Printer with automatic back-off cutter structure and automatic back-off method of printer

A printer, automatic technology, applied in the direction of printing device, printing, etc., can solve the problem of fixed blades biting each other, achieve reliable release, and reduce the effect of recording paper jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

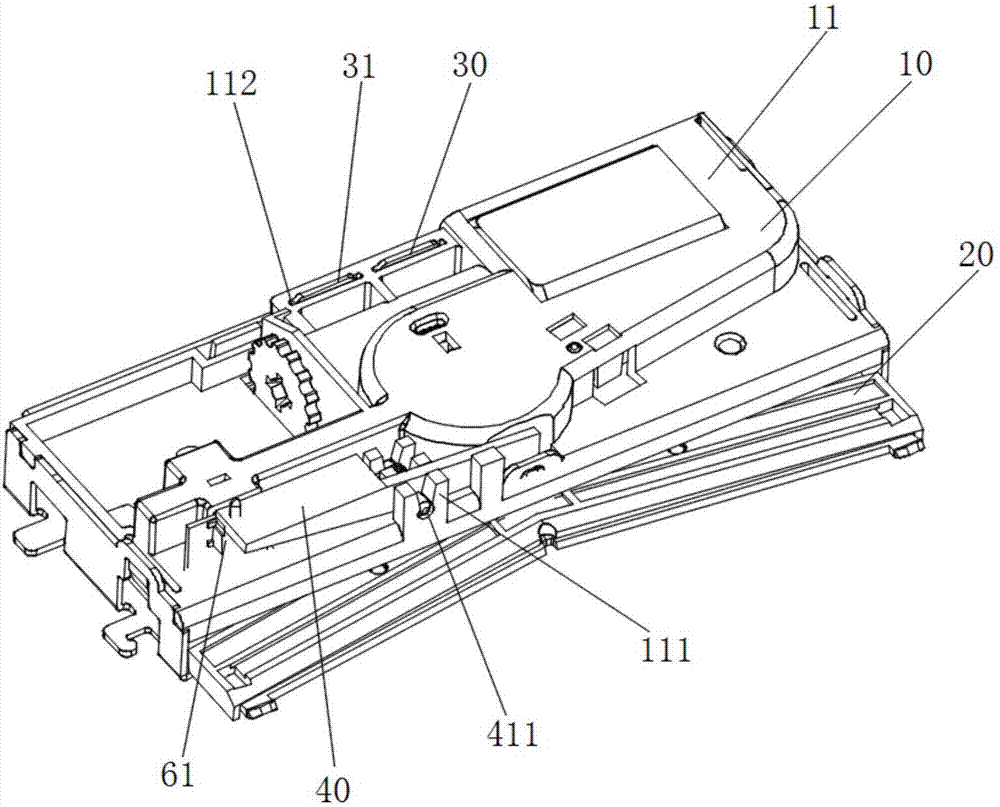

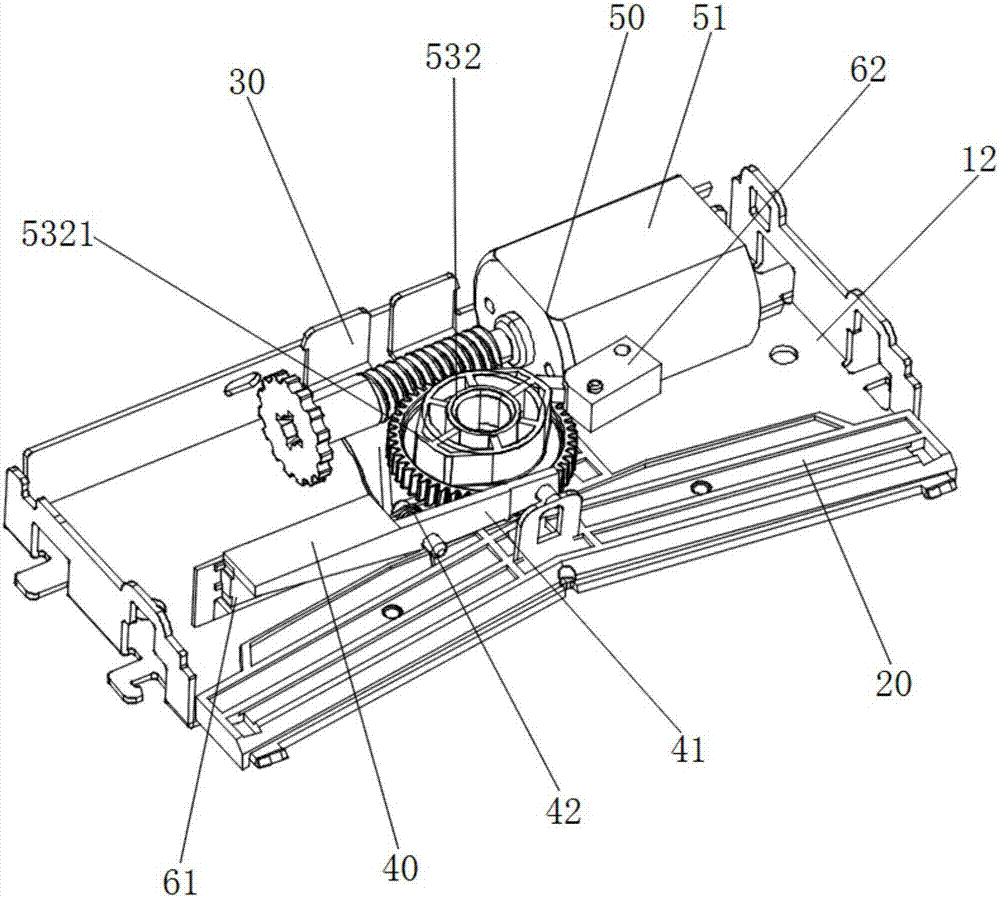

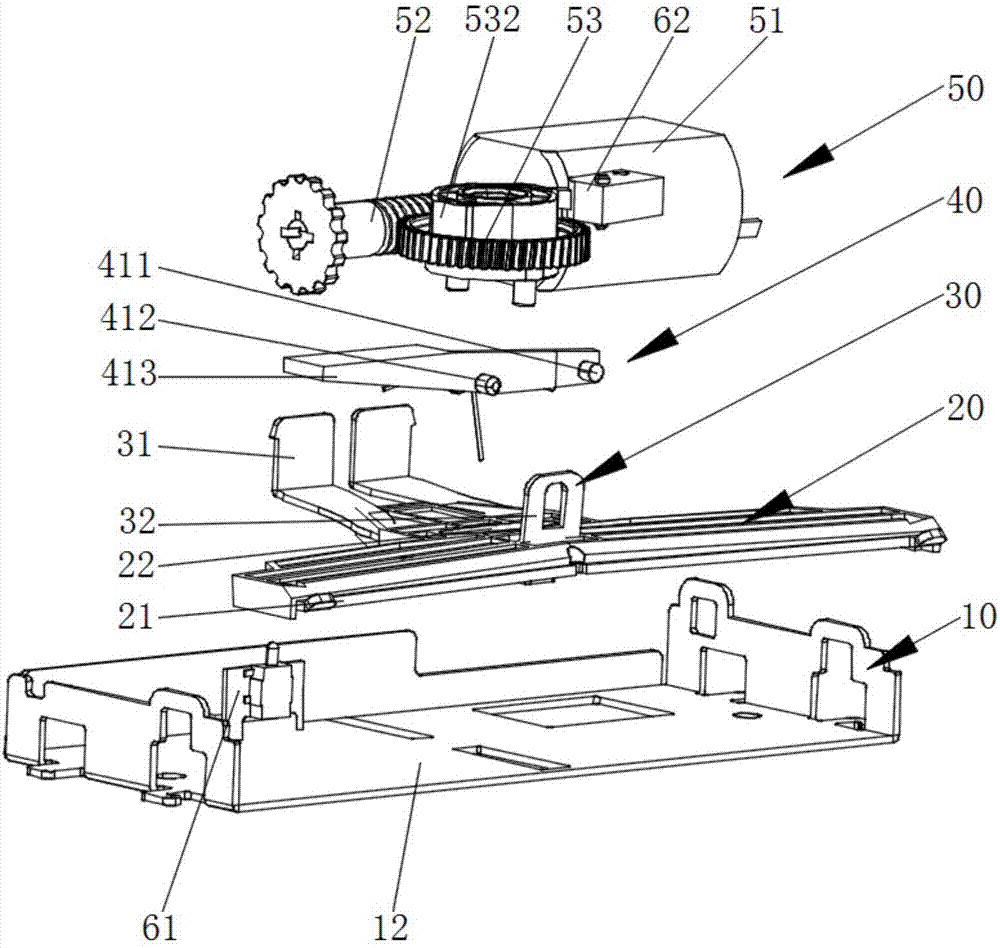

[0034] A printer capable of printing on recording paper pulled from a paper roller, and appropriately cutting the recording paper to use it as a ticket, receipt, etc. The printer mainly includes an integral housing structure, a flattening unit, and a main unit. The flattening unit includes a fixed blade and a matching cooperation mechanism. The design focus of this case is mainly on the main unit, please refer to figure 1 with image 3 The main unit includes a movable blade 20, a pre-tensioning mechanism 30, a driving system 50 and a release mechanism.

[0035] Please refer to figure 1 with figure 2 In the integral casing structure, there is a casing 10 for accommodating or assembling the main unit, and the casing 10 is a casing molded from a plastic or metal material. The casing 10 includes an inner casing and an outer casing 11. The inner casing and the outer casing 11 are combined to form a cavity. The main unit is arranged in the cavity or installed on the inner casing and ...

Embodiment 2

[0046] The difference between the second embodiment and the first embodiment is that the structure of the release mechanism used is different, and the pre-tensioning mechanism 30, the casing 10, etc. have been adapted to change.

