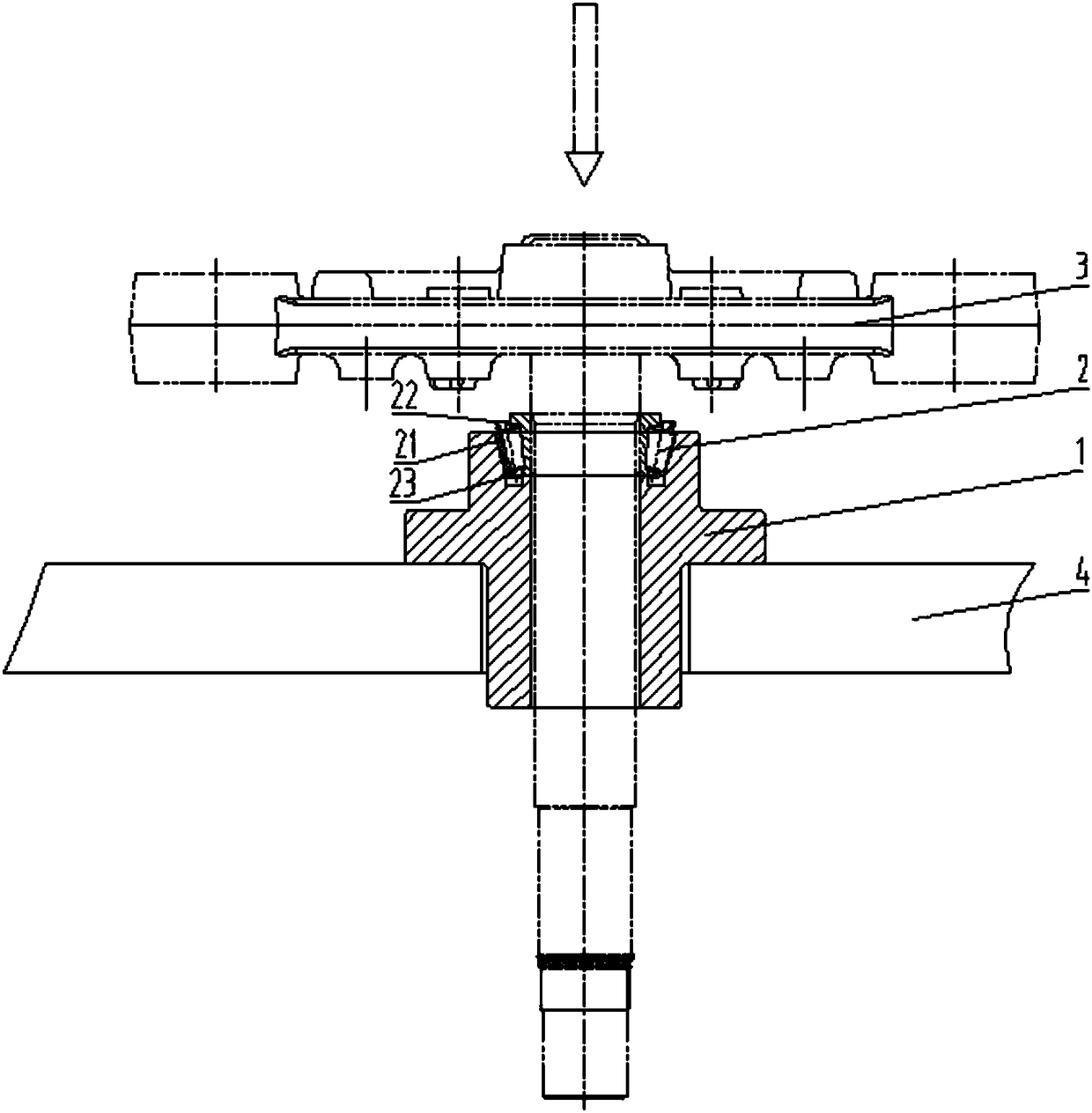

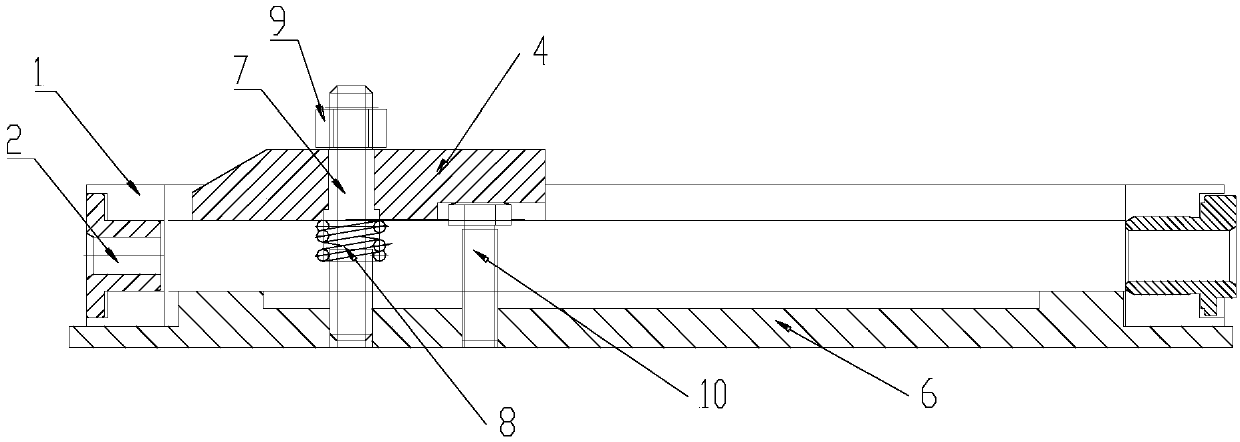

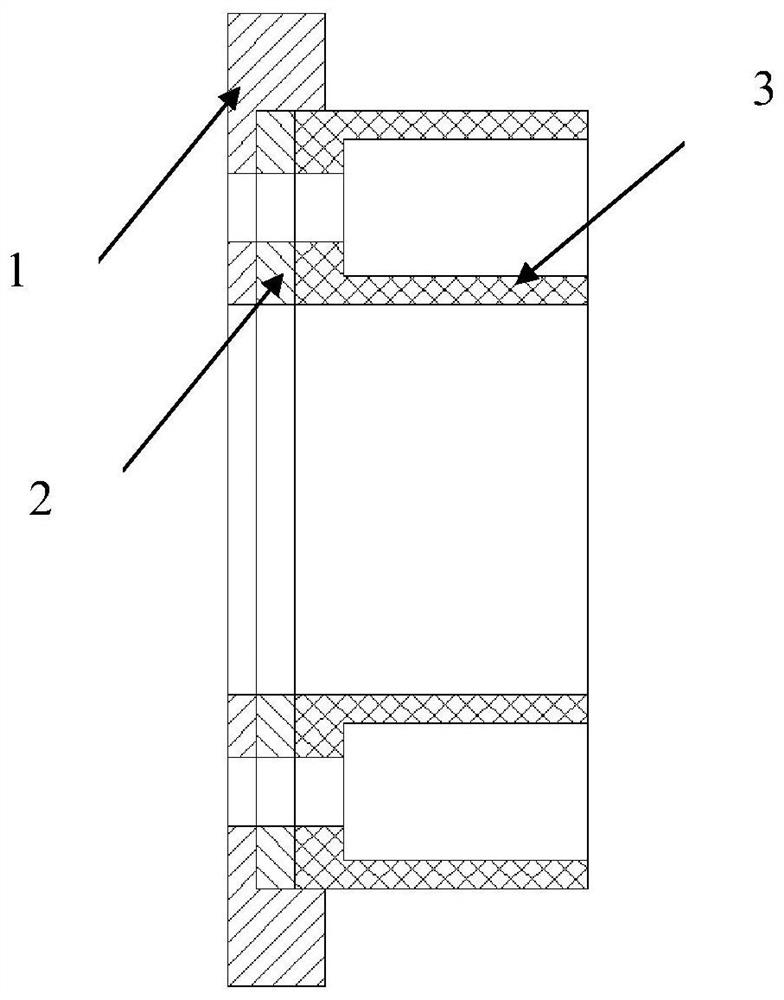

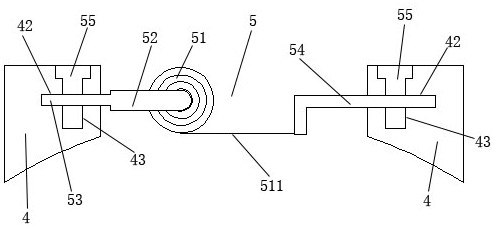

New energy automobile driving integrated system motor structure

PendingCN111987839AAchieve radial positioningEasy to assembleMechanical energy handlingSupports/enclosures/casingsNew energyElectric machinery

