Electric power construction grounding device

A grounding device and power construction technology, applied in the direction of circuits, connections, electrical components, etc., can solve the problems of insufficient contact surface, serious safety hazards, easy displacement of wires, etc., and achieve the effect of preventing slipping out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

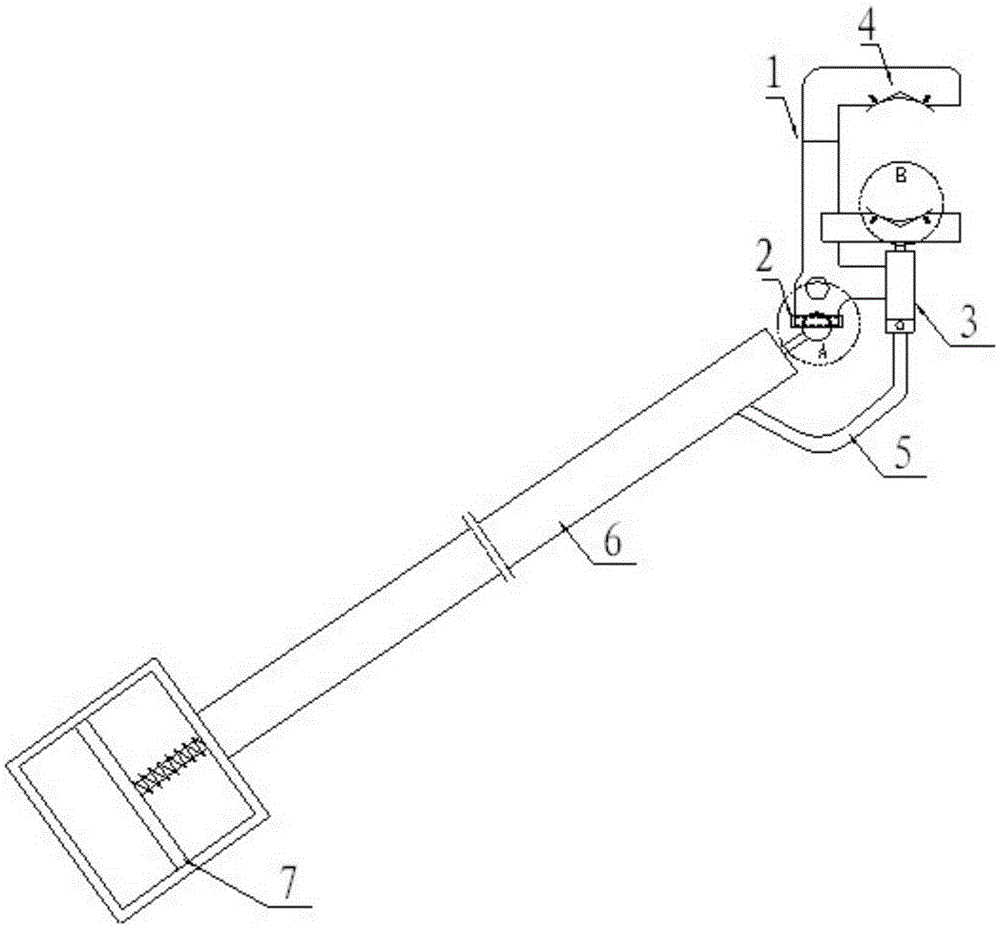

[0021] Such as figure 1 As shown, the electric power construction grounding device of the present invention mainly includes two parts, an insulating operating rod 6 and a grounding head. The universal joint 2 is used to connect the grounding head and the insulating operating rod 6 to realize any angle change of the grounding head.