[0047] Please refer to Figure 4 with Figure 5 In Embodiment 2, the release mechanism includes a push rod 41a and a connecting piece 43a, and the connecting piece 43a is arranged in the middle of the push rod 41a. The connecting piece 43a adopts a spring structure, and has two connecting pieces 43a respectively connected to the pre-tensioning mechanism 30, so that the connection stability is better and the linkage is more effective during startup. In this embodiment, the pre-tightening mechanism 30 does not need to be provided with a hooking portion 32, and the casing 10 is provided with a hollow protection column corresponding to the connecting piece 43a, and the protection column is provided with a relief groove along the pushing and returning directi...

Embodiment 3

[0050] Applying the printers in Embodiments 1 and 2 to realize the automatic fallback method includes the following steps:

[0051] S1. The release mechanism is activated, and the release mechanism linkages the pretensioning mechanism 30 to disengage the action on the movable blade 20, and the contact pressure between the movable blade 20 and the fixed blade is released:

[0052] Specifically, when the bite between the fixed blade and the movable blade 20 occurs, manually push or press the release mechanism; subsequently, the release mechanism pulls the pre-tensioning mechanism 30 to release it from pressing against the movable blade 20 This function allows the contact pressure between the movable blade 20 and the fixed blade to be released.

[0053] S2. Trigger the first detection switch 61 after the release mechanism is in place;

[0054] S3. The controller (not shown in the figure) controls the motor 51 to reverse rotation, and the motor 51 retracts the movable blade 20 to the init...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com