Sweeping robot

A sweeping robot and main machine technology, applied in the direction of cleaning carpets, floors, machine parts, etc., can solve the problems that ground stains cannot be removed, increase the range of suction, and the cleaning body has a short air intake distance, so as to reduce indoor air secondary Pollution, increasing the range of suction, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

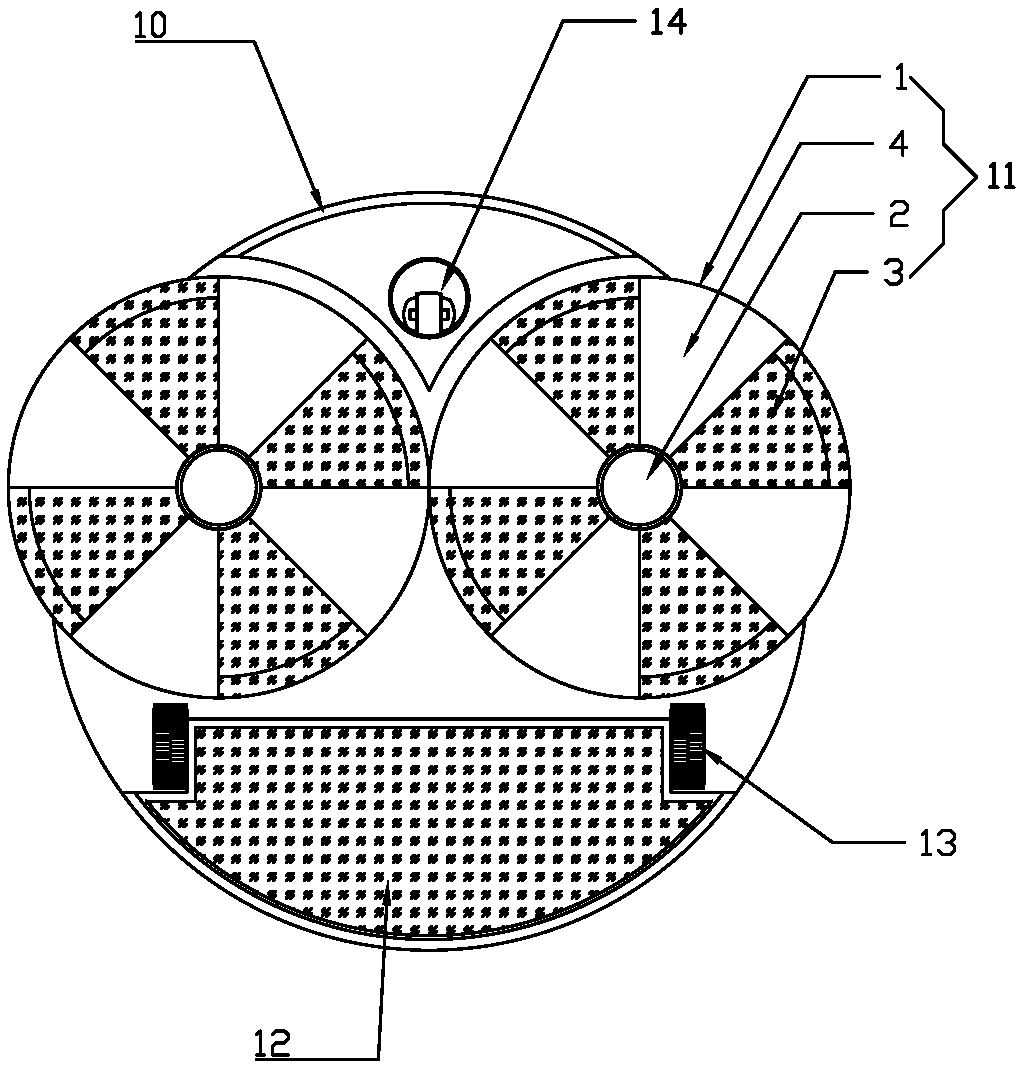

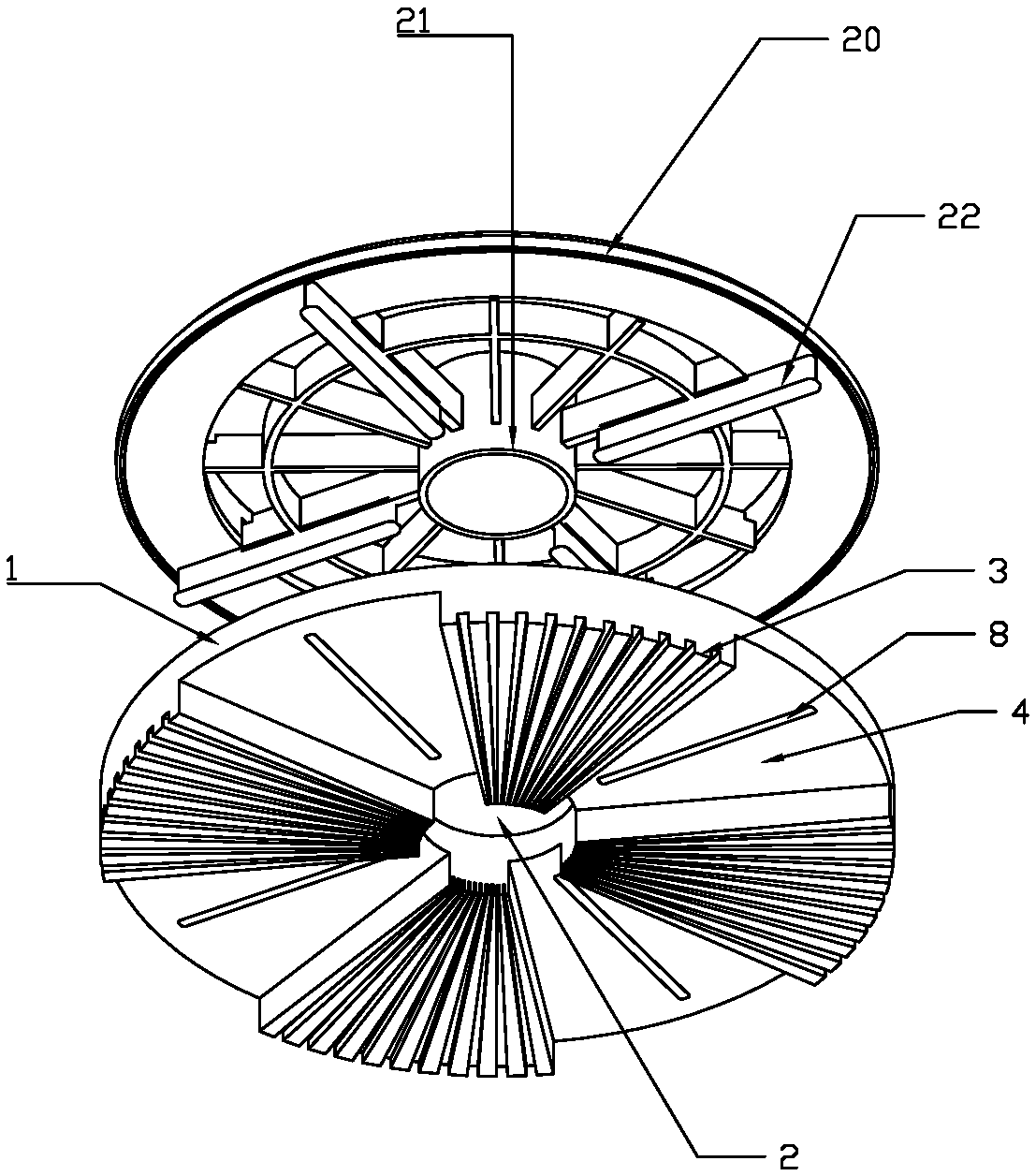

[0028] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 As shown, a preferred embodiment of the present invention includes a main machine 10, a dust suction device 26 arranged inside the main machine, two mounting plates 20 with opposite rotation directions arranged below the main machine, and a hollow The central shaft 21, the upper end of the central shaft 21 passes through the bottom shell of the main machine 10 and enters the interior of the main machine 10, and communicates with the dust suction device 26 through two non-rotating dust suction pipes 25, and the two dust suction pipes 25 can be inserted respectively In the inner cavities of the two central shafts 21, sliding bearings can be arranged at the connection between the rotating central shaft 21 and the static suction pipe 25, which can reduce friction and dynamic sealing. On the outer periphery of the upper end of the central shaft 21, a bearing The plane thrust bearing 24 of axial load, the motor 1...

