Residue soil dump vehicle with built-in horizontal-pushing environment-friendly top cover system

A built-in, dump truck technology, applied to motor vehicles, vehicles used for freight, load coverage, etc., can solve problems such as inconvenient placement, low work efficiency, waste of resources, etc., to ensure service life, work stability, clean up convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

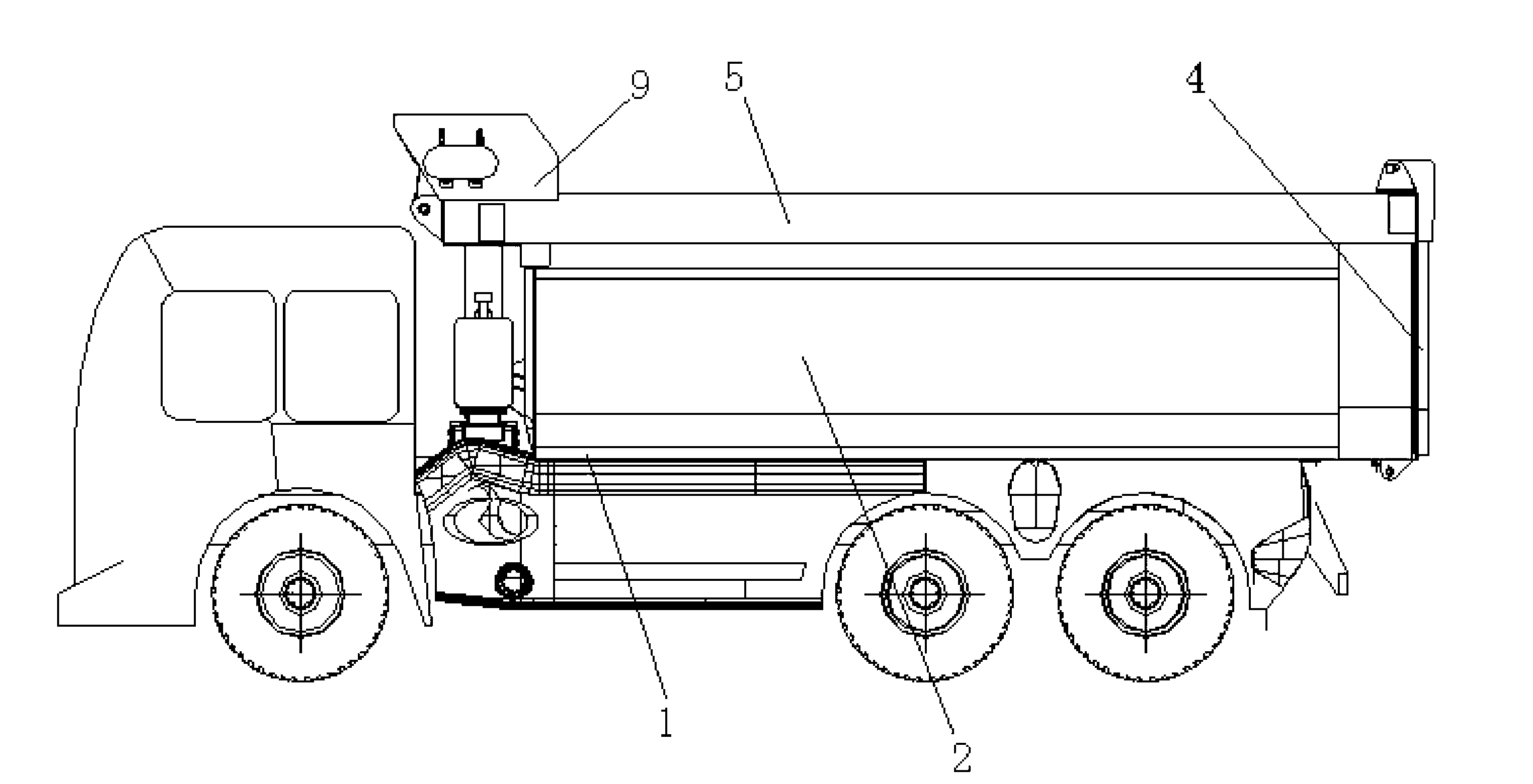

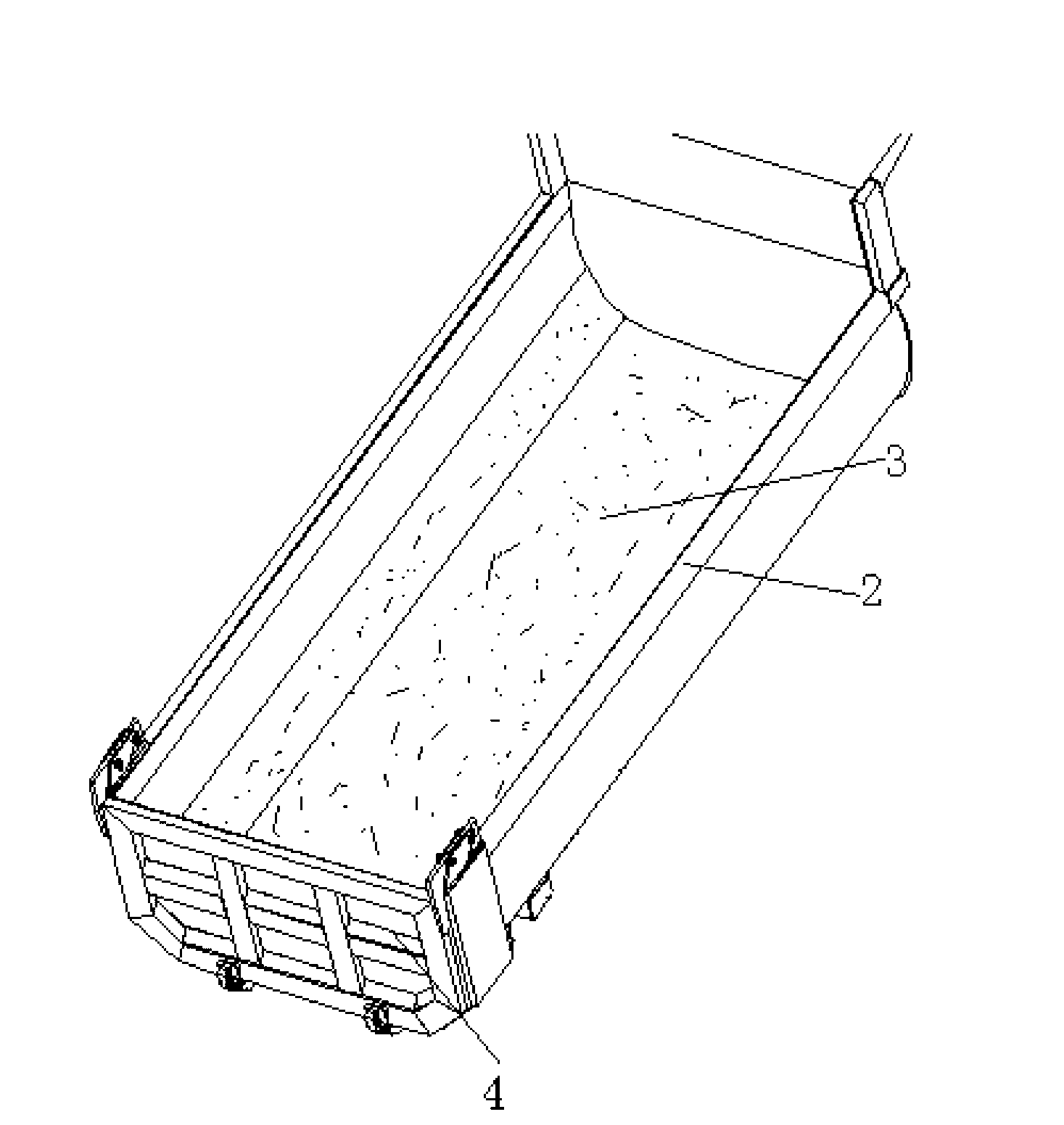

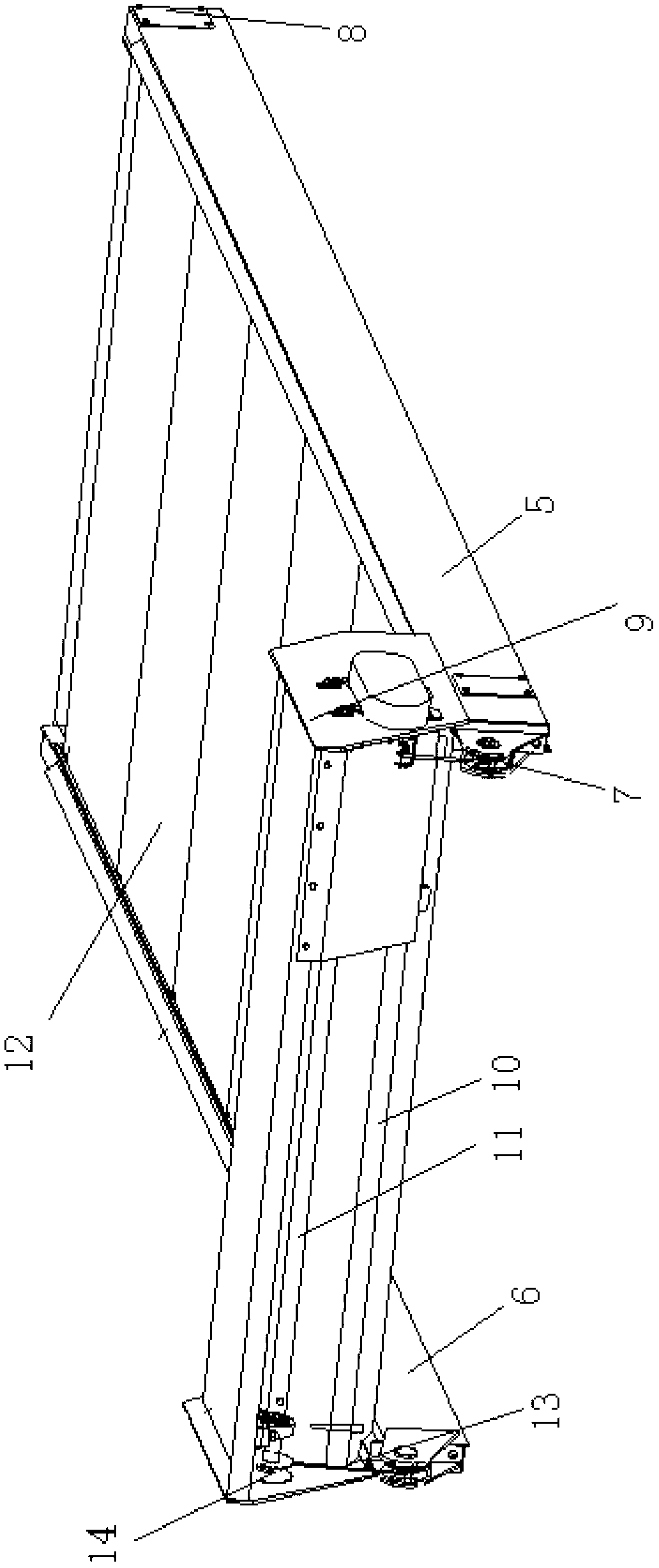

[0026] Referring to the accompanying drawings, a muck dump truck equipped with a built-in flat-push electric environmental protection roof system includes a U-shaped compartment 2 installed on the vehicle body 1, and a wear-resistant plate 3 is laid inside the U-shaped compartment 2. The rear end of the U-shaped compartment 2 is equipped with a rear door panel 4 matched therewith; the upper ends on both sides of the U-shaped compartment 2 are respectively equipped with left and right guide rail crossbeams 5,6, and the front and rear ends of the left and right guide rail crossbeams 5,6 The front and rear movable wheel mechanism assemblies 7,8 are installed respectively, and the upper end of the front end of the left and right guide rail beams 5,6 is provided with a rain cloth box 9, and a rain cloth reel assembly 10 and a rope wheel mechanism 11 are installed in the rain cloth box 9 , an end of the rain cloth assembly 12 is fixed on the rain cloth reel 11 of the rain cloth reel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com