Injection moulding machine and surface decoration mould used by same

A surface decoration, forming machine technology, applied in the direction of coating, etc., can solve the problems of high contact temperature, defective products, poor shell film bonding and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

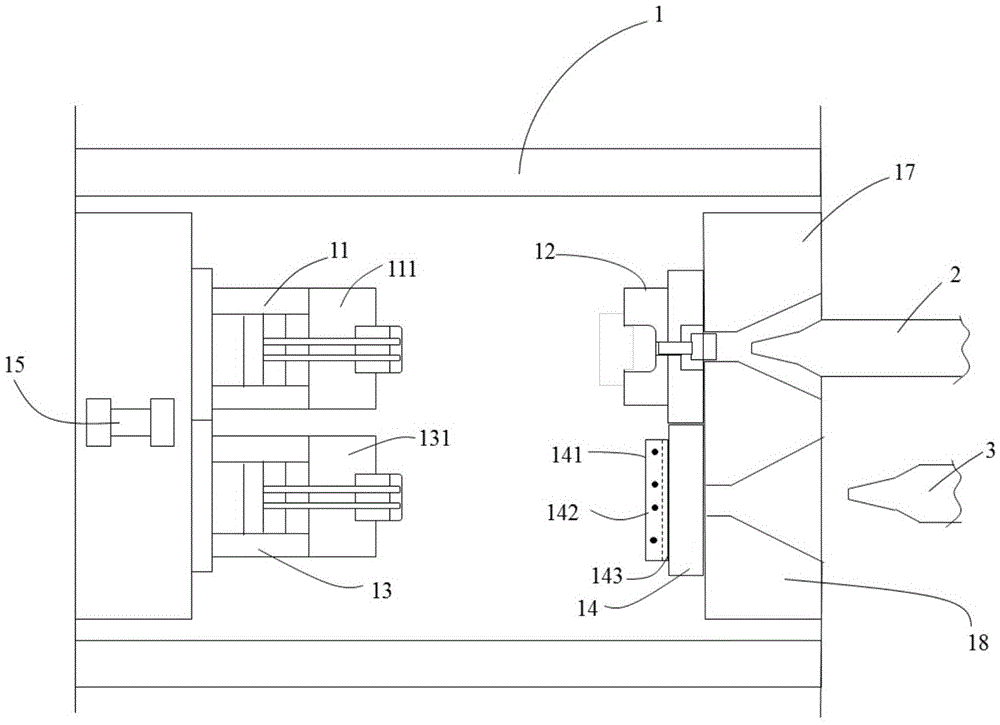

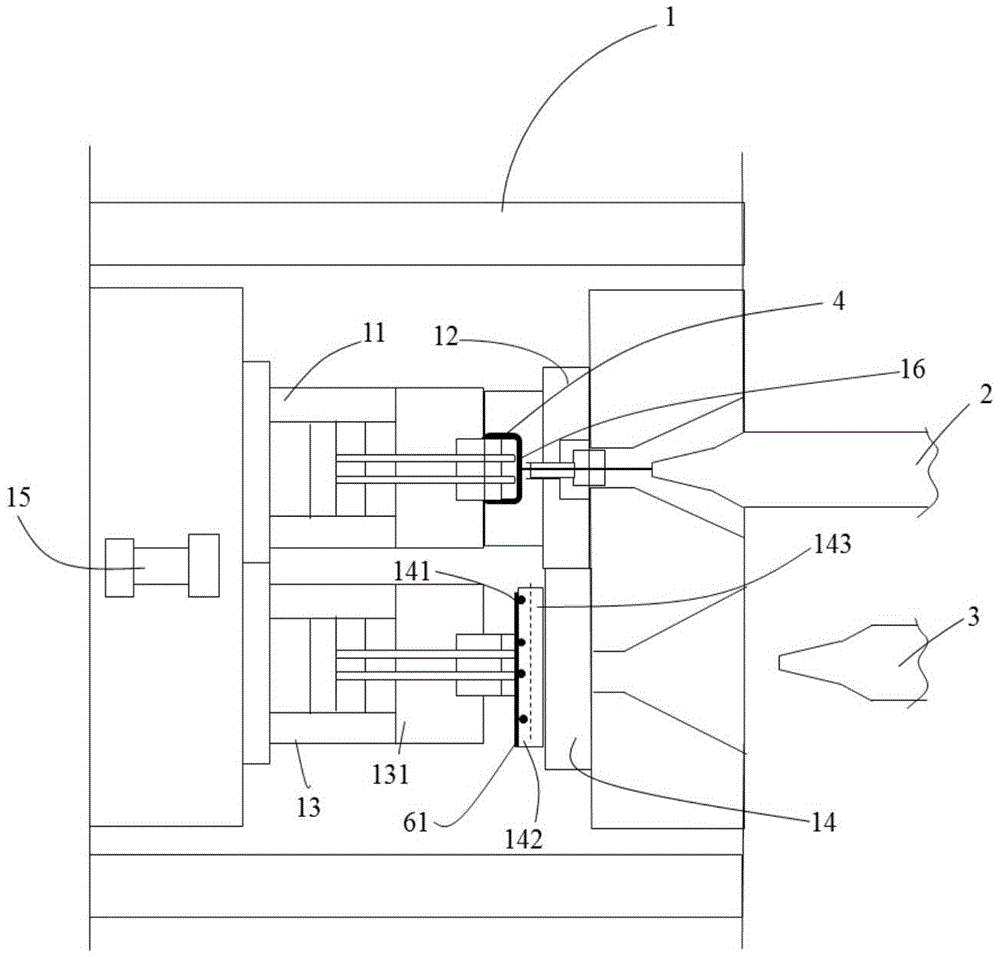

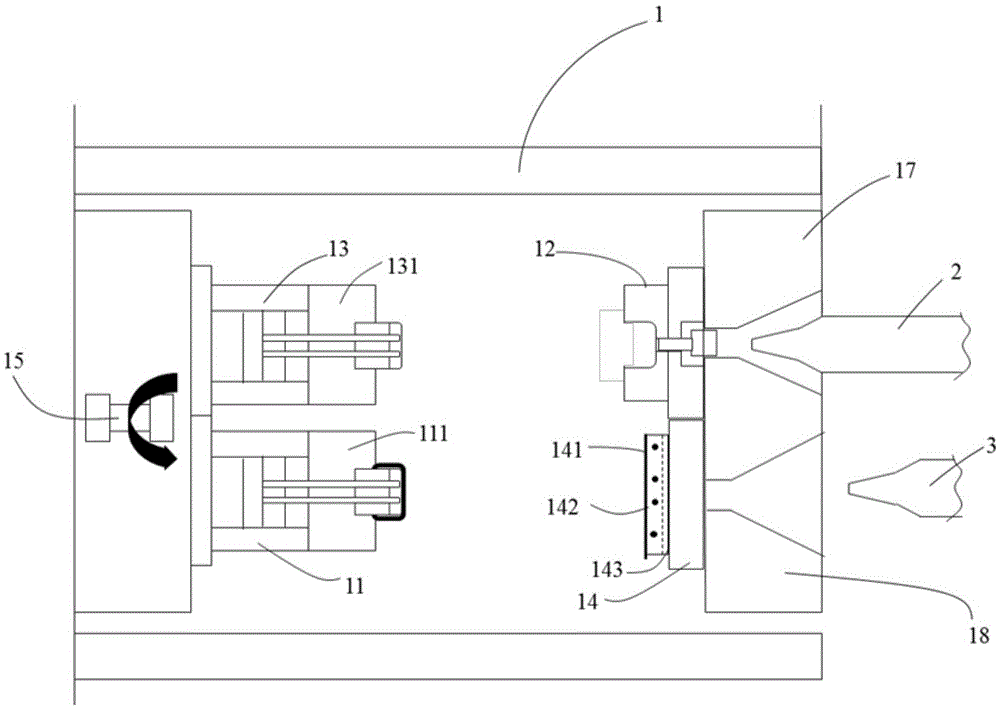

[0046] Hereinafter, the present invention will be described in detail with reference to the drawings.

[0047] figure 1 A preferred embodiment of the surface decoration mold according to the present invention is shown. A surface decoration mold 1 includes a male injection mold 11 , a first female mold 12 , a decoration male mold 13 , a second female mold 14 and a rotating disk 15 .

[0048] The injection male mold 11 has a vacuum air channel 111 on the inner surface close to the contact with the first female mold. After the first female mold 12 is closed with the injection male mold 11, the raw material 5 is injected to the injection male mold. 11 and the first mold cavity 16 formed when the first female mold 12 is closed makes the preliminary molded product 4 shape.

[0049] In this specification, "primary side 17" refers to the side where the first master mold is located.

[0050] The decoration male mold 13 has the same structure as the injection male mold 11 and has a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com