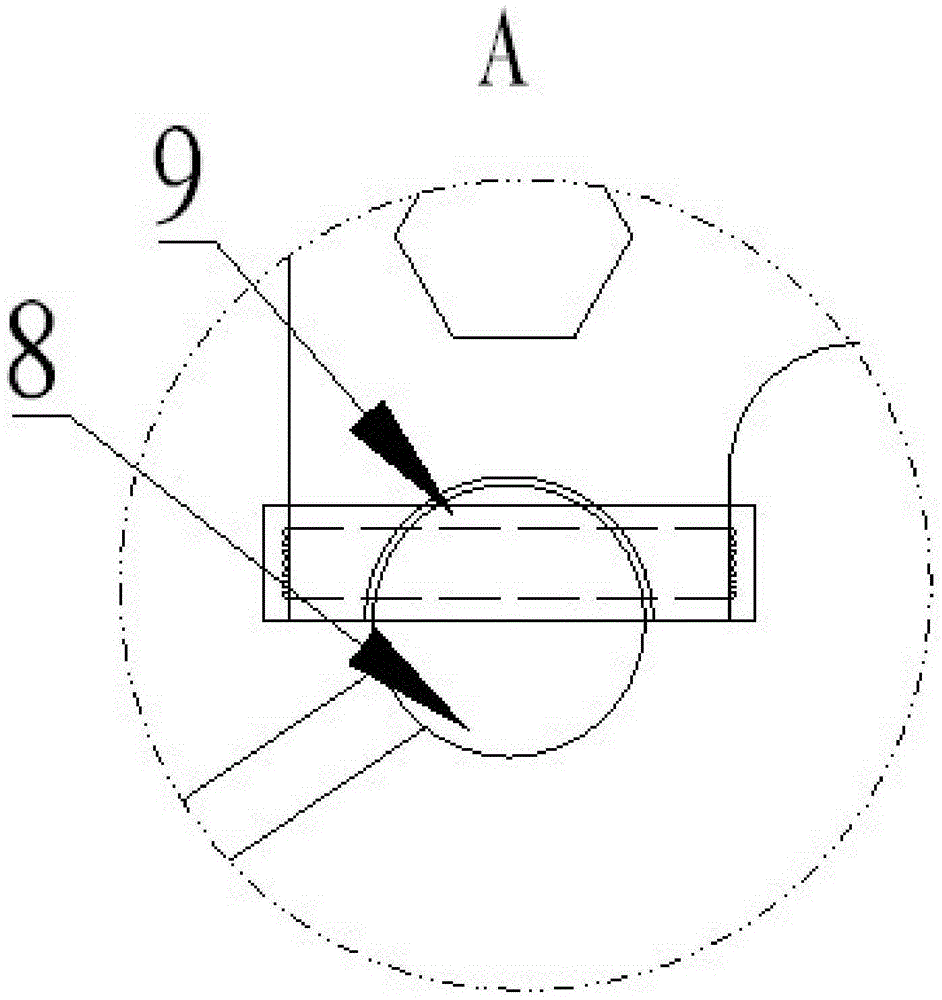

[0022] Such as figure 2 As shown, the universal joint 2 includes a spherical head 8, a hemispherical slot and a screw 9, wherein the spherical head 8 is fixed on the top of the insulating operating rod, and the bottom end of the grounding head is provided with a hemispherical slot, and the hemispherical slot and the spherical head 8 fit, so that the ground head can be rotated in any direction, and the ground head corresponding to the position of the hemispherical slot is provided with a screw 9 that penetrates the hemispherical slot and is used to fix the spherical head.

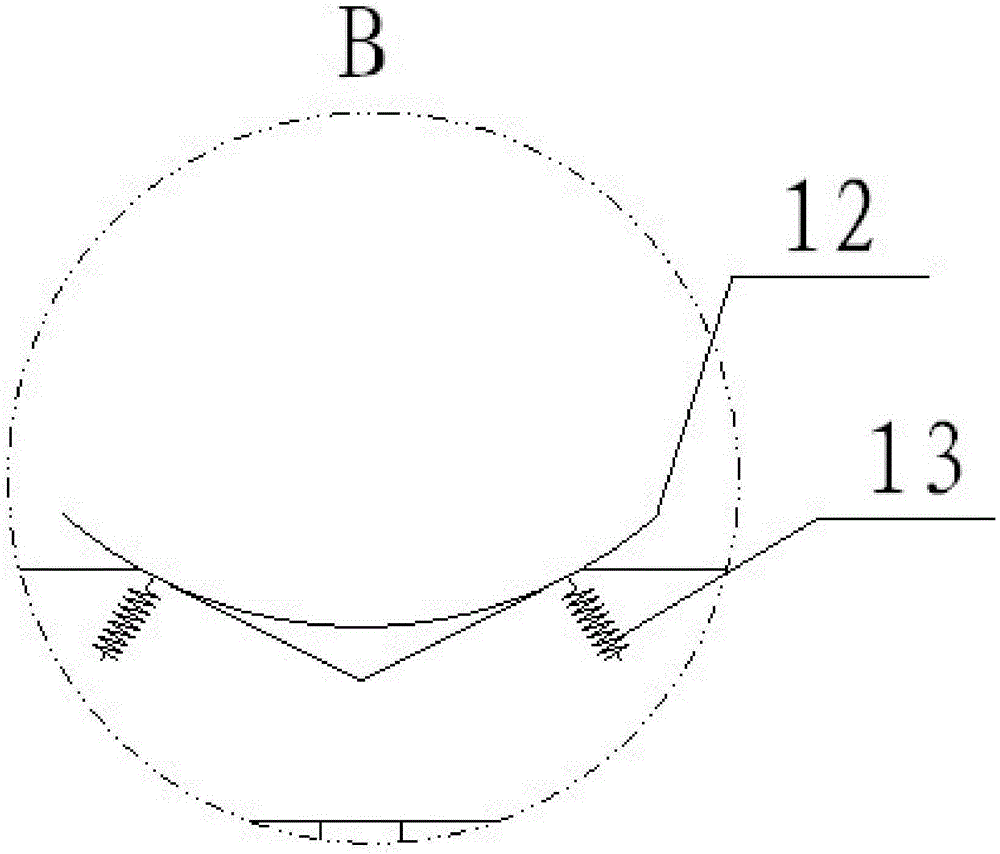

[0023] The ground head includes a handle 11 connected to the insulating op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com