Patents

Literature

78results about How to "Crop stabilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plant health diagnostic method and plant health diagnostic device

ActiveUS20130276368A1Inhibit swellingDimensionally stableImage analysisSeed and root treatmentTime courseArbitrary Fluorescence Unit

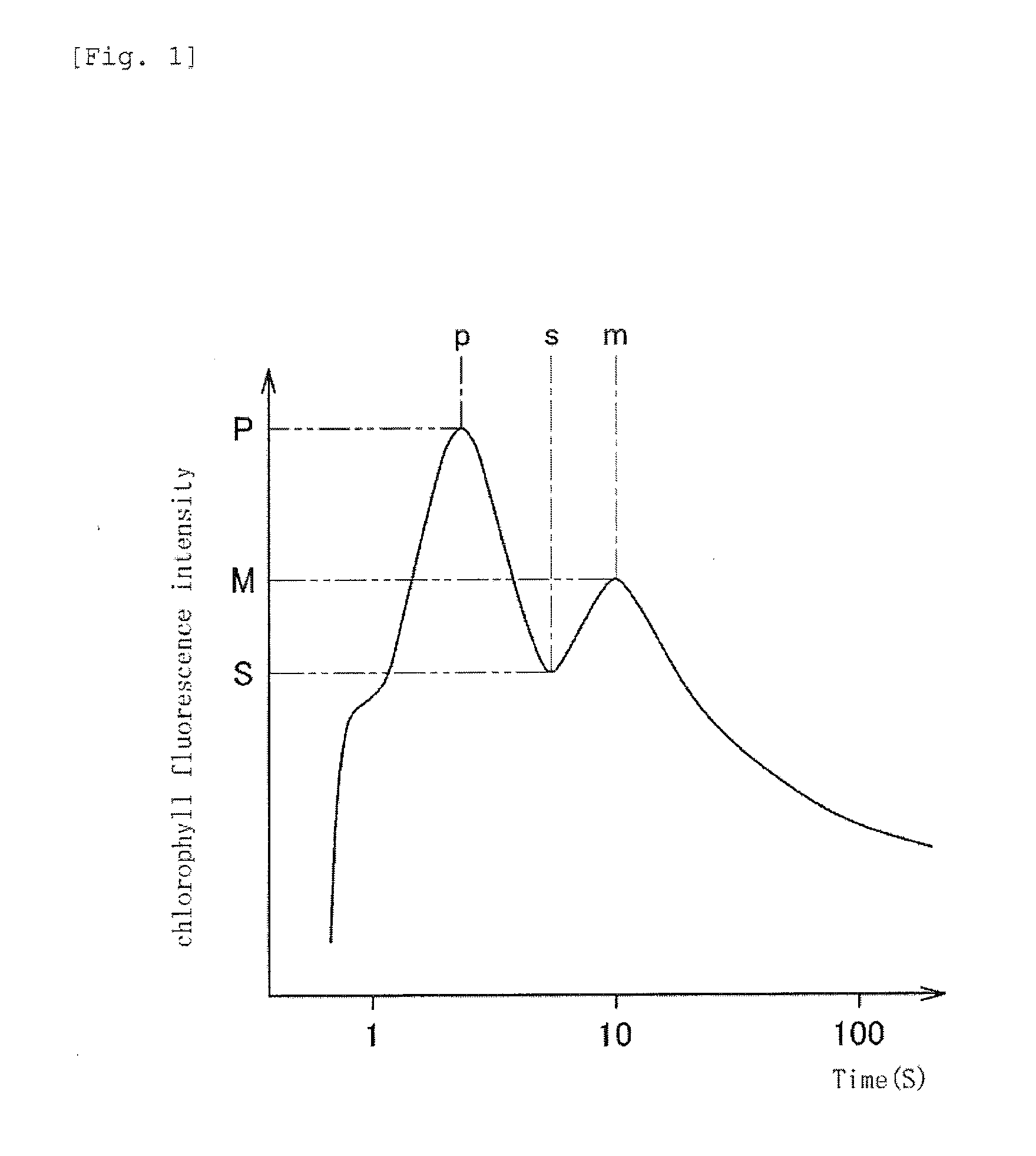

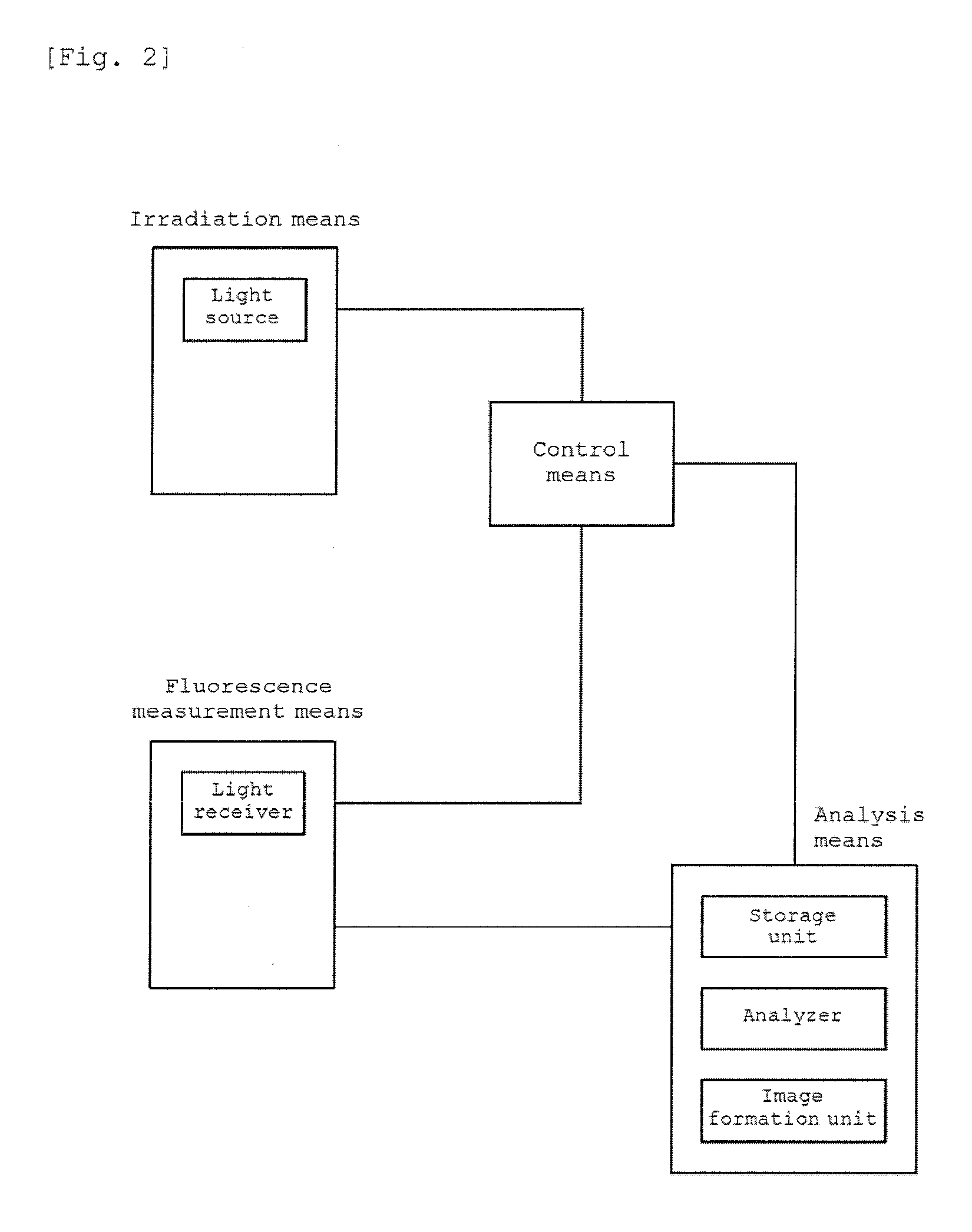

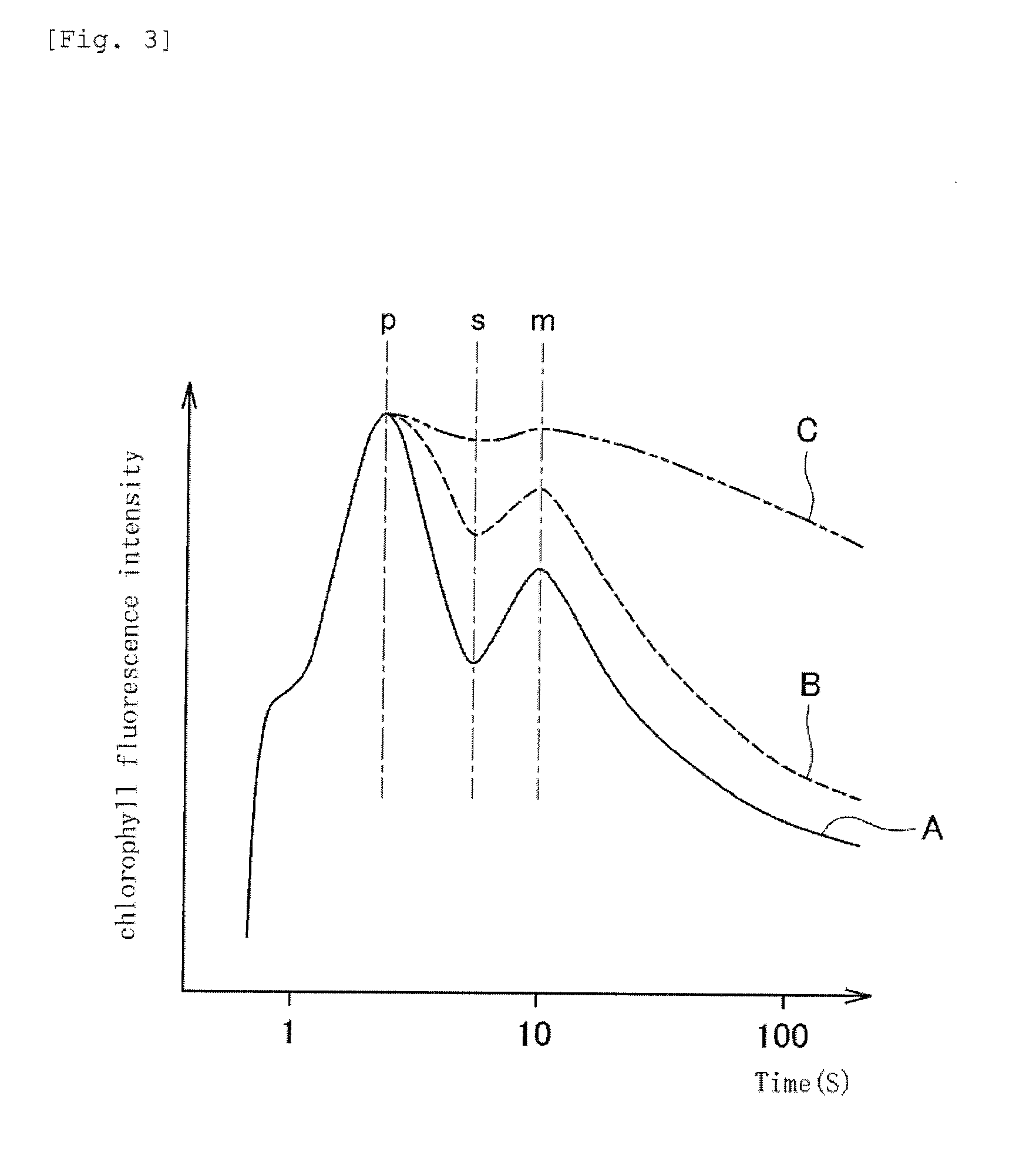

This invention provides a plant health diagnostic method and a plant health diagnostic device for detecting initial disorder of a plant individual body carrying pests or the like in a large-scale plant cultivation field. The plant health diagnostic method is for diagnosing a health state of a plant in accordance with chlorophyll fluorescence emitted from chlorophyll of a plant body. The method includes: obtaining a first minimum point s after a maximum point p having largest chlorophyll fluorescence intensity and a first maximum point m after the minimum point s on a time course curve for the chlorophyll fluorescence intensity; defining chlorophyll fluorescence intensity values at the minimum point s and the first maximum point m after the minimum point s as S and M, respectively; and comparing the value S and the value M to evaluate the state of the plant. The state of the plant, which cannot be visually recognized from outer appearance, can be detected by comparison between the chlorophyll fluorescence intensity values (S and M), thereby realizing diagnosis of the state of the plant individual body in an early stage.

Owner:NAT UNIV CORP EHIME UNIV

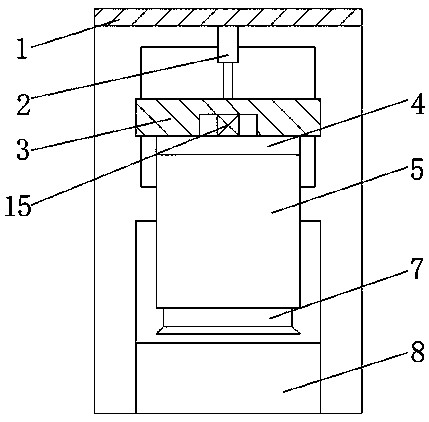

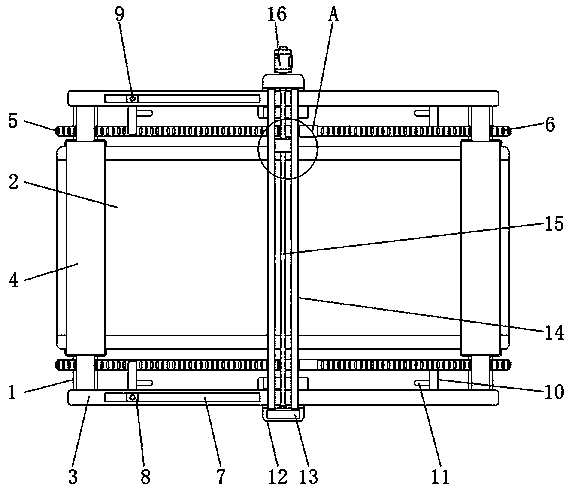

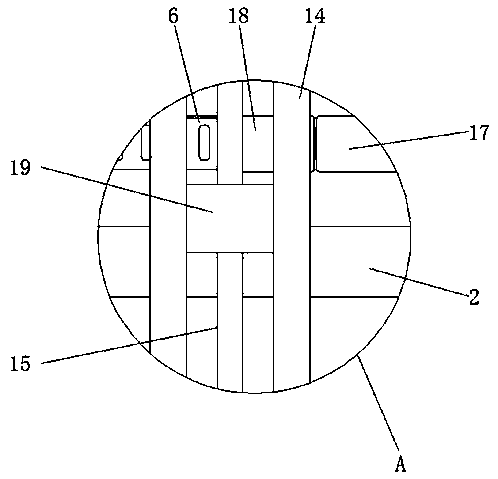

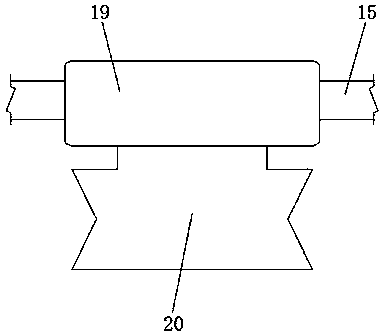

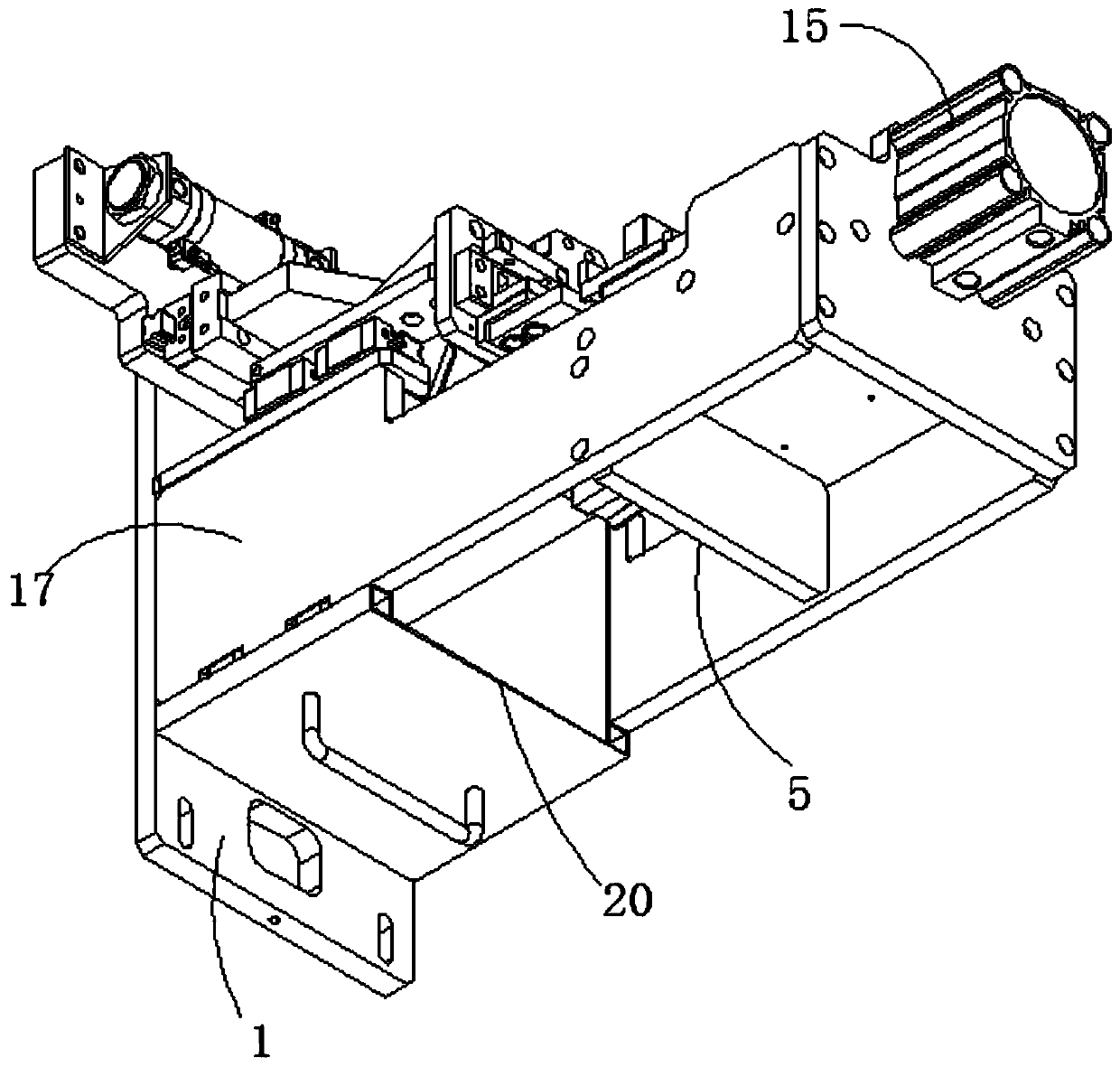

Garment cutting device wide in application range

PendingCN107761350AImprove croppingImprove cutting efficiencySevering textilesElectric machineryEngineering

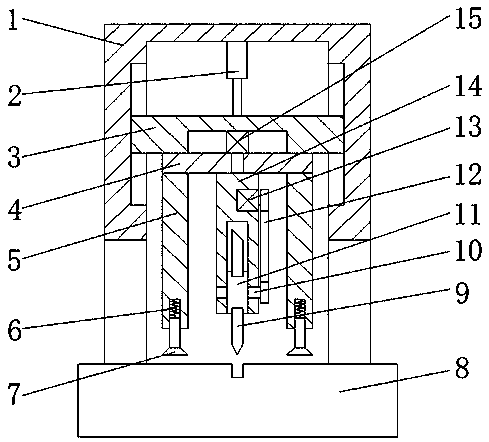

The invention discloses a garment cutting device wide in application range. The garment cutting device comprises a rack, sliding grooves are formed in the inner walls of the two sides of the rack, andthe inner walls of the two sliding grooves are connected with the same sliding table in a sliding mode; a hydraulic cylinder is fixed to the inner wall of the top of the rack through screws, and oneend of a piston rod of the hydraulic cylinder is fixed to the outer wall of the top of the sliding table through a screw; the outer wall of the bottom of the sliding table is fixedly provided with a fixing plate through screws, a rotating shaft hole is formed in the outer wall of the top of the fixing plate, and a rotating shaft is connected with the inner wall of the rotating shaft hole through abearing; the outer wall of the bottom of the rotating shaft is fixedly provided with a mounting frame through screws. By means of the cooperation of a transmission chain and the rotating shaft, cutters can be quickly replaced; the proper cutters are selected according to different cloth textures, and the cutting effect and the cutting efficiency can be improved; a second motor is arranged so thatthe cutters can rotate according to processing needs to be suitable for cutting at different angles.

Owner:盐城融凡纺织制衣有限公司

Tailoring and conveying separated spinning device

The invention discloses a tailoring and conveying separated spinning device. The tailoring and conveying separated spinning device comprises conveying rollers, the outer sides of the conveying rollersare sleeved with conveying belts, shaft end bearings of the conveying rollers are connected to a supporting frame, extrusion rollers are connected to the supporting frame through bearings, the extrusion rollers are arranged on the conveying rollers, the conveying rollers and the extrusion rollers are tightly attached to the inner sides and the outer sides of the conveying belts correspondingly, the outer sides of the shaft ends of the conveying rollers are in key connection with chain gears, the outer sides of the chain gears on the same side are in engaged connection with chains, shifting sleeves are fixed to the chains, and transmission blocks are arranged at the upper ends of the shifting sleeves. According to the tailoring and conveying separated spinning device, tailoring and conveying of cloth do not affected, the cloth is cut in a continuous conveying process of the cloth, then the working efficiency can be improved conveniently, the two sides of the tailoring part can be pressed in the cloth cutting process, then the cloth can be advantageously cut stably, and the problem that the cloth is cut to be damaged due to deviation of the cloth when the cloth is cut in the past isavoided.