The invention provides a new energy automobile driving integrated system motor structure applied to the technical field of new energy automobiles. The new energy automobile driving integrated system motor structure comprises a motor rotating shaft (1), a bearing pressing plate (2), a bearing (3) and a motor rear end cover (4). A bearing chamber is arranged on one side of the motor rear end cover (4). The motor rotating shaft (1) comprises a bearing assembling part (5) and a bearing end face (6), a pressing plate installing part (7) is arranged between the bearing assembling part (5) and the bearing end face (6), a bearing step face (8) is arranged at the pressing plate installing part (7), a middle through hole (9) is formed in the bearing pressing plate (2), and a pressing plate step face(10) is arranged at the middle through hole. The new energy automobile driving integrated system motor structure is simple in structure, the bearing pressing plate is convenient to install in the newenergy automobile drive integrated system motor, the installation process is simplified, and the installation efficiency is improved.

Owner:安徽鸿创新能源动力有限公司

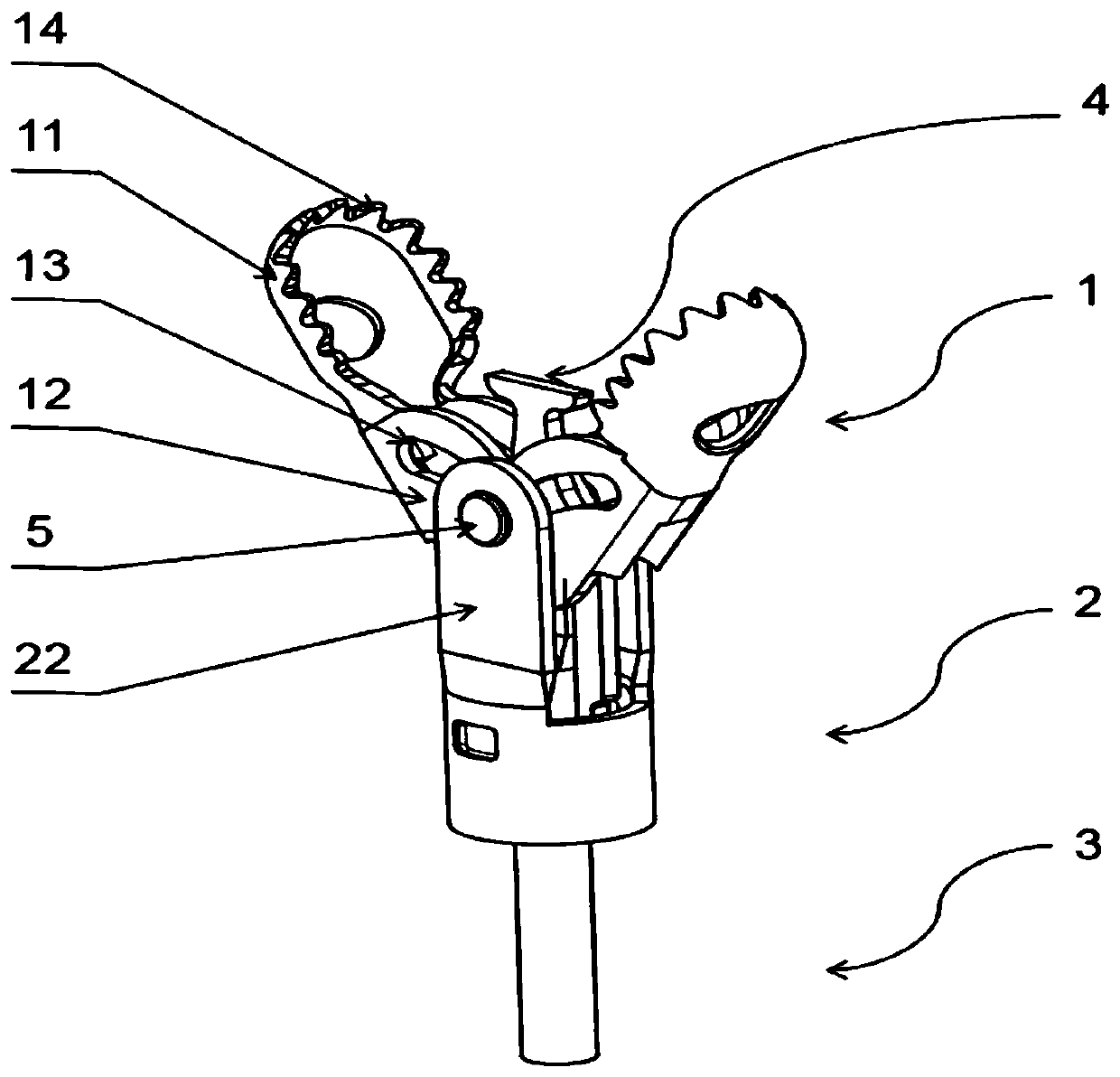

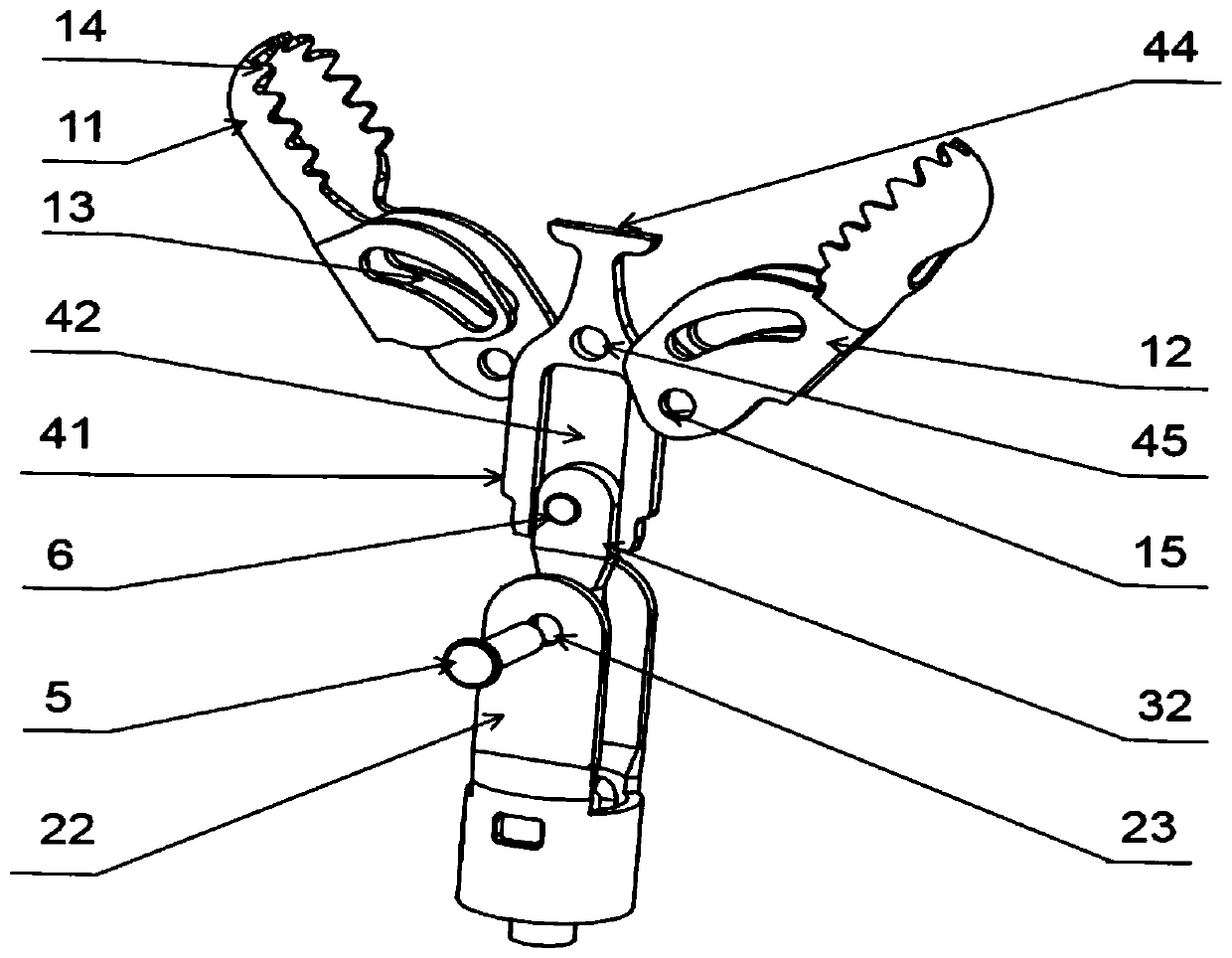

Disposable biopsy forceps

PendingCN110876631AStable positionSimple structureSurgeryVaccination/ovulation diagnosticsEngineeringBiopsy forceps

The invention relates to a disposable biopsy forceps, which at least comprise the following structures: a forceps head assembly which comprises at least two forceps heads of which the far ends can beoppositely opened or closed; a forceps seat, wherein the near end of the forceps head is connected with the far end of the forceps seat through a connecting piece; a control line, wherein the far endof the control line is connected with the near end of the forceps head assembly so as to drive the forceps head assembly to be opened or closed; a gasket, wherein the far end side of the gasket is connected with the forceps seat through the connecting piece, the near end side of the gasket is provided with two extension parts which are oppositely arranged and extend towards the near end, an extension channel is formed between the two extension parts, and the far end of the control line moves in the extension channel. The biopsy forceps have the technical effects of being simple in structure, stable and reliable.

Owner:MICRO TECH (NANJING) CO LTD

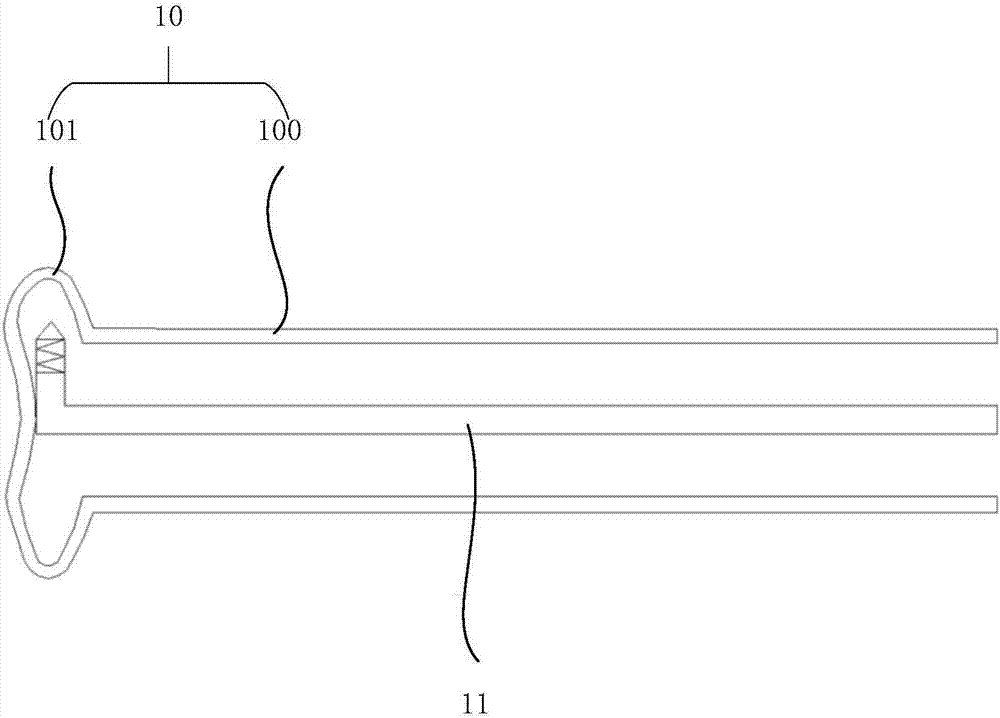

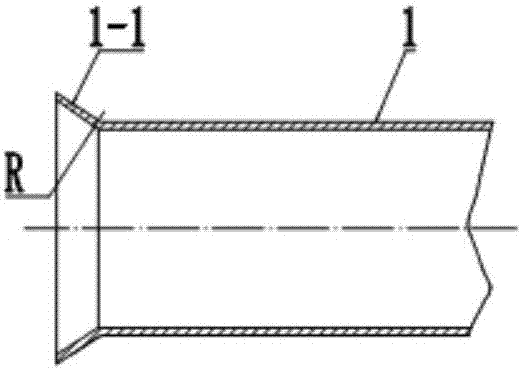

Conduit expanding part arc radius detection device

InactiveCN107218872AAvoid damageGuaranteed reliabilityMechanical diameter measurementsEngineeringInverted t

