Lubricating grease composition of automobile steering combination switch and preparation method

A combination switch and grease technology, applied in the field of grease, can solve the problem of lack of adhesion, wear-reducing plastic compatibility and shear resistance, shortened service life of vehicle combination switches, poor practical performance of grease, etc. problem, to achieve the effect of excellent oxidation stability, increased service life, increased wear reduction and anti-wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A composition of automobile steering combination switch lubricating grease, comprising the following components and mass percentages:

[0034] Base oil (2:1) 85% (850g),

[0035] Thickener (3:1) 15% (150g),

[0036] According to the total amount of the above two components, add the following additive mass percentages:

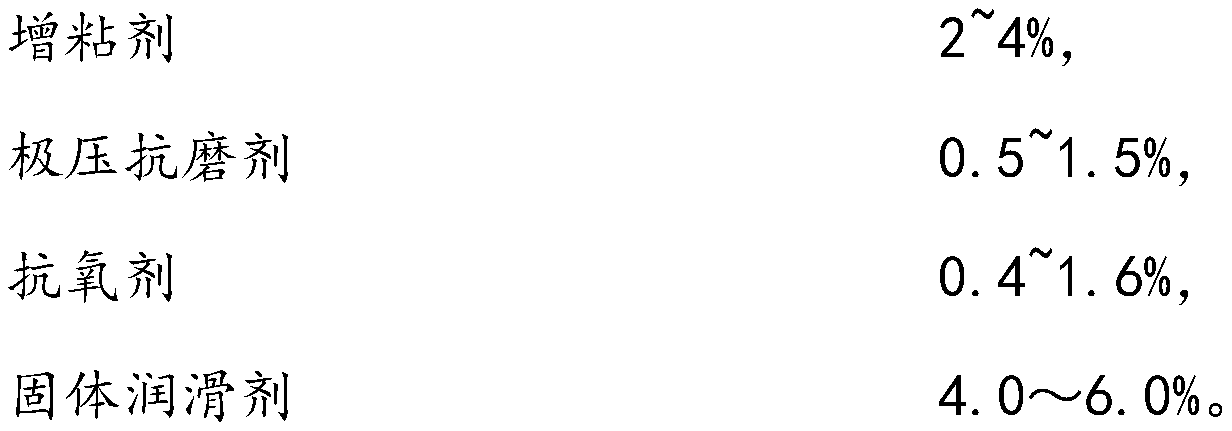

[0037]

[0038] Another technical problem to be solved in the present invention is to provide a kind of preparation method of the composition of automobile steering combination switch lubricating grease, comprising the following steps:

[0039] 1) 85% of the base oil and 15% of the thickener are added to the reactor respectively, wherein 85% of the base oil is composed of 183g of polyalphaolefin and 467g of metallocene PAO, and 15% of the thickener is composed of 112.5g of 12 hydroxystearic acid Lithium soap and 37.5g lithium stearate soap are mixed, and the stirring work is started. The stirring time is 90 minutes, so that the heating temperature i...

Embodiment 2

[0047] A composition of automobile steering combination switch lubricating grease, comprising the following components and mass percentages:

[0048] Base oil (2:1) 90% (900g),

[0049] Thickener (3:1) 10% (100g),

[0050] According to the total amount of the above two components, add the following additive mass percentages:

[0051]

[0052] Another technical problem to be solved in the present invention is to provide a kind of preparation method of the composition of automobile steering combination switch lubricating grease, comprising the following steps:

[0053] 1) Add 90% of the base oil and 10% of the thickening agent into the reactor respectively, wherein 90% of the base oil is composed of 195.5g of polyalphaolefin and 492g of metallocene PAO, and 10% of the thickening agent is composed of 143.75g of 12-hydroxystearin Lithium stearate soap and 12.5g lithium stearate soap are mixed, and the stirring work is started. The stirring time is 90 minutes, so that the heat...

experiment example

[0084] Examples 1-2 and Comparative Examples 1-4 were compared in terms of mechanical stability (shear resistance), friction (abnormal noise), plastic compatibility and colloidal stability of the grease.

[0085] 1. In terms of mechanical stability, it is evaluated by testing the grease for 100,000 shears;

[0086] 2. Friction is evaluated by SRV high-frequency linear vibration instrument (plastic to metal);

[0087] 3. Long-term contact between plastic compatible grease and POM plastic parts at 70°C, and measure the Shore hardness change rate and volume change rate of POM plastic parts to evaluate;

[0088] 4. The colloidal stability is evaluated by measuring the grease separation at 40°C storage and steel mesh at 100°C. Appropriate oil separation can effectively solve the problems of abnormal noise and seizure.

[0089] The test results are evaluated, and the specific data are as follows in Table 1:

[0090] Table 1 embodiment 1-2 and comparative example 1-4 various perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com