Sheet feeding structure of lithium battery winding machine and working method of sheet feeding structure

A technology of winding machine and lithium battery, which is applied in the direction of secondary battery, secondary battery manufacturing, circuit, etc., can solve the problem of poor structural stability of the cutter and cannot cut pole pieces, etc., so as to avoid the movement of the second nut and the pointer , Accurate readings, and increase the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

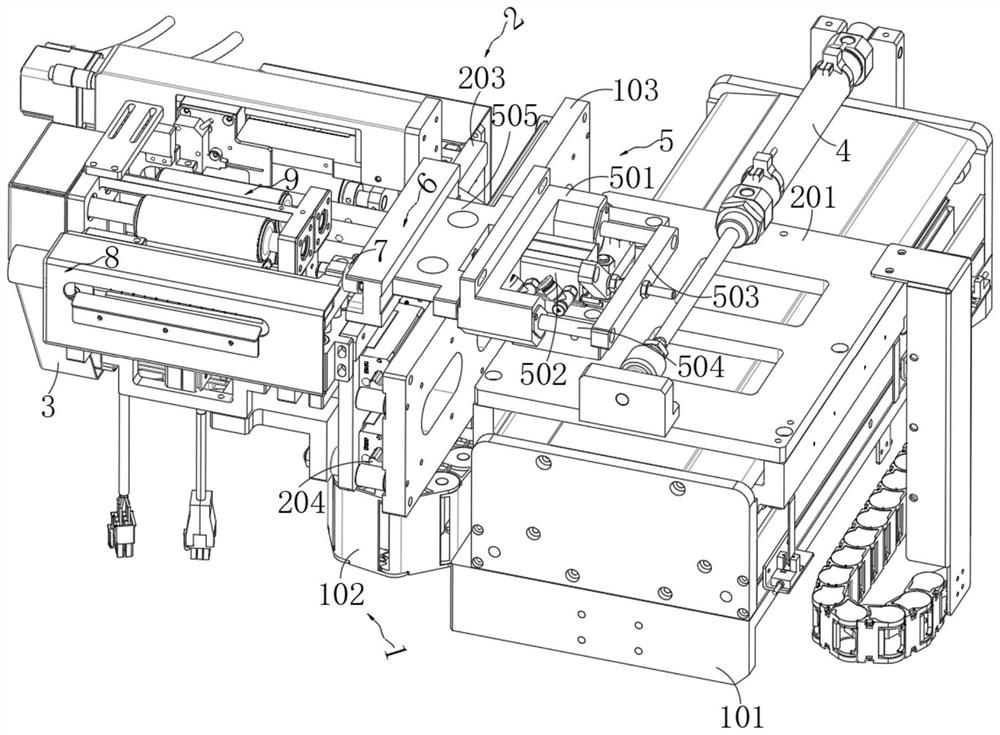

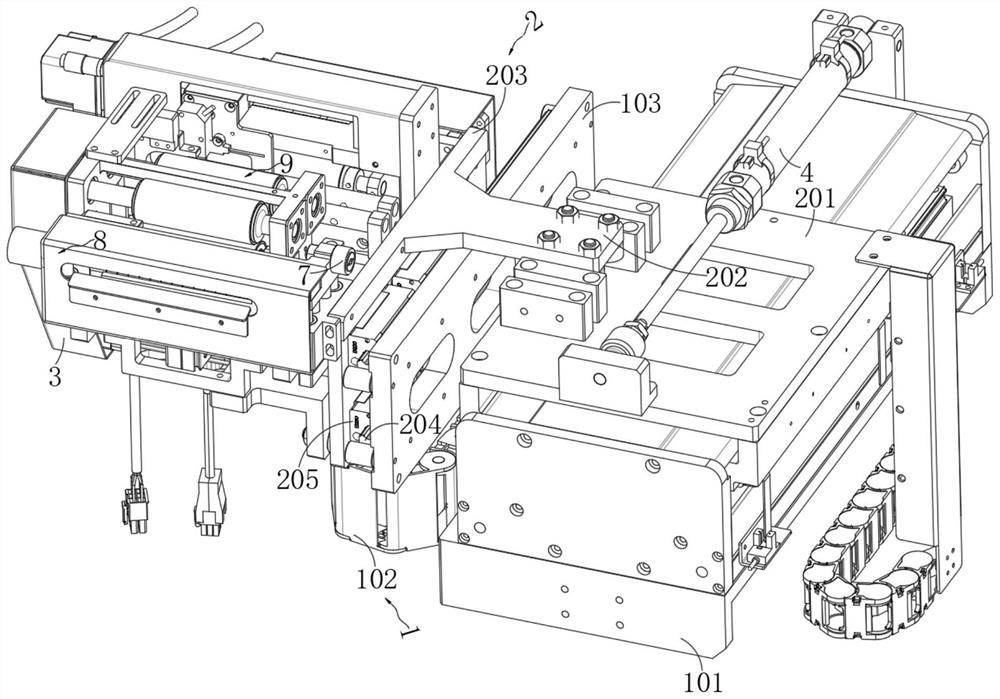

[0063] see Figure 1-Figure 9 , the present invention provides the following technical solutions:

[0064] A sheet feeding structure for a lithium battery winding machine, comprising:

[0065] The frame body 1, the frame body 1 is composed of a first support table 101, a second support table 102 and a side plate 103, such as figure 1 In the state shown, the second supporting platform 102 is located on one side of the first supporting platform 101, and the side plate 103 is fixed on the top of the second supporting platform 102;

[0066] see figure 1 , a telescopic mechanism 4 is provided on the top of the above-mentioned first supporting platform 101. In this embodiment, the telescopic mechanism 4 is a cylinder structure, but the telescopic mechanism 4 includes but is not limited to the above-mentioned embodiments. Screw nut structure, rack and pinion structure or other embodiments with linear motion, so they will not be described in detail;

[0067] see figure 1 and fi...

