Cutting method and cutting device employing overlay pieces

A cutting device and cover sheet technology, applied in application, small raw hide/large raw hide/leather/fur mechanical treatment, small raw hide/large raw hide/leather/fur treatment, etc., can solve the trouble of separating parts and cover sheets , winding cutting head, loss of time and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

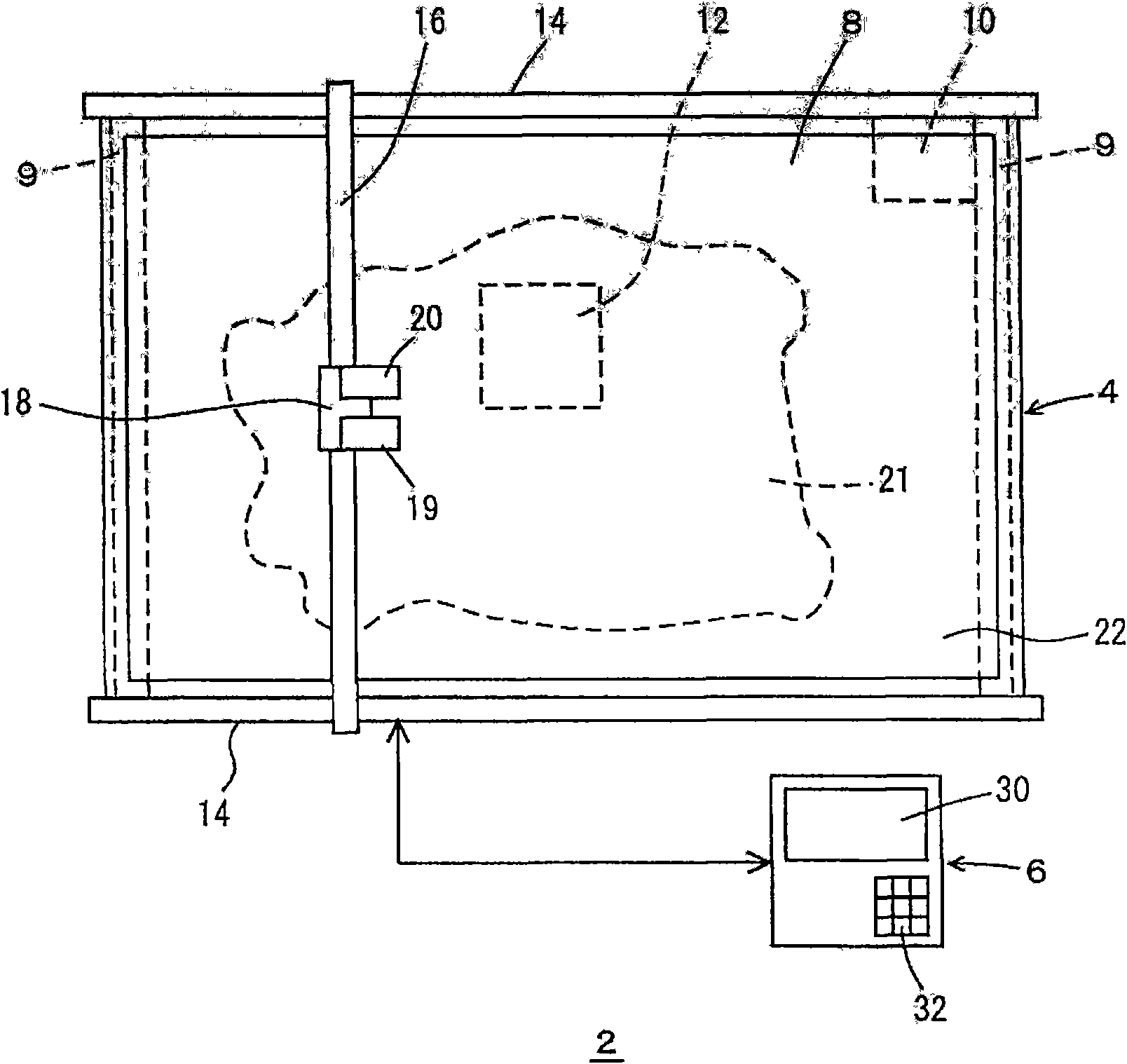

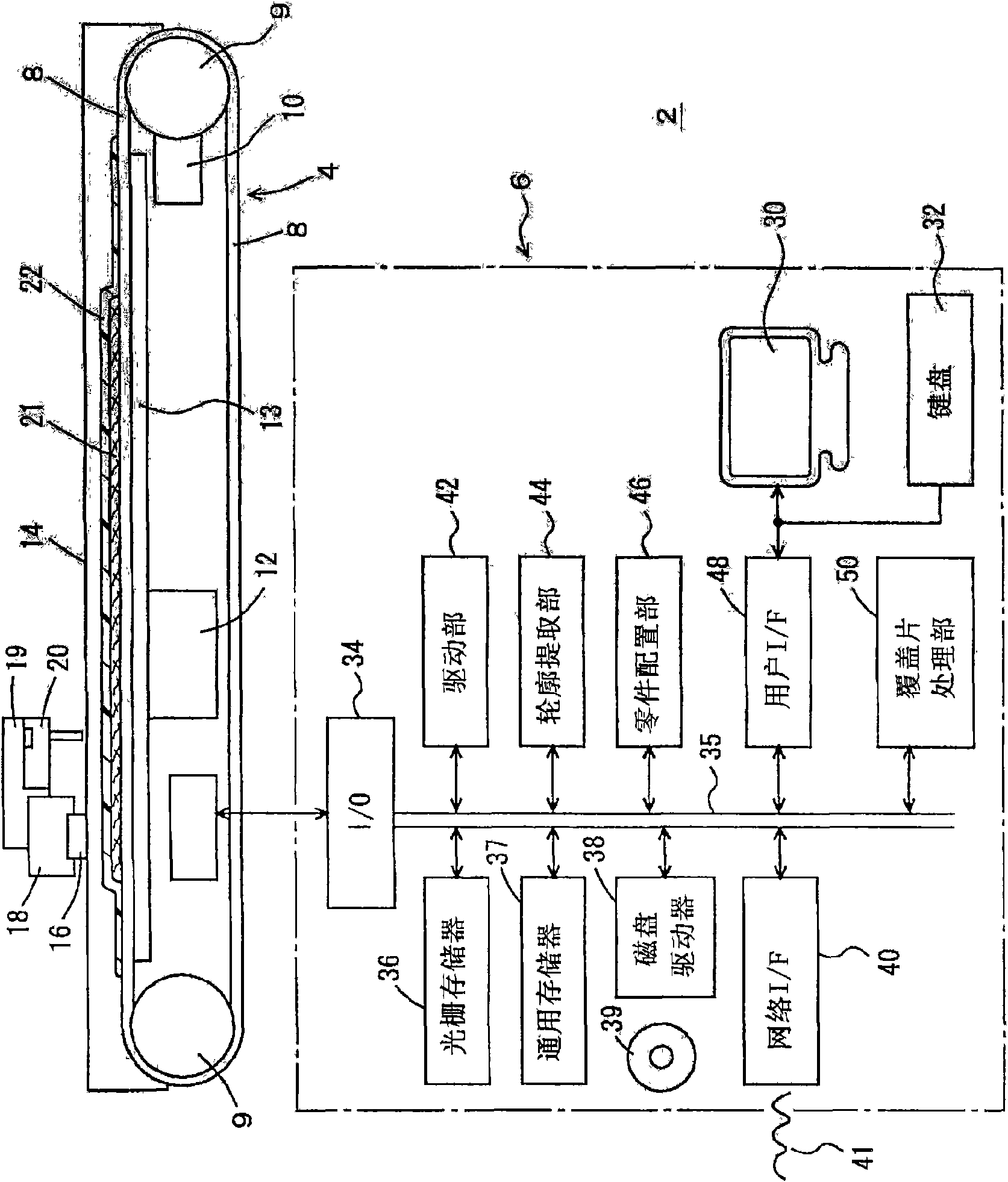

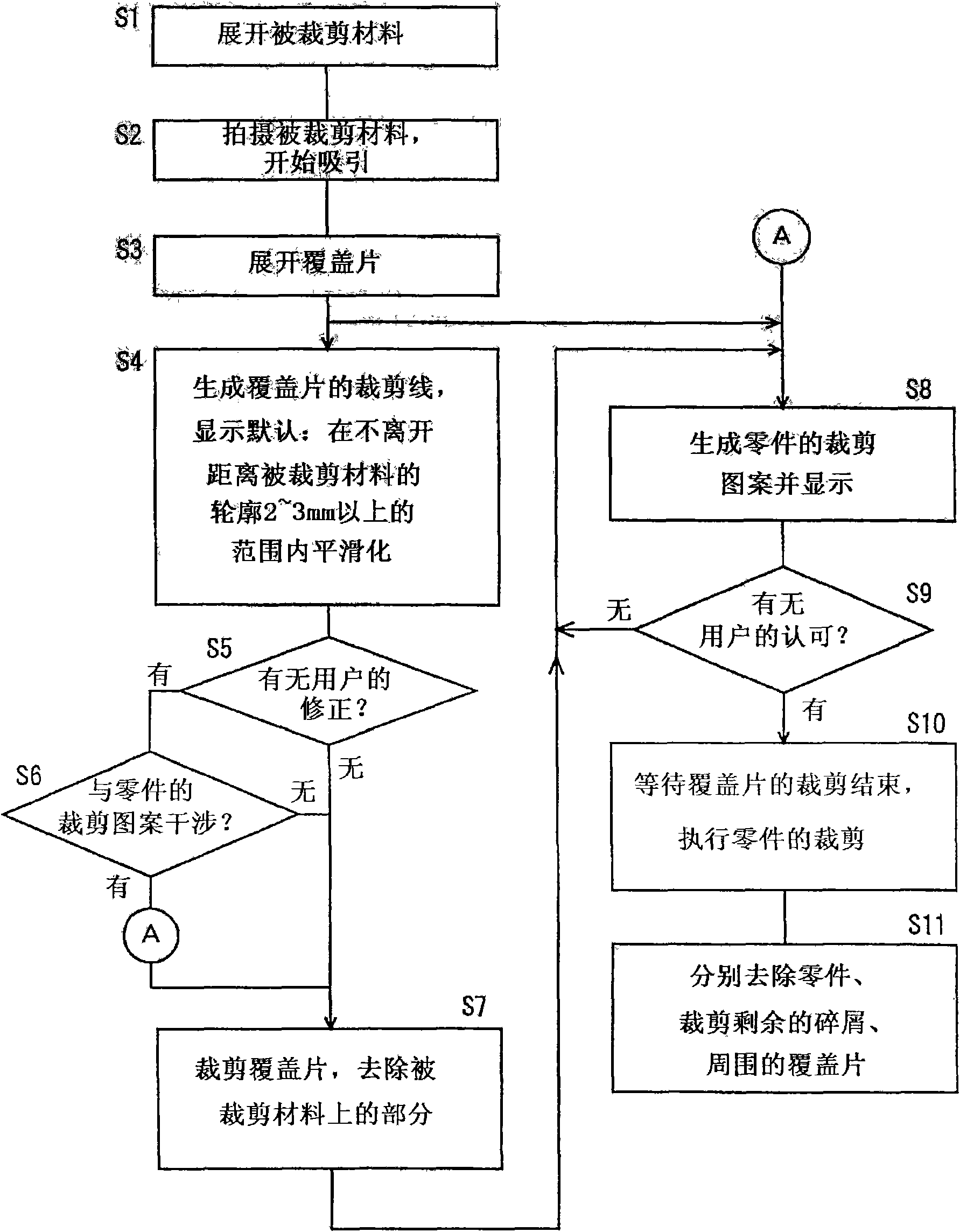

[0026] Figure 1 to Figure 5 The cutting method and cutting apparatus of the embodiment are shown. In each figure, 2 is a cutting device, which consists of a cutting bed 4 and a computer 6 for control. The cutting bed 4 includes a gas-permeable pad 8 made of bristles or the like. The gas-permeable pad 8 is, for example, annular, and is rotated by a pair of pulleys 9 , 9 . The cutting bed 4 includes a vacuum pump 12 and a suction chamber 13 to suck air from the pad 8 . 14 and 14 are a pair of rails, and the rail 16 for moving the carriage 18 is moved by a moving motor not shown. The rail 16 supports a carriage 18, and the carriage 18 may move on the rail 16 by itself with a built-in motor, or may move by a driving source provided on the side of the rail 16, such as a timing belt.

[0027] The carriage 18 has a camera head 19 with a CCD camera and a cutting head 20 with a free-moving knife or a circular knife, and the heads 19 and 20 move on the cutting bed 4 in two-dimension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com