Owner:尹宝珍

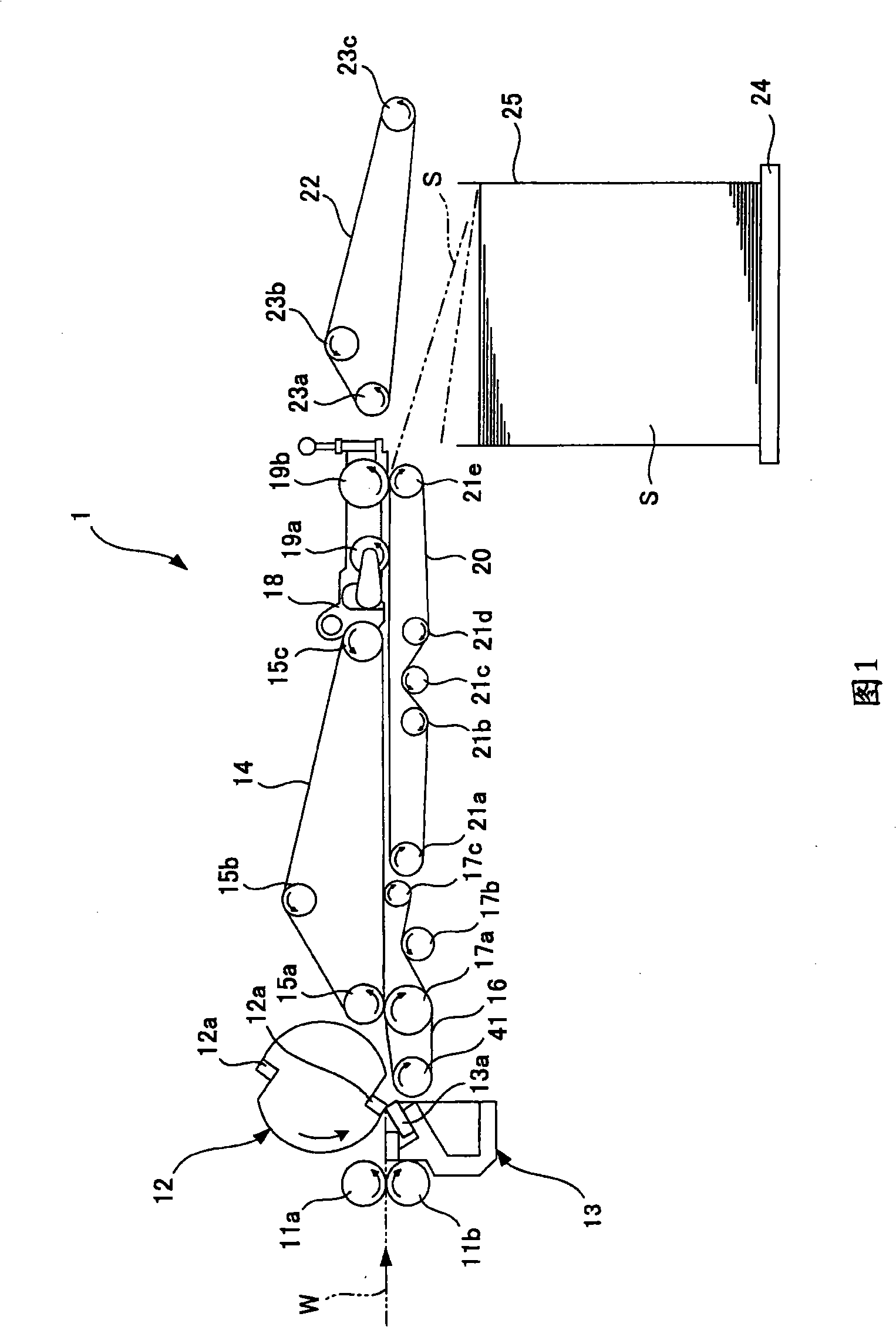

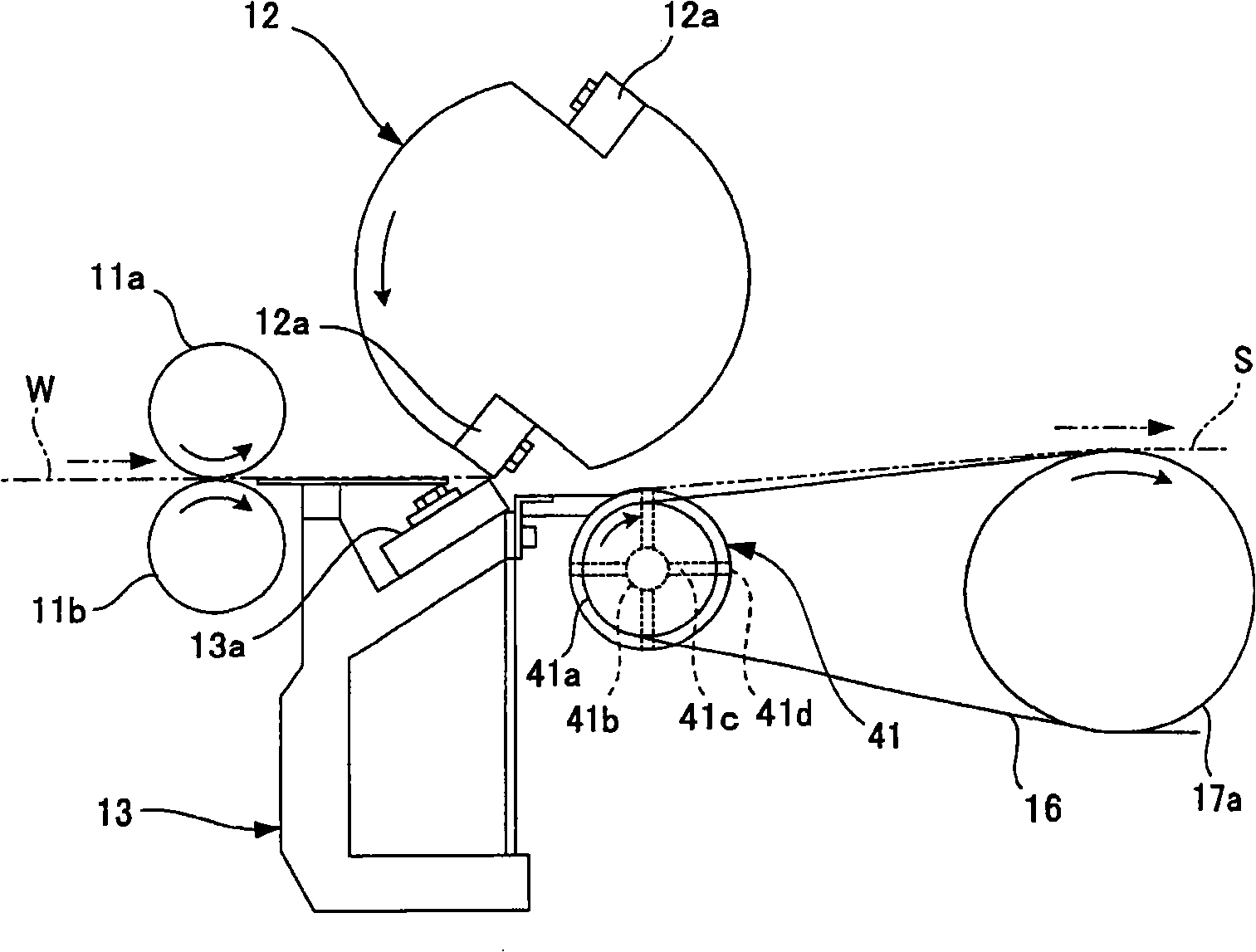

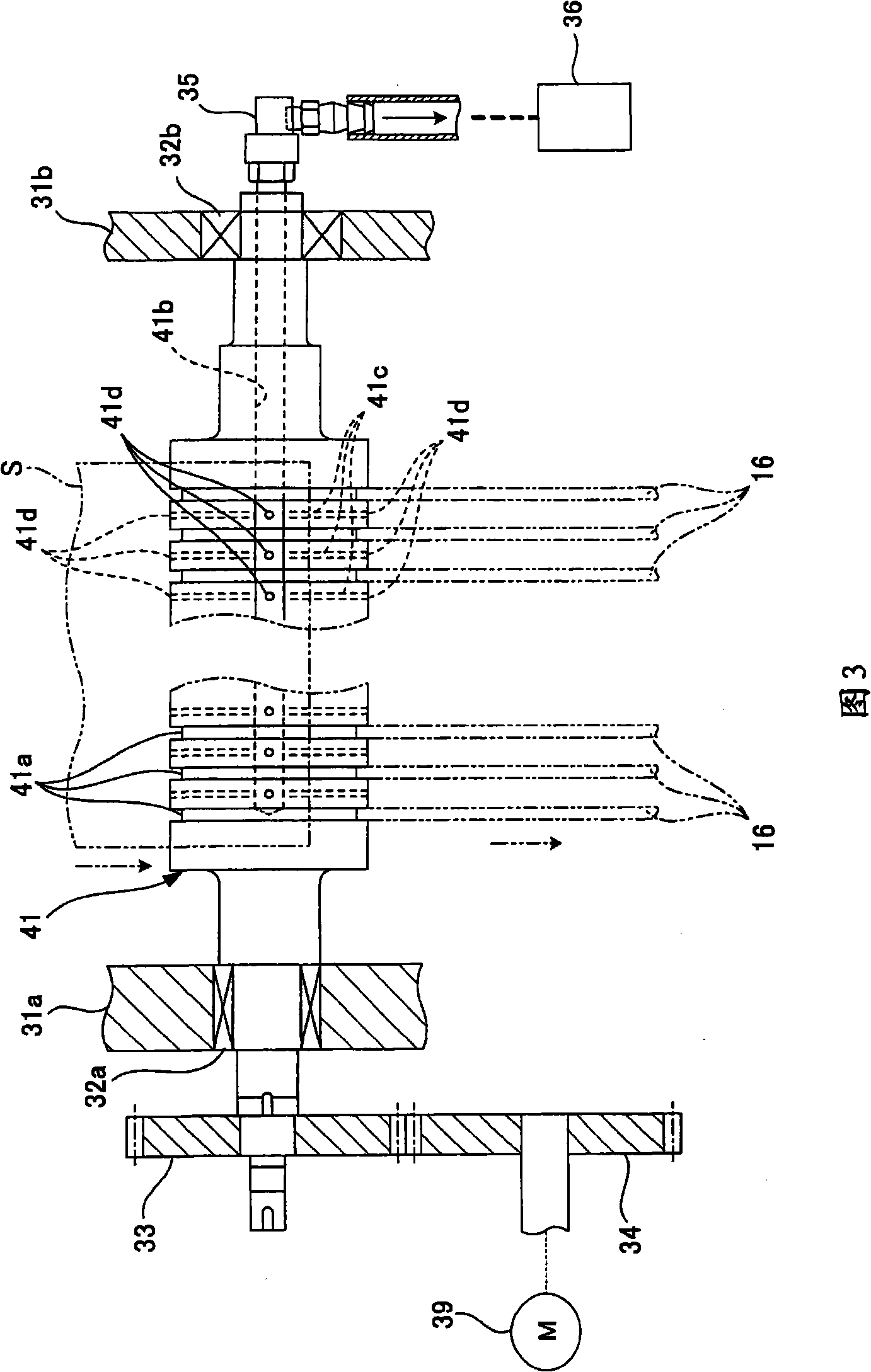

Cutting device

InactiveCN101293418AAvoid adsorptionPrevent erratic behaviorRotary pressesMetal working apparatusMechanical engineeringEngineering

A sheeter apparatus includes: a cutter cylinder 12 for cutting a transported web W into sheets S in cooperation with a fixed knife 13; lower high-speed transportation belts 16 for transporting a cut sheet S; and a suction device 36 for sucking the cut sheet S from suction ports 41d of a suction roller 41, which causes the lower high-speed transportation belts 16 to travel, in such a manner that a surface of the sheet S which is on the other side of the surface facing the cutter cylinder 12 adheres to the outer peripheral surface of the suction roller 41.

Owner:KOMORI CORP

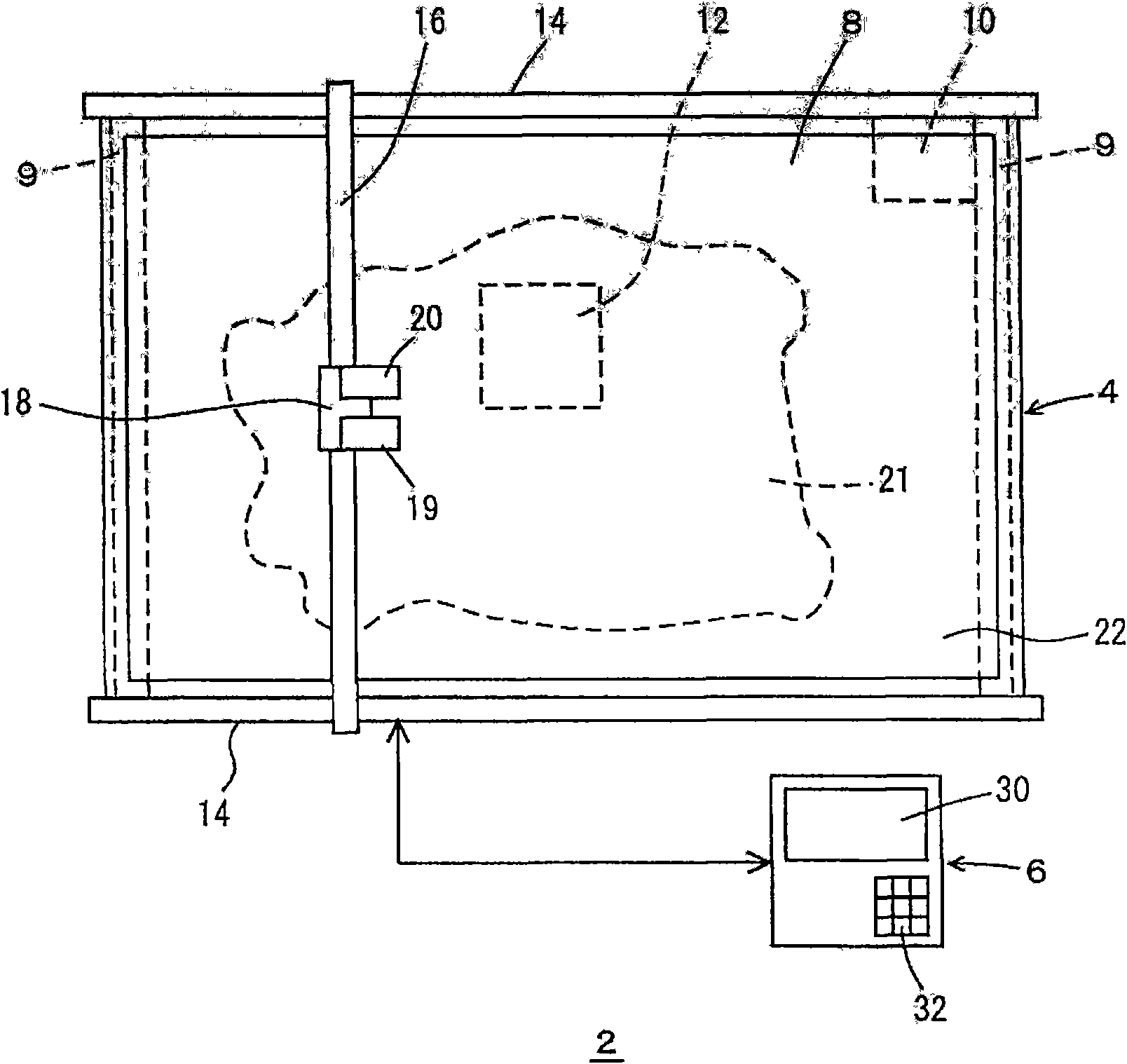

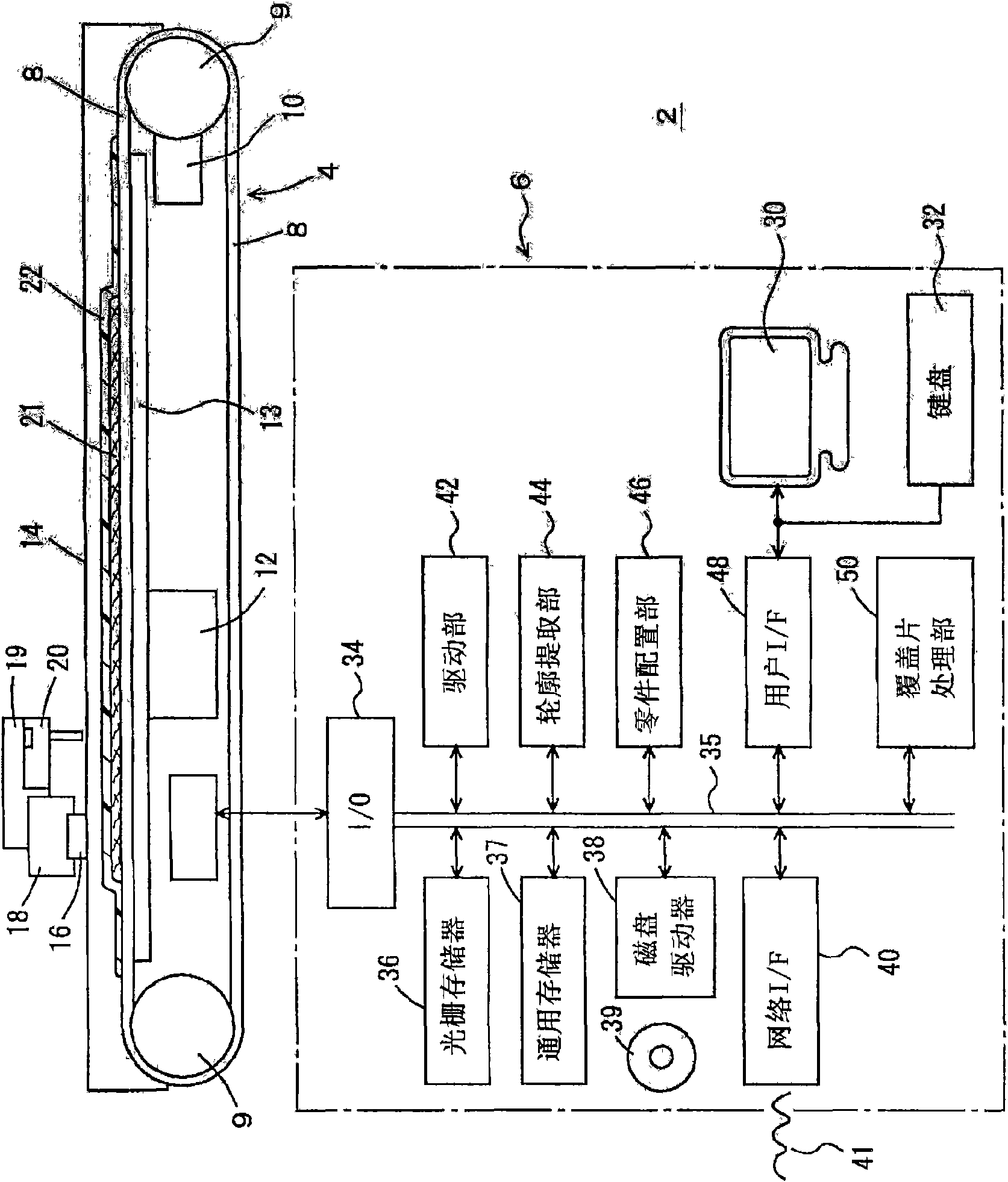

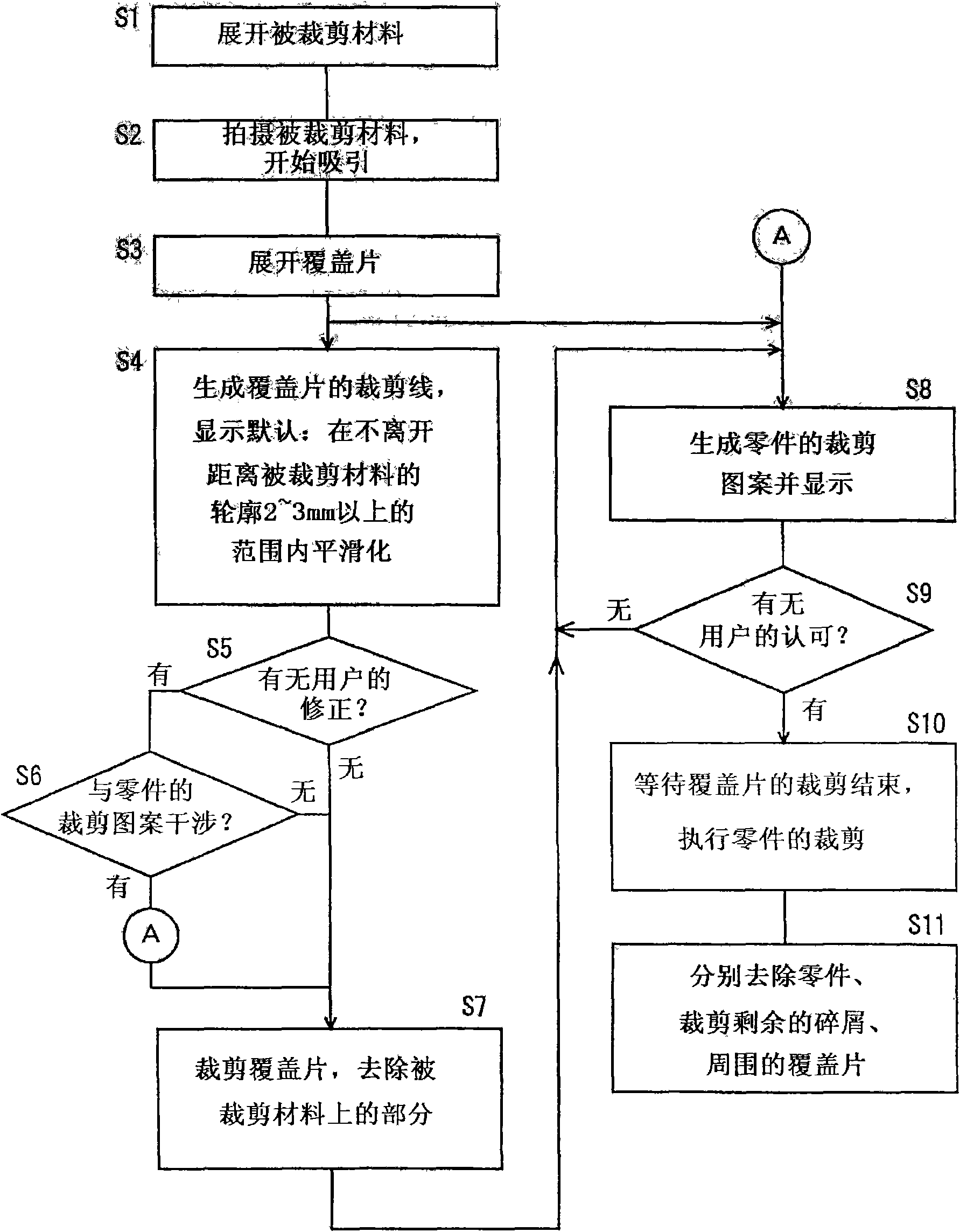

Cutting method and cutting device employing overlay pieces

The present invention relates to a cutting method and a cutting device employing overlay pieces, wherein material to be cut is arranged on a cutting bed having an attraction source, is filmed to obtain the contour of the material to be cut, and is covered by a non-permeability overlay piece. Parts are arranged in the contour, and the material to be cut is cut into parts by a cutting head moving on the cutting bed. overlay pieces are cut according to cutting lines along the material contour, and parts is cut after removing the overlay pieces on the material. The overlay piece will not be coiled on the material to forbid the cutting, and the parts after cutting will not be separated from the overlay pieces.

Owner:SHIMA SEIKI MFG LTD

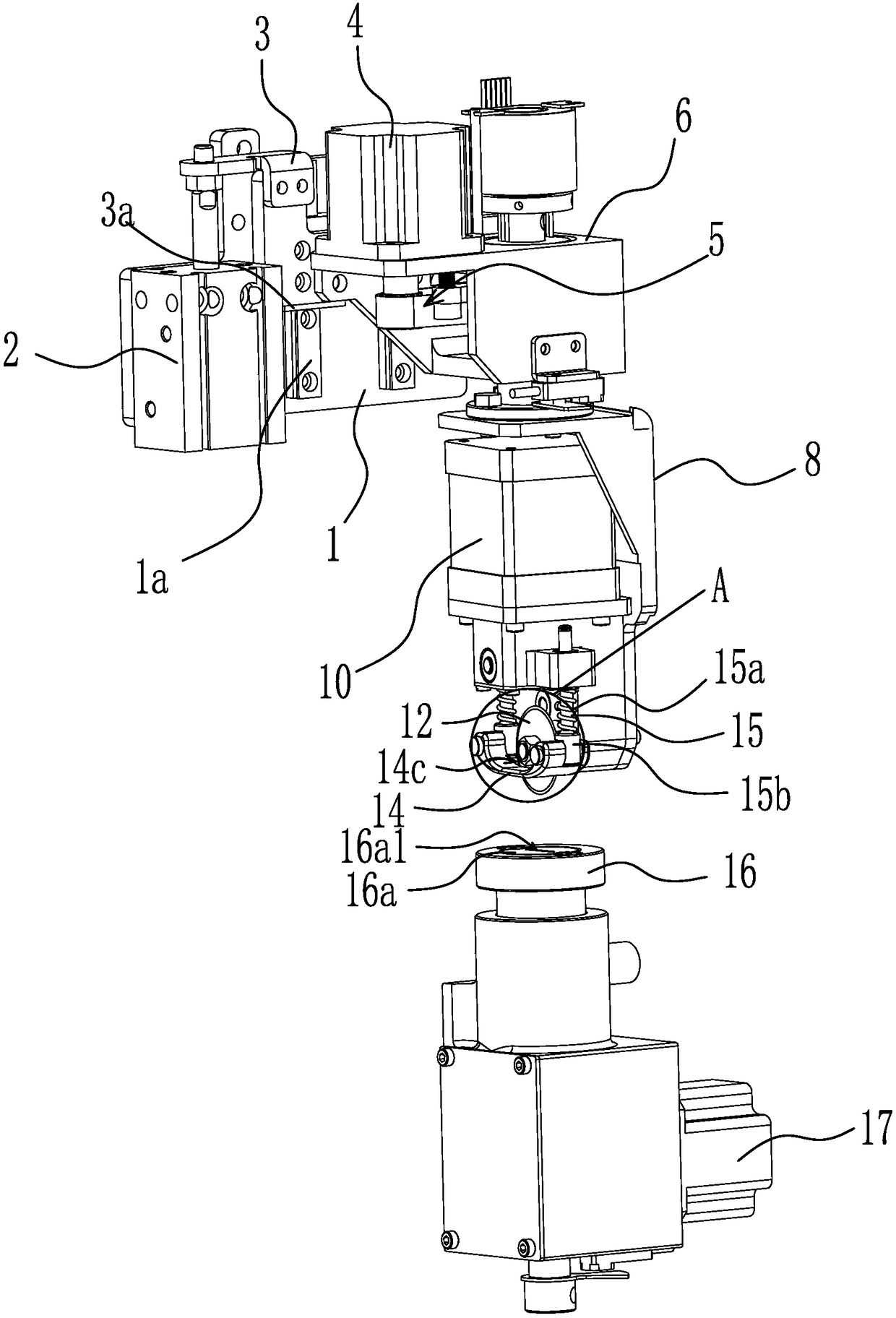

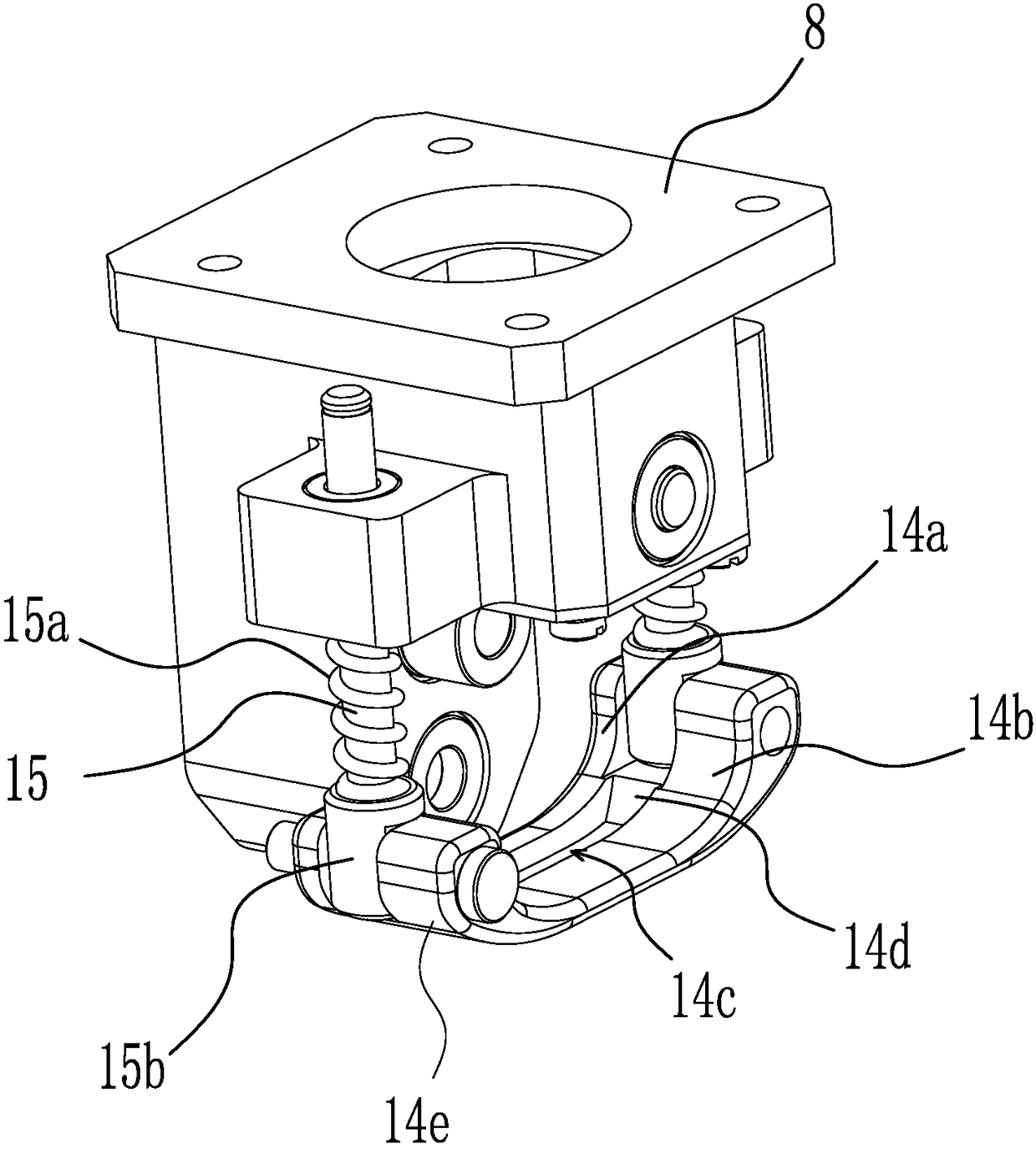

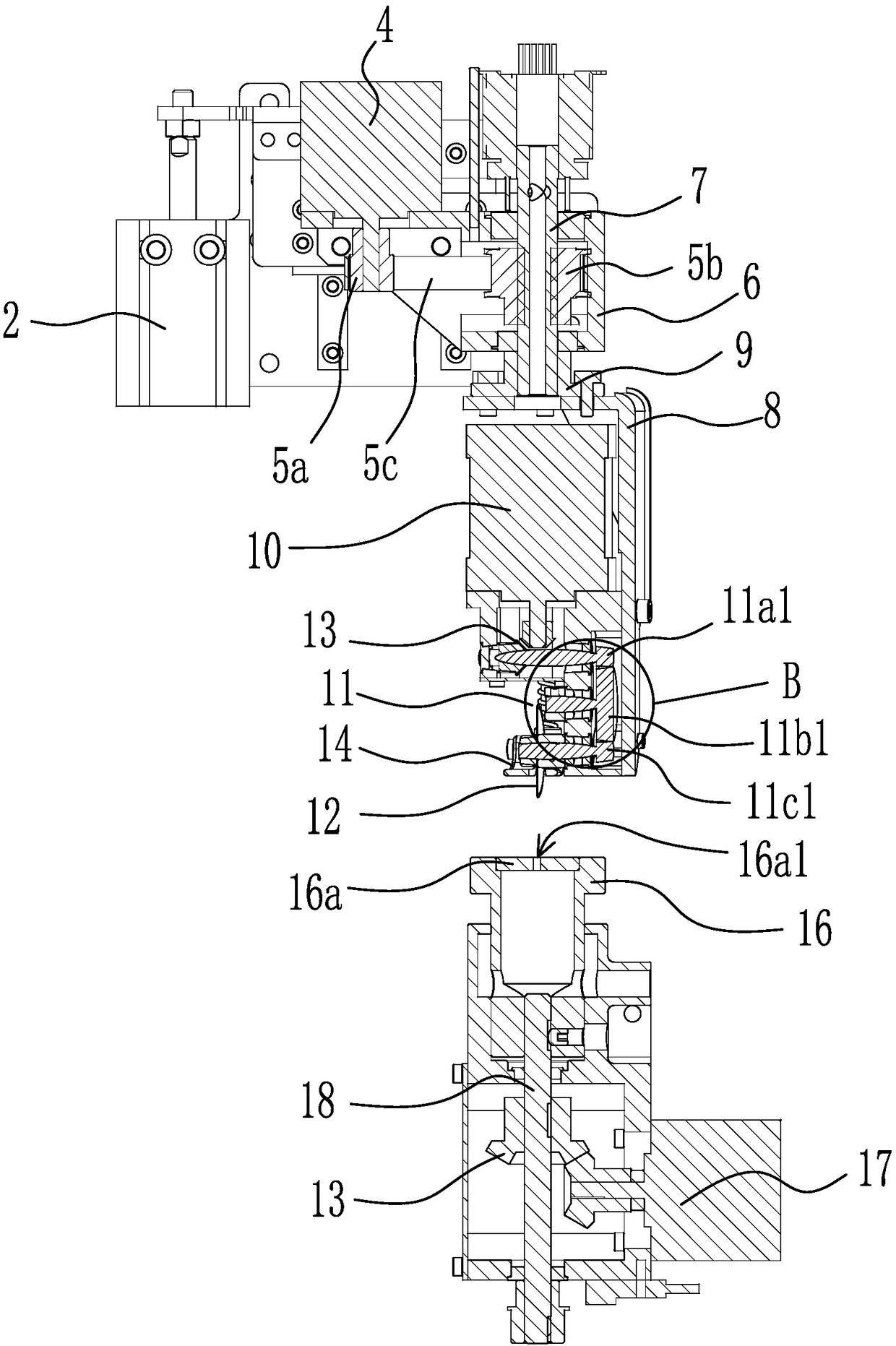

Cutter device for sewing machine

ActiveCN108301132AWon't wrinkleGuaranteed accuracyWorkpiece carriersPressersBlade plateCotton material

The invention provides a cutter device for a sewing machine and belongs to the technical field of machinery. The problem of low cloth cutting precision of an existing cutter device is solved. The cutter device for the sewing machine comprises a lifting rack, a cutter, a pressure foot and a lower cutter plate which can rotate, a rotation rack which can rotate along with the lower cutter plate synchronously is arranged on the lifting rack, and the pressure foot and the cutter are arranged on the lower portion of the rotation rack; the pressure foot comprises a first press plate and a second press plate, a strip-shaped gap for the lower portion of the cutter to penetrate through is formed between the first press plate and the second press plate, and the width of the strip-shaped gap is slightly larger than the thickness of the cutter. The cutter device for the sewing machine is reasonable in structure and high in cutting precision.

