Wall tile construction method and special member

A construction method and component technology, applied in building construction, covering/lining, construction, etc., can solve problems such as endangering personal safety, low water absorption, complex stress of facing bricks, etc., to improve safety and reliability, and improve bonding quality. , Improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

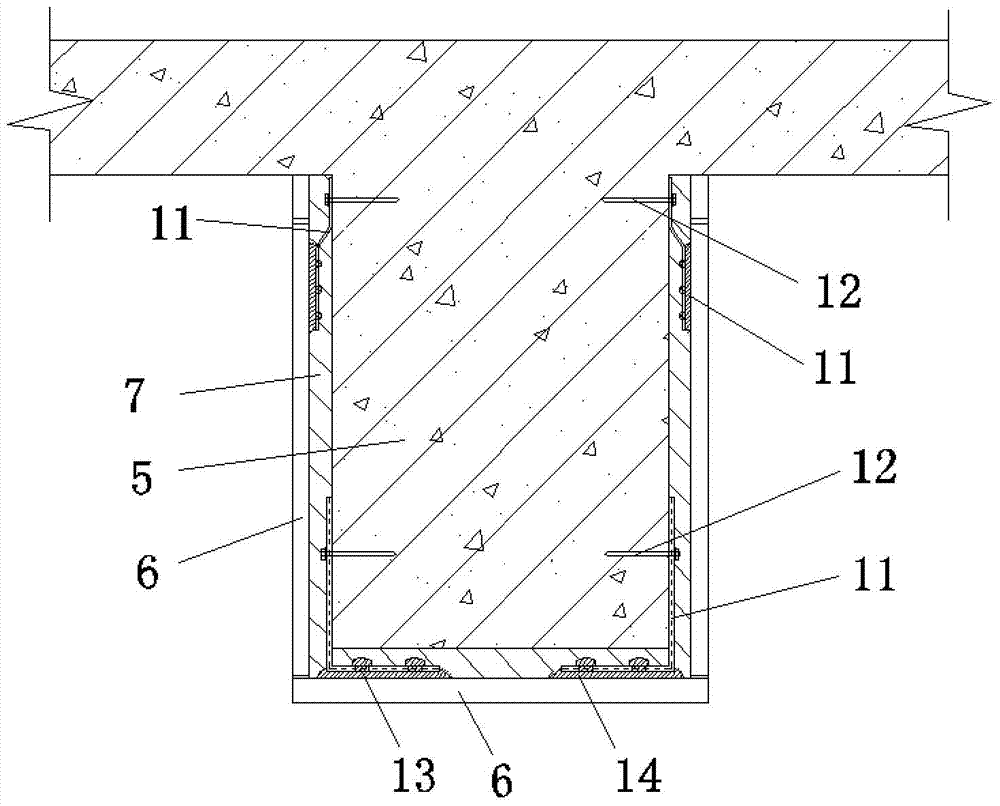

[0075] Example 1, see Figure 1 to Figure 10 , the wall tiling construction method that the present embodiment provides to prevent the displacement of facing bricks, it comprises the following steps:

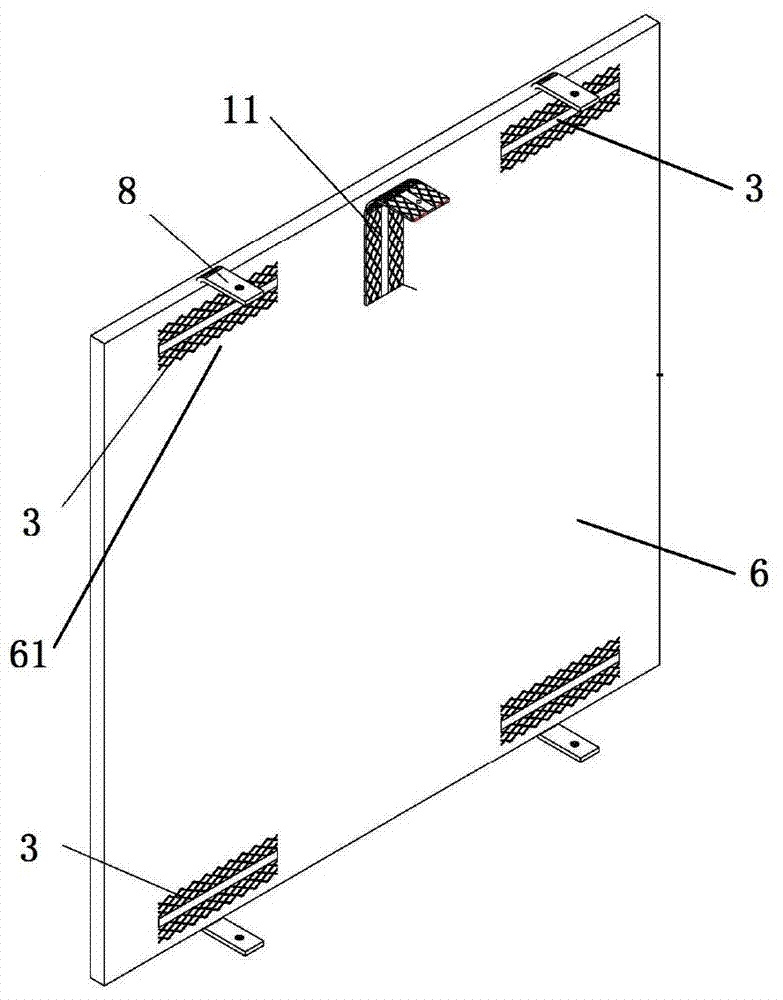

[0076] (1) Preparing the decorative tile 6 and the sheet-shaped metal special component 11 provided with the bonding through hole 13 and the adhesive 14 for the bonding special component 11;

[0077] (2) The upper part of the special component 11 protrudes from the facing brick 6, and the lower part of the special component 11 is bonded and fixed on the back of the facing brick 6 with the adhesive 14, and glued The adhesive 14 fills the bonding surface of the special component 11 and the through hole 13, and after curing, the special component 11 and the facing brick 6 are connected as one; the adhesive in this embodiment is an epoxy resin adhesive;

[0078] (3) Paste the facing brick 6 in step (2) on the wall base 4 with a cement-based adhesive, and bury the special component ...

Embodiment 2

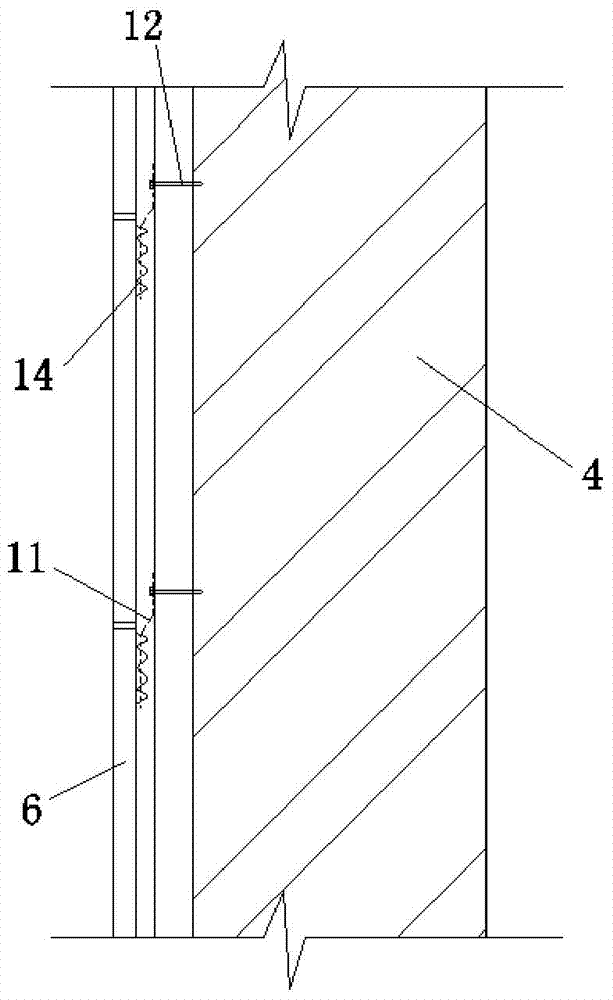

[0115] Example 2, see Figure 11 ~ Figure 12 , the wall tiling construction method and special components of this embodiment are basically the same as those of Embodiment 1, the difference being that

[0116] When the special component 11 is used to paste the upper decorative brick 6 on the bottom of the span beam or door and window lintel 5, its lower section is bonded to the back of the decorative brick 6, and its upper section protrudes outside the decorative brick 6 after being bent. .

Embodiment 3

[0117] Embodiment 3, the wall tiling construction method and special components of this embodiment are basically the same as Embodiment 1, the difference is that

[0118]When the decorative brick 6 is pasted or embedded on the top of the wall surface and spliced to the top grid, the special member 11 that is fixed on the back of the decorative brick 6 extends out of the upper section of the decorative brick 6 beyond the top edge surface, are anchored to the corresponding top grid base layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com