Full-automatic soft bag filling machine

A filling machine, fully automatic technology, applied in packaging, transportation and packaging, types of packaging items, etc., can solve the problems of equipment cost increase, occupation of large space, high labor cost, reduce equipment cost, reduce labor cost, cut Stable effect of cutting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

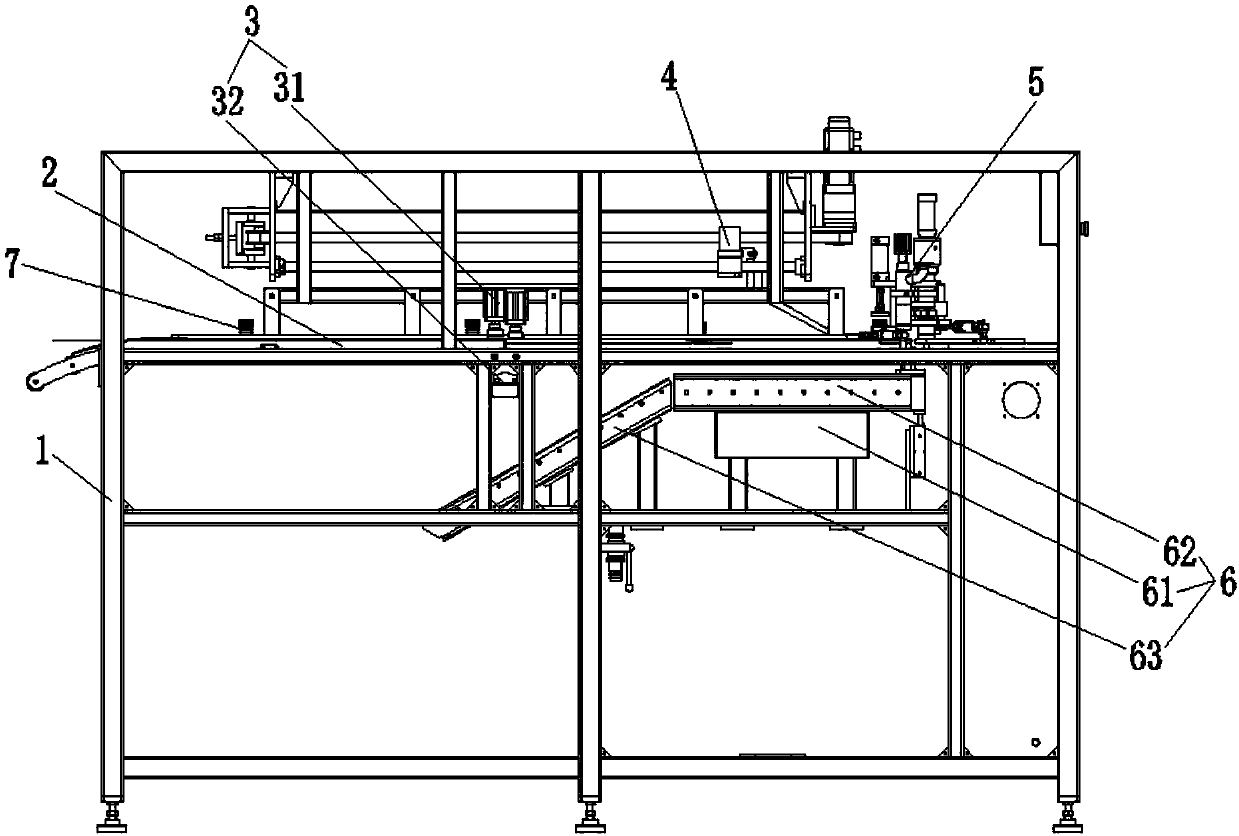

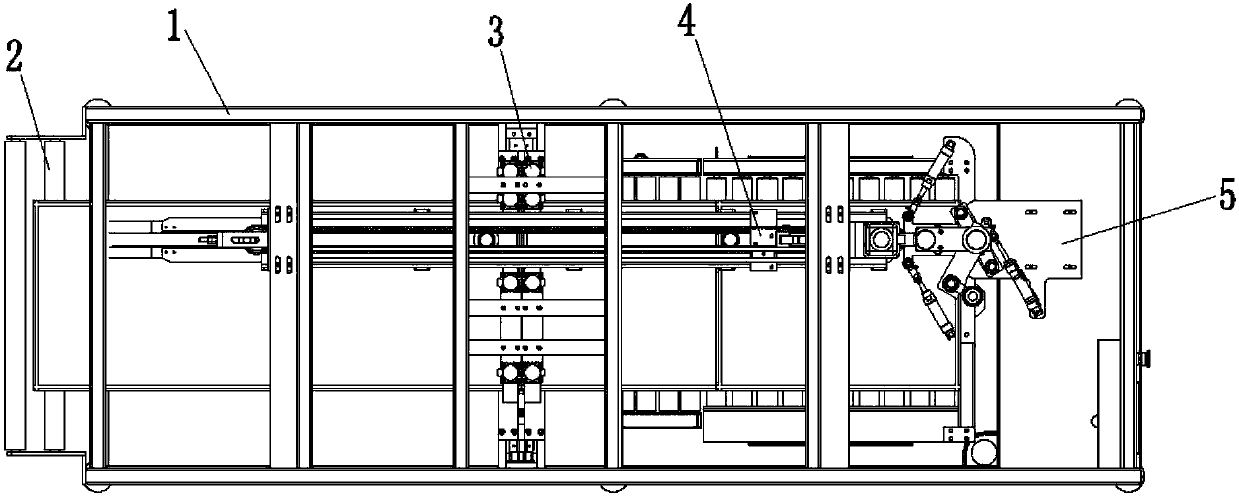

[0041] See Figure 1 to Figure 8 , the fully automatic soft bag filling machine of this embodiment includes a frame 1, and a soft bag delivery platform 2 installed on the frame 1, a cutting mechanism 3, a bag feeding mechanism 4, and a three-in-one mechanism for pulling, filling and pressing 5 And unloading mechanism 6.