Owner:ZHEJIANG ZOJE SEWING MACHINE

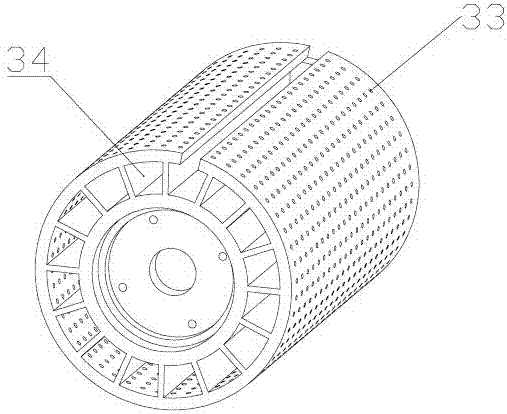

Roller type woven bag automatic cutting device

ActiveCN106808511ANovel structural designImprove cutting efficiencyMetal working apparatusEngineeringMechanical engineering

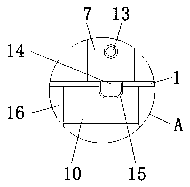

The invention discloses a roller type woven bag automatic cutting device integrating transportation, clamping and cutting into one, which has the advantages of achieving a high cutting efficiency, smooth cut, smooth cutting process, long service life and adjustable cutting specifications. The roller type woven bag automatic cutting device comprises a frame, and a rotatable main spindle arranged on the frame. The main spindle is provided with a plurality of support rod sets arranged radially along the main spindle. Each support rod set consists of two support rods fixed at both ends of the main spindle, and a plurality of support rod sets is outwardly emitted and symmetrically arranged. The ends of the two support rods in each set of support rod set are respectively provided with a clamping and shearing mechanism for clamping the woven bag.

Owner:来宾市昌平食品包装有限公司

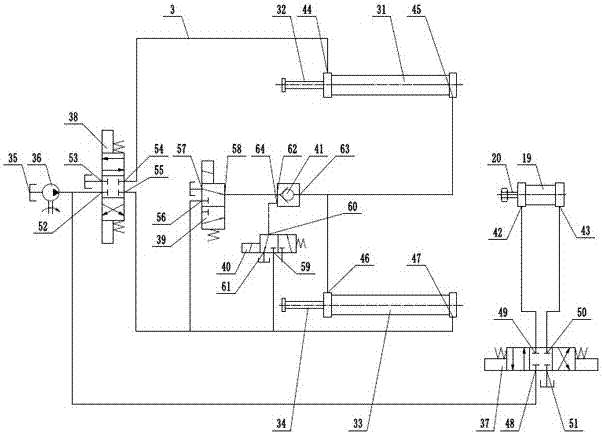

Hot pickled mustard tuber slicing device

The invention provides a hot pickled mustard tuber slicing device, and belongs to the technical field of hot pickled mustard tuber processing. The hot pickled mustard tuber slicing device comprises a clamping mechanism, a slicing mechanism and a hydraulic driving mechanism; the two ends of an n-shaped upper clamping spring sheet of the clamping mechanism are installed on the lower side of the left end of an upper clamping jaw through fastening screws, and the two ends of an n-shaped lower clamping spring sheet are installed on the upper side of the left end of a lower clamping jaw through fastening screws; a slicing supporting base of the slicing mechanism is arranged on supporting base guide rails in a left-right sliding mode through an upper connecting plate and a lower connecting plate, and slicing knives are installed on a slicing knife base at equal distance; the other end of a hydraulic pump of the hydraulic driving mechanism is connected with a valve port C of a three-position four-way reversing valve A and a valve port G of a three-position four-way reversing valve B, a valve port I of the three-position four-way reversing valve B is connected with a third valve port of an upper slicing cylinder, and a valve port J of the three-position four-way reversing valve B is connected with a valve port K of an electromagnetic reversing valve, a valve port N of an electromagnetic valve and a sixth valve port of a lower slicing cylinder. According to the hot pickled mustard tuber slicing device, hot pickled mustard tuber slicing is automatically achieved, hot pickled mustard tuber slices are uniform in thickness, and the device is reasonable in structure and good in reliability.

Owner:涪陵天然食品有限责任公司

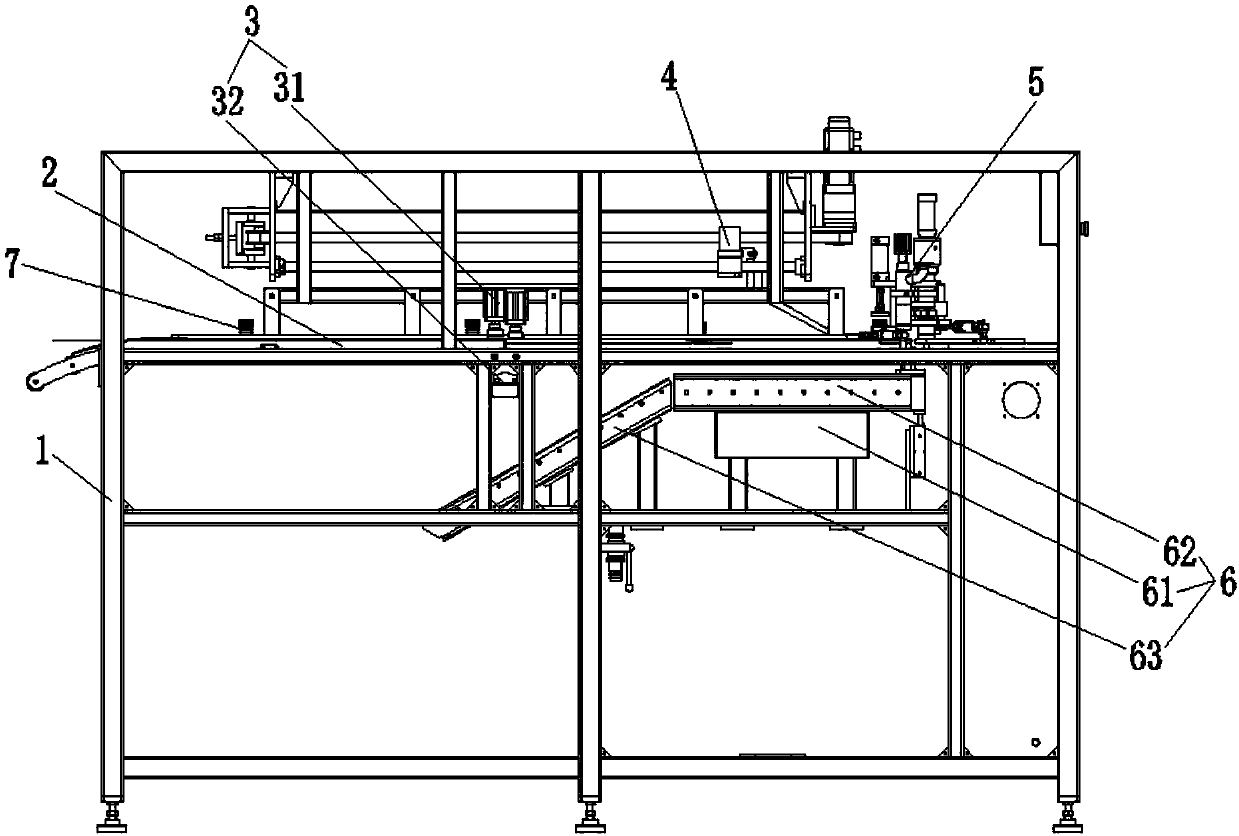

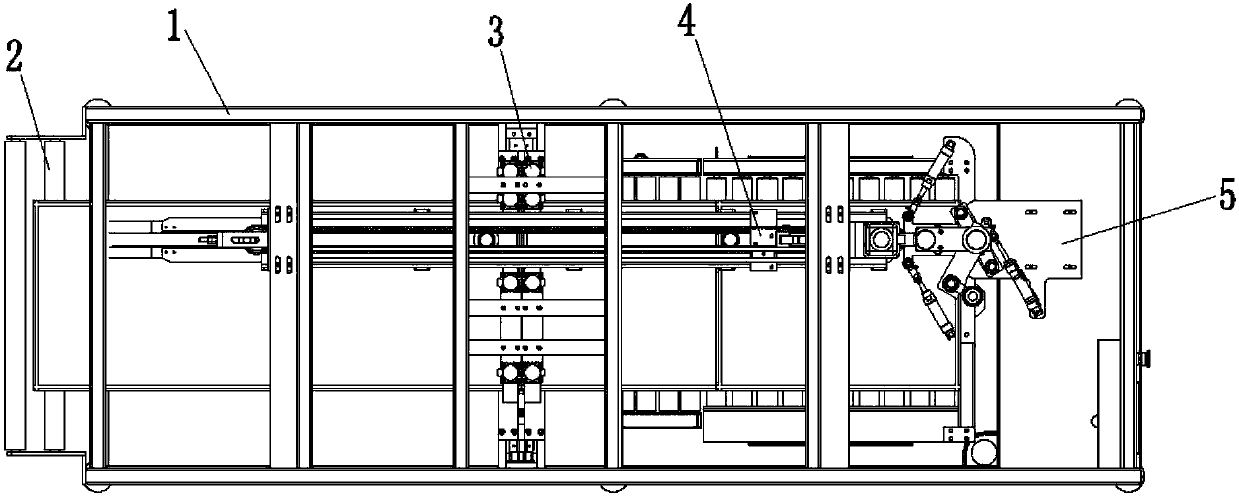

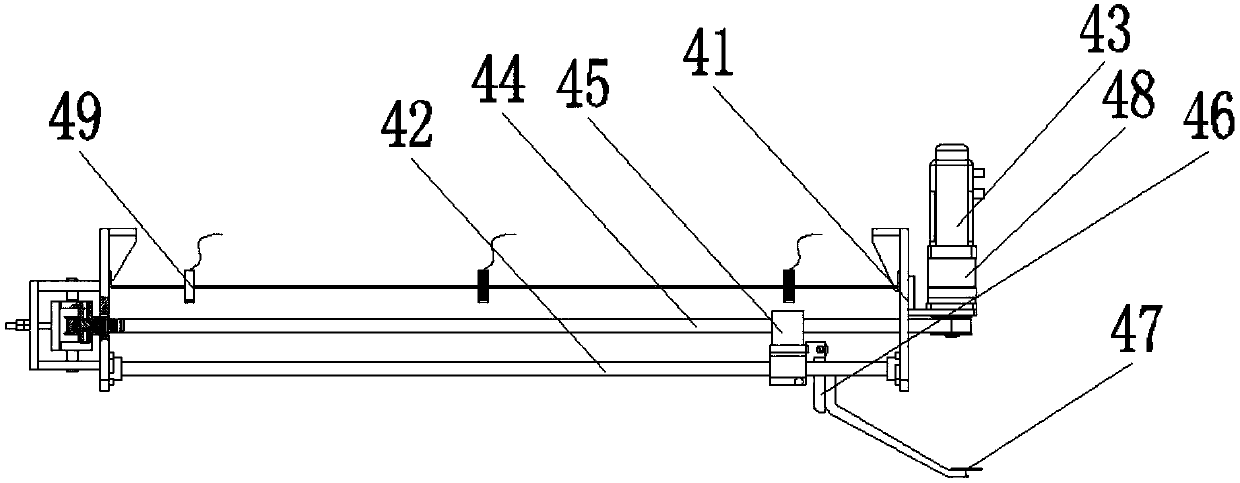

Full-automatic soft bag filling machine

PendingCN107776928AFully automatedReduce labor costsLiquid materialMechanical engineeringFully automated

The invention discloses a full-automatic soft bag filling machine. A soft bag conveying table is provided with a gap perpendicular to a soft bag conveying direction. A cutting mechanism is arranged atthe gap of the soft bag conveying table and used for cutting off a first soft bag at a bag outlet end of the soft bag conveying table. A bag sending mechanism is arranged above the soft bag conveyingtable and used for sending the first soft bag at the bag outlet end of the soft bag conveying table to a pulling, filling and pressing integrated mechanism which is arranged on a bag outlet side of the soft bag conveying table, and a bag falling gap is reserved between the pulling, filling and pressing integrated mechanism and the soft bag conveying table. The pulling, filling and pressing integrated mechanism completes cover pulling, filling and cover pressing operations on soft bags. A discharging mechanism is arranged below the bag falling gap between the pulling, filling and pressing integrated mechanism and the soft bag conveying table. The full-automatic soft bag filling machine has advantages that full automation in soft bag filling is realized, labor cost is effectively saved, andproduction efficiency is greatly improved.

Owner:江苏汤姆森智能装备有限公司

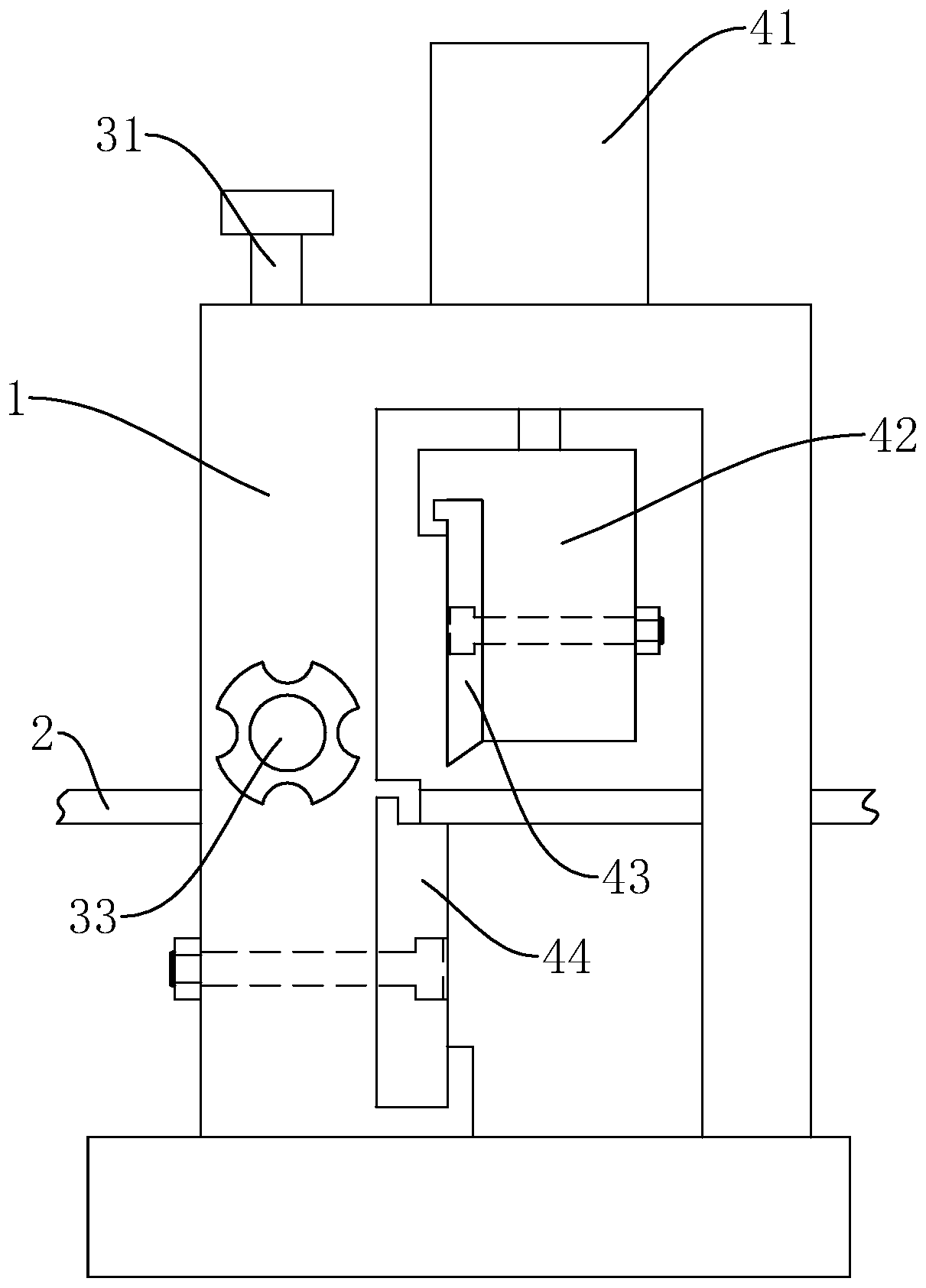

New energy automobile lithium battery positive and negative electrode material ceramic cutting tool

InactiveCN111113536AAchieve fixationQuick changeFinal product manufactureFeeding apparatusNew energyGear wheel

The invention relates to the technical field of material cutting, and discloses a new energy automobile lithium battery positive and negative electrode material ceramic cutting tool. The ceramic cutting tool comprises a fixing plate, a supporting plate is arranged on one side of the bottom of the fixing plate, a connecting plate is arranged at the bottom of one side of the supporting plate, and apositive and negative motor is arranged on one side of the top of the connecting plate; limiting frames are arranged on the two sides of the outer surface of the positive and negative motor, and a transmission gear is arranged at one end of an output shaft of the positive and negative motor; a supporting frame is arranged at the top of the fixing plate, a sliding rod is arranged on one side of thetop of the fixing plate, and a clamping mechanism is arranged on one side of the top of the fixing plate; and a sliding sleeve is arranged at the top of the outer surface of the sliding rod, a connecting rod is arranged on one side of the sliding sleeve, and a hollow block is arranged at the bottom of the connecting rod. The ceramic cutting tool has the beneficial effects that a first bolt is used for rotating a rotating shaft to drive a limiting block to move left and right, so that positive and negative electrode materials of different sizes are fixed, and a cutting device can limit the positive and negative electrode materials of different sizes.