Embodiment 2

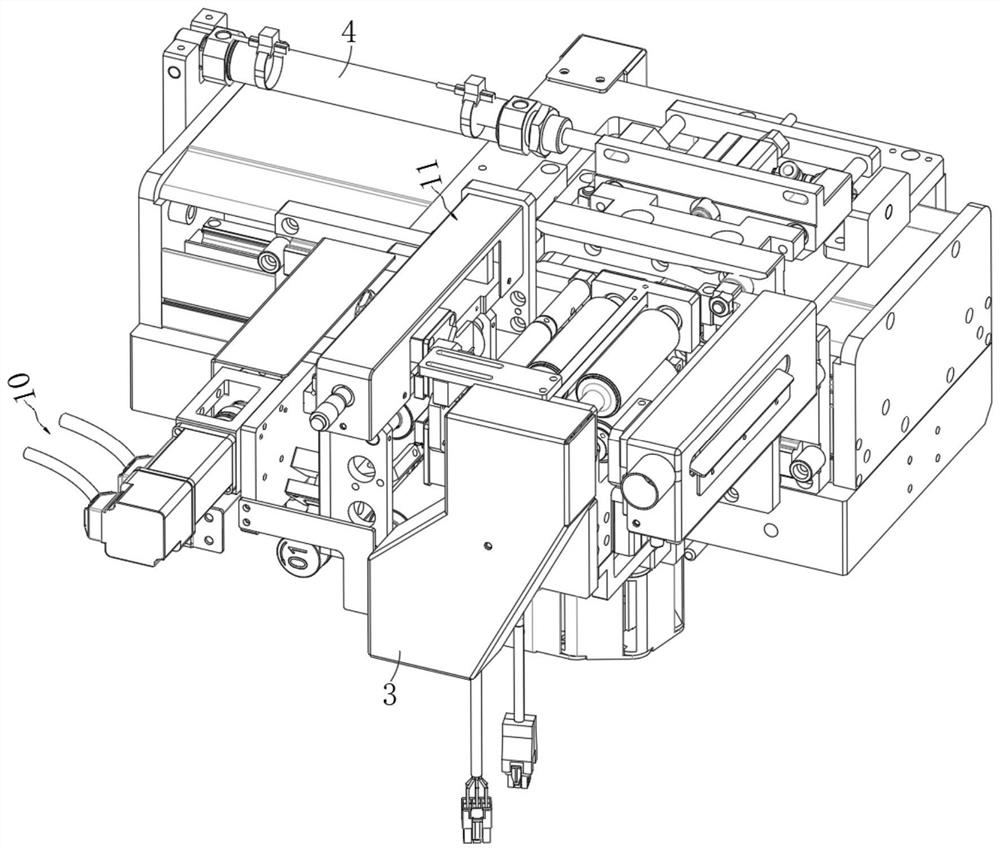

[0092] see Figure 1-Figure 9 , Since the pole piece is prone to deviation during the conveying process, this embodiment additionally sets up a deviation correction detection mechanism 10 and a deviation correction reading mechanism 11 on the basis of the embodiment 1, and the details are as follows:

[0093]The deviation correction detection mechanism 10 is arranged on the conveying table 3 and is located at the feeding position of the roller shaft feeding mechanism 9. It is also electrically connected with the upper control system to output the deviation correction signal. The deviation correction detection mechanism 10 is composed of the first screw nut assembly and the deviation correction detection mechanism. The first screw nut assembly is composed of a forward and reverse rotation motor 1001, a first screw rod 1002, a first nut 1003, an L-shaped plate 1004 and an adjustment block 1005. The L-shaped plate 1004 is fixed on the inner wall of the conveying table 3, The forw...

Embodiment 3

[0097] A working method for a sheet feeding structure of a lithium battery winding machine, comprising the following steps:

[0098] S1, the upper control system automatically brakes the moving mechanism 5 to shorten to realize the contact between the cutter orbit mechanism 6 and the signal transmission roller 7, when the cutter orbit mechanism 6 contacts the signal transmission roller 7, the upper control system stops the moving mechanism 5;

[0099] specific: as Figure 7 The pole piece walking path is set in the state shown, and the servo motor is driven to realize pole piece transportation. The upper control system automatically brakes the moving cylinder 502 to shorten, and the moving cylinder 502 shortens to drive the connecting bar 503 to move in a straight line, and then it moves through the guide rod 504 and moves. The seat 505 realizes that the track body 601 gradually approaches the signal transmission roller 7. When the innermost inner wall of the track body 601 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com