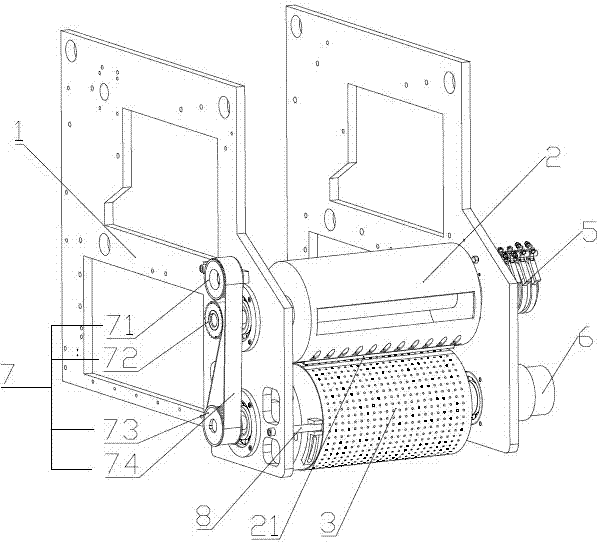

Cutting mechanism of window patching machine

A window sticking machine and cutting technology, which is applied in the direction of container manufacturing machinery, rigid/semi-rigid container manufacturing, paper/cardboard containers, etc., can solve the problem that the sticking position cannot meet the qualified requirements and affect the adsorption position of the lower roller, etc. Problems, to achieve the effect of improving the qualified rate and ensuring the processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: The cutter assembly includes an upper cutter 21 fixed on the outer peripheral surface of the upper roller 2 in the axial direction, and an upper cutter 21 arranged on the outer peripheral surface of the lower roller 3 and cutting off the uncut blade together with the contact. Cut the hard surface of the film, the lower roller 3 is provided with a hard strip 31 corresponding to the upper cutter 21, and the hard strip 31 is embedded in the outer circumference of the lower roller 3 along the axial direction, so The hard strip 31 has an arc surface and is flush with the circumferential surface of the lower roller 3. The hard strip 31 is made of hard alloy material. The advantage of the first embodiment is that the material cost is saved. When the upper cutter and the hard strip rotate The synchronization requirements are high.

Embodiment 2

[0028] Embodiment 2: The cutter assembly includes an upper cutter 21 fixed on the outer peripheral surface of the upper roller 2 in the axial direction, and an upper cutter 21 arranged on the outer peripheral surface of the lower roller 3 and cutting off the uncut material together with the contact. Cutting the hard surface of the film, the lower roller 3 is made of hard alloy material as a whole, which has the advantage of not requiring high synchronization of the transmission mechanism. The upper roller and the lower roller can have their own power components, and can also realize The effect of embodiment one.

Embodiment 3

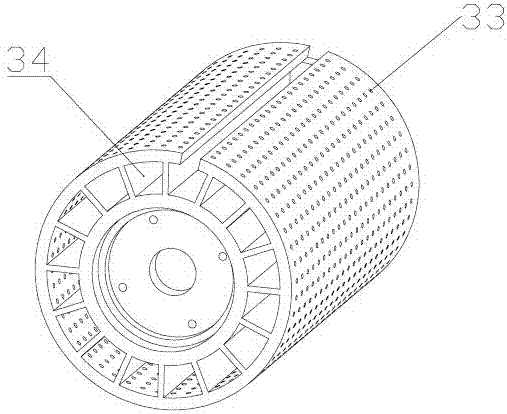

[0029] Embodiment 3: The cutter assembly includes an upper cutter 21 fixed on the outer peripheral surface of the upper roller 2 in the axial direction, and an upper cutter 21 arranged on the outer peripheral surface of the lower roller 3 and cutting off the uncut blade together with the contact. Cut the hard surface of the film, the outer circumference of the lower roller 3 is wrapped with a hard layer 32 made of cemented carbide material and with several through holes, the through holes of the hard layer correspond to the air suction holes on the lower roller , the advantages of the third embodiment are similar to those of the second embodiment, but the use of materials is less than that of the second embodiment, and the effect of the first embodiment can be achieved.

[0030] The other end of the upper roller 2 is provided with an electric heating element 5 that transfers heat to the upper cutter 21 through the upper roller 2. The inside of the upper roller 2 is hollowed out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com