Owner:柳州四通材料科技有限公司

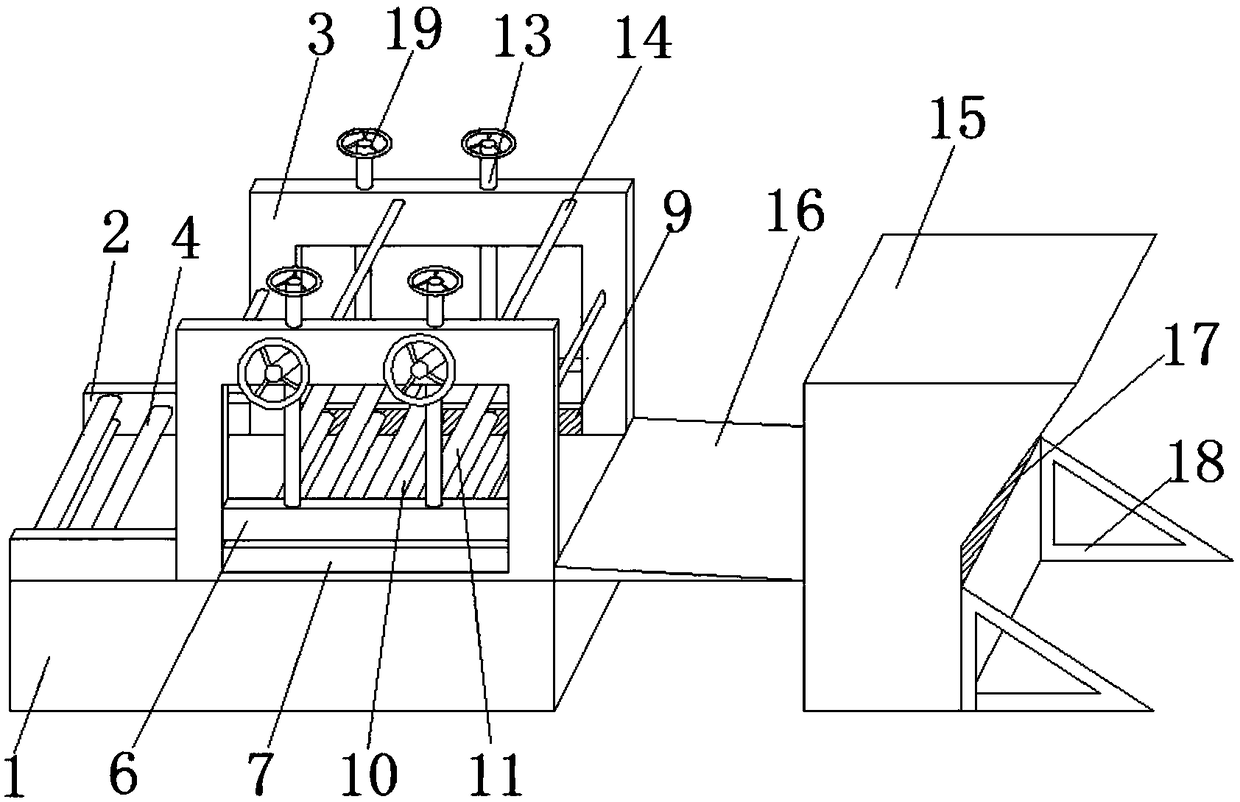

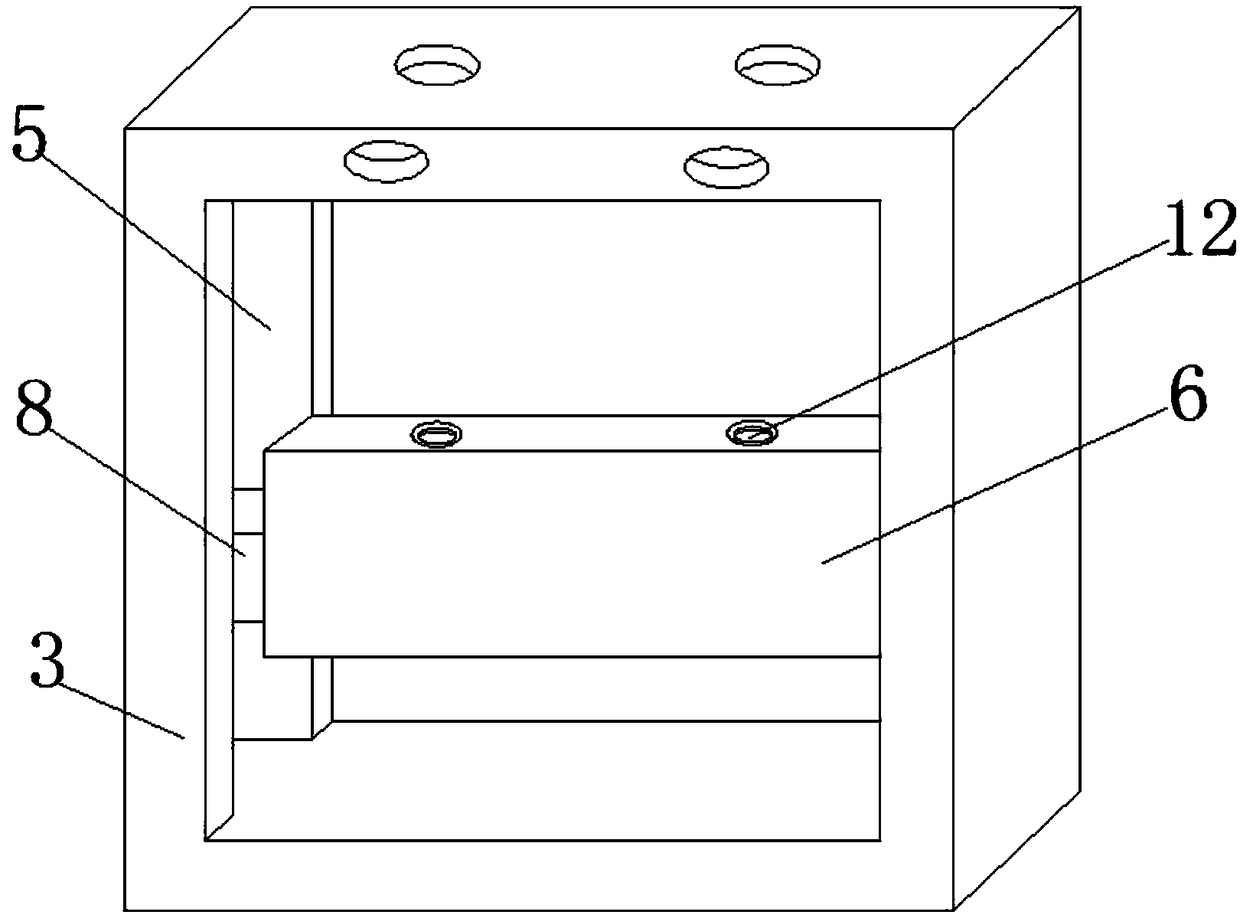

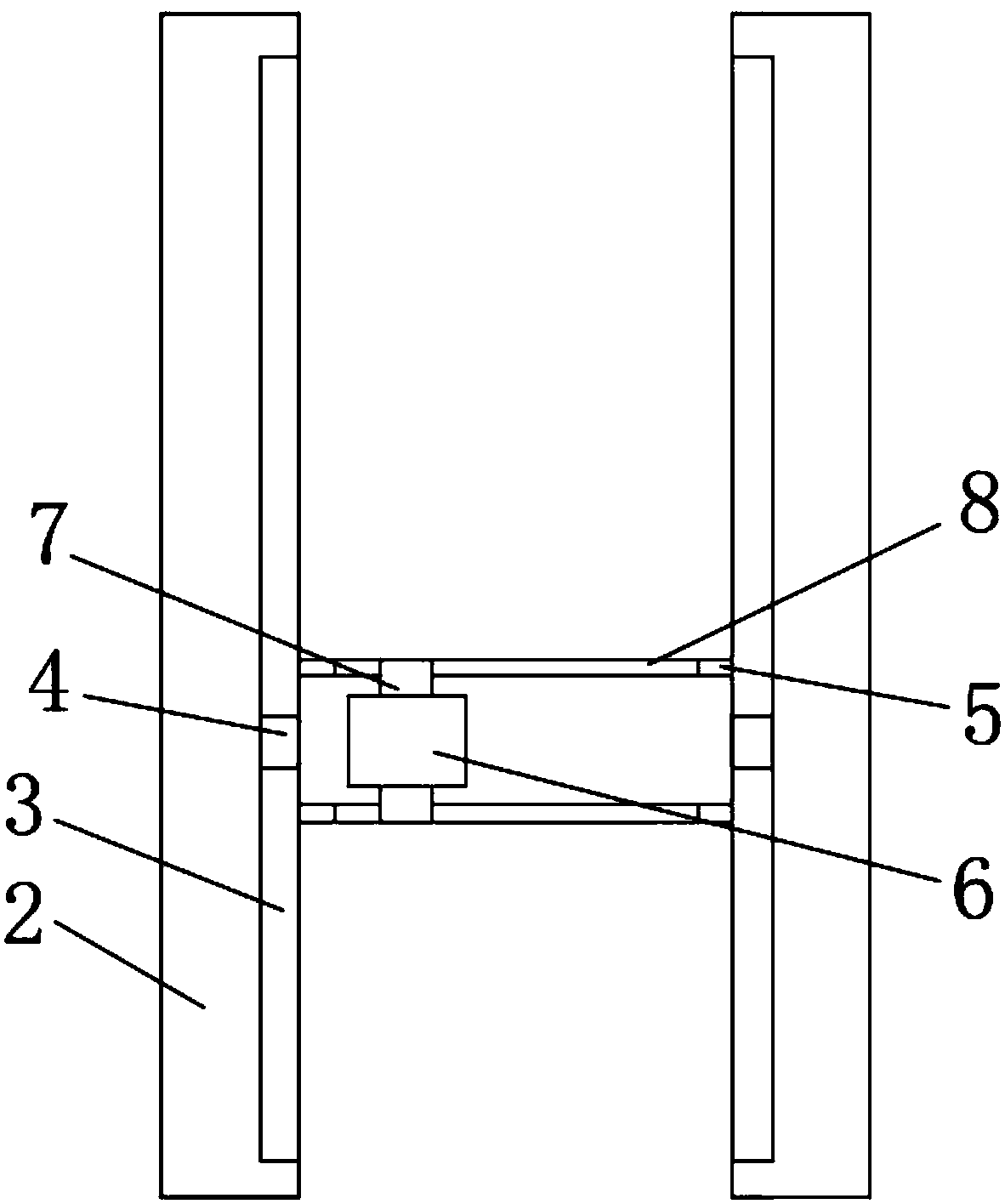

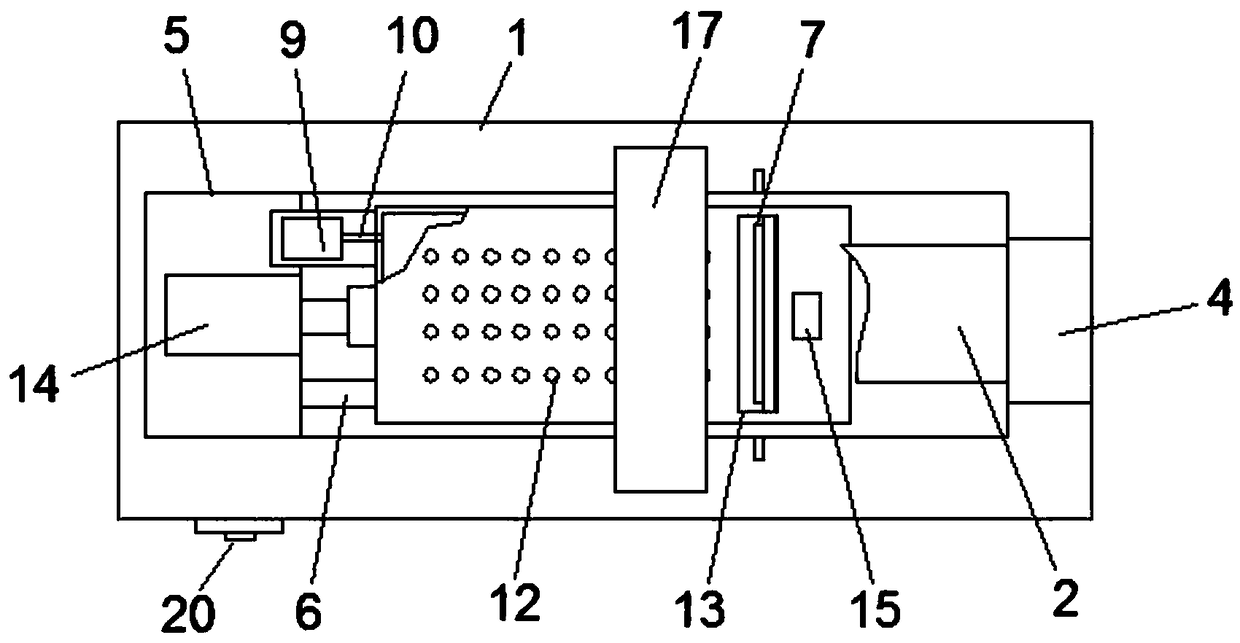

Sheet cutting machine

ActiveCN108394739AGuaranteed smoothCrop stabilizationMetal working apparatusArticle feedersTransverse axisRight triangle

The invention discloses a sheet cutting machine. The machine comprises a base, two fixed plates symmetrically distributed relative to the transverse axis of the base and two symmetrically distributedframe bodies are sequentially connected to the top of the base in the horizontal direction, three first roller shafts are rotatably connected between the two fixed plates through a rotating shaft, thefirst roller shafts are distributed in a right triangle manner, concave sliding grooves are formed in the inner side walls of the two frame bodies, a first fixed base and a second fixed base are arranged on the inner side wall of each of the two frame bodies in the vertical direction, a convex sliding block is arranged between each first fixed base and the corresponding concave sliding groove, the first fixed bases are arranged on the inner walls of the corresponding concave sliding grooves in a sleeving manner through the convex sliding blocks, the second fixed bases are fixedly clamped to the inner side walls of the frame bodies, the inner walls of the second fixed bases are fixedly provided with transmission assemblies, and second roller shafts which are evenly distributed are in key connection between the second fixed bases on the two frame bodies through the transmission assembly. The sheet cutting machine is simple in structure and convenient to operate, sheets of different thicknesses can be stably conveyed, and cutting is stable and efficient.