The invention provides a conduit expanding part arc radius detection device, and belongs to the technical field of test and measurement. The conduit expanding part arc radius detection device comprises a workpiece locating base and a detection sample plate. The workpiece locating base is provided with a workpiece locating mechanism and a sample plate guiding mechanism. The workpiece locating mechanism is an inverted V-shaped groove of which the opening is downward. The sample plate guiding mechanism is a slide groove hole which is arranged on the workpiece locating mechanism. The central locating surface of the slide groove hole is overlapped with the central locating surface of the V-shaped groove. The detection sample plate is assembled in the slide groove hole. The detection sample plate has an inverted T-shaped structure and is provided with a guiding handle and a pressing plate which are mutually perpendicular. The guiding handle penetrates into the slide groove hole of the workpiece locating base. The bottom surface of the pressing plate is provided with a detection cutting edge which is matched with the axial cross section external contour dimension of the standard conduit workpiece expanding part. Radial locating of the detected conduit can be realized so that the arc curve of the detection sample plate and the central axis of the detected conduit are ensured to be in the same plane, and the reliability of the detection result can be enhanced.

Owner:FACTORY 5721 OF PLA

Large-outer-diameter pin clamp

InactiveCN104551765AAchieve radial positioningAchieve clampingPositioning apparatusMetal-working holdersBiomedical engineering

The invention relates to the technical field of mechanical clamping, in particular to a large-outer-diameter pin clamp. A first limit device comprises a first V-shaped limit block arranged on the vertical portion of a support; a second limit device comprises a supporting column, and a second V-shaped limit block is arranged on the supporting column and corresponds to the first V-shaped limit block; a third limit device comprises a support nail arranged on the transverse portion of a base, the nail head of the support nail faces downwards, and the nail point of the support nail faces upwards; a slide groove is arranged among the supporting column, the nail head of the support nail and the transverse portion of the support; a first slide rail matched with the slide groove is arranged on the bottom surface of the support column, and the bottom surface of the nail head of the support nail is provided with a second slide rail cooperatively used with the slide groove. The large-outer-diameter pin clamp can be used for clamping pin parts large in outer diameter and is firm in clamping.

