Combined type fuel oil guide pipe connecting structure for aircraft

A connecting structure and combined technology, applied in the field of aviation flight test, can solve problems such as strip breakage, and achieve the effects of reduced damage, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

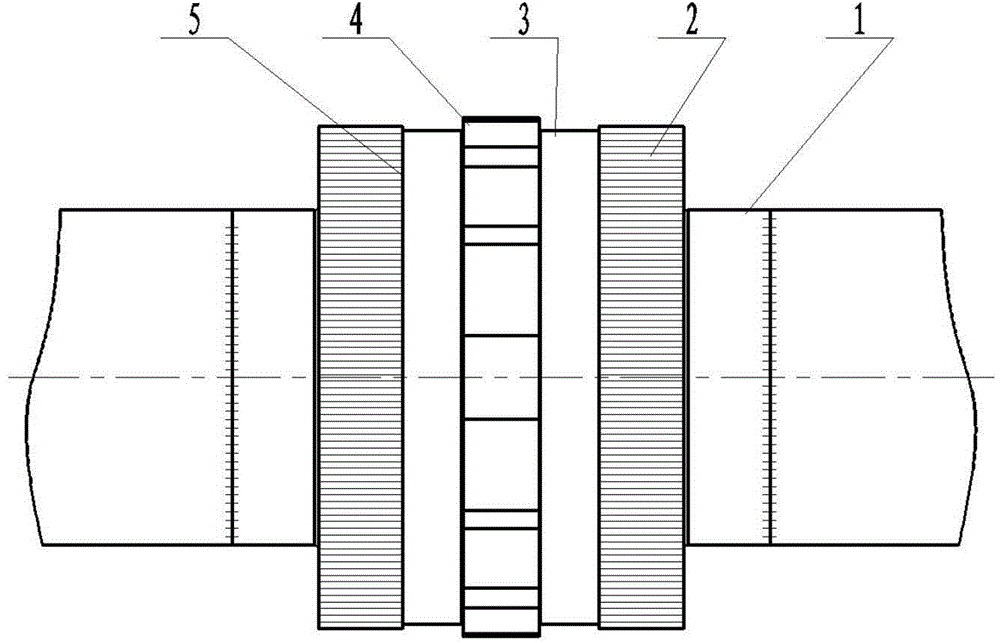

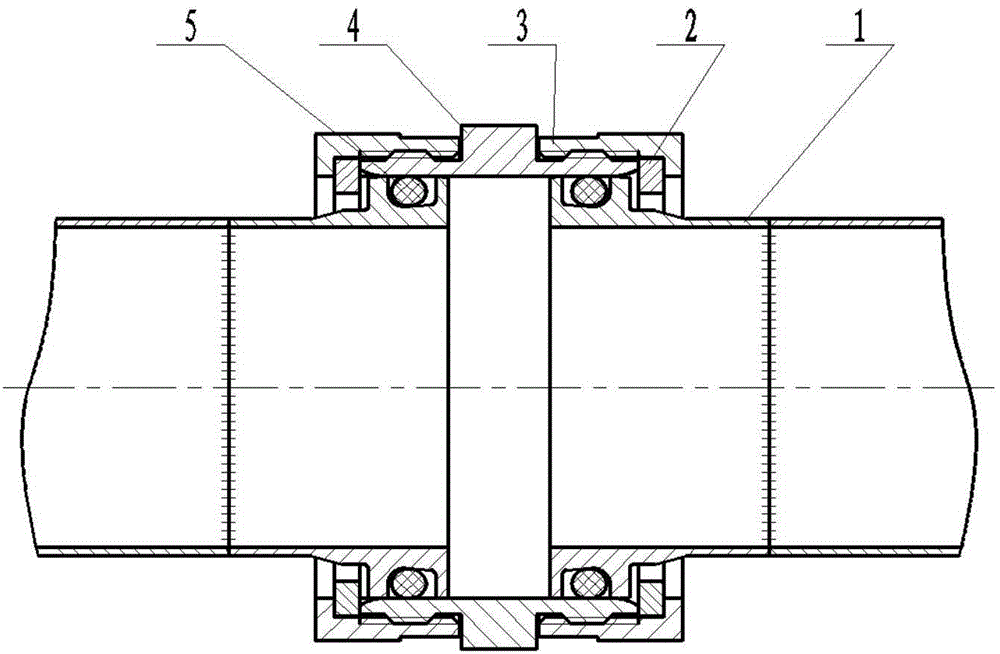

[0014] The connecting structure of the aircraft fuel conduit will be further described in detail below. see figure 1 The combined aircraft fuel conduit connection structure includes two pipe sleeves 1, two retaining rings 2, two nuts 3, one outer sleeve 4 and two sealing rings 5, and the outer sleeve 4 completes the connection of the two connecting conduits. Pairs. The installation steps are as follows:

[0015] Step 1. Weld the pipe sleeve 1 at one end of the two conduits to be connected respectively. The inspection standard after welding the pipe sleeve 1 is in accordance with the quality inspection standard of navigation mark HB5135 structural steel and stainless steel welding joint and the quality inspection standard of navigation mark HB5375 aluminum and aluminum alloy fusion welding. implement;

[0016] Step 2. Install the sealing ring 5 at the rectangular groove on the pipe sleeve 1 to facilitate the sealing of the fuel pipeline system; the surface roughness of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com