Owner:安徽雄风防护设施有限公司

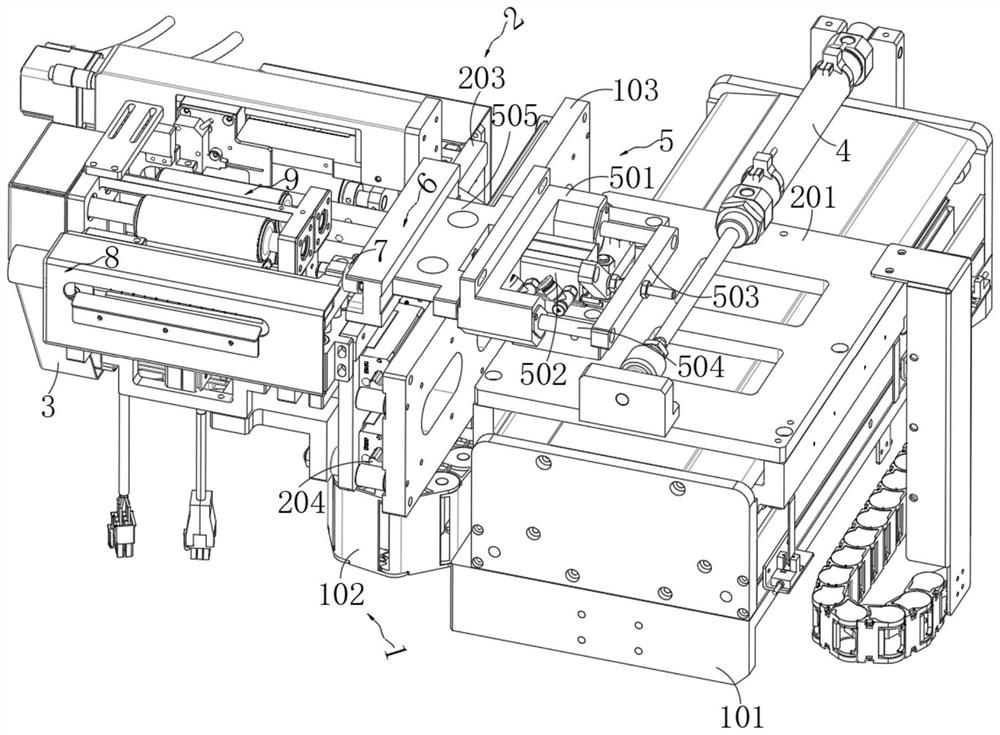

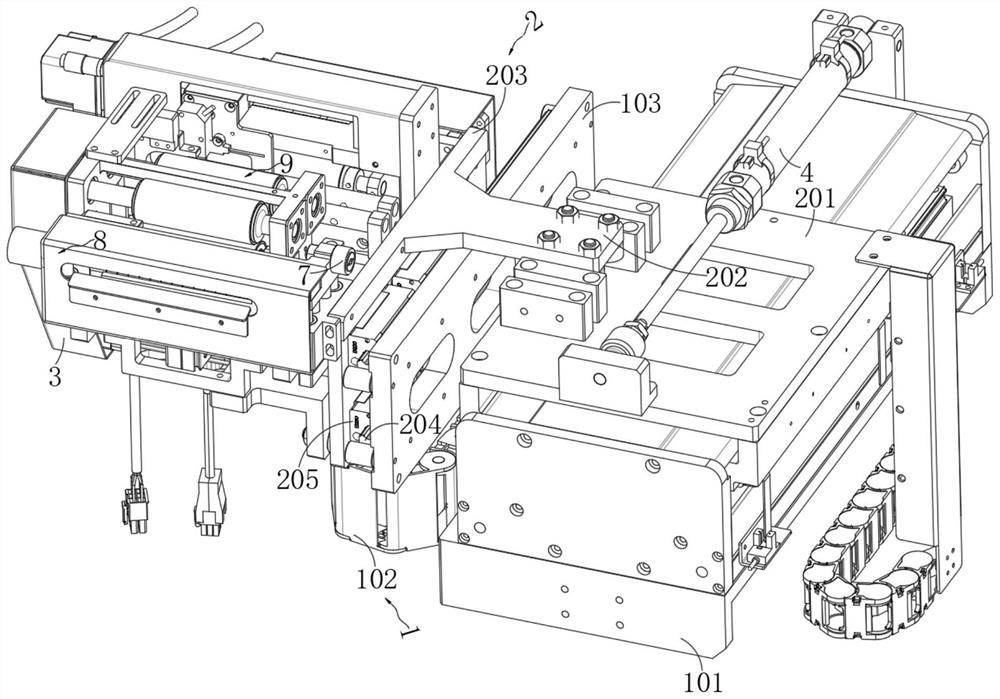

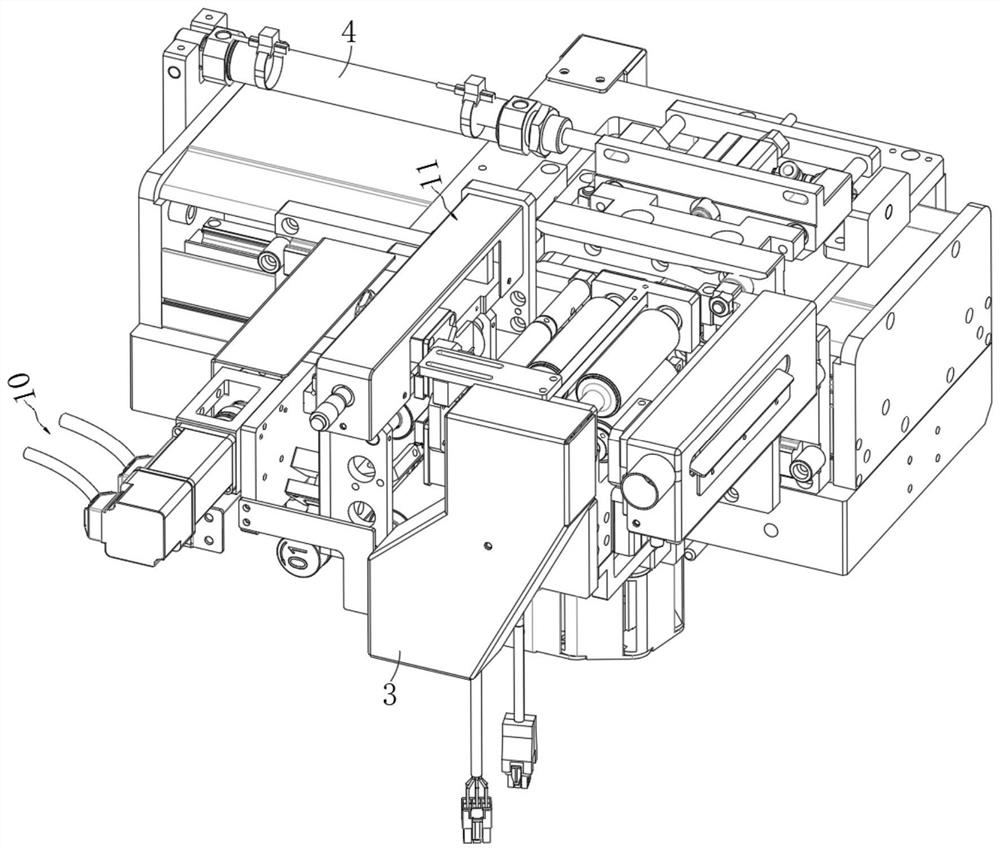

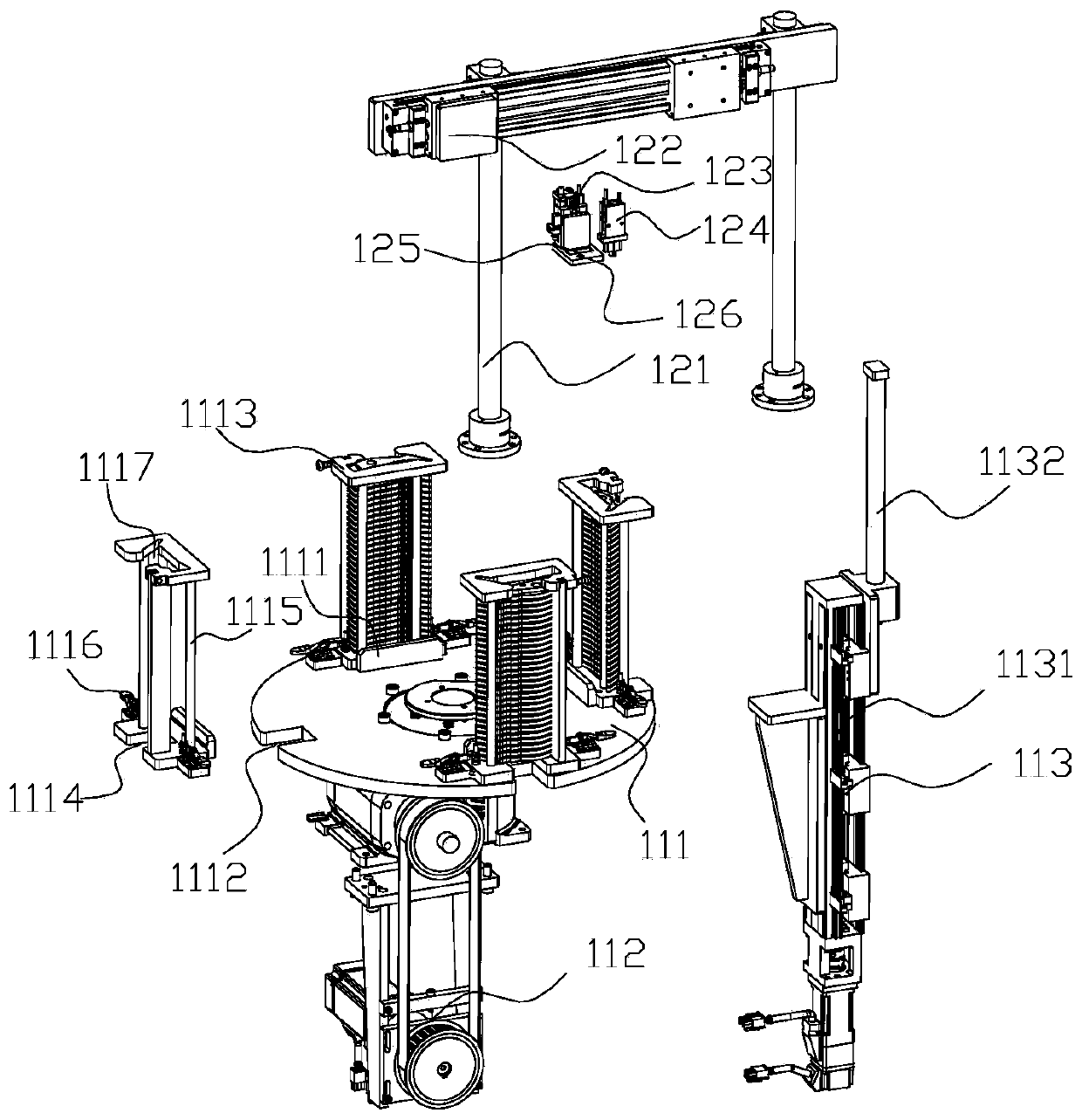

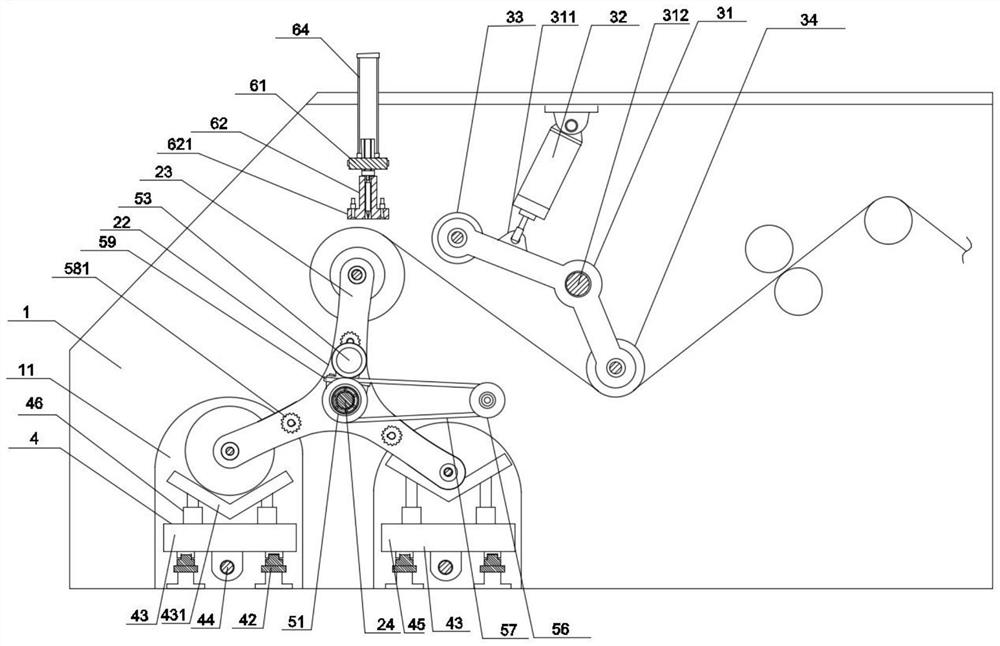

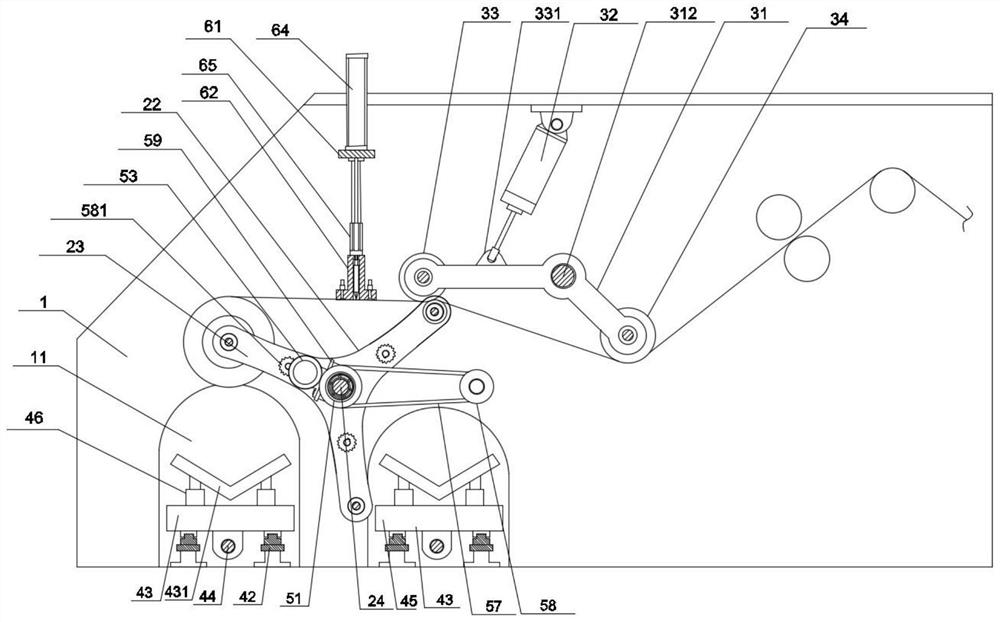

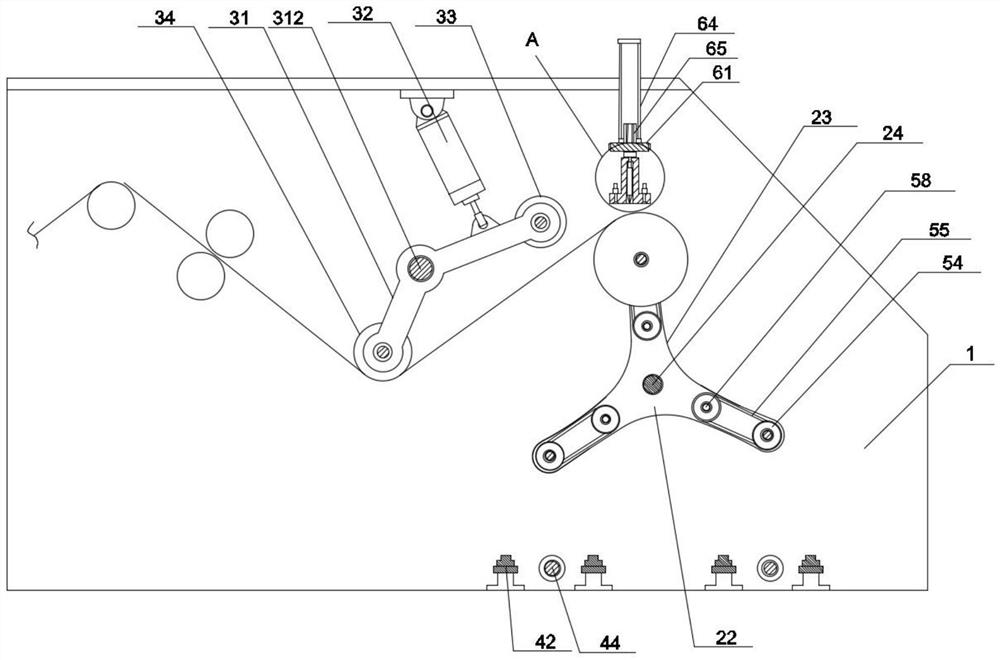

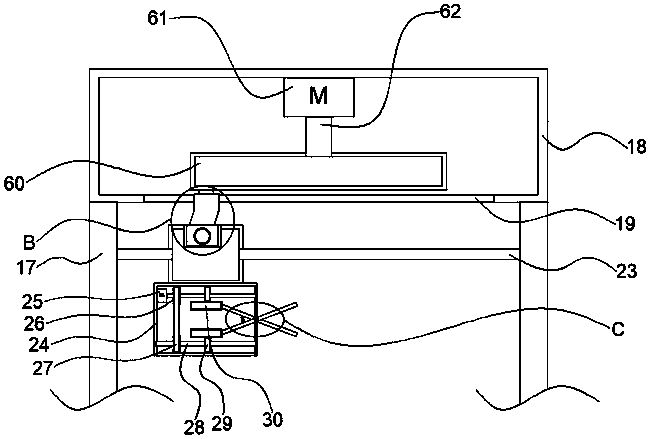

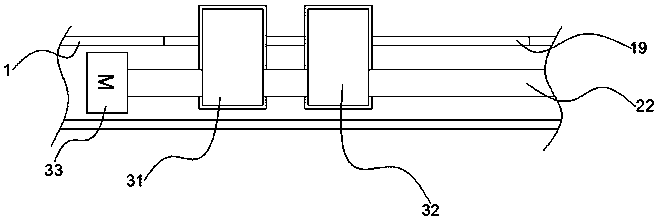

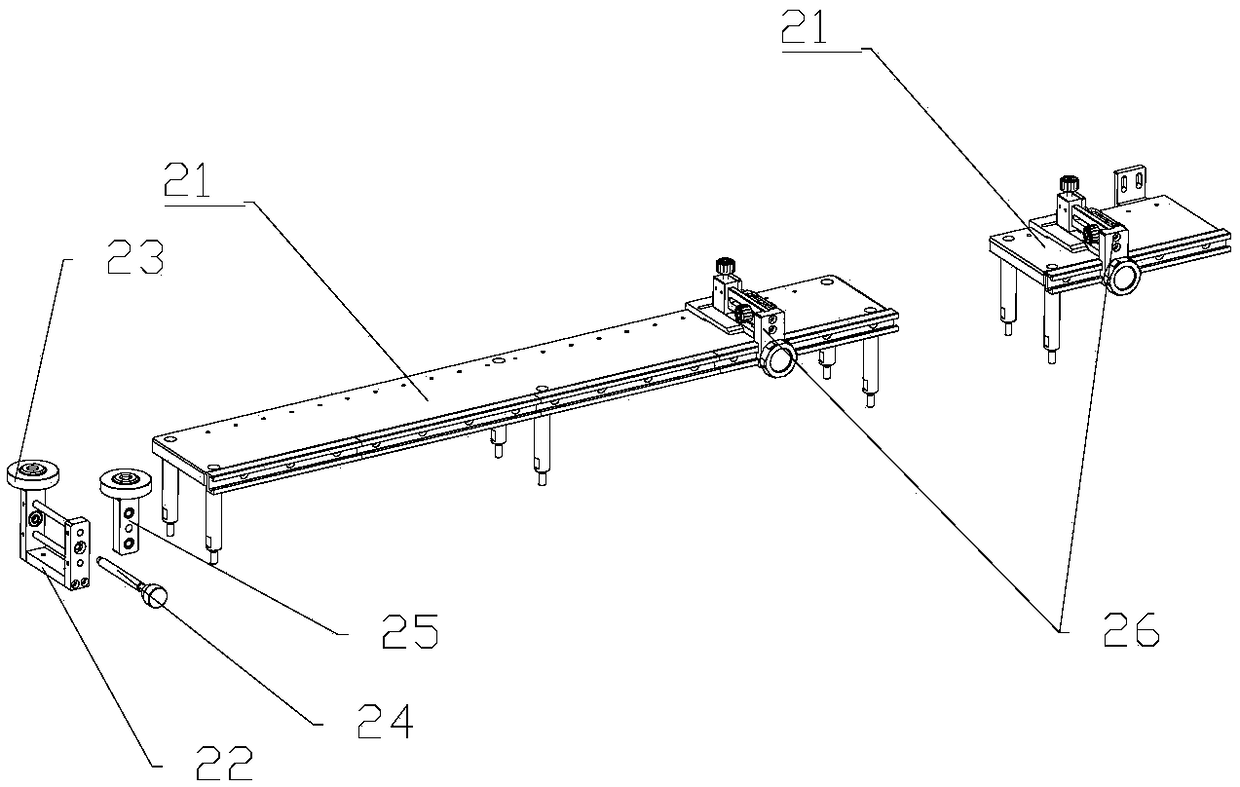

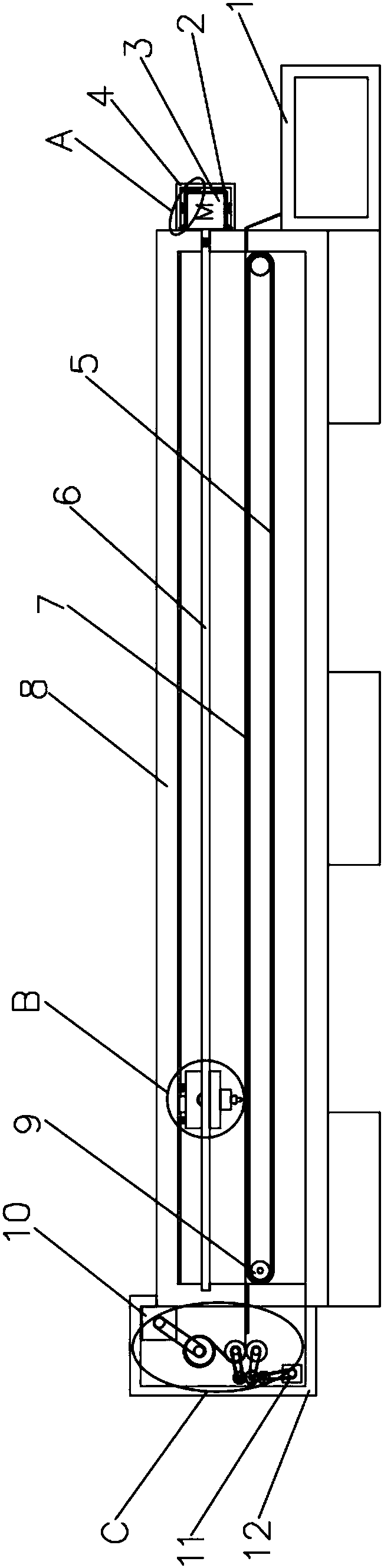

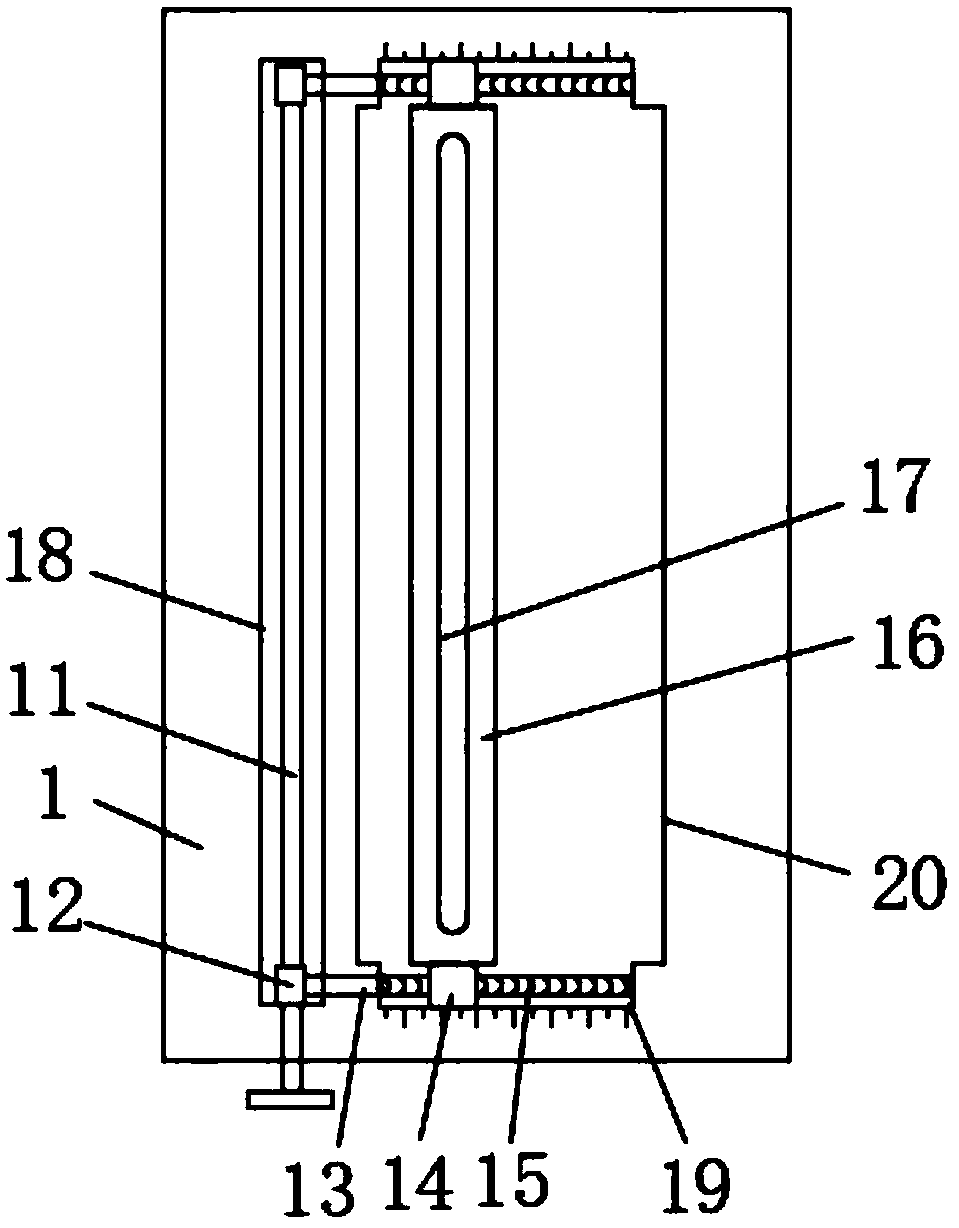

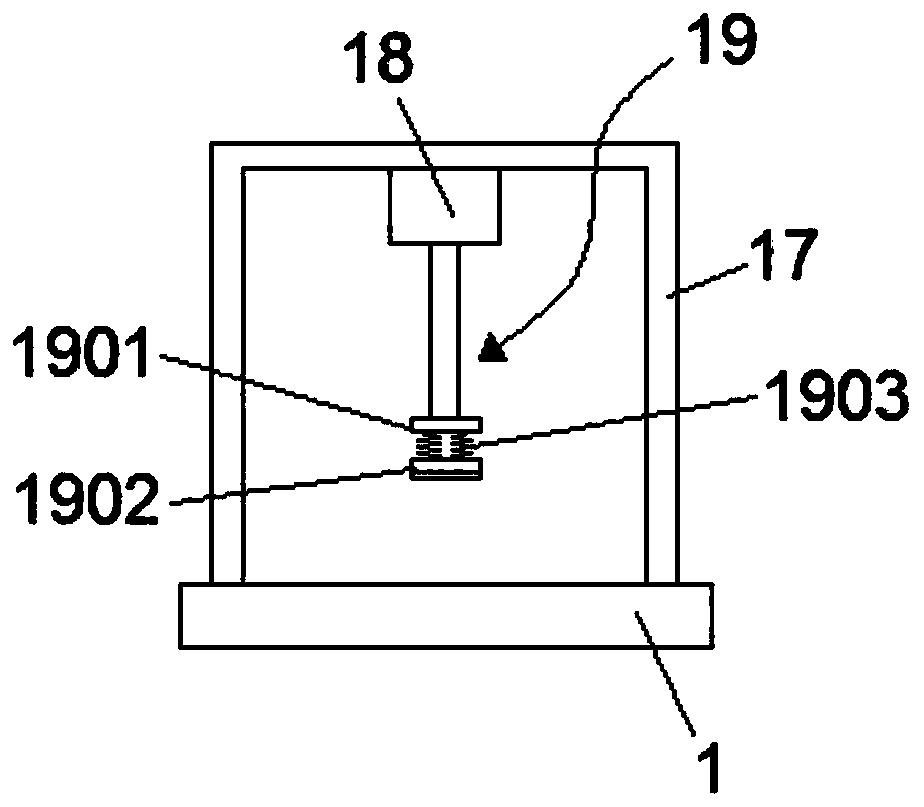

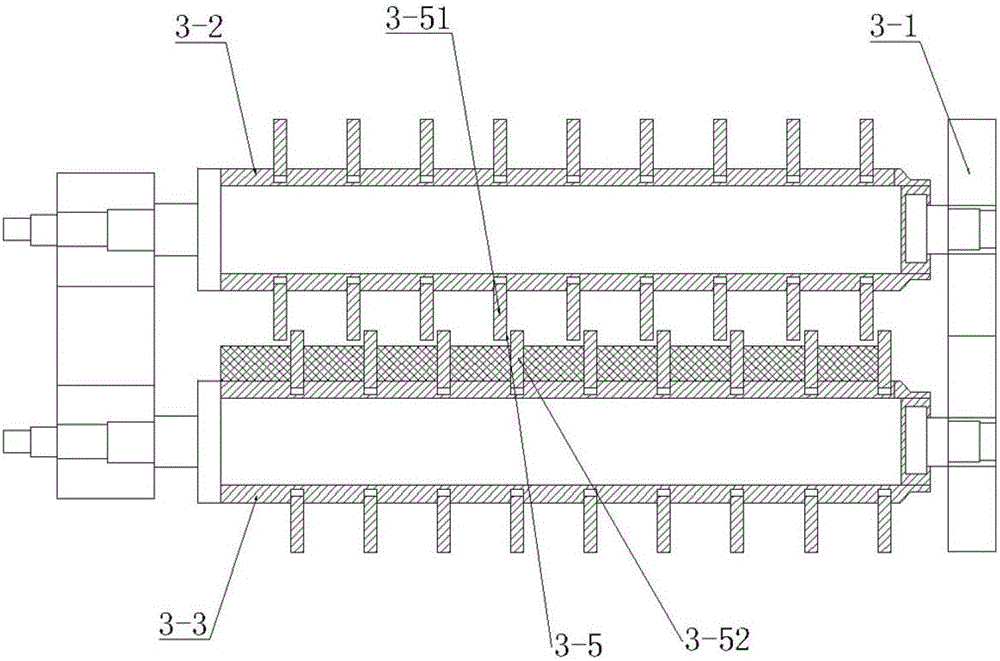

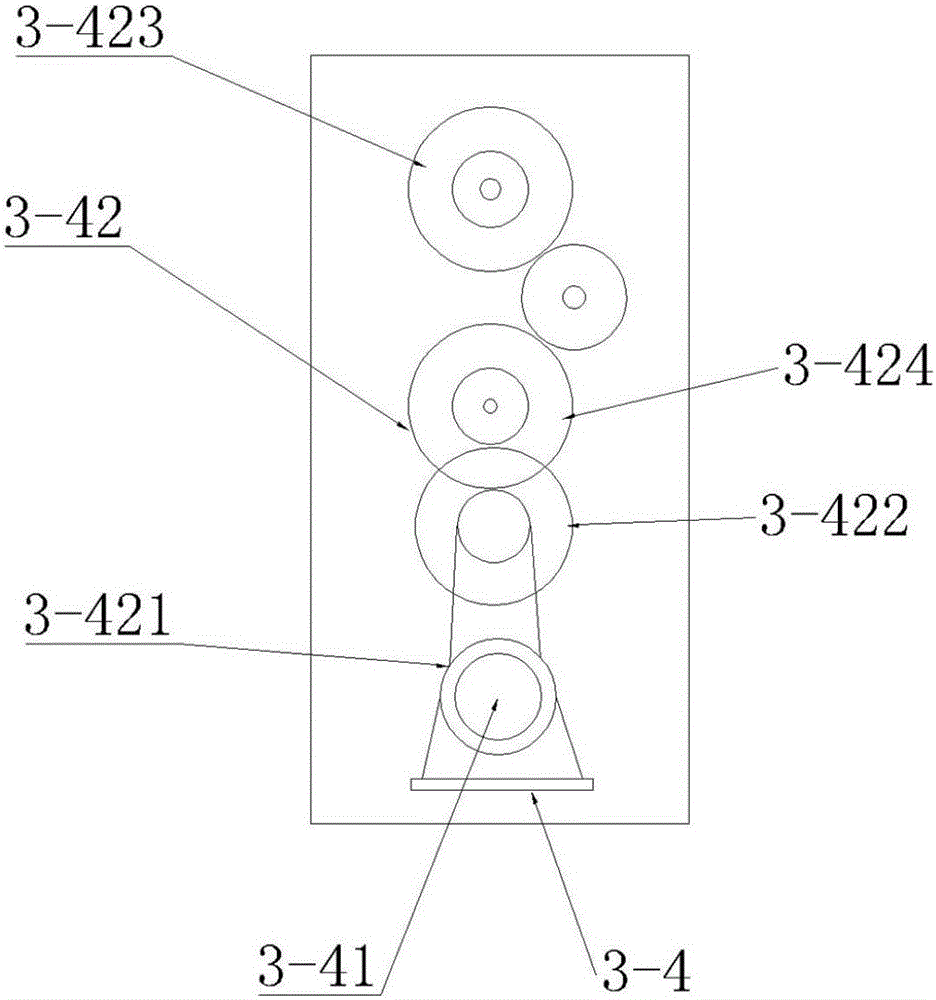

Sheet feeding structure of lithium battery winding machine and working method of sheet feeding structure

PendingCN114735502ACrop stabilizationAccurate, fast and stable outputAssembling battery machinesFinal product manufactureWinding machineEngineering

The invention provides a sheet feeding structure of a lithium battery winding machine and a working method of the sheet feeding structure, and belongs to the technical field of lithium battery winding machines. The conveying table is arranged on the frame body; the roll shaft piece conveying mechanism is arranged on the conveying table and is used for conveying the pole pieces; the telescopic mechanism is arranged on the frame body; the sliding mechanism is arranged on the frame body in a sliding mode and connected with the telescopic mechanism, and sliding is achieved based on stretching and retracting of the telescopic mechanism; the moving mechanism is arranged on the sliding mechanism; the signal transmission roller is arranged on the conveying table; and the cutter track mechanism is arranged on the moving mechanism, the signal transmission roller makes contact with the cutter track mechanism based on stretching and retracting of the moving mechanism, and then the telescopic mechanism drives the sliding mechanism to slide so that the signal transmission roller can roll in the cutter track mechanism. The pole piece cutting device aims at solving the technical problem that in the prior art, due to the fact that a cutter is poor in structural stability, pole piece cutting cannot be rapidly and accurately achieved.

Owner:深圳市兴盛林科技有限公司

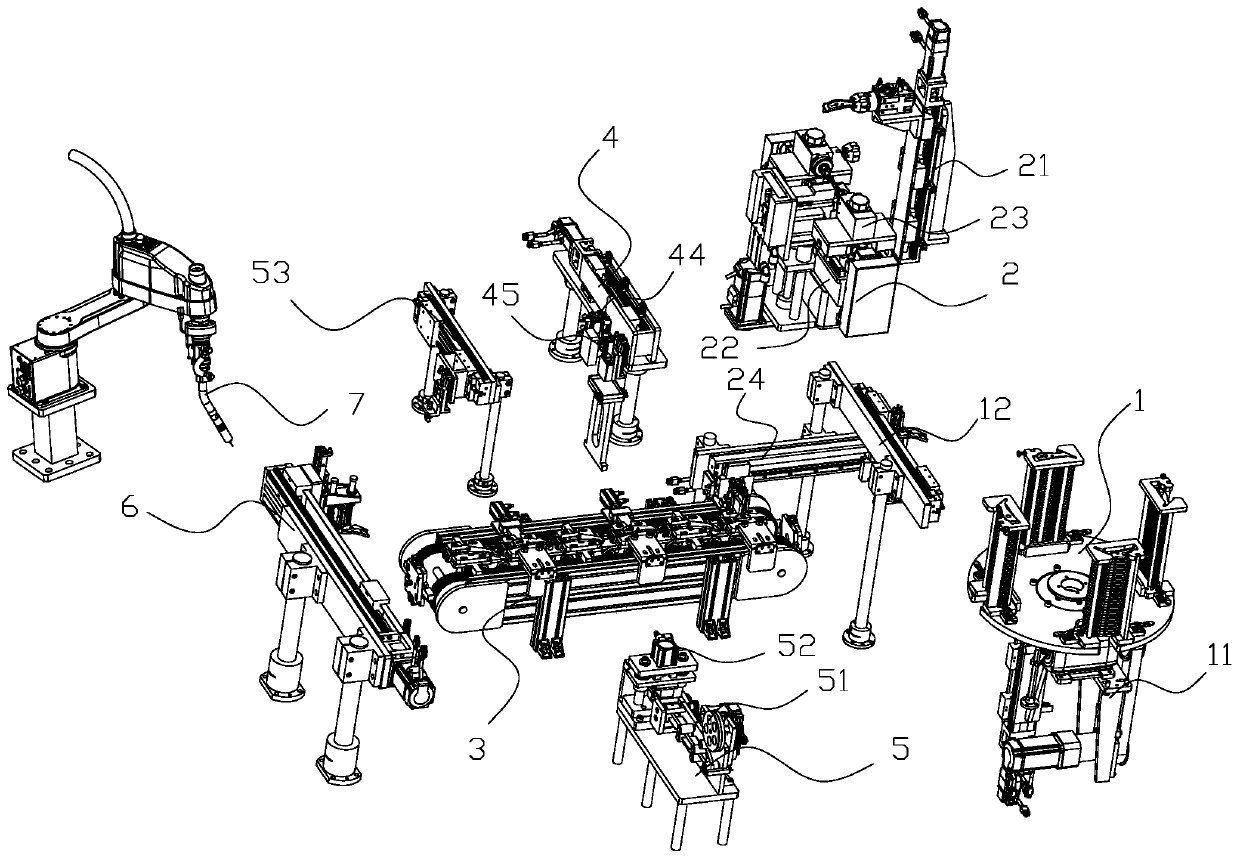

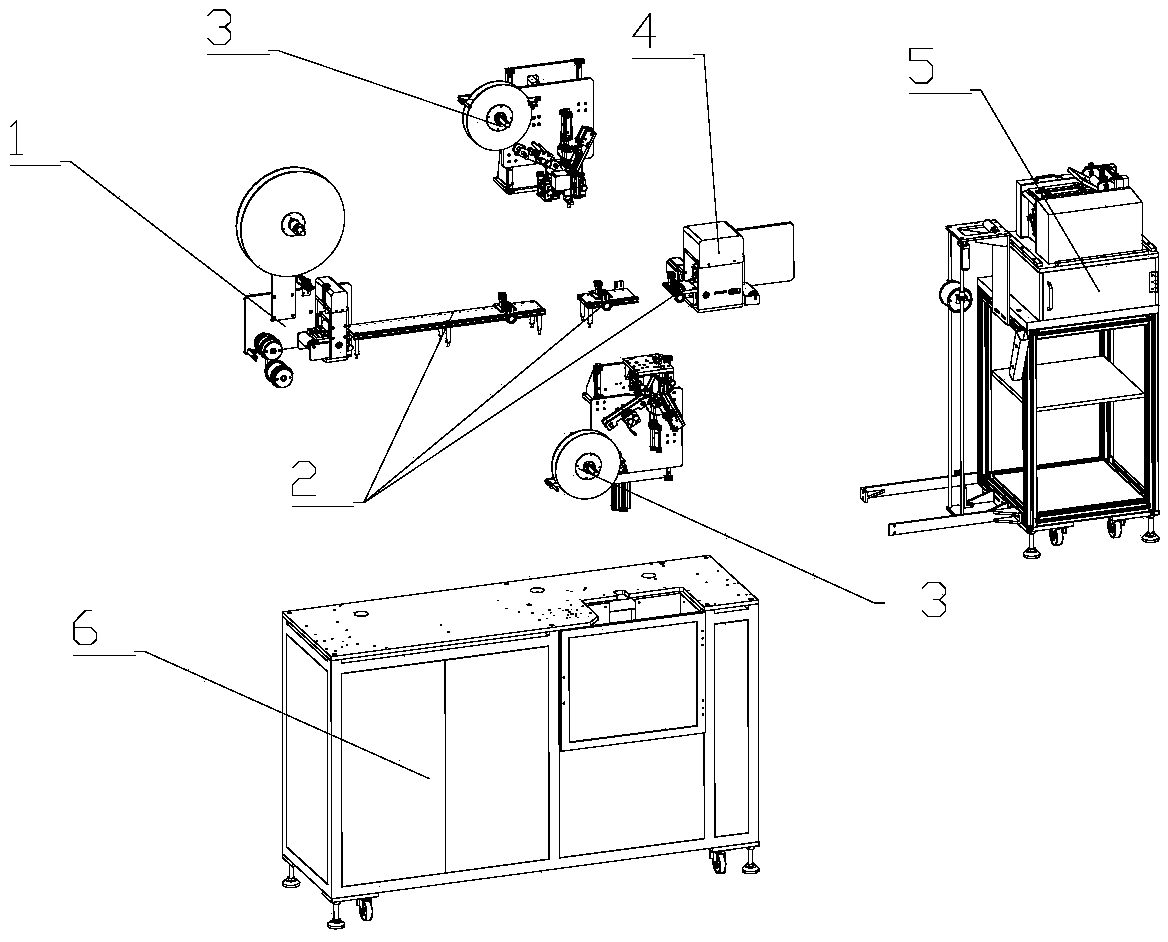

Assembly device and method of copper sheets for circuit breaker

InactiveCN111376059AEasy to transportStable and accurate transferMaterial gluingCleaning using toolsEngineeringMaterials science

The invention relates to the technical field of production of circuit breakers. An assembly device of copper sheets for a circuit breaker comprises a copper sheet feeding bracket, a copper sheet feeding assembly, a copper sheet cutting assembly and a copper sheet assembling assembly, wherein the copper sheet feeding assembly and the copper sheet cutting assembly are arranged on the copper sheet feeding bracket separately, the copper sheet feeding assembly is located at the feeding end of the copper sheet cutting assembly, and is used for conveying a copper sheet band for feeding, the copper sheet cutting assembly is used for cutting the copper sheet band sheet by sheet, and the copper sheet assembling assembly is located at the discharging end of the copper sheet cutting assembly, and is used for transferring and assembling the cut copper sheets. The assembly device has the advantages of being capable of improving the copper sheet cutting quality and stability as well as the copper sheet assembling efficiency and quality.

Owner:丁水珍

Integrated preparation system for green and environment-friendly packaging film

PendingCN114275578AMeet the needs of productionIncrease productivityWebs handlingElectric machineryEngineering

The invention relates to an integrated preparation system for a green and environment-friendly packaging film, the integrated preparation system comprises a rack and a winding mechanism, a guide mechanism and a cutter mechanism which are arranged on the rack, the winding mechanism comprises a left winding frame, a right winding frame and a driving motor for driving the winding frames to rotate, and the left winding frame and the right winding frame are rotationally arranged on the two sides of the rack respectively; three supporting arms are distributed on the left winding frame and the right winding frame in the circumferential direction, the supporting arms on the left winding frame are movably connected with the left winding frame through hinges, a folding mechanism is arranged on the left winding frame, and a connecting shaft is connected between the centers of the two winding frames. One end of the connecting shaft penetrates through one side of the machine frame and is driven by the driving motor installed on the outer side of the machine frame, the rotating wheel type winding frame is adopted for winding, the three supporting arms are used for dividing into three stations, winding, coil unloading and coil loading operation is conducted, the production efficiency is improved, the production continuity is guaranteed, and the requirement for flow line production is met.

Owner:镇江现代包装有限公司

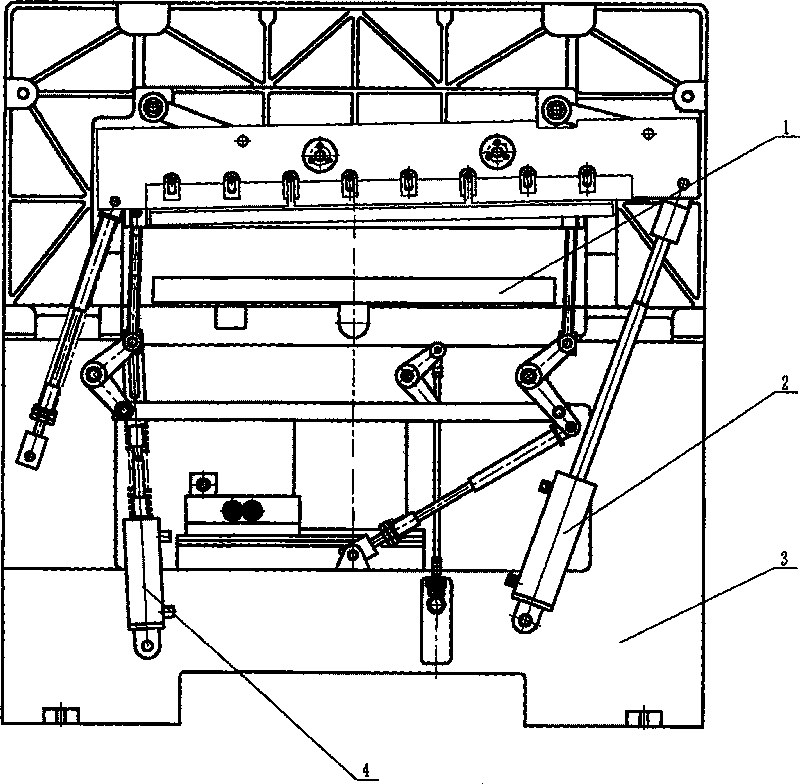

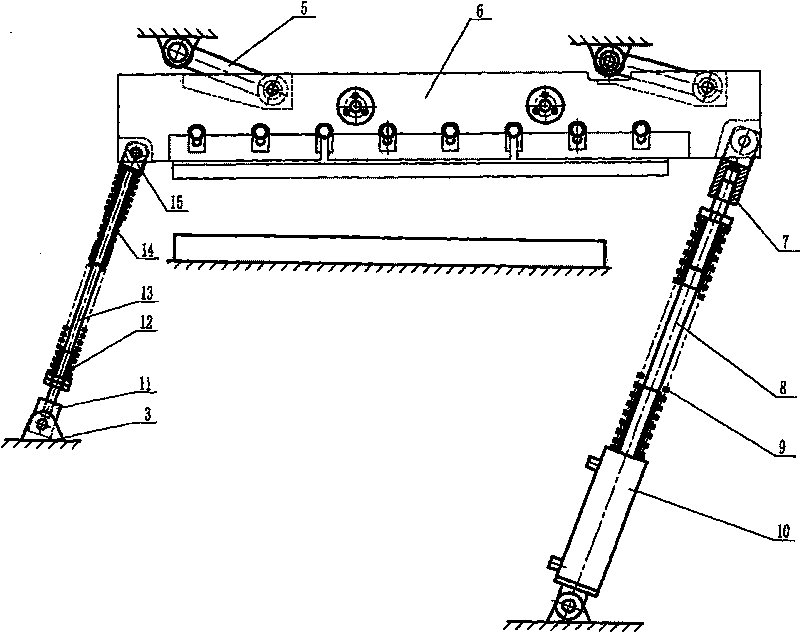

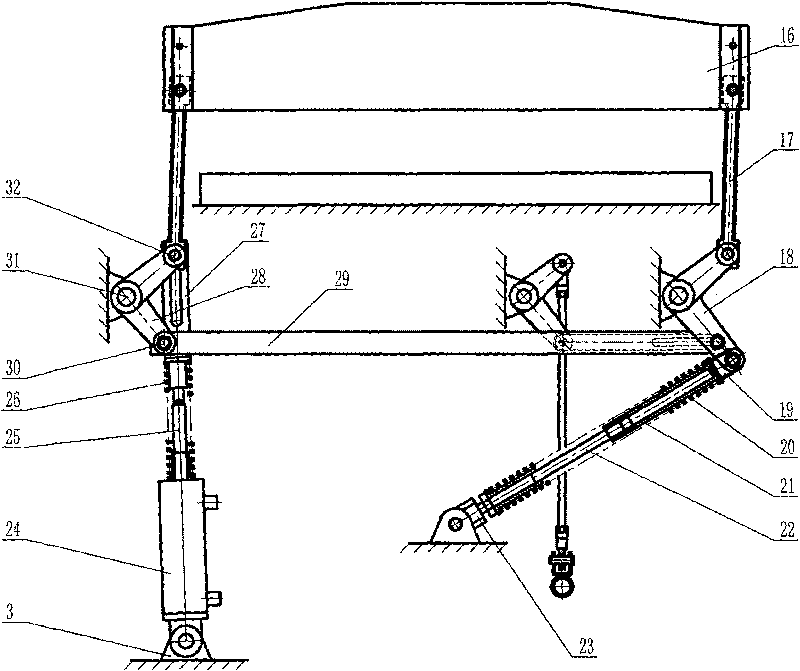

All-hydraulic guillotines machine

ActiveCN101298145BCrop stabilizationReduce noiseMetal working apparatusPulp and paper industryCutting oil

Owner:ZHEJIANG HUAYUE PACKING MACHINERY

Automatic fabric cutting and blanking machine

InactiveCN108715326AReduce labor intensityPromote sustainable developmentMechanical conveyorsArticle deliveryUltimate tensile strengthMachining

The invention discloses an automatic fabric cutting and blanking machine. The automatic fabric cutting and blanking machine comprises a machining table, wherein two fixing bases are symmetrically fixed on the left side and the right side of the machining table respectively; a first rotating shaft is arranged between the two fixing bases, one end of the first rotating shaft is rotationally connected to the fixing base located on the left side, and one side, close to the first rotating shaft, of the fixed base on the right side is fixedly provided with a first servo motor; the other end of the first rotating shaft is fixedly connected to the driving end of the first servo motor, a cloth winding roller is fixedly installed on the first rotating shaft, and a first mounting opening is formed inone side above the machining table; and one side, close to the cloth winding roller, of the machining table is fixedly provided with a first mounting base and a second servo motor, and the first mounting base and the second servo motor are symmetrically installed on the machining table. According to the automatic fabric cutting and blanking machine, the automation degree is high, the working efficiency is high, the labor intensity of workers is low, the sustainable development of enterprises is facilitated, and the enterprise benefits are improved.