Owner:TERRENCE ENERGY

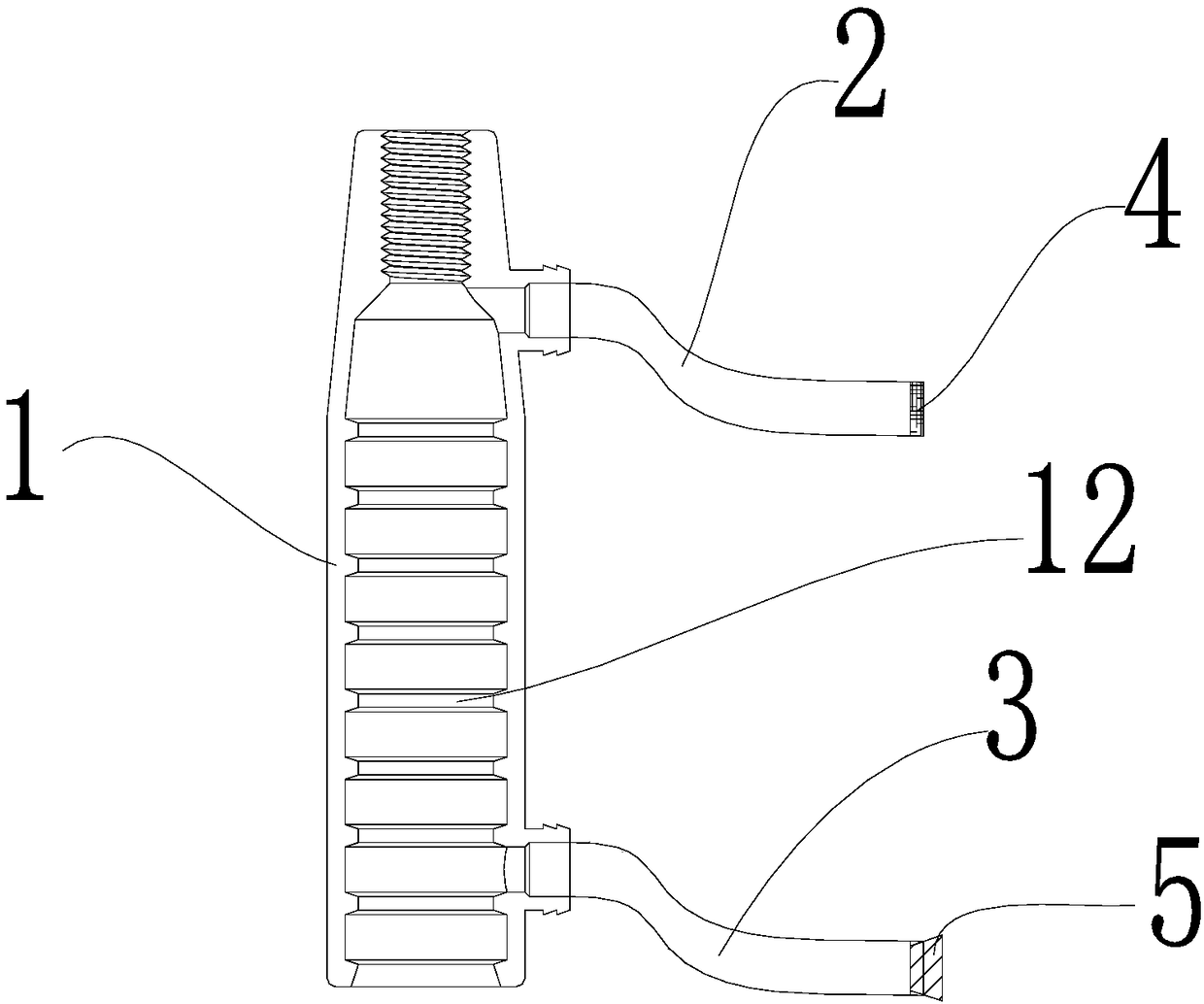

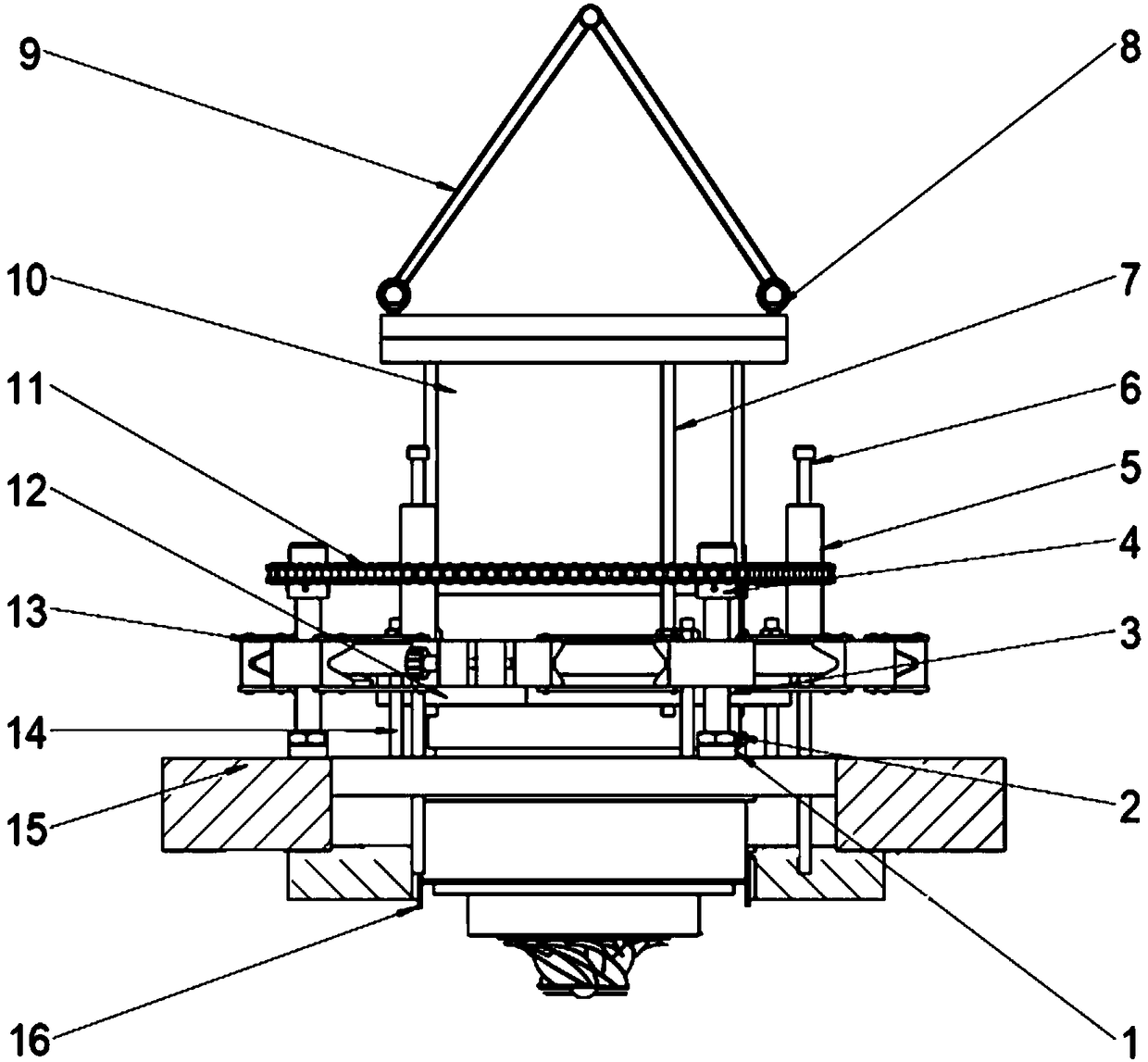

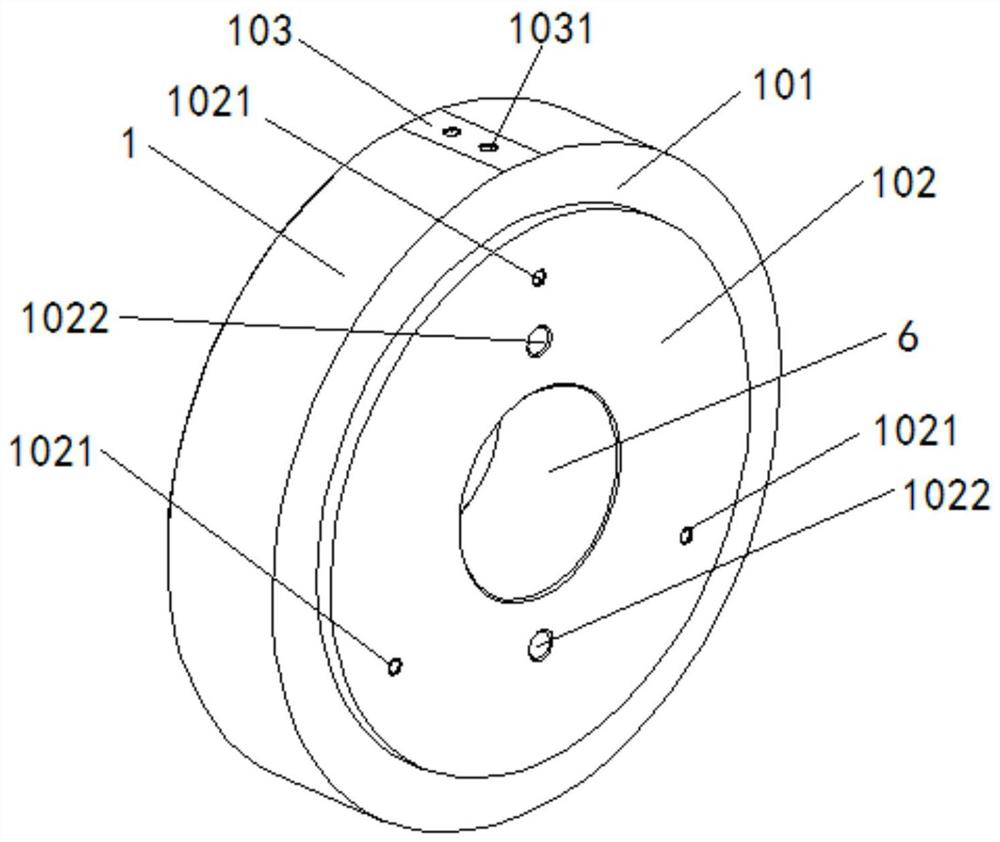

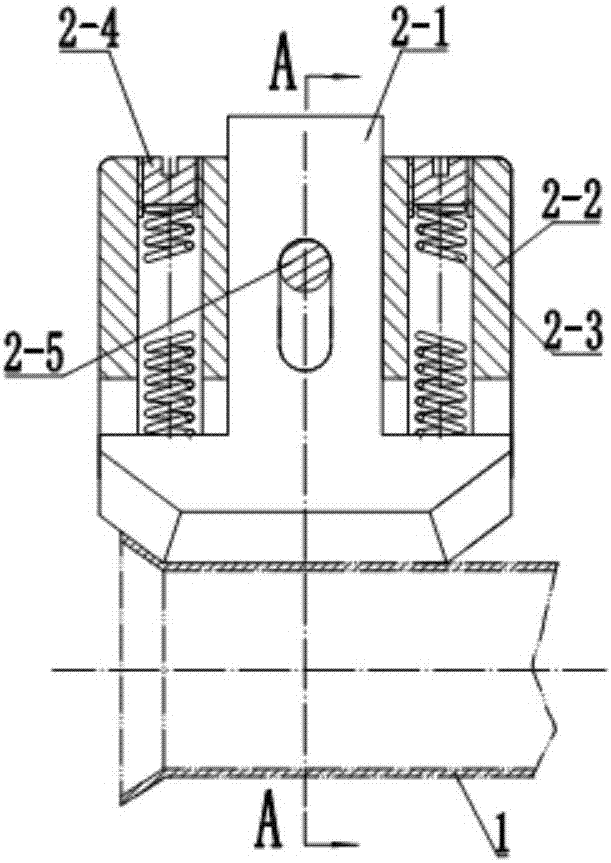

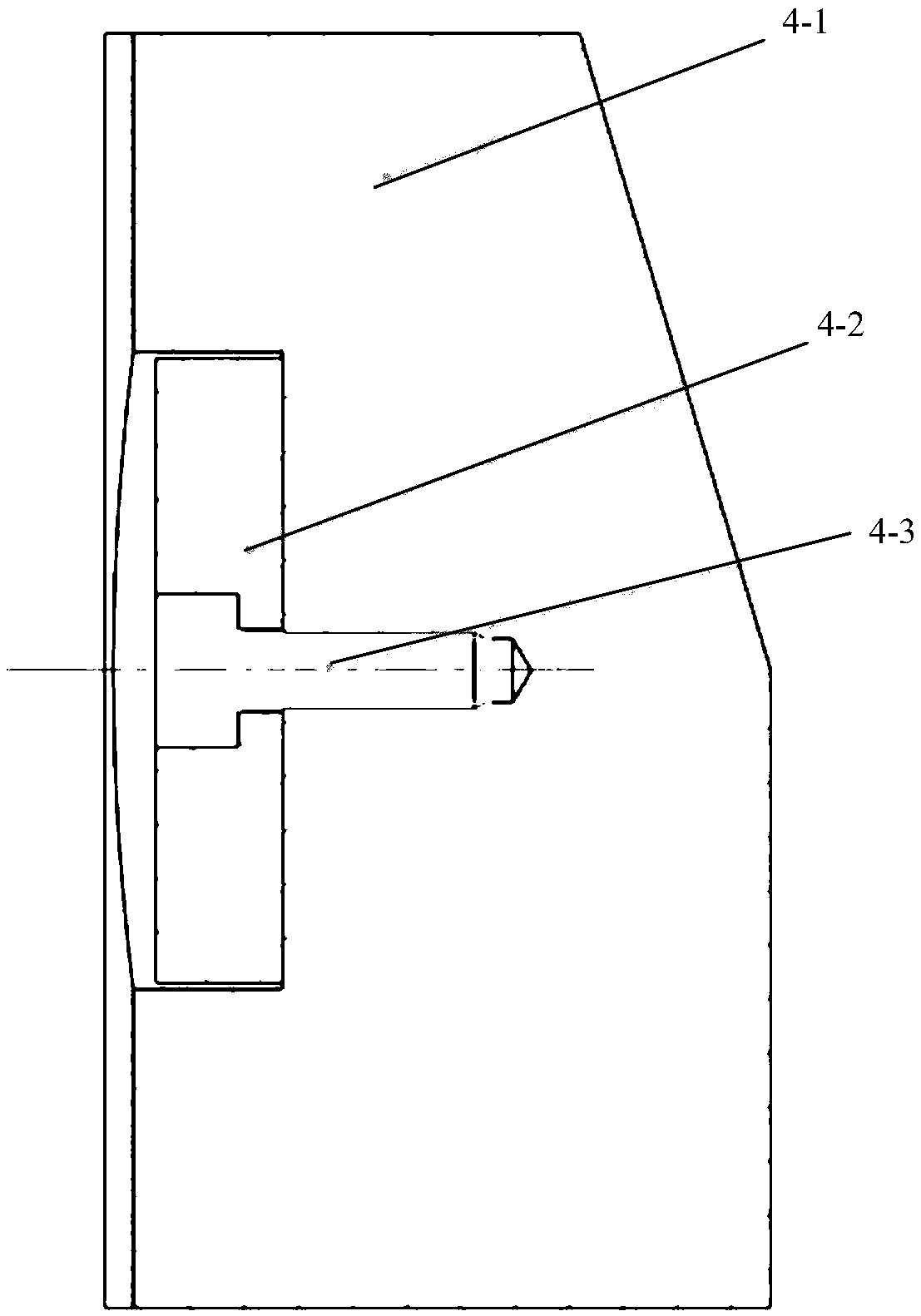

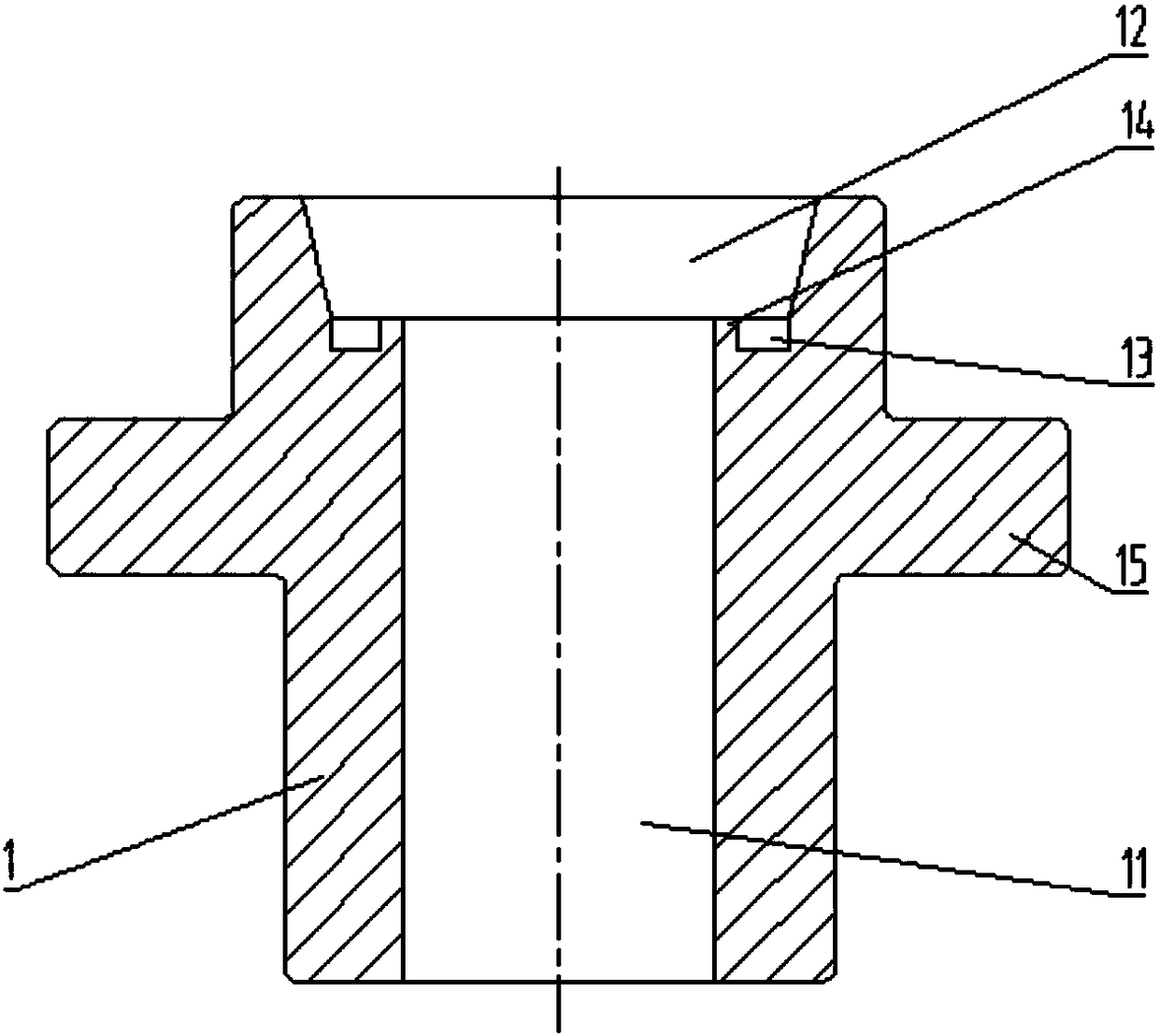

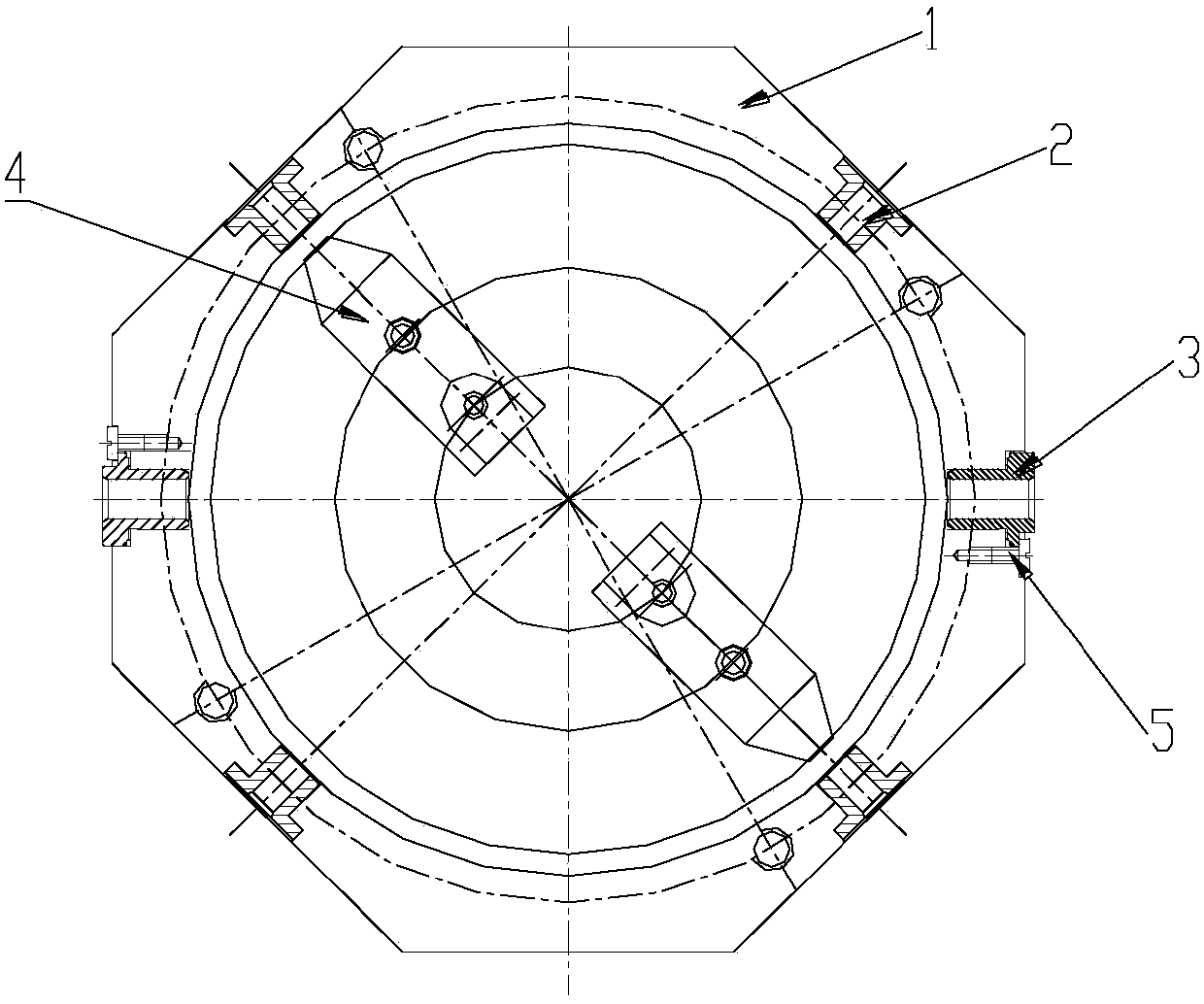

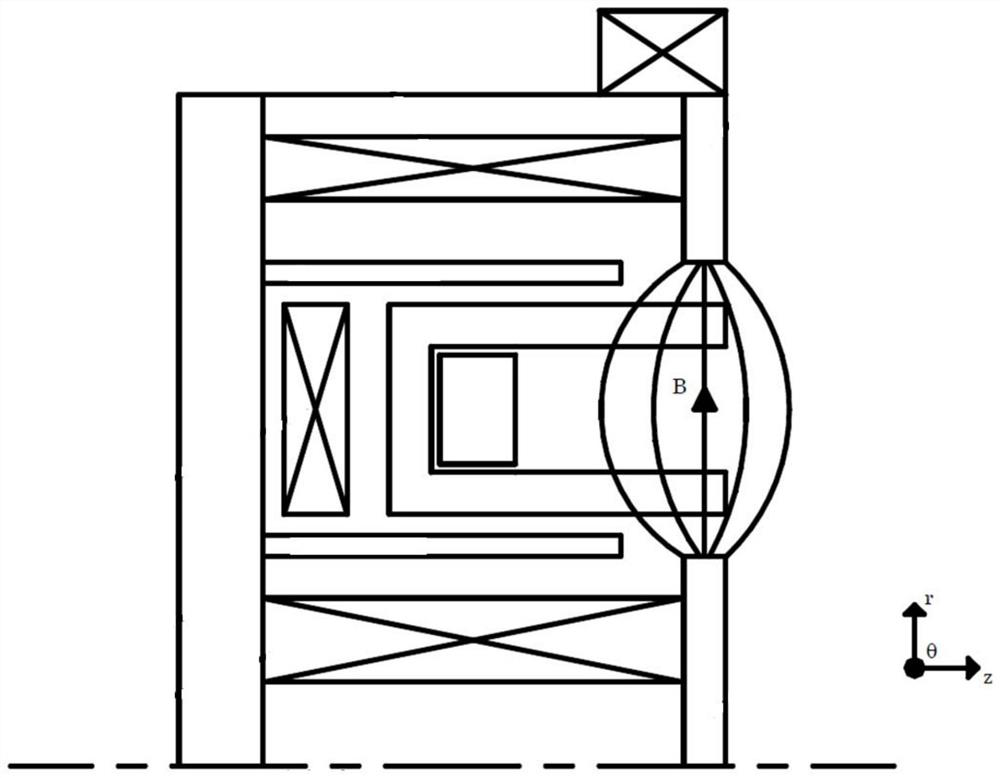

Large-aperture main lens lifting mechanism

ActiveCN109655995AImprove radial positioning accuracyAchieve radial positioningMountingsEngineeringPrimary mirror

The invention provides a large-aperture main lens lifting mechanism. A hoisting screw (1) is fixedly connected with the upper part of a hoisting cylinder (2), the upper part of a transition cylinder (3) is fixedly connected with the lower part of the hoisting cylinder (2); the lower part of the transition cylinder (3) is mounted on a