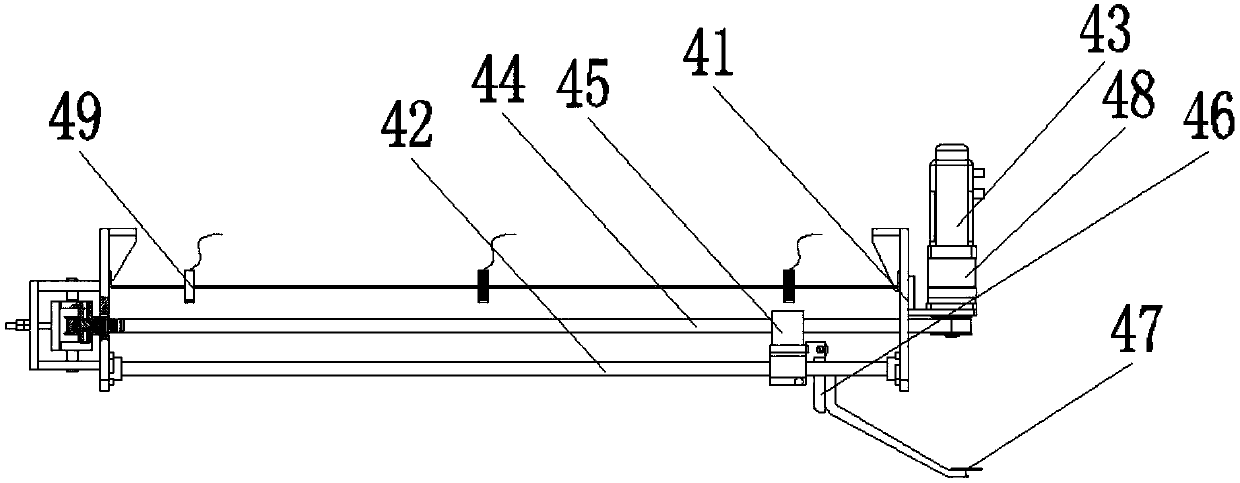

[0042] The soft bag conveying platform 2 is provided with a gap perpendicular to the conveying direction of the soft bag. The cutting mechanism 3 is arranged at the gap on the soft bag delivery platform 2, and the cutting mechanism 3 is used to cut off the first soft bag 7 at the bag-out end of the soft bag delivery platform 2. The bag feeding mechanism 4 is arranged above the soft bag conveying platform 2, and is used to send the first soft bag 7 at the bag-out end of the soft bag conveying platform 2 to the pulling-filling-pressing three-in-one mechanism 5. The pull-fill-press three-in-one mechanism 5 is arranged on the bag-out side of the soft bag convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com