Owner:JIANGSU JINFENG LIGHT IND EQUIP CO LTD

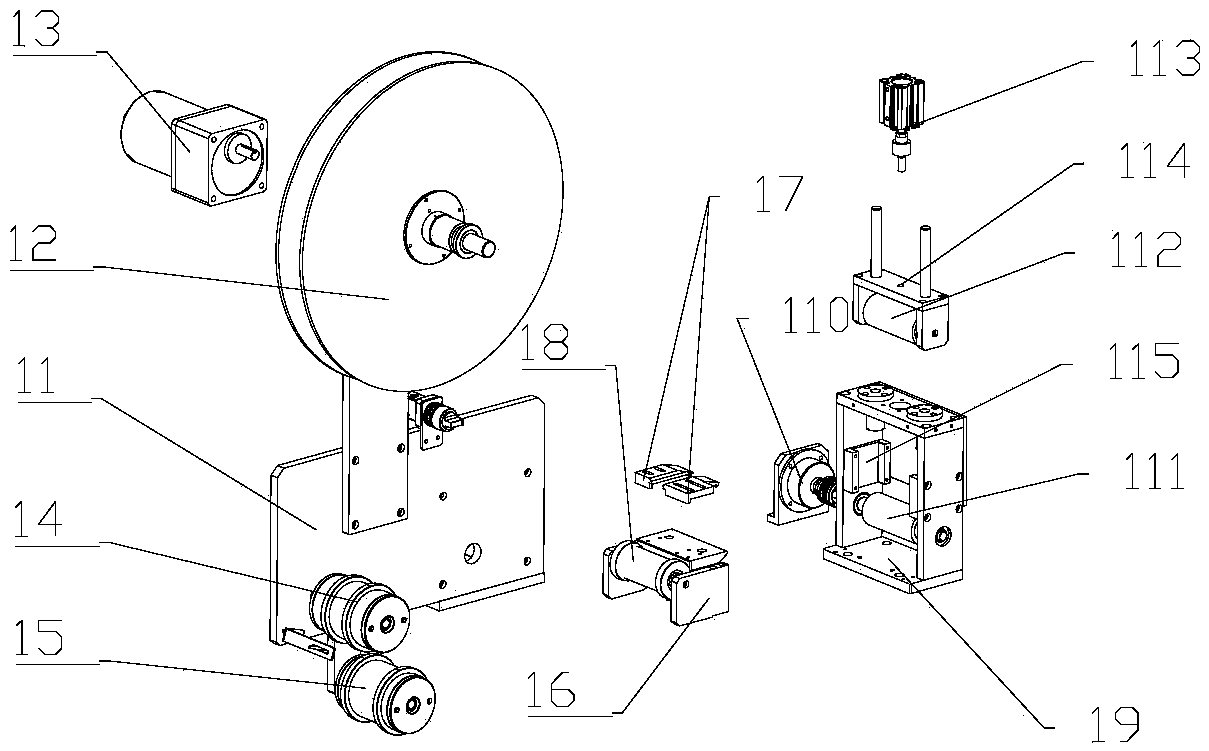

Glue-pasting module and glue-pasting device and flexible circuit board processing machine

InactiveCN108990285ASolve the phenomenon of easy slippingNot easy to slipPrinted circuit manufactureFlexible circuitsPulp and paper industry

The invention relates to the production technical field of a flexible circuit board. The adhesive pasting module comprises a mounting side plate, an adhesive paper material tray, a friction damping part, an adhesive paper guide rod assembly, an adhesive paper pressing mechanism and an adhesive paper cutting mechanism. The glue module has the advantages of stable feeding and accurate cutting of glue paper.

Owner:张金仙

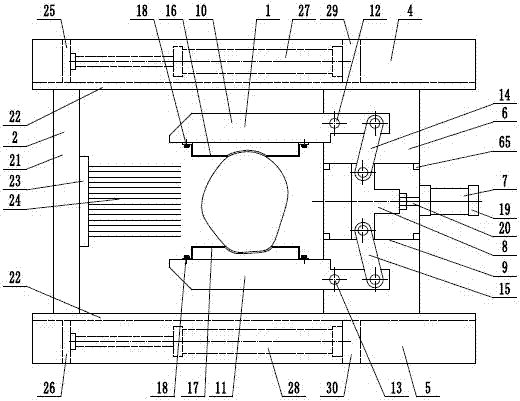

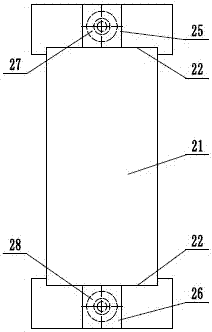

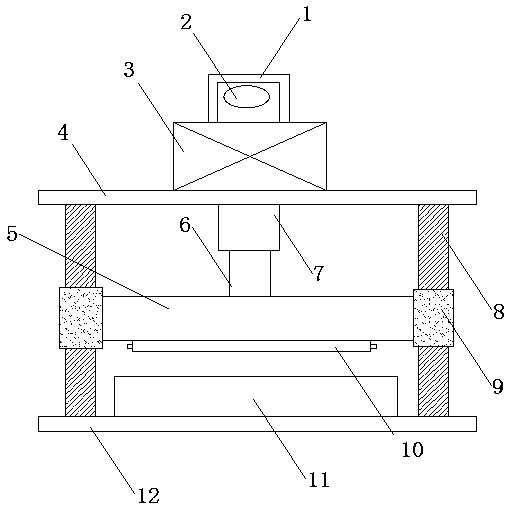

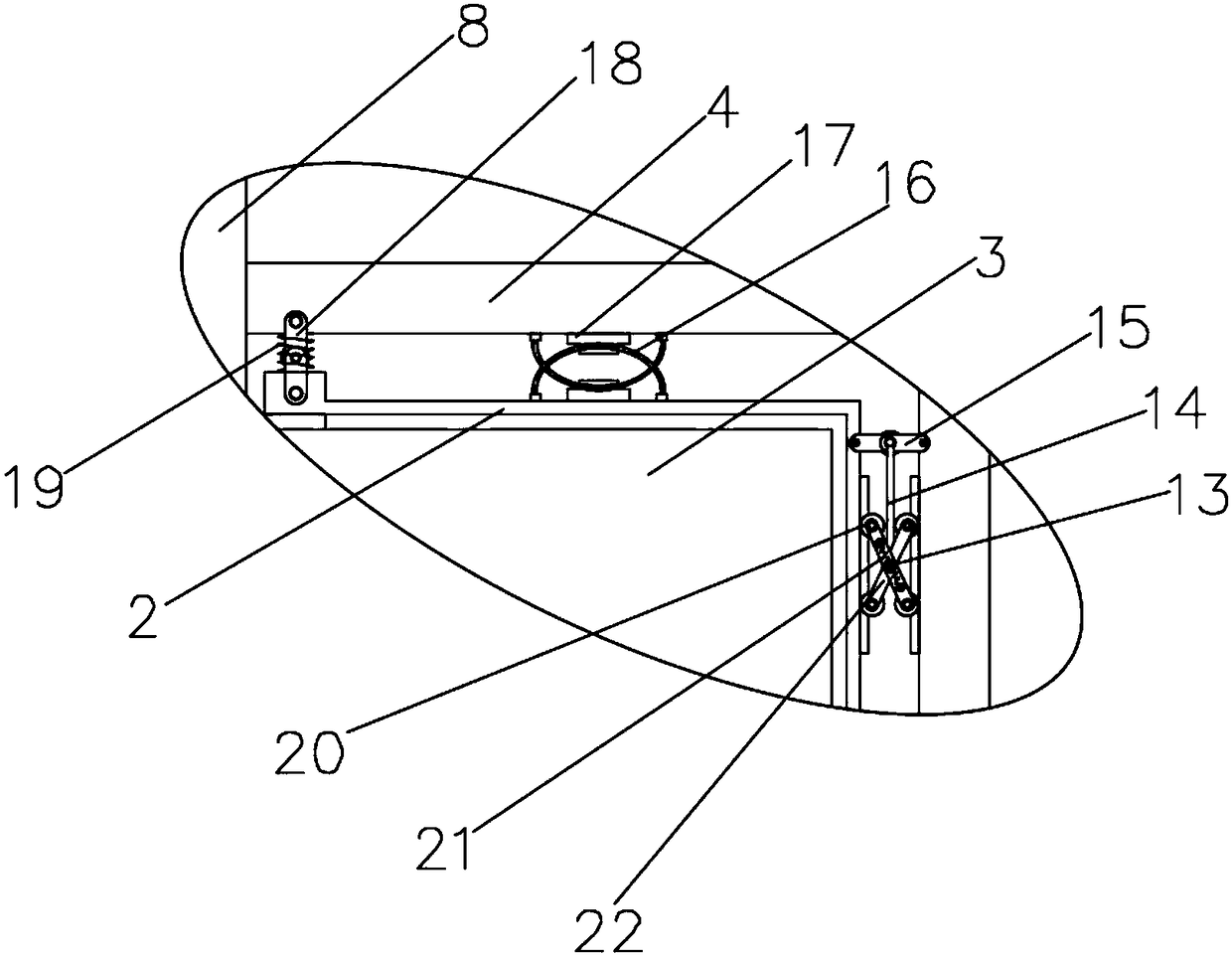

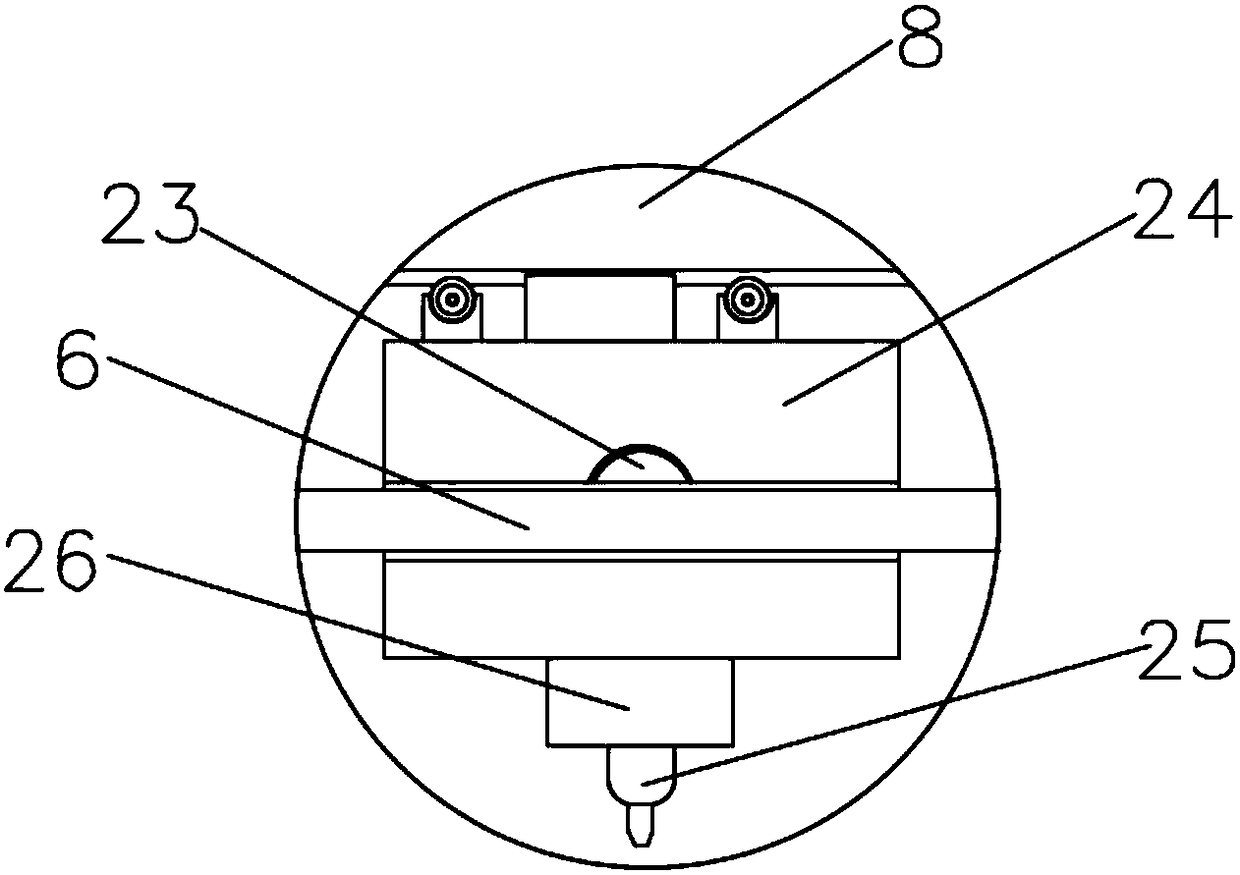

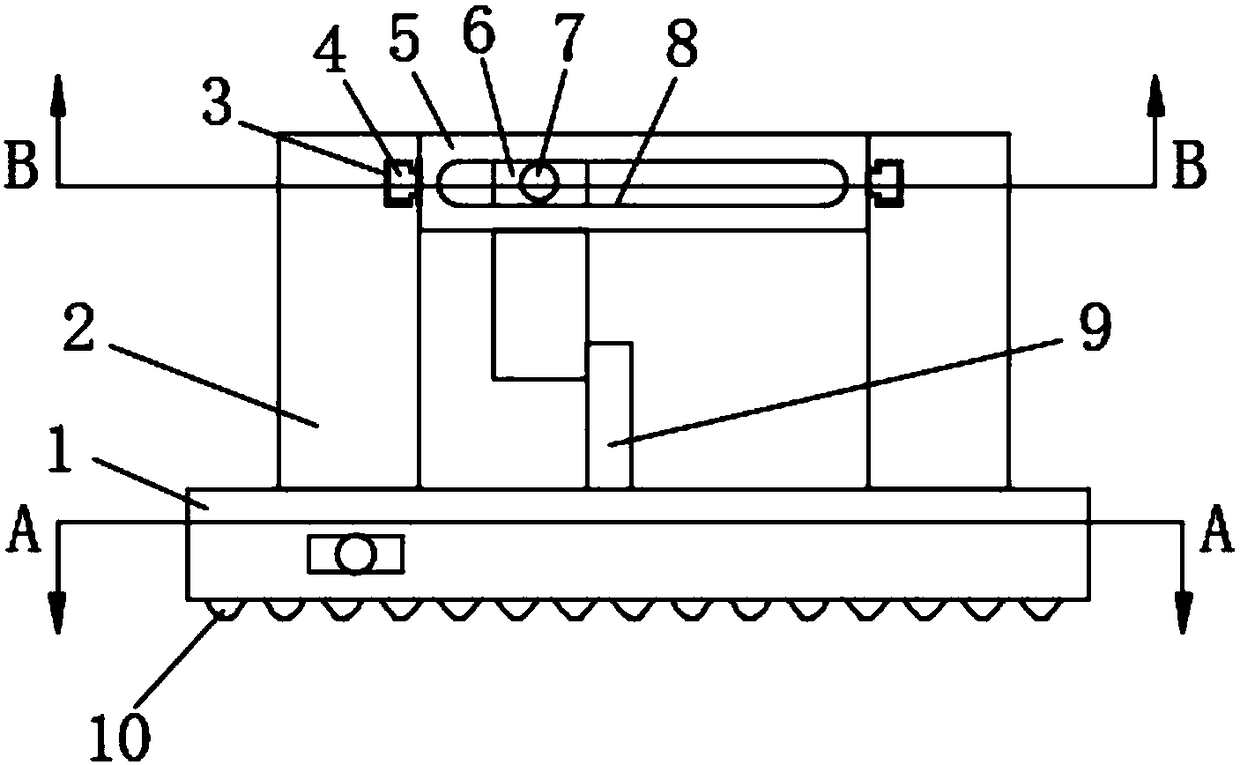

Jelly connected bag product cutting mechanism

InactiveCN109434891ACrop stabilizationReasonable designPackagingMetal working apparatusHydraulic cylinderPulp and paper industry

The invention discloses a jelly connected bag product cutting mechanism. The jelly connected bag product cutting mechanism comprises an electromagnetic hydraulic cylinder controller, an electromagnetic hydraulic cylinder, an upper support plate, a movable plate, a telescopic rod I, a telescopic rod II, a cutting blade and a cutting base. The bottom of the electromagnetic hydraulic cylinder controller is fixedly and electrically connected with the electromagnetic hydraulic cylinder. The bottom of the electromagnetic hydraulic cylinder is movably connected with the telescopic rod II. The bottomend of the telescopic rod II is movably connected with the telescopic rod I. According to the jelly connected bag product cutting mechanism, the electromagnetic hydraulic cylinder is controlled by theelectromagnetic hydraulic cylinder controller to drive the telescopic rod II and the telescopic rod I; the movable plate is movably connected with upright columns through sliding shells; and a jellyconnected bag is placed on the cutting base and is cut by the cutting blade, and some debris attached to the cutting blade is removed by a brush. The jelly connected bag product cutting mechanism is reasonable in design and easy to operate, the jelly connected bag can be stably cut, and some debris attached to the cutting blade can be removed by the brush as well.

Owner:周翠华

Preparation method of TPU material protective film

InactiveCN112608591ACrop stabilizationStable mechanical propertiesFlat articlesPolyesterPolymer science

The invention discloses a preparation method of a TPU material protective film, which comprises the following steps: S1, pulverizing polyester TPU particles to prepare a liquid A; S2, crushing polytetrafluoroethylene, crushing TPU particles, mixing the two components, and then performing melt mixing to prepare a liquid B; S3, putting the liquid A and the liquid B into a mixer in proportion to obtain a mixed material A; S4, conveying the mixed material A into a dehumidification dryer for drying; S5, extruding the mixed material A to form a film; S6, dragging the finished film in the step S5 through a traction device, achieving the constant tension of traction in a tension closed-loop control mode, so that the stability of the tension is guaranteed; and S7, winding through a winding device. Aiming at the situation that a TPU material covers the interior of a paper box to serve as a protective inner film material, the invention provides a novel manufacturing method of the TPU material, a TPU film which is dry, stable in cutting and stable in mechanical property is generated by controlling a production material, a film extruder and a traction device, and the use effect is good.

Owner:深圳市爱比欧新材料科技有限公司

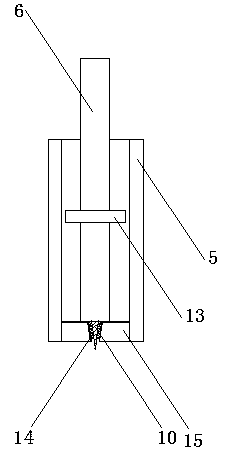

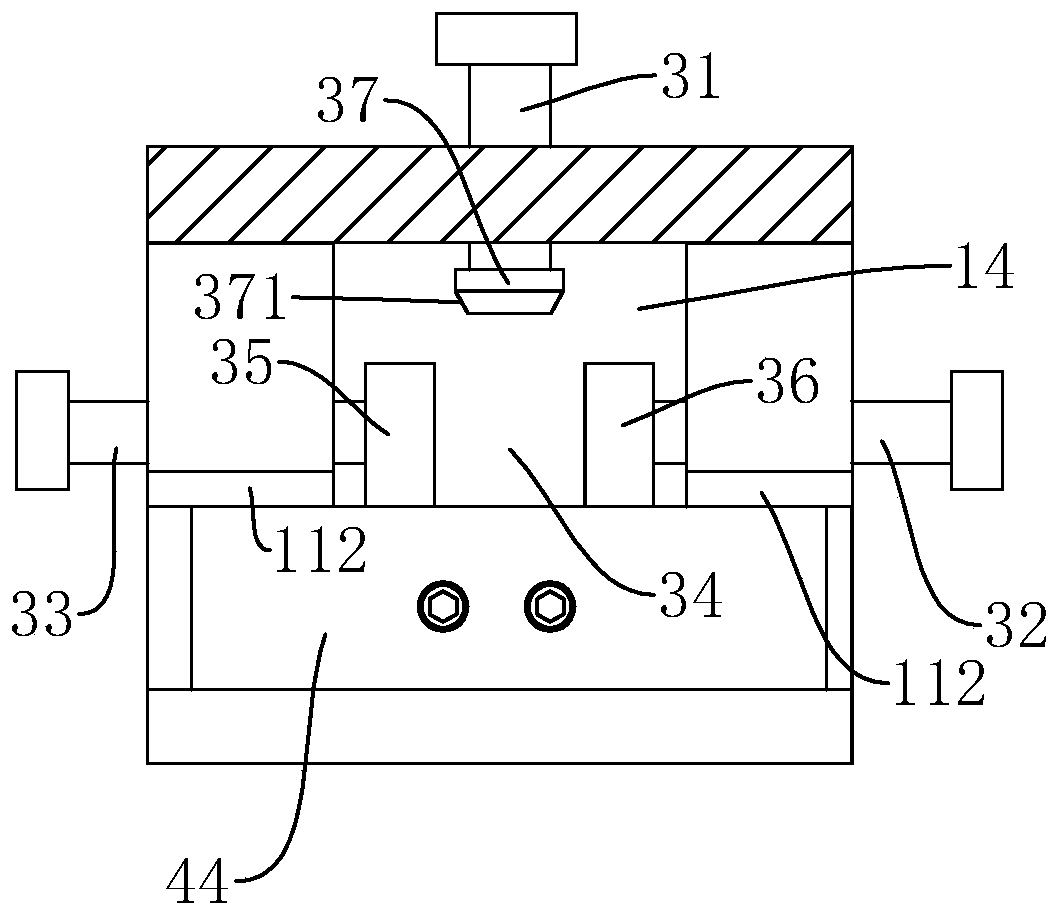

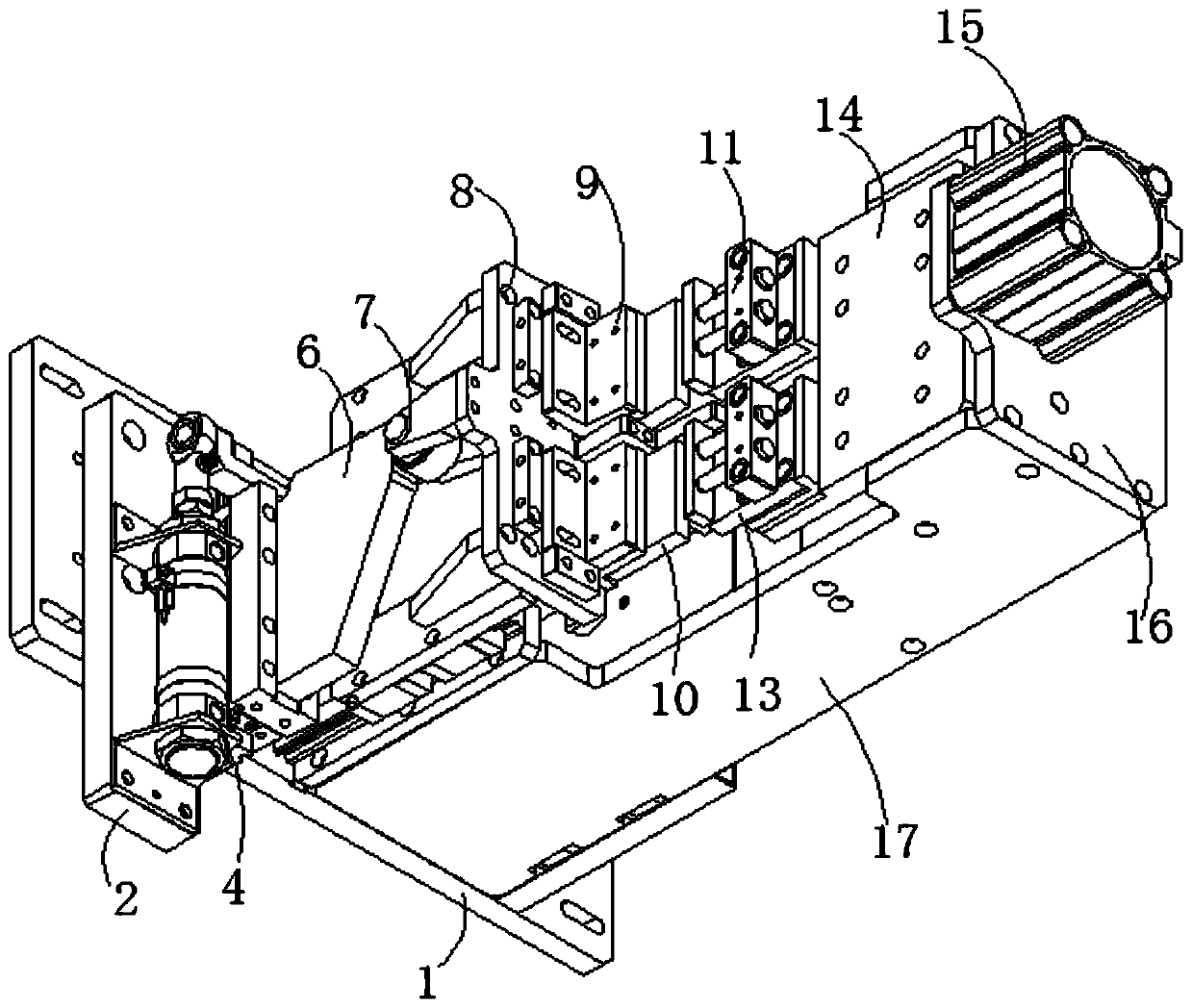

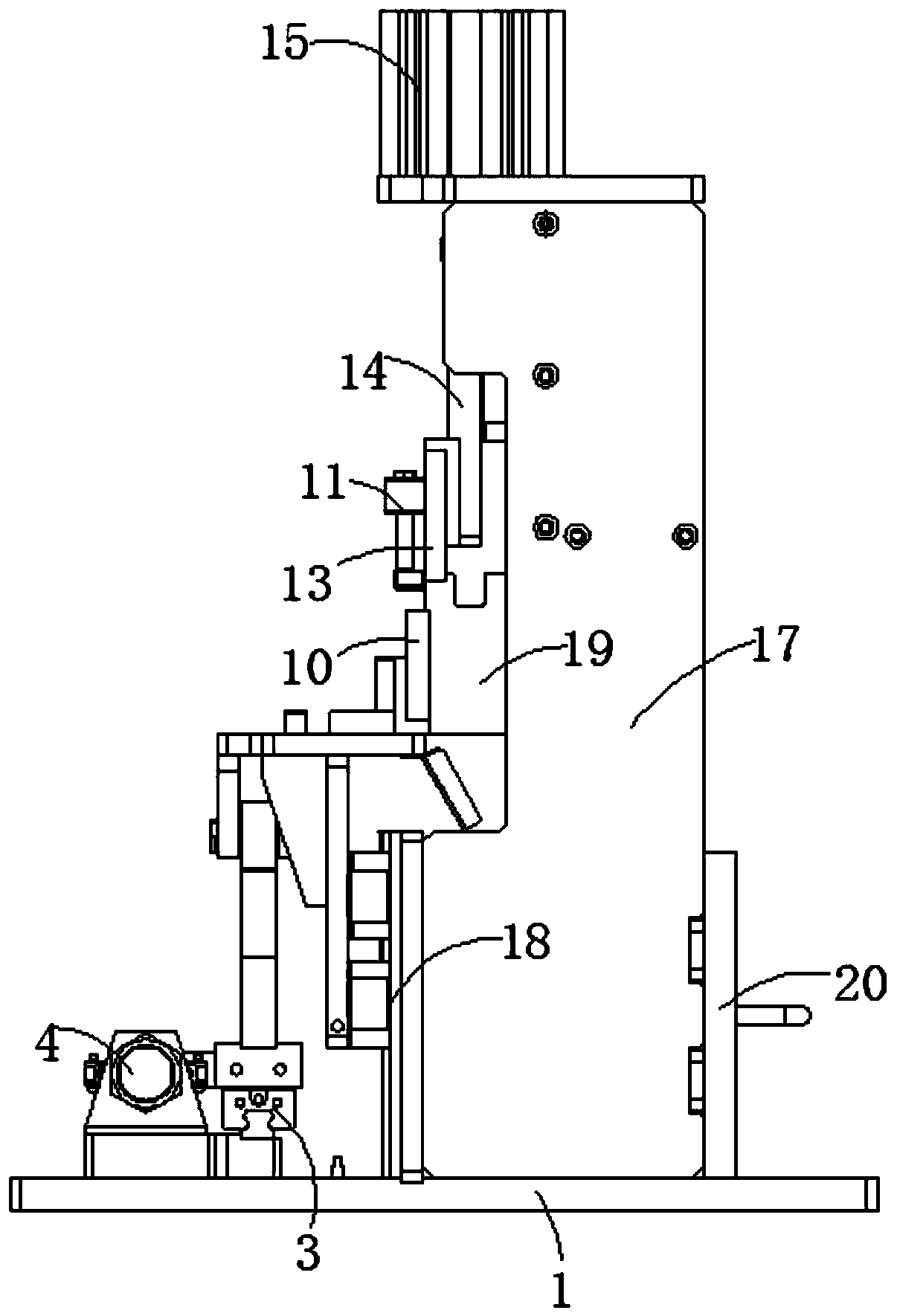

Cutting device of straightening cutting machine

ActiveCN111001731AAchieve radial positioningCrop stabilizationStructural engineeringMechanical engineering

The invention discloses a cutting device of a straightening cutting machine. The cutting device is characterized by comprising a frame body, a workpiece limiting mechanism, a fixed cutter and a movable cutter mechanism, wherein the frame body comprises a vertical plate and a top plate, a workpiece channel is formed on the vertical plate, the workpiece limiting mechanism comprises a left adjustingrod, a right adjusting rod and an upper adjusting rod, the left adjusting rod, the right adjusting rod and the upper adjusting rod are in threaded fit with a left side wall, a right side wall and a top wall of the workpiece channel correspondingly, first ends of the left adjusting rod, the right adjusting rod and the upper adjusting rod are all located in the workpiece channel and form a limitingchannel, the fixed cutter is installed on a back face of the vertical plate, a cutting edge of the fixed cutter and a low point of the limiting channel are located on the same horizontal line, the movable cutter mechanism comprises a movable cutter and an oil cylinder, and the oil cylinder is installed on the top plate and connected with the movable cutter so as to drive the movable cutter to moverelative to the fixed cutter. The cutting device is advantaged in that the cutting quality of a workpiece can be improved, the service life of the cutting knife can be prolonged, and a replacement period of the cutting knife is shortened.