bottom transition plate (8); a radial positioning assembly (4) is mounted on the outer circumference of the transition cylinder (3); the radial positioning assembly (4) can move up and down along the transition cylinder (3); a bottom circular plate (7) is mountedon the bottom transition plate (8); the bottom circular plate (7) is arranged around the outer circumference of the transition cylinder (3); and the bottom positioning assembly (6) is fixedly installed at the bottom of the bottom round plate (7). According to the large-aperture main lens lifting mechanism provided by the invention, the lifting process of a main lens is realized by utilizing the central hole of the main lens and the central edge of the bottom. The structure is compact, and the outer edge of the main lens cannot be occupied; and the large-aperture main lens lifting mechanism isapplied widely.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

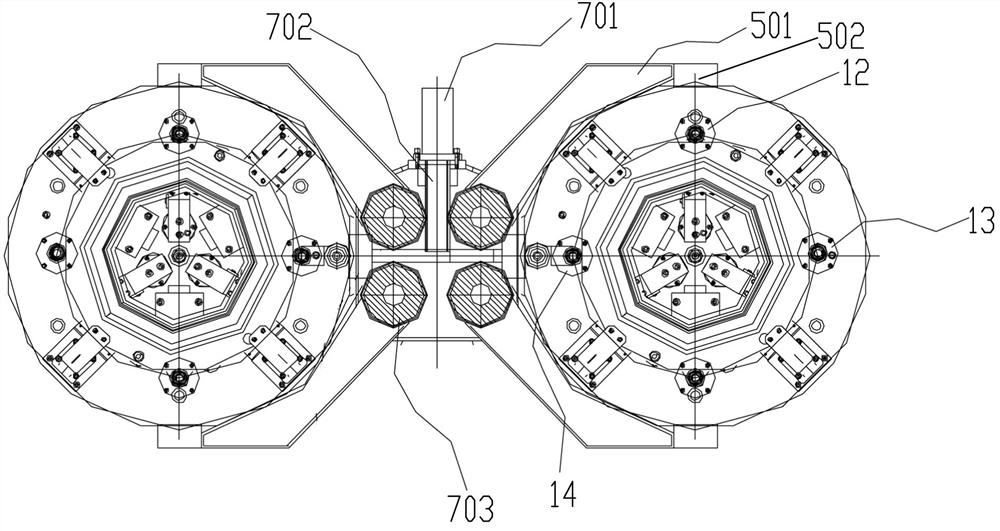

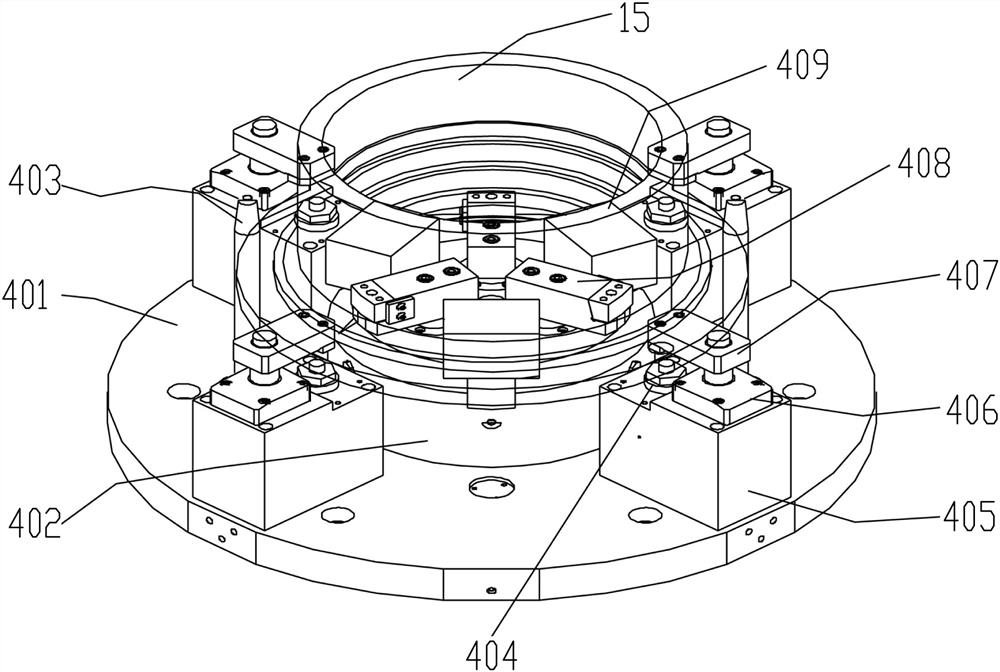

Medium-sized gear shaping machine clamp pallet changer mechanism and operation method

ActiveCN112222541AGuaranteed Position Accuracy RequirementsGuaranteed stiffness requirementsGear-cutting machinesGear teethDetentControl engineering

The invention provides a medium-sized gear shaping machine clamp pallet changer mechanism and an operation method. A gear shaper body is arranged on a gear shaper machine tool body, positioning tabletops are symmetrically arranged at the top of the gear shaper machine tool body, a clamp body used for clamping a workpiece is located and arranged on the positioning table tops through a zero point positioner, the clamp body is matched with a clamping supporting claw structure used for clamping the clamp body, the clamping supporting claw structure is matched with a clamping power mechanism usedfor providing a clamping force, the clamping power mechanism is fixedly arranged at the top of a rotation mechanism used for driving the whole clamping supporting claw structure to rotate, and in therotation mechanism and a lifting mechanism used for driving the rotation mechanism to integrally ascend and descend are arranged in the gear shaping machine body, the lifting mechanism is fixedly arranged on the gear shaper machine tool body. A double-station structure is adopted in the mechanism, it is guaranteed that in the workpiece machining process, clamping and positioning of the workpiecesare alternately achieved, and the problem that double workbenches cannot be adopted for medium gear shaping is solved.

