Cutter device for sewing machine

A sewing machine and cutting knife technology, applied in the direction of sewing machine control devices, sewing machine components, sewing equipment, etc., can solve the problems of fabric wrinkles, affecting the accuracy of fabric cutting, affecting the aesthetics of products, etc., to achieve stable cutting, stable and accurate cutting , The cutting process is smooth and continuous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

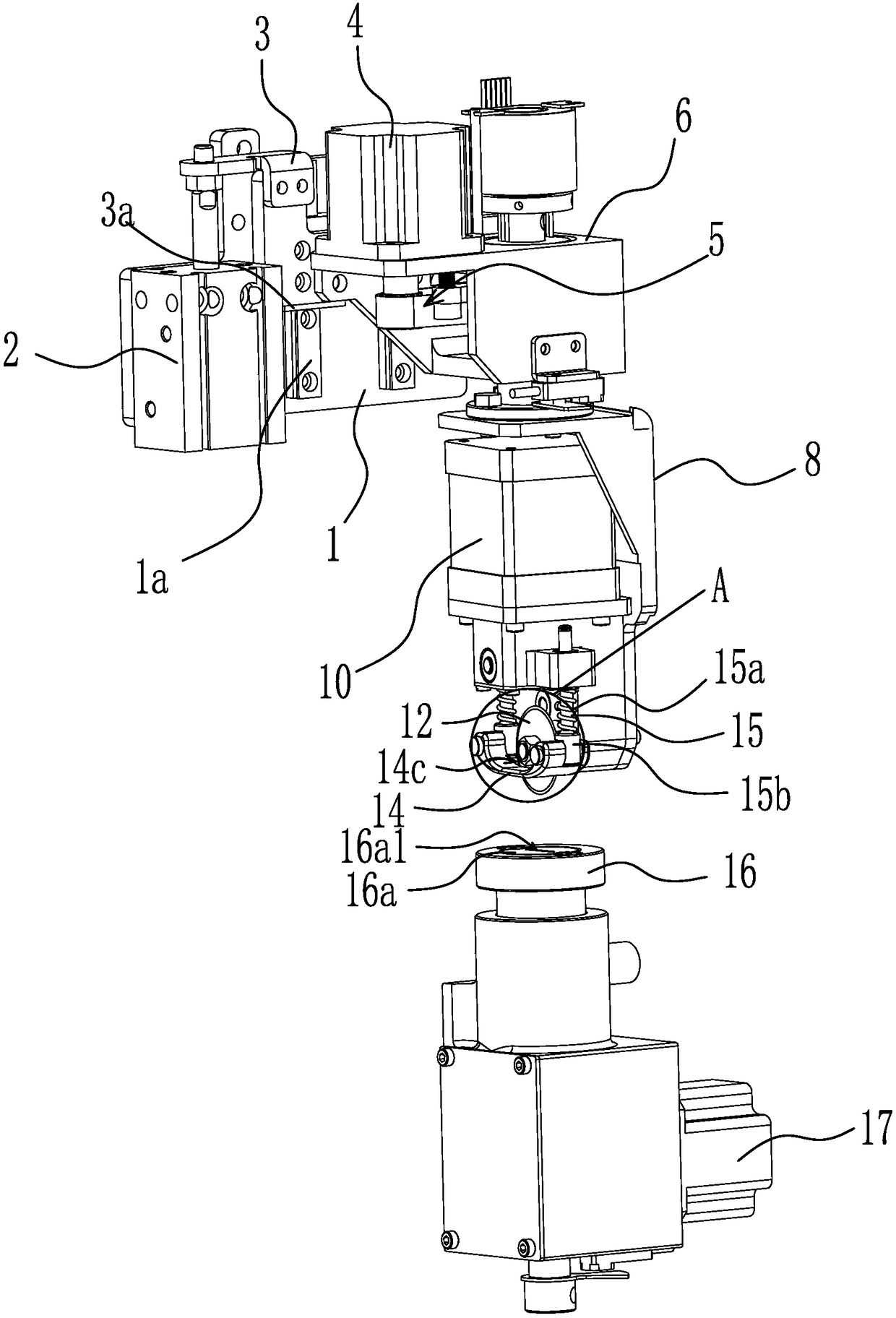

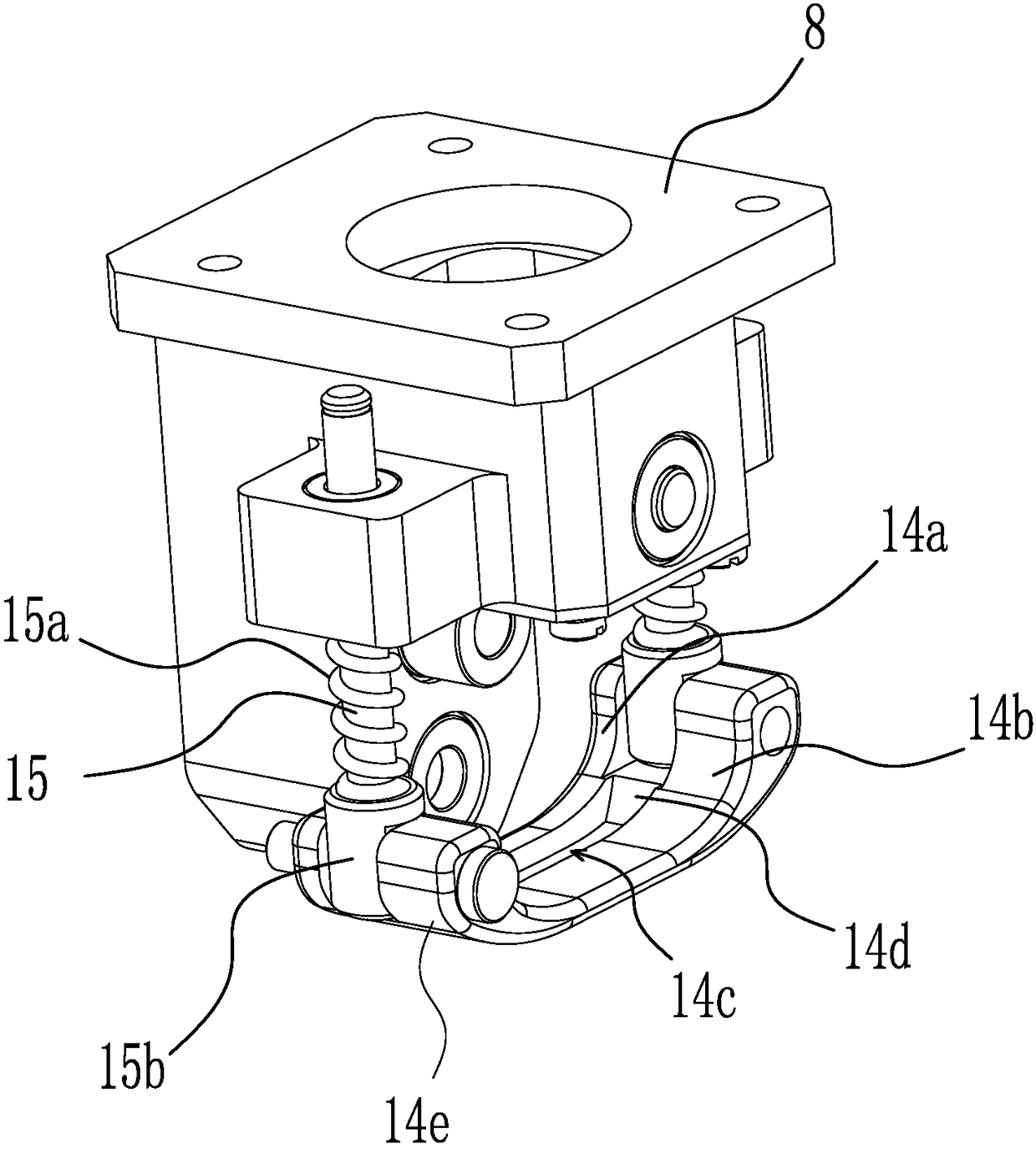

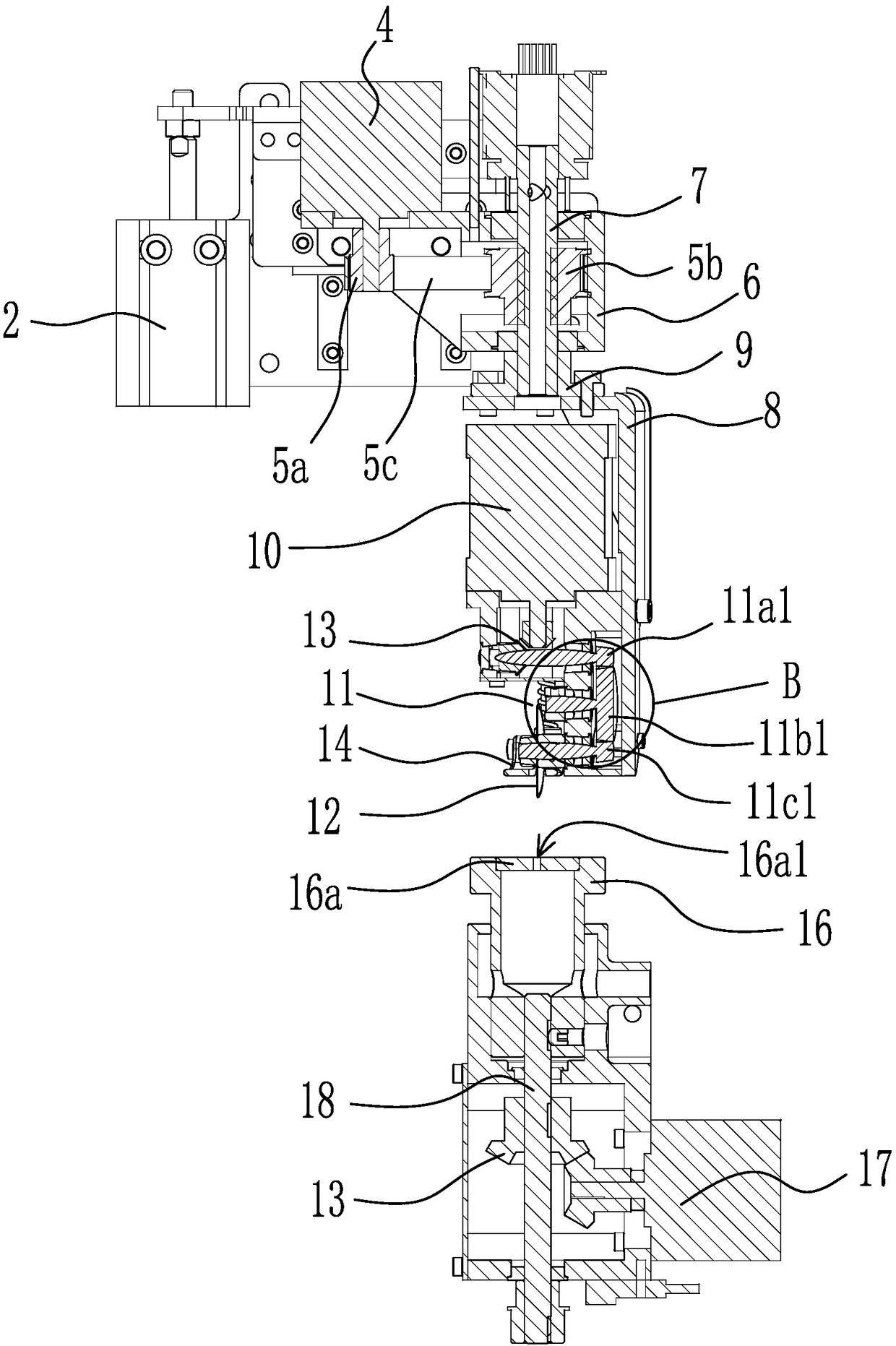

[0023] Such as figure 1 with Figure 4 As shown, the sewing machine is provided with a mounting plate 1. The cutting device of this sewing machine includes a lifting cylinder 2, a connecting plate 3, a second motor 4, a second transmission mechanism 5, a lifting frame 6, a cutting knife 12, a presser foot 14, and The rotating lower knife plate 16a and the rotating shaft 7, the lifting cylinder 2 are fixedly installed on the mounting plate 1. Two slide rails 1a are provided in parallel on the mounting plate 1, and the connecting plate 3 is provided with a slider 3a corresponding to the slide rail 1a. The top rod of the lifting cylinder 2 is fixedly connected to the connecting plate 3. The second motor 4 and the lifting frame 6 are fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com