Owner:嘉兴凯鑫五金科技股份有限公司

Cloth leveling and noise reduction and shock absorption laser cutting machine

InactiveCN108340083AAvoid wrinklesEasy to operateLaser beam welding apparatusLaser cuttingEngineering

The invention discloses a cloth leveling and noise reduction and shock absorption laser cutting machine which comprises a rack; a second driving box is arranged at one end of the rack; a leveling device is arranged on the second driving box; the rack is rotationally connected with a first threaded rod; a moving device is arranged on the first threaded rod; a first driving box is arranged at the other end of the rack; a first motor is arranged in the first driving box; a shock absorption device is arranged between the first motor and the first driving box; the driving end of the first motor isrotationally connected with the first threaded rod; and a collecting tank is formed below the first driving box. The cloth leveling and noise reduction and shock absorption laser cutting machine is simple to operate; through mutual matching of the rack, the leveling device, the moving device and the shock absorption device, cutting can be realized stably, input cloth is leveled, the cloth is prevented from being folded, noise reduction and shock absorption can be achieved, and the cutting precision is improved; and the cloth leveling and noise reduction and shock absorption laser cutting machine is provided to a user.

Owner:东港巨华服装有限公司

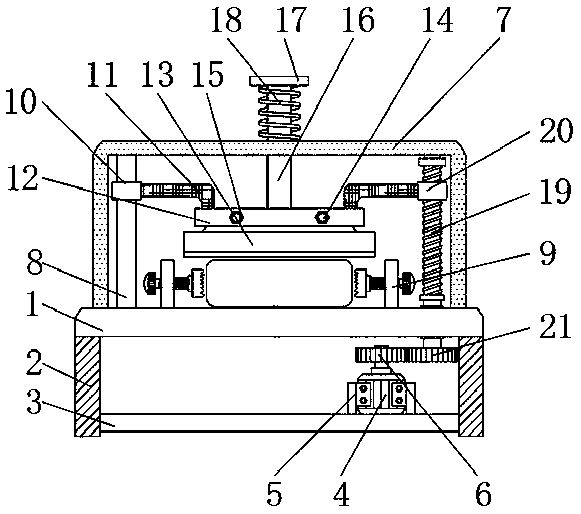

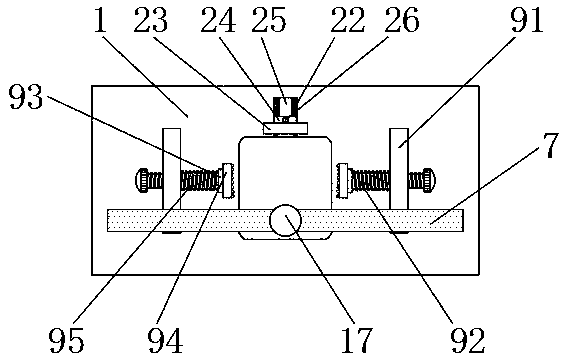

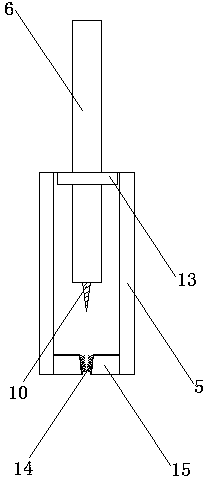

Pouch lithium battery tab cutting device

PendingCN111531217APrecise positioningCooperate accuratelySecondary cellsShearing machinesBolt connectionElectrical and Electronics engineering

The invention discloses a pouch lithium battery tab cutting device. The tab cutting device comprises a base; a fixed plate is fixedly connected with the surface of the base; a first linear slide railis fixedly connected with the upper side of the fixed plate; an upper jacking bearing cushion is fixedly connected with the upper side of the sliding end of the first linear slide rail; a first air cylinder is fixedly connected with the upper side of the fixed plate; a protruding end of the first air cylinder is fixedly connected with one side of the upper jacking bearing cushion; the upper jacking bearing cushion is a ladder-shaped block; a supporting plate is fixedly connected with the upper side of the base; and a second linear slide rail is fixedly connected with one side of the supportingplate and is fixedly installed via a bolt. A compaction buffer structure is arranged so a cell of a lithium battery is convenient to position precisely. The cutting process is stable, cutting tools are precisely matched, and a tab cutting burr and a roll rim can be easily controlled; and an upper cutting tool and a lower cutting tool are connected via a bolt, so the cutting tools is convenient toreplace rapidly and the device can improve the cutting quality of a product.

Owner:江西优特汽车技术有限公司

Cutting device for wood product processing

InactiveCN108145799ASimple structureEasy to operateProfiling/shaping machinesGauging meansProduct processingWood product

The invention discloses a cutting device for wood product processing. The cutting device for the wood product processing comprises a base; two mounting blocks are arranged at the upper end of the baseand located on the two sides of the base separately; a movable frame is arranged between the two mounting blocks; the two ends of the movable frame are in sliding connection with the two mounting blocks; the movable frame is of a frame structure; slide rails are arranged on two opposite side walls of the movable frame in a penetrating mode; a movable block is arranged between the two slide rails;a slide rod is arranged in the middle of the movable block; the two ends of the slide rod are connected with the two slide rails in a sliding mode; a cutting machine is detachably installed on the movable block; a mounting cavity is formed in the base and internally provided with a worm; and one end of the worm is rotationally connected to the side wall of the mounting cavity. The cutting devicefor wood product processing is simple in structure, convenient and rapid to operate, stable in cutting and good in cutting effect, and can flexibly adjust the cutting length according to actual demands.

Owner:天津红秀科技有限公司

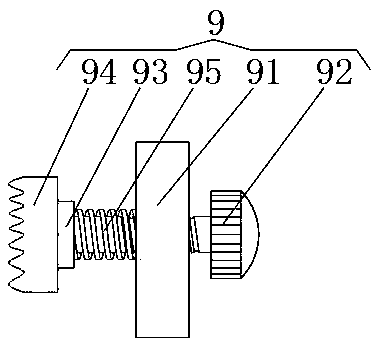

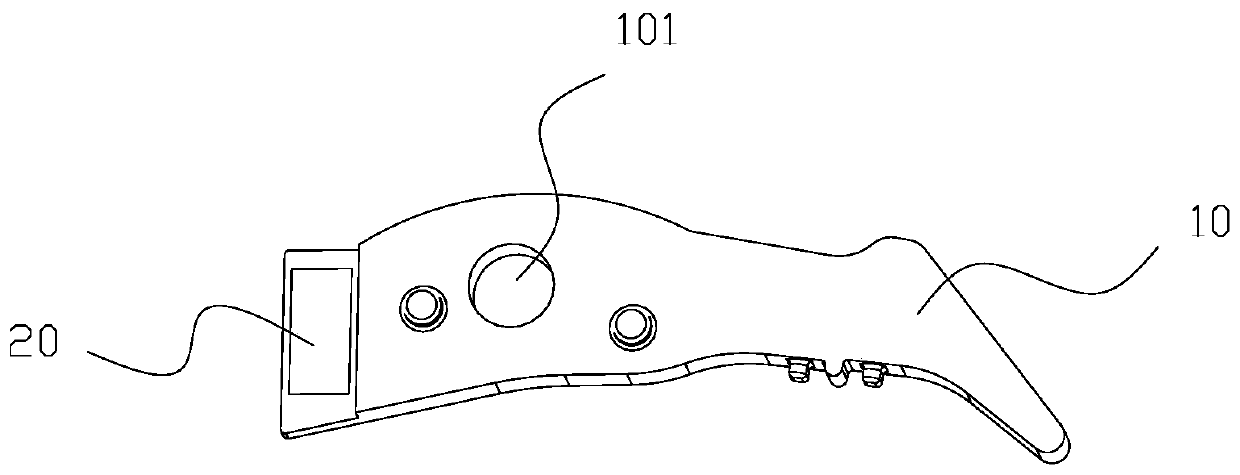

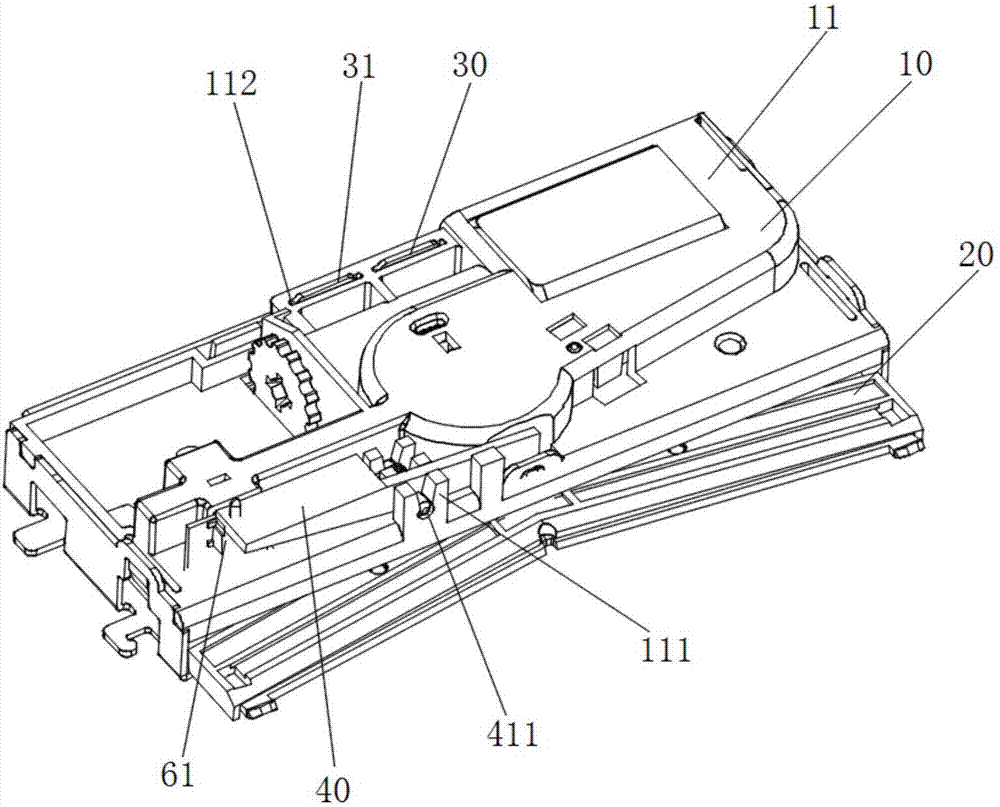

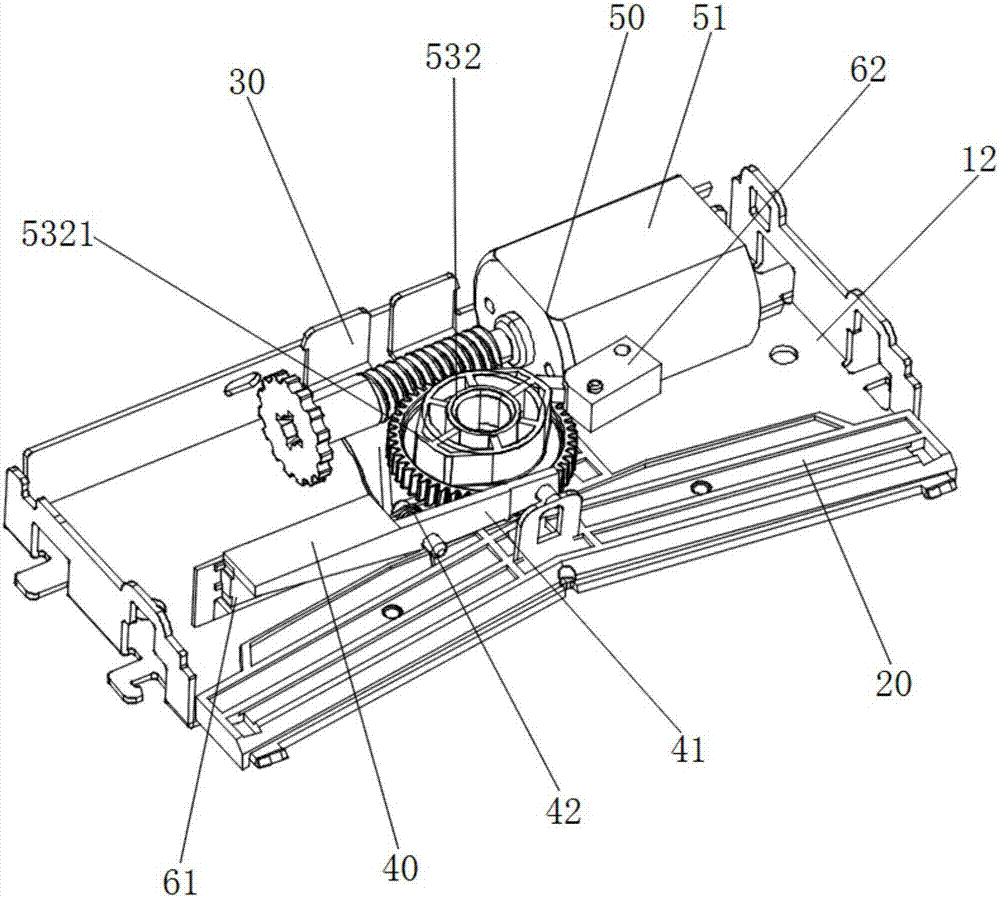

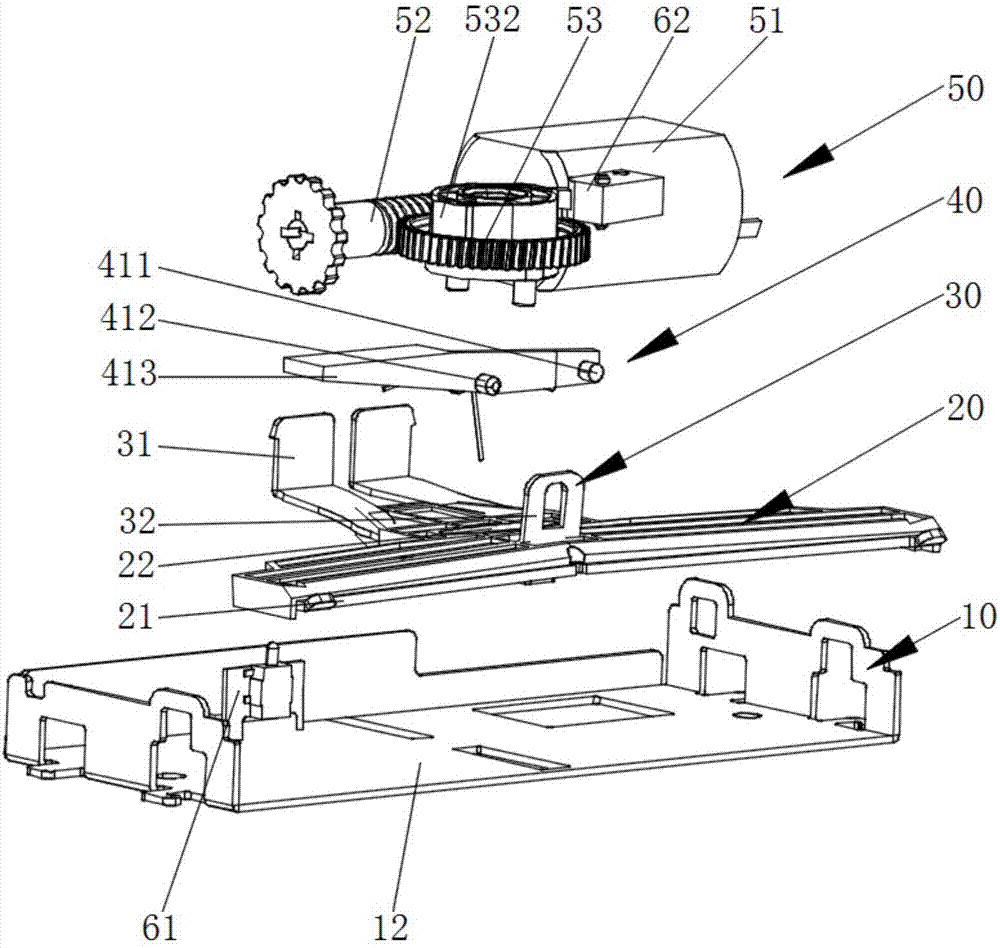

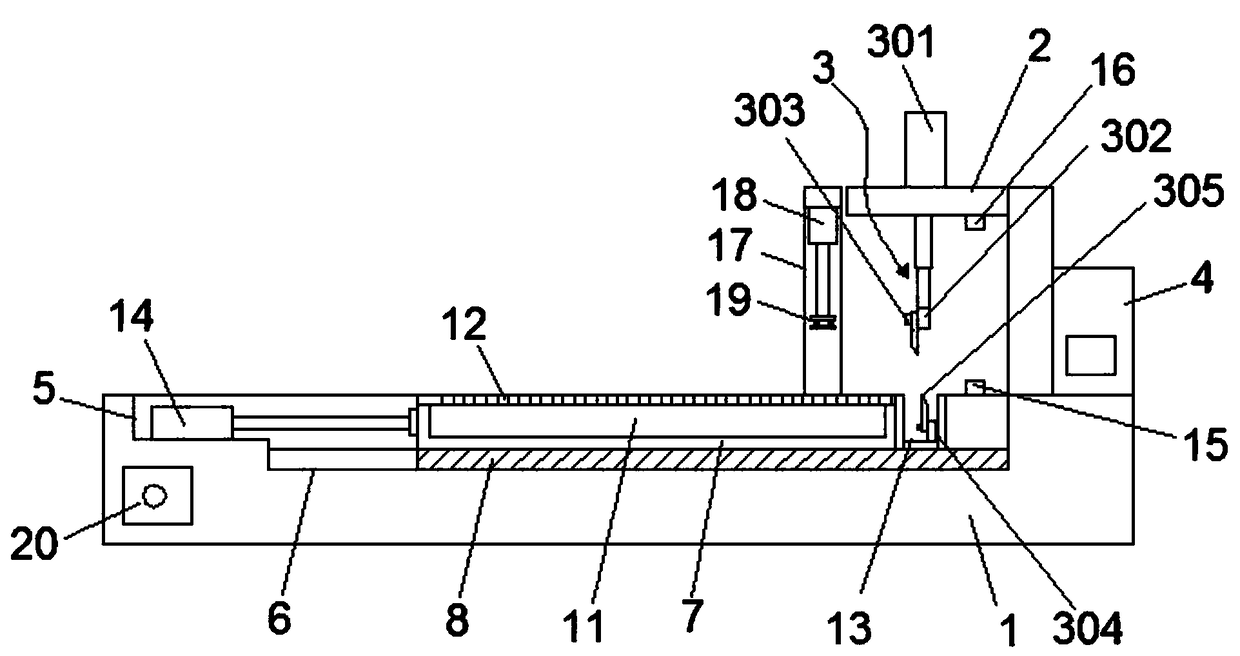

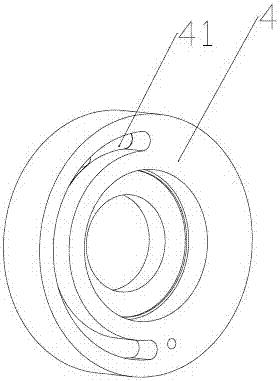

Printer with automatic back-off cutter structure and automatic back-off method of printer

ActiveCN106926592AReduce problems such as stuckReduce the chance of biting each otherOther printing apparatusContact pressureElectric machinery

The invention discloses a printer with an automatic back-off cutter structure. The automatic back-off cutter structure comprises a movable blade, a driving system, a pre-tightening mechanism and a release mechanism. The movable blade is movably arranged relative to a fixed blade. The driving system comprises a gear tooth assembly in linkage with the movable blade and a motor for driving the gear tooth assembly. The gear tooth assembly drives the movable blade to move back and forth linearly. The pre-tightening mechanism is used for acting on the movable blade, and therefore contact pressure is produced between the movable blade and the fixed blade. The release mechanism is connected with the pre-tightening mechanism and used for releasing acting of the pre-tightening mechanism on the movable blade. The invention further discloses an automatic back-off method of the printer. The method comprises the steps that the release mechanism is started, and the release mechanism is in linkage with the pre-tightening mechanism to release acting on the movable blade; 2, a first detection switch is triggered; 3, the motor is controlled by a controller to rotate reversely, and the motor backs off the movable blade to the initial position through the gear tooth assembly.

Owner:XIAMEN HANIN ELECTRONICS TECH CO LTD

Cutting scissors for costume designing

The invention discloses cutting scissors for costume designing. The cutting scissors for costume designing comprise a tailoring table, a tailoring mechanism fixedly installed at the top of the tailoring table through a supporting frame and a control cabinet fixedly installed on one side of the supporting frame, a square groove is formed in the side, located on the supporting frame and away from the control cabinet, on the tailoring table, a sliding groove is formed in the bottom, located in the groove, on the tailoring table, a positioning plate is arranged inside the groove, a sliding block which is in sliding fit with the sliding groove is arranged at the bottom of the positioning plate, an air pumping hole is formed in the positioning plate, a negative pressure pump is fixedly installedat the portion, located on the side wall of the positioning plate, inside the groove through a fixing plate, and is connected with the air pumping hole through a negative pressure pipe, and a negative pressure cavity is formed inside the positioning plate. The cutting scissors are high in automatic degree, time and labor are saved, cutting path offsetting can be effectively avoided, stable cutting of a garment fabric is achieved, the cutting quality and personal safety are guaranteed, and tailoring efficiency is high.

Owner:HUNAN UNIV OF ARTS & SCI

Cloth fixed-length cutting device for students majoring in garments

The invention discloses a cloth fixed-length cutting device for students majoring in garments. The cloth fixed-length cutting device comprises a mounting plate, supporting frames are arranged at the lower end of the mounting plate, limiting grooves are reserved in the upper surface of the mounting plate, limiting blocks are connected in the limiting grooves and arranged at lower ends of supportingstands and a supporting rod, the supporting rod is arranged between the supporting stands, and a cutter is mounted at the upper end of the supporting rod. The supporting rod is connected to the outerside of a threaded rod which is connected to the upper surface of the mounting plate, the outer end of the threaded rod is connected with a second hand wheel, and a worm is connected in the mountingplate. The cloth fixed-length cutting device has advantages that convenience in cutting of cloth in different widths and convenience in fixed-length cutting of the cloth can be achieved, so that problems of waste caused by overmuch cutting or failure in use due to insufficient cutting are avoided; in addition, convenience is provided for the students to cut the cloth stably, and skewing in a clothcutting process is avoided.