Embodiment 2

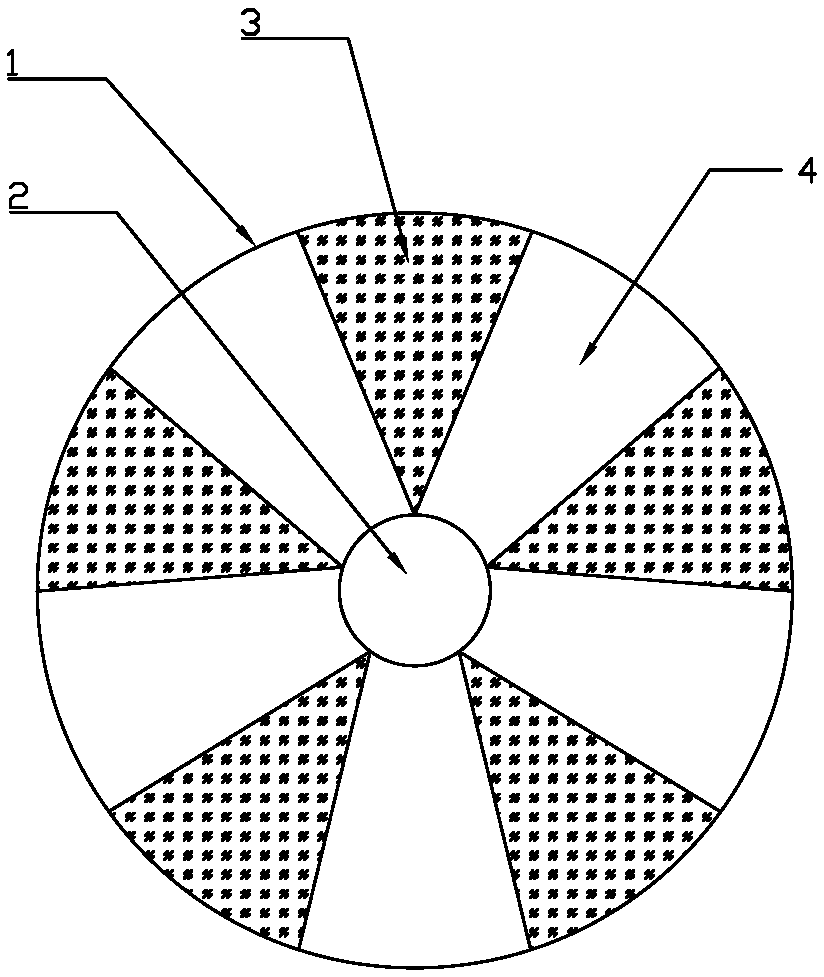

[0029] Embodiment 2: as Figure 5 As shown, a preferred embodiment of the present invention includes a main machine 10, two cleaning heads 11 installed below the mounting plate and rotating in opposite directions are arranged under the main machine 10, the cleaning heads 11 include an upper cover 1, the A dust suction hole 2 is provided at the center of the upper cover 1, and a plurality of radially extending and downwardly protruding cleaning bodies 3 are provided at intervals around the bottom of the upper cover 1 with the dust suction hole 2 as the center. The cleaning body 3 is made of flexible wiping material. The lower surface of the cleaning body 3 is in contact with the surface to be cleaned. The motor in the main machine drives the mounting plate to drive the cleaning head 11 on the mounting plate to rotate. The cleaning head 3 wipes the surface to be cleaned in a rotating manner. On the cleaning surface, the space between the adjacent cleaning body 3 and the upper co...

Embodiment 3

[0030] Embodiment 3: as Figure 6 , Figure 7 As shown, a preferred embodiment of the present invention comprises a main frame 10, two cleaning heads 11 installed below the mounting plate below the main frame 10, and each of the two mounting plates is driven by a stepping motor to drive the cleaning head 11 below the mounting plate. The head 11 rotates. When the rotation speeds of the two cleaning heads are different, the cleaning head with a faster rotation speed will rotate relative to the cleaning head with a slower rotation speed. While sweeping the ground and vacuuming, the main machine can twist and move or turn, canceling the walking wheels and universal wheels usually used by sweeping robots.

[0031] In a preferred embodiment of the present invention, the cleaning head is as Figure 9 , Figure 10 As shown, the upper cover 1 is included, and the central position of the upper cover 1 is provided with a dust suction hole 2, and the bottom of the upper cover 1 is cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com