Owner:宜昌长机科技有限责任公司

Taper bearing press-fitting fixture and bearing press-fitting fixture for vehicle steering column

PendingCN108326795ASimple structureAchieving Positioning AccuracyMetal-working hand toolsSteering columnConical surface

The invention discloses a taper bearing press-fitting fixture. The taper bearing press-fitting fixture comprises a cylindrical fixture body, wherein an axially-penetrating guide hole is formed in thefixture body; a placement groove coaxial with the guide hole and used for placing a taper bearing is formed in one end of the fixture body; the sidewall of the placement groove is a conical surface used for forming transition fit with the outer race of the bearing; and an annular bypass groove used for accommodating a bearing retainer is formed in the bottom of the placement groove. During taper bearing press-fitting, the taper bearing is placed in the placement groove of the fixture body, radial location for the taper bearing is realized, and the deformation of the bearing retainer due to extrusion during taper bearing installation can be avoided; then the fixture body sleeves a steering column through the guide hole, and the guide hole is capable of playing the role of preliminary guide;then the taper bearing is pressed into a specified position on the steering column by virtue of a tool; and the taper bearing press-fitting fixture is simple and convenient, and capable of improvingthe bearing press-fitting quality and the bearing press-fitting efficiency. The invention further discloses a bearing press-fitting fixture comprising the taper bearing press-fitting fixture, for a vehicle steering column.

Owner:力帆科技(集团)股份有限公司

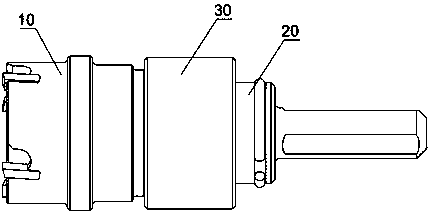

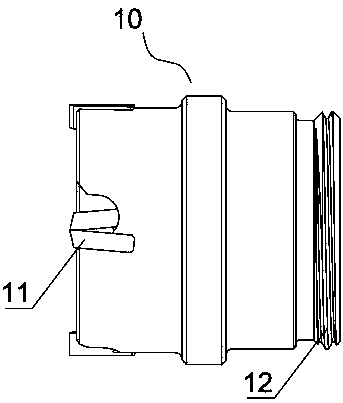

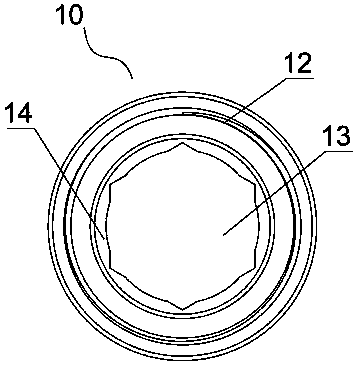

A quick-loading tool

ActiveCN106583808BAchieve radial positioningImprove machining accuracyTool adaptersTorque transmissionMachining process

The invention relates to the technical field of cutting tools, discloses a cutter whose cutter body and shank are separated, and particularly provides a rapidly installed cutter. The cutter adopting the structure is characterized in that corresponding structures for realizing radial positioning, limiting in peripheral direction and torque transmission are arranged between the cutter body and the shank, thereby having the technical advantages of high machining precision, high installation precision, stable rotation and cutting, large transmission torque and higher rigidity; meanwhile, the cutter body and the shank are connected through threads of a fixing sleeve and the cutter body, and the technical advantages of convenient uninstallation and installation and high uninstallation and installation efficiency are realized; an elastic piece is arranged between a limiting boss and an annular step and is in a compressed state when the cutter body and a cutter head are connected, a damping action is realized by elastic force, loose threaded connection caused by vibration in a drilling process is prevented, and the drilling force is enabled to be more steady in the drilling machining process.

Owner:ZHEJIANG XINXING TOOLS CO LTD

Cylindrical part drilling and positioning device

InactiveCN110405255AAchieve radial positioningAchieve axial positioningDrill jigsEngineeringBiomedical engineering

The invention discloses a cylindrical part drilling and positioning device. The cylindrical part drilling and positioning device comprises a clamp body, wherein a round positioning hole penetrating through the front end face and the rear end face of the clamp body is formed in the clamp body; a plurality of first installation holes are uniformly distributed in the side wall of the clamp body, anda first drill sleeve is embedded in each first installation hole; a plurality of second installation holes which are symmetrically distributed are formed in the side wall of the clamp body, and a second drill sleeve is embedded in each second installation hole; and an end cover is fixed to the rear end face of the clamp body, and multiple pressing structures which are used for pressing a to-be-drilled cylindrical part and conducting axial positioning on the cylindrical parts are symmetrically arranged on the end cover. According to the cylindrical part drilling and positioning device, positioning of the cylindrical part can be realized, so that drilling machining of the holes in different angles of the cylindrical surface of the cylindrical part can be rapidly completed. The machining quality of the part is guaranteed, and the production progress is guaranteed.

Owner:HUBEI SANJIANG SPACE WANSHAN SPECIAL VEHICLE

An Axial Clearance Adjustment Structure at the High Temperature End of a Hall Thruster

ActiveCN112012897BMake up axial playReduce in quantityMachines/enginesUsing plasmaMetal rubberStainless steel wire

The invention relates to an axial gap adjustment structure at the high temperature end of a Hall thruster, comprising a metal base, a metal rubber pad and a ceramic channel; the above three components are coaxially arranged, and the metal rubber pad is fixed in the groove of the metal base; the above The three realize stable connection with other parts in the Hall thruster through screws. The invention adopts the structure composed of metal base with groove, metal rubber pad wound by stainless steel wire, and channel ceramics, so as to adapt to the gap change caused by temperature change before and after the thruster works.

Owner:BEIJING INST OF CONTROL ENG

Rotary driving type steel wire rope winding device

The invention discloses a rotary driving type steel wire rope winding device which comprises a bracket, a winding mechanism and a driving mechanism. The winding mechanism includes limiting plates, floating plates, a driving screw, a tapered driving block and driven wedge blocks. By means of the rotary driving type steel wire rope winding device, the traditional winding structure of a cylinder is changed, the driving screw is connected to the other side of the bracket in threaded rotating and penetrating manners, one end of the driving screw penetrates through the other limiting plate to extendto the position between the two floating plates, the end, extending into the position between the two floating plates, of the driving screw is provided with the tapered driving block, and the tapereddriving block abuts against the two driven wedge blocks; and when rotationally and transversely moving, the tapered driving block can abut against the two driven wedge blocks to move longitudinally,so that the two floating plates relatively float between the two limiting plates, the distance between the two floating plates can be adjusted, and the effect of adjusting the tightening force of a steel wire rope is achieved.

Owner:江苏艾可森钢绳有限公司

Cutting device for straightening and cutting machine

ActiveCN111001731BAchieve radial positioningCrop stabilizationStructural engineeringMechanical engineering

The invention discloses a cutting device for a straightening and cutting machine, which is characterized in that it includes a frame body, a workpiece limit mechanism, a fixed knife and a moving knife mechanism; the frame body includes a vertical plate and a top plate, and the vertical plate has a The workpiece channel; the workpiece limit mechanism includes a left adjustment rod, a right adjustment rod and an upper adjustment rod; On the top wall, as well as the first ends of the left adjusting rod, the right adjusting rod and the upper adjusting rod are located in the workpiece channel and form a limiting channel; The low point of the channel is on the same horizontal line; the moving knife mechanism includes a moving knife and an oil cylinder, and the oil cylinder is installed on the top plate and connected with the moving knife to drive the moving knife to move relative to the fixed knife. The invention can not only improve the cutting quality of workpieces, but also increase the service life of cutting knives and reduce the replacement cycle of cutting knives.

Owner:嘉兴凯鑫五金科技股份有限公司

Radial locking floating cable

PendingCN111917077AAchieve radial positioningImprove extrusion resistanceElectrical apparatusElectric/fluid circuitSlide plateScrew thread

The invention discloses a radial locking floating cable which comprises a cable inner core, a wire group, an outer shell, an expansion mechanism and a radial locking mechanism. According to the present invention, the outer side of a sliding plate is slidably clamped with an arc-shaped clamping groove, the position setting is more flexibly by using a rotating threaded head and a positioning threaded hole, and the rotating threaded head is rotatably connected into the positioning threaded hole in a threaded mode, so that the radial positioning of a cable inner core can be achieved, and the structure is more stable. Meanwhile, with the elastic supporting of multiple springs, the extrusion resistance of the whole cable inner core is improved.

Owner:江苏诸成电缆有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com