Owner:LINGNAN NORMAL UNIV

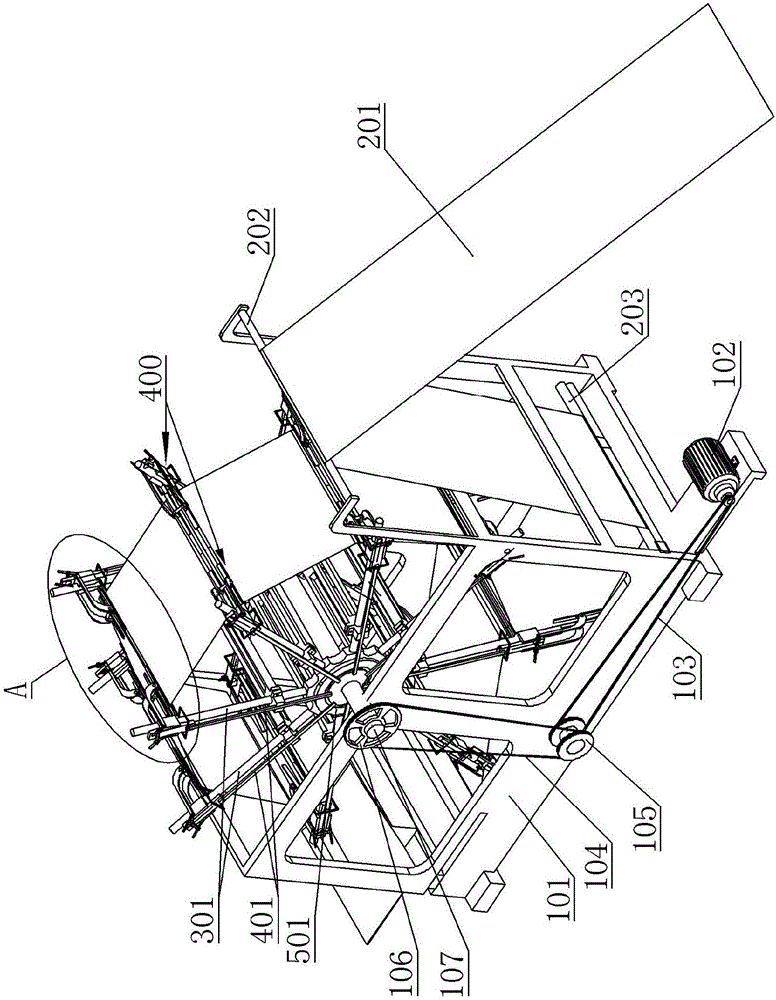

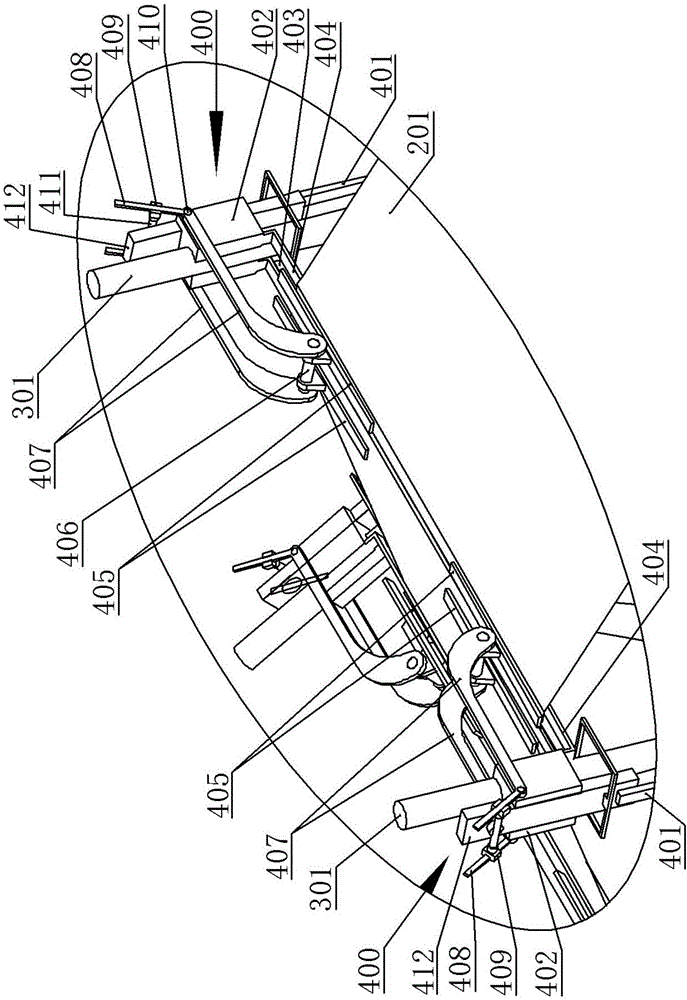

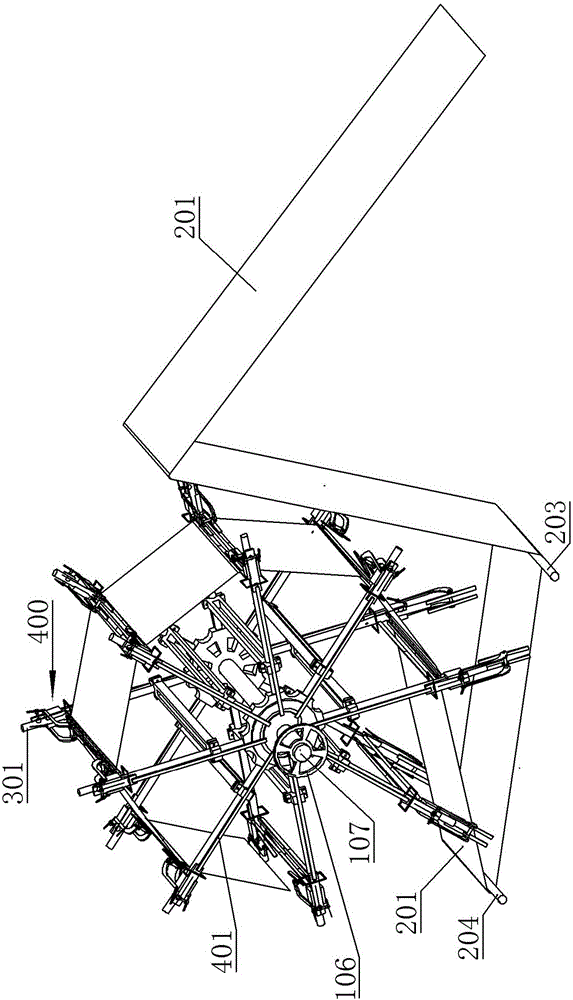

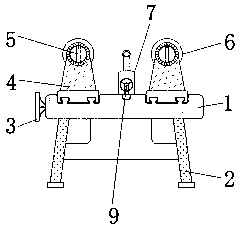

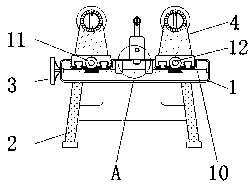

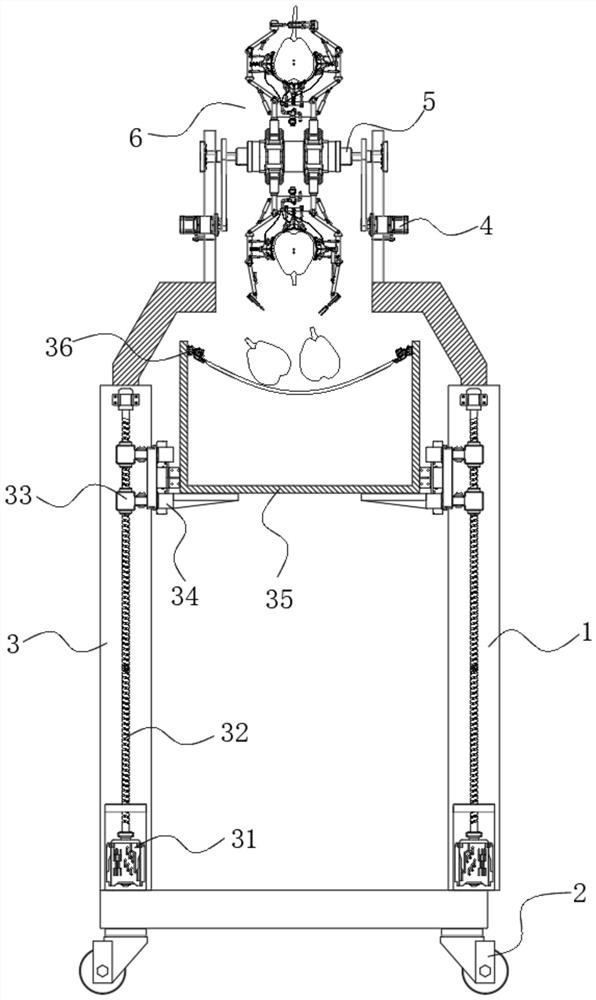

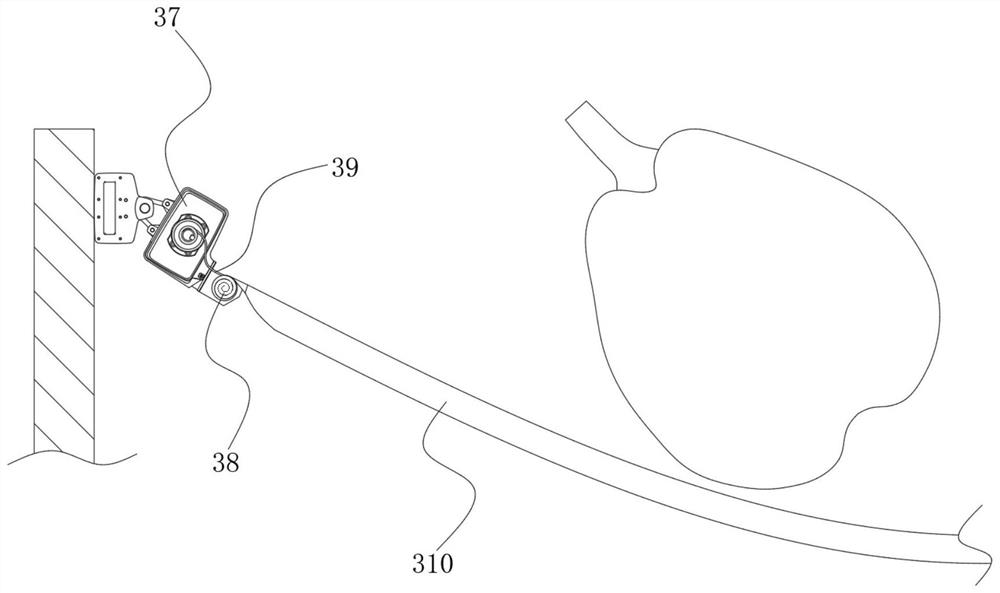

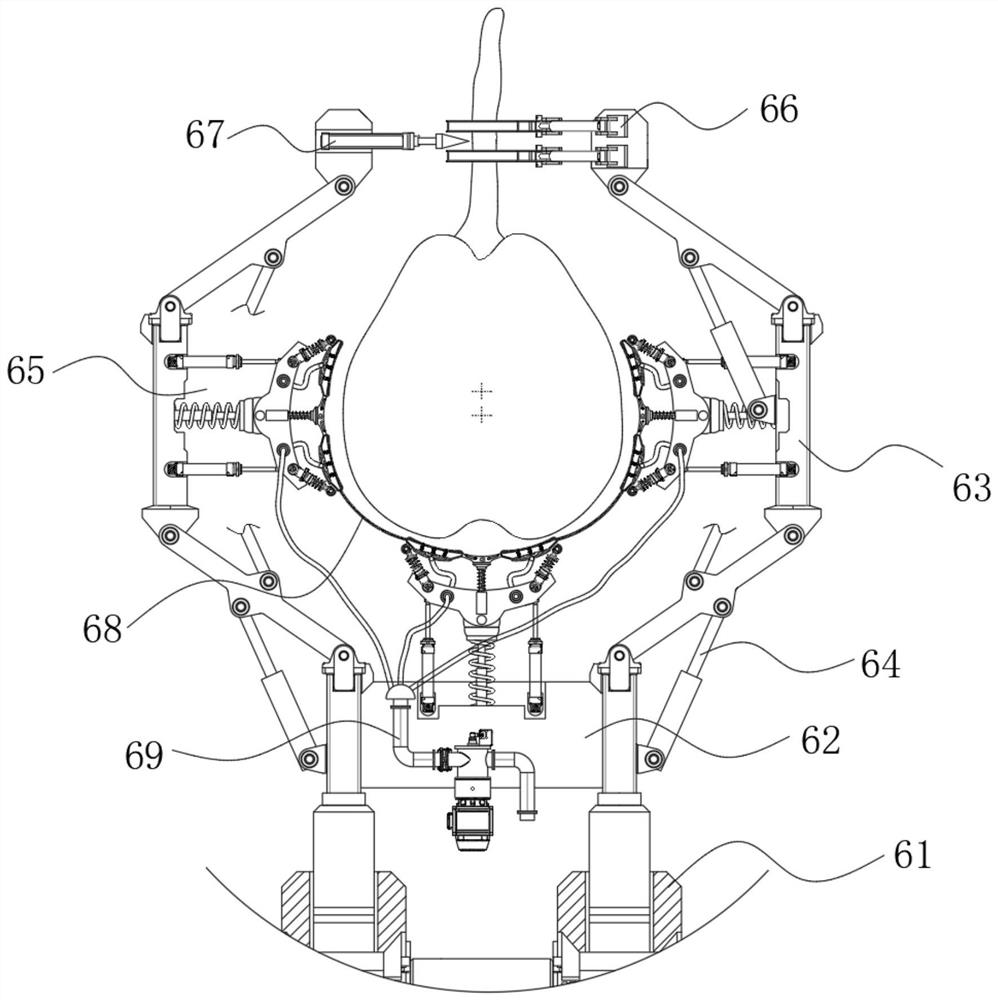

Multifunctional picking and pruning device for bergamot pears

The invention discloses a multifunctional picking and pruning device for bergamot pears. The device comprises a picking bottom frame, universal wheels, collecting devices and picking devices, wherein the universal wheels are installed at the lower end of the picking bottom frame, the collecting devices are installed in left and right side plates of the picking bottom frame, a transverse rotating shaft is installed between left and right parallel plate frames above the picking bottom frame, the rotating shaft is connected with the output end of a first motor through a belt, a plurality of groups of double-support telescopic seats are installed on the rotating shaft in a circumferential arrangement mode, and the picking devices are installed on the double-support telescopic seats; each collecting device comprises a second motor, a screw rod, a fixing seat, a clamping bracket and a collecting box, the screw rod is sleeved with the fixing seat, a front-back sliding rail is installed on a right side plate of the fixing seat, the clamping bracket is slidably connected to the front-back sliding rail and is of a right-angle auxiliary supporting structure, the collecting box is placed on flat supporting plates in the clamping brackets on the left side and the right side, and net supporting assemblies are installed on the portions, close to the left wall and the right wall, of an upper end opening of the collecting box.

Owner:TARIM UNIV

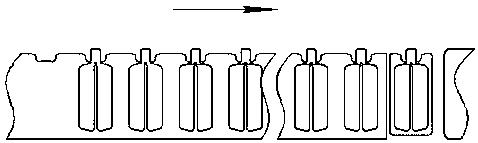

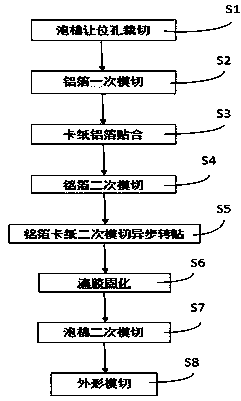

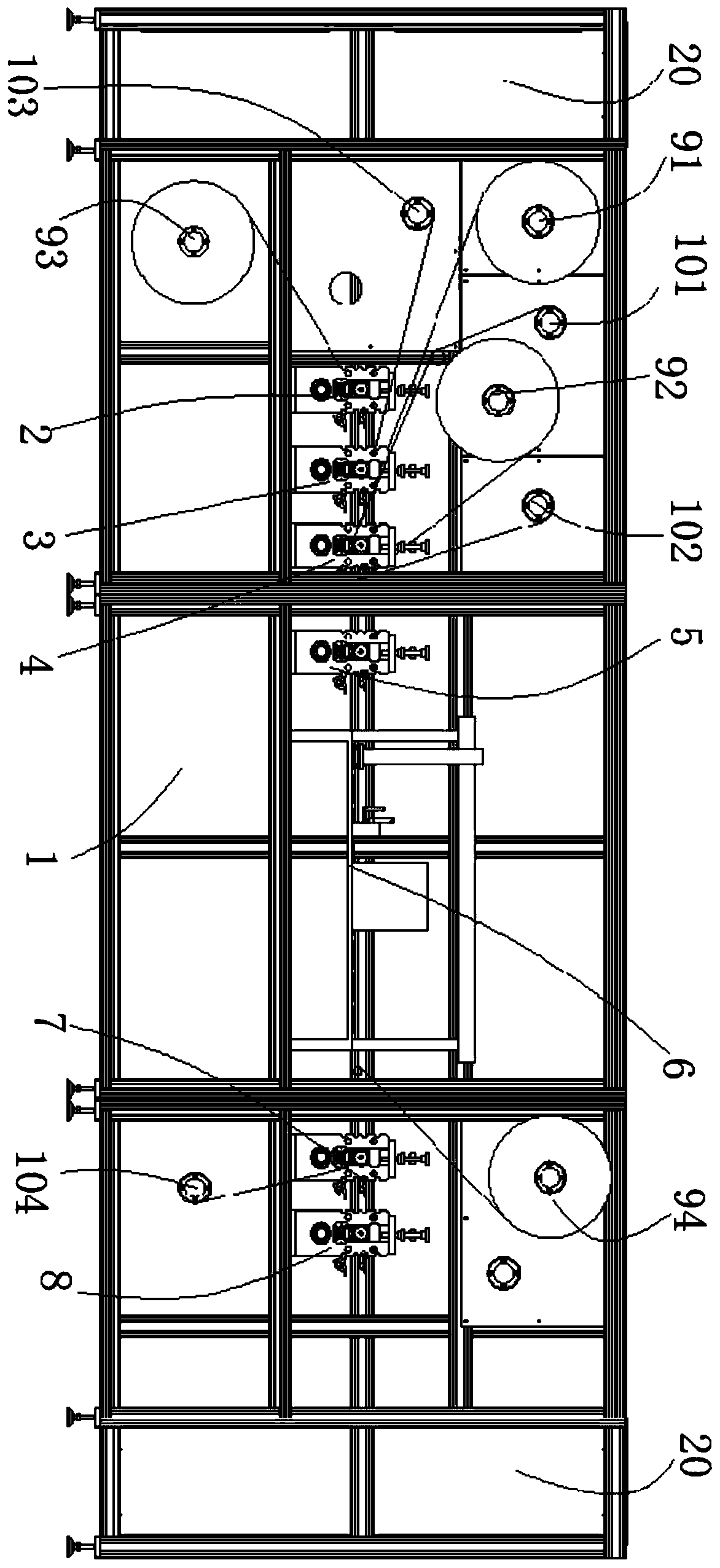

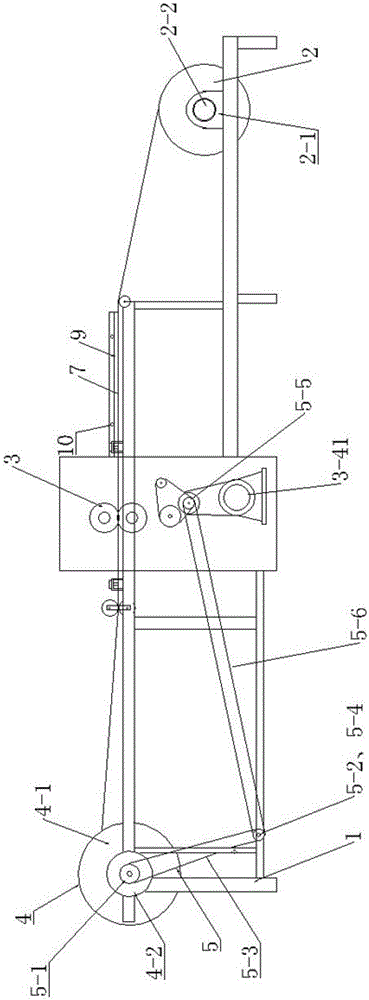

Forming device for neutral pole plate

PendingCN110978555AAvoid quality differencesAvoid wastingPaper/cardboard layered productsSurgical instruments for heatingPaperboardEngineering

The invention discloses a forming device for a neutral pole plate. The forming device for the neutral pole plate comprises a rack, a foam traction mechanism, a foam receding hole die cutting mechanism, an aluminum foil first die cutting mechanism, an aluminum foil paperboard secondary die cutting asynchronous repasting mechanism, a glue dripping optical fixation mechanism, a foam secondary die cutting mechanism and a shape die cutting structure, wherein the foam traction mechanism, the foam receding hole die cutting mechanism, the aluminum foil first die cutting mechanism, the aluminum foil paperboard secondary die cutting asynchronous repasting mechanism, the glue dripping optical fixation mechanism, the foam secondary die cutting mechanism and the shape die cutting structure are successively installed on the rack according to a production direction of single-pole and dual-pole neutral pole plates. The forming device disclosed by the invention has the beneficial effects that the wholeneutral pole plate is completed by one device, so highly integrated automatic production is completed, and efficiency and quality of production are increased; and quality differences and material waste caused by manual pasting are avoided.

Owner:厦门钧晟智能科技有限公司

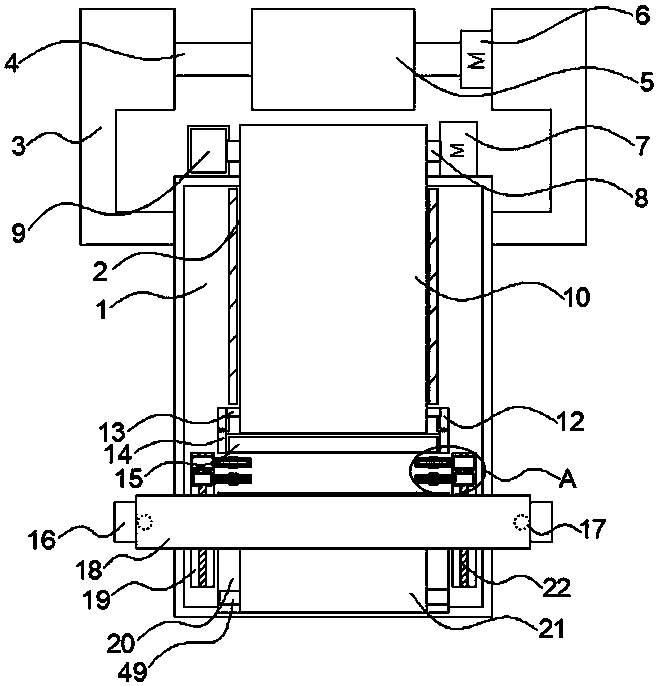

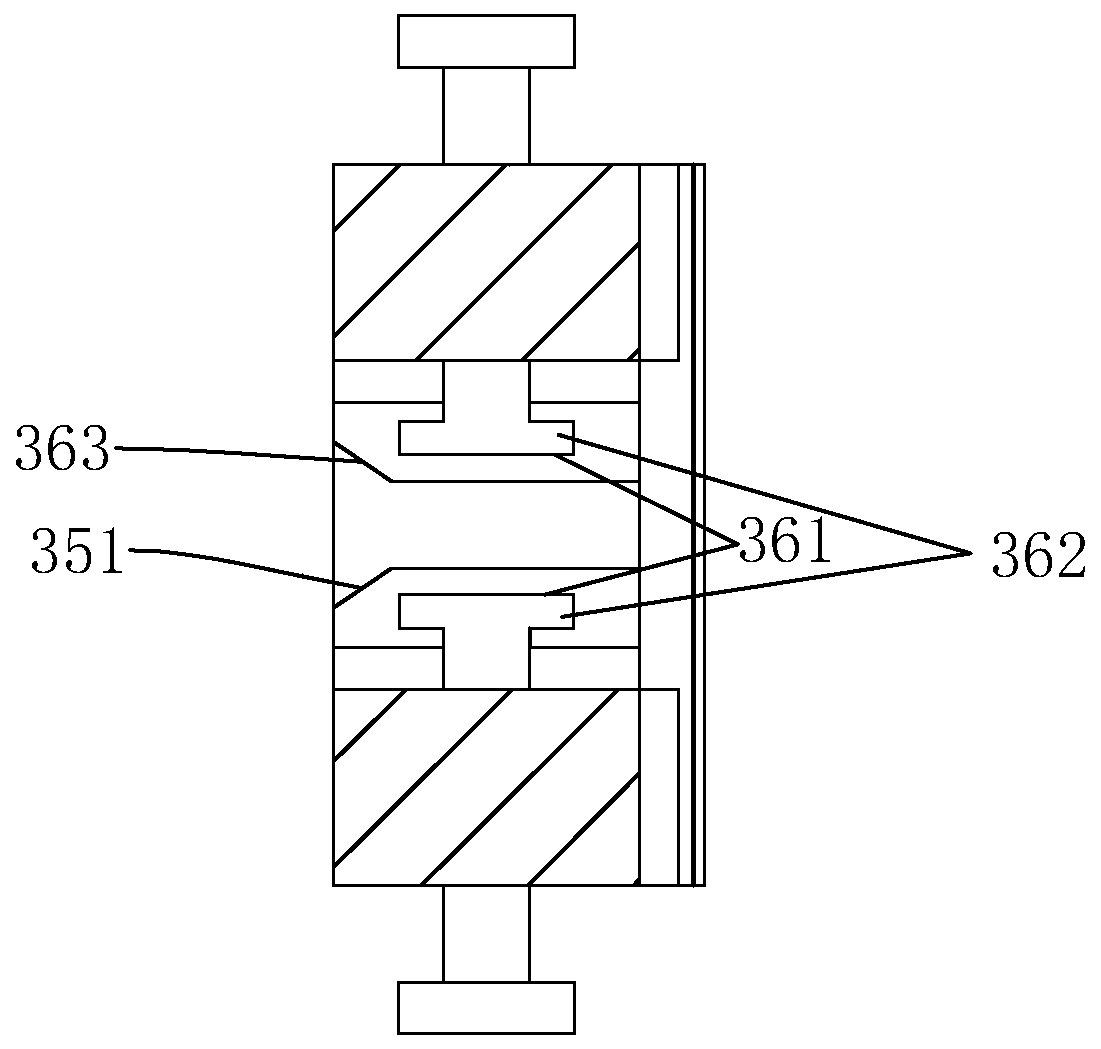

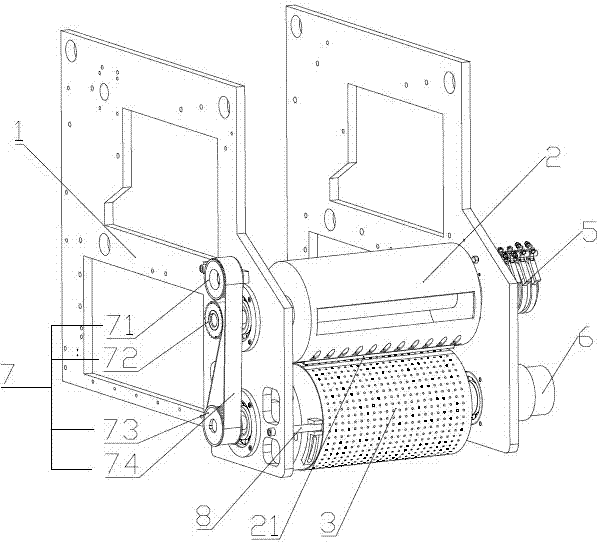

A sheet slitting machine

ActiveCN104275714BCrop stabilizationHigh precisionShearing machinesMetal working apparatusEngineeringPlastic film

The invention discloses a sheet stock slitting machine. The sheet stock slitting machine comprises a rack as well as a strip feeding mechanism, a slitting device and a strip rolling mechanism which are arranged on the rack, wherein the strip feeding mechanism and the strip rolling mechanism are respectively arranged in the front of and behind the slitting device. The sheet stock slitting machine is characterized in that the slitting device comprises a cutter shaft bracket, an upper cutter shaft, a lower cutter shaft and a cutter shaft power device for driving the upper cutter shaft and the lower cutter shaft to rotate; a plurality of groups of shearing modules are arranged at certain intervals between the upper cutter shaft and the lower cutter shaft; each group of shearing module is composed of an upper cutter on the upper cutter shaft and a lower cutter on the lower cutter shaft, and the upper cutters and the lower cutters are staggered at a horizontal interval of 0-2mm, and the distance between the upper cutter shaft and the lower cutter shaft is less than the radius sum of the upper cutters and the lower cutters. The sheet stock slitting machine is capable of slitting materials such as sheet metal strips and plastic films and is simple in structure, stable in operation and high in precision, the cutters are durable, and products are good in quality and free of deckle edges.

Owner:韶关市高信塑胶制品有限公司

Cutting mechanism of window patching machine

PendingCN107877926ASolve the displacementSolve the situationBox making operationsPaper-makingMechanical engineeringClose contact

The invention discloses a cutting mechanism of a window patching machine, relates to the field of window patching machining equipment, and solves the problem of displacement after cutting. The cuttingmechanism comprises a rack as well as an upper roller and a lower roller which are capable of oppositely rotating and installed on the rack at top and bottom in parallel, wherein the lower roller isprovided with an adsorption assembly used for tightly attaching a film to be cut to the outer circumferential surface of the lower roller; a cutter assembly used for accurately cutting the film to becut in the case of no displacement and no desorption of the film to be cut is arranged on the upper roller and the lower roller; and a distance capable of ensuring the normal working of the cutter assembly is formed between the upper roller and the lower roller. The cutting mechanism disclosed by the invention has the advantages of being stable in cutting and high in qualification rate.

Owner:袁新国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com